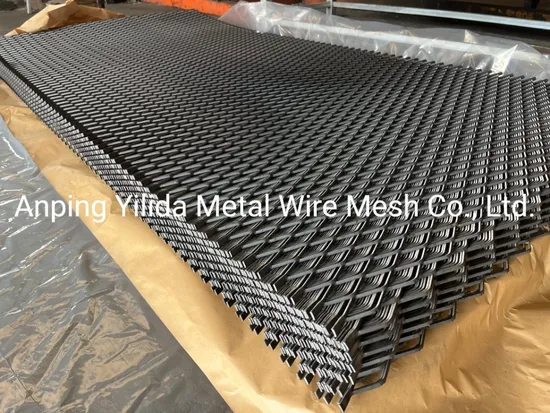

The global expanded metal mesh market is experiencing robust growth, driven by rising demand across construction, industrial manufacturing, and infrastructure sectors. According to a 2023 report by Mordor Intelligence, the market is projected to grow at a CAGR of 5.8% from 2023 to 2028, fueled by the increasing need for durable, lightweight, and cost-effective metal solutions. Expanded metal 4×8 sheets—versatile, structurally strong, and widely used in fencing, walkways, ventilation systems, and architectural facades—are at the forefront of this demand. With North America and Asia-Pacific leading in industrial expansion and infrastructure development, manufacturers are scaling production and innovating in material efficiency and customization. In this competitive landscape, identifying top-tier producers who combine quality, capacity, and technical expertise is critical for sourcing professionals and project planners. Based on production volume, industry reputation, global reach, and material certifications, the following nine manufacturers stand out as leaders in the expanded metal 4×8 sheet market.

Top 9 Expanded Metal 4X8 Sheet Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Metals Supplier & Service Center

Domain Est. 1997

Website: sss-steel.com

Key Highlights: Triple-S Steel is one of the largest metals distributor and service center in North and South America. Whether your project is large or small, local or global,…

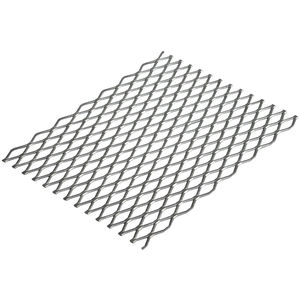

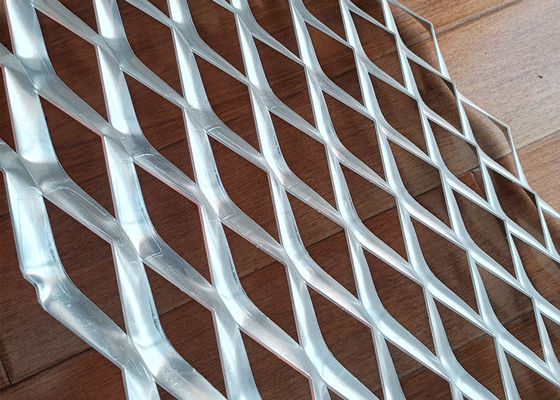

#2 Flat and Raised Expanded Steel Sheet

Domain Est. 1999

Website: industrialmetalsupply.com

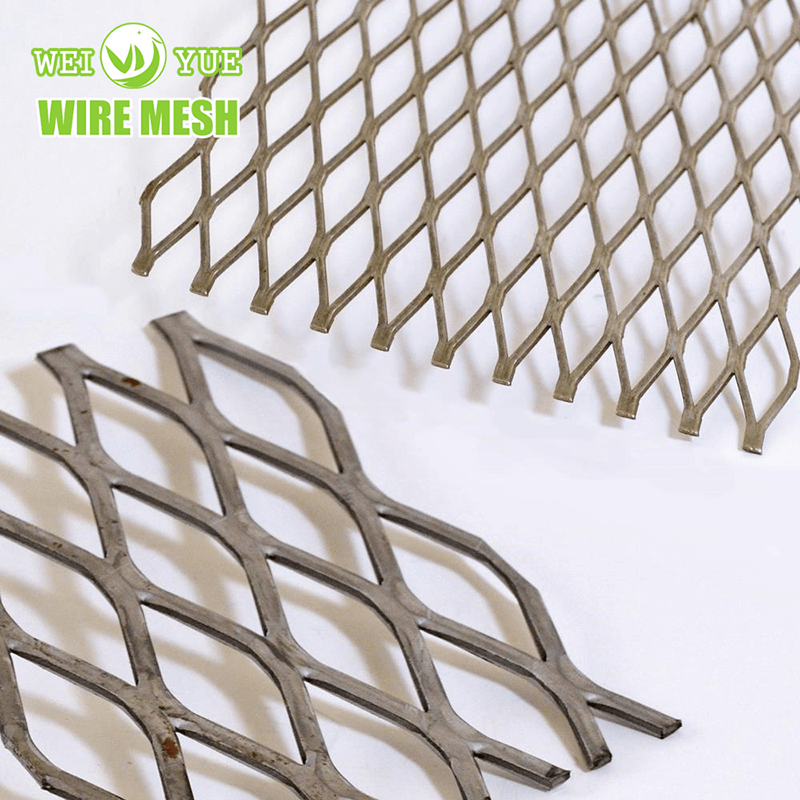

Key Highlights: Expanded steel sheet is manufactured with flat and raised diamond-shaped openings that allow light, sound, air, and liquid passage….

#3 Carbon Steel Expanded Metal / Expanded Steel

Domain Est. 1996

Website: alro.com

Key Highlights: Alro offers expanded metal in carbon steel, stainless steel, and aluminum, providing strength and anti-slip performance for walkways, platforms, barriers, ……

#4 Expanded Metal Sheets and Grating Supplier

Domain Est. 1997

Website: chathamsteel.com

Key Highlights: Expanded Metal Sheets and Grating Supplier. Chatham Steel offers a large inventory of expanded metal sheet and grating for a wide variety of construction needs….

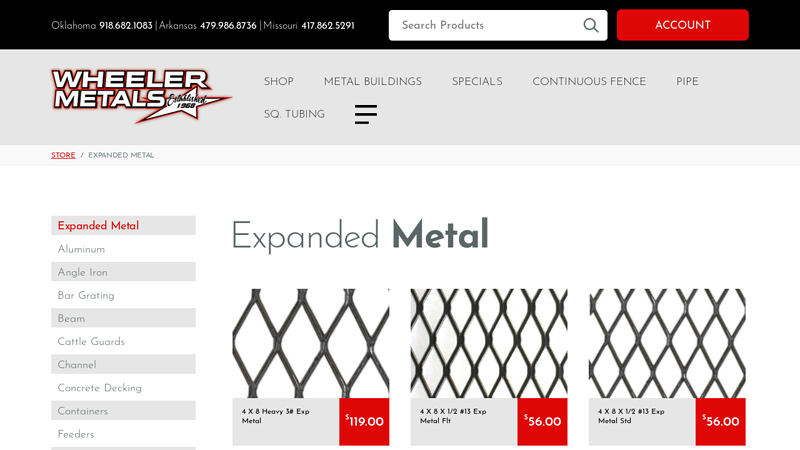

#5 Expanded Metal

Domain Est. 1999

Website: wheelermetals.com

Key Highlights: Expanded Metal. 4 X 8 Heavy 3# Exp Metal. $119.00 · 4 X 8 X 1/2 #13 Exp Metal Flt. $56.00 · 4 X 8 X 1/2 #13 Exp Metal Std. $56.00 · 4 X 8 X 3/4 #9 Exp Metal ……

#6 Niles Expanded Metals

Domain Est. 1999

Website: nilesexpandedmetals.com

Key Highlights: Niles can customize expanded metal to meet your specific needs. We specialize in expanded metal, micromesh, ExPerf, & more. Request a quote today!…

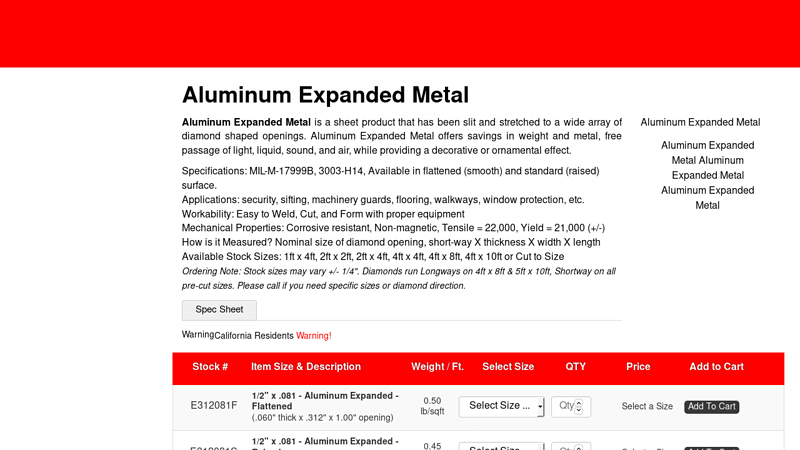

#7 MetalsDepot®

Domain Est. 1999

Website: metalsdepot.com

Key Highlights: Buy Aluminum Expanded Online at MetalsDepot – America’s Small Quantity Store. Huge selection of steel expanded, stainless expanded, and aluminum expanded….

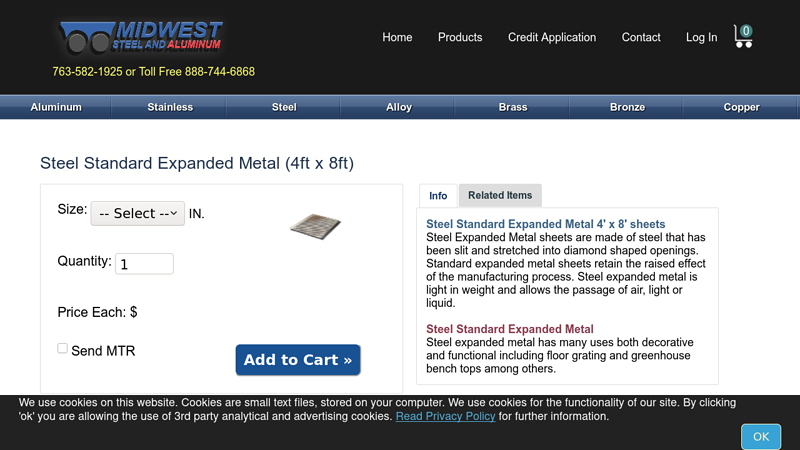

#8 Steel Standard Expanded Metal (4ft x 8ft)

Domain Est. 2005

Website: midweststeelsupply.com

Key Highlights: In stockSteel Standard Expanded Metal 4′ x 8′ sheets. Steel Expanded Metal sheets are made of steel that has been slit and stretched into diamond shaped openings….

#9 Expanded Metal

Domain Est. 2011

Website: kloecknermetals.com

Key Highlights: Kloeckner offers both standard expanded metal and flattened expanded metal, each designed to serve distinct functional and aesthetic applications….

Expert Sourcing Insights for Expanded Metal 4X8 Sheet

2026 Market Trends for Expanded Metal 4X8 Sheet

The global market for Expanded Metal 4X8 Sheet is poised for significant evolution by 2026, driven by advancements in manufacturing technology, rising demand across key industries, and a growing emphasis on sustainable materials. As a versatile and durable product used in construction, industrial manufacturing, transportation, and architectural design, expanded metal sheets—particularly the standard 4×8-foot size—are adapting to meet changing market needs. This analysis explores the major trends expected to shape the Expanded Metal 4X8 Sheet market in 2026.

Rising Demand in Construction and Infrastructure

By 2026, the construction sector is anticipated to remain the largest consumer of Expanded Metal 4X8 Sheets. Urbanization, especially in emerging economies, and the global push for resilient infrastructure are increasing the need for lightweight, strong, and cost-effective materials. Expanded metal is increasingly favored for its strength-to-weight ratio and ability to allow airflow, light, and drainage—making it ideal for walkways, façades, fencing, and safety barriers. Governments investing in smart cities and sustainable public infrastructure are likely to adopt expanded metal in larger volumes, particularly in applications such as noise barriers and pedestrian bridges.

Growth in Green Building and Sustainable Design

Environmental concerns are reshaping material selection in architecture and construction. Expanded metal aligns well with green building standards due to its recyclability and minimal waste during production—since the expansion process creates no scrap. The 4×8 sheet size, being standardized, optimizes transportation and reduces carbon footprint. By 2026, demand is expected to grow among architects and developers seeking LEED-certified or energy-efficient building components. Expanded metal is being used innovatively in solar panel supports, ventilated façades, and shading systems, contributing to energy efficiency.

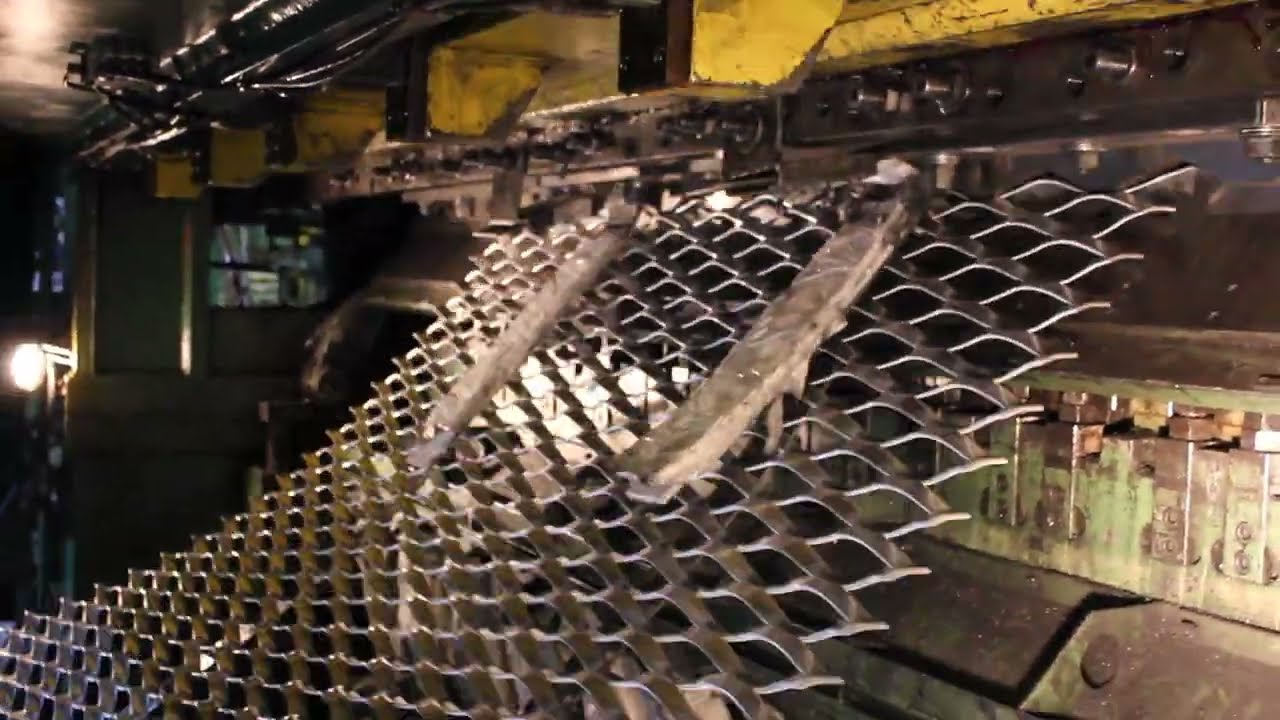

Technological Advancements in Manufacturing

Automation and precision engineering are enhancing the production efficiency of expanded metal sheets. By 2026, manufacturers are expected to leverage AI-driven design software and robotics to customize 4×8 sheets with specific patterns, strand widths, and opening sizes—tailored to client requirements. This allows for greater design flexibility and performance optimization. Additionally, the integration of Industry 4.0 technologies enables real-time quality control and inventory management, reducing lead times and improving supply chain responsiveness.

Expansion in Transportation and Automotive Applications

The transportation industry is increasingly adopting expanded metal for lightweight structural components, grilles, and interior panels. In electric vehicles (EVs) and public transit systems, 4×8 expanded metal sheets are used in battery enclosures, flooring, and HVAC systems due to their durability and ventilation properties. With the global EV market expanding rapidly, this trend is expected to accelerate through 2026, creating new opportunities for expanded metal suppliers.

Regional Market Dynamics

Asia-Pacific is projected to lead global demand for Expanded Metal 4X8 Sheets by 2026, driven by rapid industrialization in countries like India, Vietnam, and Indonesia. North America and Europe will follow, supported by infrastructure modernization projects and strict environmental regulations promoting sustainable materials. Meanwhile, the Middle East is expected to see increased usage in large-scale architectural and oil & gas projects, where corrosion-resistant aluminum and stainless steel expanded sheets are preferred.

Material Innovation and Diversification

While steel remains dominant, alternative materials such as aluminum, stainless steel, and composite-based expanded metals are gaining traction. By 2026, manufacturers are likely to offer more 4×8 sheets made from high-strength, corrosion-resistant alloys tailored for harsh environments. Innovations in coating technologies—such as powder coating and galvanization—are further enhancing longevity and aesthetic appeal, expanding use in decorative applications.

Price Volatility and Supply Chain Resilience

Raw material costs, particularly for steel and aluminum, may introduce price volatility into the market. However, by 2026, companies are expected to focus on supply chain diversification and vertical integration to mitigate risks. Regional production hubs and strategic partnerships with recyclers will help stabilize input costs and support sustainable growth.

Conclusion

The Expanded Metal 4X8 Sheet market in 2026 will be shaped by sustainability imperatives, technological innovation, and expanding applications across sectors. As industries prioritize efficiency, durability, and environmental responsibility, expanded metal is well-positioned to meet these demands. Companies that invest in customization, eco-friendly production, and strategic market expansion are likely to gain a competitive edge in the evolving landscape.

Common Pitfalls When Sourcing Expanded Metal 4×8 Sheets (Quality and IP Considerations)

Logistics & Compliance Guide for Expanded Metal 4×8 Sheet

Material Specifications and Handling

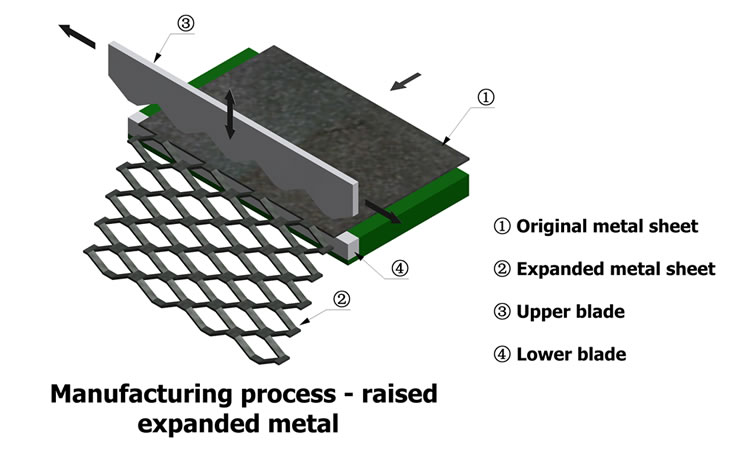

Expanded metal 4×8 sheets are pre-cut panels typically measuring 4 feet by 8 feet (48″ x 96″), manufactured by slitting and stretching metal to form a diamond or decorative pattern. Common materials include carbon steel, stainless steel, aluminum, and galvanized steel. Proper handling is critical due to sharp edges and potential for cuts. Always use cut-resistant gloves, eye protection, and safe lifting techniques. Sheets should be stored flat on level surfaces to prevent warping and separated by protective spacers or cardboard if stacked.

Packaging and Protection

Sheets must be packaged to prevent scratching, corrosion, and edge damage during transit. Standard practices include:

– Wrapping in kraft paper or plastic film to reduce moisture exposure.

– Bundling multiple sheets with edge protectors and steel or nylon strapping.

– Placing wooden skids or pallets underneath to elevate from ground moisture.

– Labeling bundles clearly with material type, gauge/thickness, finish, and handling instructions (e.g., “Fragile Edges,” “Do Not Stack Heavily”).

Transportation Requirements

When shipping expanded metal 4×8 sheets, consider the following:

– Mode of Transport: Suitable for flatbed trucks, enclosed trailers, or containerized freight. Over-the-road freight is common for domestic shipments.

– Load Securing: Use straps, load bars, or edge protectors to prevent shifting. Sheets must be tightly secured to avoid vibration damage.

– Environmental Protection: Cover loads with tarps if exposed to weather; moisture can cause rust on carbon steel unless galvanized or coated.

– Weight Considerations: Account for total bundle weight—aluminum is lighter than steel, but large gauges can still be heavy. Confirm vehicle weight limits and proper forklift capacity at delivery points.

Storage Guidelines

Store expanded metal sheets in a dry, indoor environment when possible. If outdoor storage is unavoidable:

– Elevate bundles off the ground using pallets.

– Cover with waterproof tarps, ensuring edges are sealed to prevent water ingress.

– Avoid direct contact with dissimilar metals to prevent galvanic corrosion.

– Rotate stock using a first-in, first-out (FIFO) system to prevent long-term exposure and potential degradation.

Regulatory and Safety Compliance

Ensure compliance with relevant safety and environmental standards:

– OSHA Regulations (U.S.): Follow guidelines for material handling, personal protective equipment (PPE), and workplace safety. Sharp edges require hazard communication and training.

– Hazard Communication Standard (HazCom): Provide Safety Data Sheets (SDS) if coatings or treatments (e.g., oil, paint) are applied.

– DOT Regulations: For transport, classify material appropriately. Uncoated metal typically is not hazardous, but treated or oiled sheets may require specific labeling.

– International Standards: For export, comply with destination country regulations (e.g., REACH in the EU, CCC in China), especially regarding metal composition and coatings.

Customs and Import/Export Documentation

When shipping internationally:

– Provide accurate Harmonized System (HS) codes (e.g., 7314.31 or 7314.49 for steel expanded metal).

– Include commercial invoices, packing lists, and certificates of origin.

– Declare material composition, country of manufacture, and value.

– Confirm any import duties, anti-dumping regulations, or trade restrictions applicable to metal products.

Quality Assurance and Documentation

Maintain quality control through:

– Mill test reports or certification (e.g., ASTM A666 for stainless steel, ASTM A467 for aluminum).

– Inspection upon receipt for damage, warping, or dimensional accuracy.

– Traceability via lot numbers or heat numbers where applicable, especially in regulated industries (construction, aerospace, transportation).

Sustainability and Recycling Compliance

Expanded metal is highly recyclable. Ensure:

– Proper disposal or recycling of packaging materials (plastic, wood, steel strapping).

– Compliance with local and federal recycling regulations.

– Documentation of recycling practices for environmental compliance reporting (e.g., LEED certification support).

By following this guide, businesses can ensure safe, efficient, and compliant handling, transport, and use of expanded metal 4×8 sheets across supply chains.

In conclusion, sourcing expanded metal 4×8 sheets requires careful consideration of material type, gauge, opening size, and finish to ensure the product meets the specific requirements of the intended application. Evaluating reputable suppliers based on quality, lead times, pricing, and customer service is essential for a successful procurement process. Additionally, obtaining samples, verifying compliance with industry standards, and considering logistics such as shipping and handling will contribute to an efficient and cost-effective sourcing strategy. With proper research and due diligence, businesses can secure high-quality expanded metal sheets that offer durability, functionality, and value for a wide range of architectural, industrial, and decorative uses.