The global expandable bolt market is experiencing steady growth, driven by rising demand in construction, infrastructure, and industrial maintenance sectors. According to Mordor Intelligence, the Fasteners Market—encompassing expand bolts—is projected to grow at a CAGR of over 5.2% from 2024 to 2029, with expanding urbanization and infrastructure development acting as key growth catalysts. Similarly, Grand View Research reported that the global industrial fasteners market size was valued at USD 92.6 billion in 2023 and is expected to expand at a CAGR of 5.8% through 2030. Within this landscape, expand bolts—valued for their reliability in securing materials to concrete, masonry, and hollow substrates—are gaining traction across applications in aerospace, energy, and commercial building. As demand intensifies, a competitive manufacturing ecosystem has emerged, with innovation in corrosion resistance, load capacity, and installation efficiency shaping market differentiation. Below are the top 10 expand bolt manufacturers leading this evolution through technology, scale, and global reach.

Top 10 Expand Bolt Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Bolt Products Inc

Domain Est. 1998

Website: boltproducts.com

Key Highlights: Bolt Products is a stocking distributor industrial standard and specialty fasteners for commercial applications for OEMS and distributors….

#2 Anchor Fasteners Industrial co., Ltd.

Domain Est. 1998 | Founded: 1986

Website: anchorfast.com.tw

Key Highlights: For more than 30 years since 1986, Anchor has been dedicated in manufacturing high quality fasteners for the Construction, Automotive and Electronic industries….

#3 U

Domain Est. 1999

Website: uboltit.com

Key Highlights: At U-Bolt-It, we custom manufacture bolts and fasteners made to meet all your requirements and in all materials from stainless steel and exotic materials….

#4 Midwest Fastener

Domain Est. 2000

Website: fastenerconnection.com

Key Highlights: Midwest Fastener is a fastener supplier and fastener manufacturer offering construction fasteners, drywall screws, and much, much more….

#5 Lamons

Domain Est. 2002

Website: lamons.com

Key Highlights: Lamons is one of the largest custom gasket, bolt, & seal manufacturers globally, committed to providing industry leading sealing solutions. Call us today!…

#6 Bolt Manufacturers

Domain Est. 2002

Website: industrial-bolts.net

Key Highlights: Expansion Bolts: Designed to anchor objects into masonry or concrete, expansion bolts expand upon tightening to create a strong hold in brittle materials….

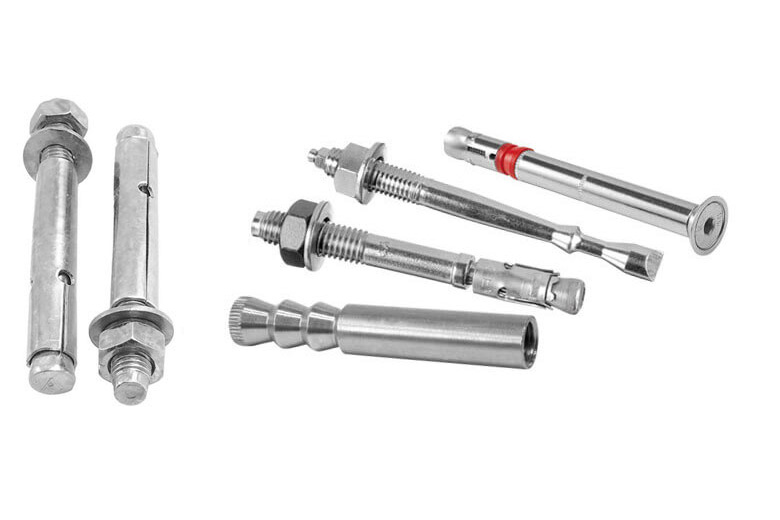

#7 Stainless Steel Expansion Bolts

Domain Est. 2022

Website: aozhanfasteners.com

Key Highlights: Stainless steel expansion bolts are one of the main products of Aozhan Hardware Factory, with a wide range of products that are strong and durable….

#8 Bolt anchor

Domain Est. 1997

Website: fischer-international.com

Key Highlights: The cone bolt expands against the wall of the drill hole. The anchors are made from normal steel, hot-dip galvanised steel, stainless steel, and highly ……

#9

Domain Est. 1997

Website: arp-bolts.com

Key Highlights: ARP was the first company to design and engineer fasteners specifically for racing. We developed many patented process for manufacturing high strength ……

#10 Chicago Expansion Bolt

Domain Est. 2015 | Founded: 1916

Website: chicagoexpansionbolt.com

Key Highlights: The Chicago Expansion Bolt performs so well that it has been used to secure the seating in most theaters and stadiums in the United States since 1916….

Expert Sourcing Insights for Expand Bolt

2026 Market Trends for Expansion Bolts (H2 Analysis)

The global expansion bolt market is poised for steady growth in 2026, driven by robust construction activity, infrastructure modernization, and evolving engineering demands. Here’s an analysis of key trends shaping the market in the second half (H2) of 2026:

-

Accelerated Infrastructure Investment:

- Trend: Major government stimulus packages (e.g., US Infrastructure Bill, EU Green Deal investments, China’s renewed infrastructure focus) will be in full execution phase by H2 2026. This translates directly into high-volume demand for anchoring solutions in bridges, highways, rail networks, power substations, and water treatment plants.

- Impact on Expansion Bolts: Significant increase in demand for heavy-duty, high-strength expansion bolts (like wedge anchors, drop-in anchors) designed for concrete and masonry in large-scale civil engineering projects. Focus will be on reliability, speed of installation for large crews, and adherence to stringent safety codes.

-

Sustainability and Green Building Mandates:

- Trend: Building codes and corporate ESG (Environmental, Social, Governance) goals are increasingly prioritizing sustainable construction. This includes material efficiency, reduced waste, and lower carbon footprints.

- Impact on Expansion Bolts:

- Material Innovation: Growing demand for high-performance bolts made from recycled steel or alloys with lower embedded energy. Zinc flake coatings (e.g., Geomet, Delta Protekt) will gain further traction over traditional hot-dip galvanizing due to better corrosion resistance with less environmental impact.

- Design for Deconstruction: Increased interest in temporary or removable anchoring systems for prefabricated elements, though standard expansion bolts remain dominant. Research into easier removal methods may intensify.

- Lifecycle Focus: Buyers will prioritize bolts with proven long-term durability and minimal maintenance requirements, reducing the need for future replacements and associated environmental costs.

-

Rise of Off-Site Construction (OSC) & Modularization:

- Trend: The push for faster project timelines, improved quality control, and reduced on-site labor shortages is accelerating the adoption of prefabricated modules, facades, and MEP (Mechanical, Electrical, Plumbing) racks.

- Impact on Expansion Bolts:

- Standardization & Pre-Assembly: Increased demand for standardized anchor types and sizes suitable for factory integration into modules. Pre-drilled holes with specified anchor types become common.

- Speed & Reliability: Anchor systems enabling rapid, foolproof installation on-site (e.g., setting tools integrated into installation guns, consistent performance) will be highly valued. Reliability is paramount to avoid module rework.

- Specialized Applications: Growth in anchors designed specifically for connecting modular units or securing heavy prefab components to concrete slabs/cores.

-

Smart Construction & Digitalization:

- Trend: Wider adoption of BIM (Building Information Modeling), digital twins, and on-site digital tools for planning, monitoring, and quality assurance.

- Impact on Expansion Bolts:

- Digital Product Passports: Leading manufacturers may offer digital twins for critical anchors, providing installation data, batch traceability, load specifications, and inspection records accessible via QR codes or NFC tags embedded in packaging.

- Integration with BIM: Detailed digital models of specific anchor types (including load capacities, tolerances, installation requirements) become standard, improving planning accuracy and clash detection.

- Smart Installation Tools: Wider use of torque-controlled or displacement-controlled setting tools that digitally record installation parameters (torque, depth, setting sequence), providing verifiable proof of correct installation for quality audits and safety compliance.

-

Supply Chain Resilience & Regionalization:

- Trend: Lingering effects of past disruptions and geopolitical factors will continue to drive efforts to shorten supply chains and reduce dependency on single sources.

- Impact on Expansion Bolts:

- Regional Manufacturing Hubs: Increased investment in manufacturing capacity closer to key markets (e.g., Southeast Asia, Eastern Europe, Mexico) to serve local/regional demand faster and mitigate risks.

- Dual Sourcing: Major construction firms and distributors will actively seek multiple qualified suppliers for critical anchor types.

- Focus on Inventory Management: Distributors and large contractors will prioritize suppliers with robust inventory visibility and reliable logistics, even at a slight premium.

-

Material & Performance Advancements:

- Trend: Continuous innovation to meet stricter safety standards, harsher environments, and complex designs.

- Impact on Expansion Bolts:

- Higher Strengths: Development and adoption of expansion bolts using advanced high-strength steels (e.g., ASTM A193 B7 equivalent or higher) for demanding applications in high-rise buildings, seismic zones, and industrial settings.

- Enhanced Corrosion Protection: Beyond coatings, research into base material corrosion resistance and innovative barrier systems (e.g., integrated sealants) for aggressive environments (coastal, chemical plants, wastewater).

- Specialty Applications: Growth in anchors designed for specific challenges: high-temperature resistance (fire protection systems), vibration damping (HVAC, machinery), and post-installed rebar systems.

Conclusion for H2 2026:

The expansion bolt market in H2 2026 will be characterized by strong volume growth fueled by infrastructure, coupled with increasing sophistication driven by sustainability, digitalization, and modular construction. Success for manufacturers will depend on:

- Reliability & Compliance: Meeting stringent international standards (ETA, ICC-ES) consistently.

- Innovation: Offering products with improved performance, sustainability credentials, and digital integration.

- Supply Chain Agility: Providing reliable delivery through regionalized networks.

- Support & Solutions: Moving beyond just selling bolts to offering technical expertise, digital tools (BIM objects, installation apps), and comprehensive project support.

Expansion bolts will remain a fundamental, but increasingly high-tech, component in the built environment, adapting to the demands of modern, efficient, and sustainable construction.

Common Pitfalls Sourcing Expand Bolts (Quality, IP)

Sourcing expand bolts—especially for critical structural or safety applications—can present several challenges related to quality control and intellectual property (IP) protection. Being aware of these pitfalls helps mitigate risks and ensures reliable performance and legal compliance.

Quality Inconsistencies and Substandard Materials

One of the most frequent issues when sourcing expand bolts, particularly from low-cost manufacturers, is inconsistent quality. Suppliers may use substandard materials such as low-grade steel or incorrect alloy compositions, leading to reduced tensile strength, poor corrosion resistance, and premature failure under load. Inadequate heat treatment processes can further compromise structural integrity. Without proper quality assurance protocols—such as ISO certifications, material test reports (MTRs), or third-party inspections—buyers risk receiving products that do not meet required mechanical specifications.

Lack of Compliance with International Standards

Expand bolts must often comply with regional or international standards (e.g., ASTM, DIN, ISO, or EN specifications). A common pitfall is sourcing bolts labeled as compliant but lacking actual certification or traceability. Some suppliers may misrepresent product conformity, resulting in non-compliant components being used in construction or industrial applications. This not only poses safety risks but may also lead to project delays, rework, or liability issues.

Inadequate Testing and Performance Validation

Many expand bolts require specific performance under load, vibration, and environmental conditions. However, sourced products may not undergo proper testing for expansion force, pull-out resistance, or long-term durability. Relying solely on supplier-provided data without independent validation (e.g., through lab testing or field trials) can result in selecting bolts unsuitable for the intended application, especially in high-stress or dynamic environments.

Intellectual Property (IP) Infringement Risks

Expand bolt designs, particularly proprietary anchoring mechanisms or patented installation methods, may be protected by intellectual property rights. A major pitfall arises when sourcing from suppliers offering “compatible” or “generic” versions that closely mimic patented designs. Using such products without due diligence may expose the buyer to IP infringement claims, legal disputes, and shipment seizures. It is essential to verify that the design and manufacturing processes do not violate existing patents, especially when sourcing from regions with lax IP enforcement.

Insufficient Traceability and Documentation

Reliable sourcing requires complete traceability—from raw material origin to final production batch. Poor documentation practices by suppliers can hinder quality audits, failure analysis, and regulatory compliance. Missing or falsified test reports, unclear labeling, and lack of batch tracking increase the risk of counterfeit or non-conforming products entering the supply chain.

Overlooking Environmental and Corrosion Resistance Requirements

Expand bolts used in harsh environments (e.g., marine, chemical, or outdoor applications) require appropriate surface treatments or material selection (e.g., stainless steel, hot-dip galvanization). A common oversight is assuming all bolts with a similar appearance offer the same corrosion protection. Inadequate coatings or incorrect material grades can lead to rapid degradation, compromising both safety and longevity.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Partner with reputable, certified suppliers with verifiable quality management systems.

– Require full documentation, including material certifications and test reports.

– Conduct independent product testing and factory audits.

– Perform IP due diligence, including patent landscape reviews.

– Specify exact standards and performance requirements in procurement contracts.

By addressing these common pitfalls proactively, organizations can ensure they source expand bolts that are both high-quality and legally compliant.

Logistics & Compliance Guide for Expand Bolt

This guide outlines the essential logistics and compliance considerations for the import, export, distribution, and use of Expand Bolts—a type of mechanical fastener used in construction, manufacturing, and infrastructure projects. Adhering to these guidelines ensures smooth operations, regulatory compliance, and product safety.

Product Classification and HS Code

Identify the correct Harmonized System (HS) code for Expand Bolts to ensure accurate customs declarations and tariff application. Typical classifications include:

- HS Code Example: 7318.15 (Threaded items of iron or steel, including bolts and screws)

- Note: Confirm the exact HS code based on material composition (e.g., stainless steel, carbon steel), dimensions, and intended use, as codes may vary by country.

Ensure all product specifications (material, finish, size, load capacity) are documented to support customs verification.

Packaging and Labeling Requirements

Proper packaging and labeling are critical for safe transit and regulatory compliance:

- Packaging: Use moisture-resistant, durable packaging (e.g., sealed plastic bags inside sturdy cardboard boxes) to prevent corrosion and damage during shipping.

- Labeling: Each package must include:

- Product name and part number

- Material specification (e.g., A2-70 stainless steel)

- Quantity

- Manufacturer name and country of origin

- Batch/lot number for traceability

- Language: Labels must be in the official language of the destination country (e.g., English for the U.S., French for Canada).

Export Documentation

Prepare complete and accurate documentation for international shipments:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin (required for preferential tariff treatment under trade agreements)

- Export Declaration (if required by the exporting country)

Ensure all documents reflect consistent product descriptions and HS codes.

Import Regulations and Duties

Comply with destination country import requirements:

- Customs Clearance: Provide all required documents to customs authorities. Delays may occur if documentation is incomplete or inconsistent.

- Import Duties and Taxes: Research applicable tariffs, VAT, or GST. Some countries offer duty exemptions for industrial components under specific conditions.

- Product Standards: Confirm that Expand Bolts meet local mechanical and safety standards (e.g., ASTM, DIN, ISO).

Regulatory Compliance

Ensure Expand Bolts meet relevant technical and safety regulations:

- Material Compliance: Adhere to RoHS (Restriction of Hazardous Substances) and REACH (EU chemical regulations) if shipping to the European Union.

- Mechanical Standards: Comply with recognized standards such as:

- ASTM F1554 (Standard specification for anchor bolts)

- DIN 524 (Wedge anchor bolts)

- ISO 898-1 (Mechanical properties of bolts and screws)

- Testing and Certification: Maintain test reports (e.g., tensile strength, corrosion resistance) and certifications (e.g., CE marking, UKCA) where required.

Restricted and Prohibited Destinations

Be aware of trade restrictions:

- Avoid shipping to countries under international sanctions (e.g., Iran, North Korea) without proper export licenses.

- Check the U.S. Department of Commerce’s Bureau of Industry and Security (BIS) or EU Consolidated List for updates on restricted destinations.

Transportation and Handling

Follow best practices for safe and efficient logistics:

- Mode of Transport: Choose sea, air, or land freight based on urgency, cost, and destination.

- Storage: Store bolts in a dry, temperature-controlled environment to prevent rust and degradation.

- Handling: Use appropriate equipment to avoid damage during loading/unloading.

Product Liability and Traceability

Maintain robust traceability systems:

- Keep records of raw material sources, production batches, and quality control tests.

- Implement a recall procedure in case of non-conforming products.

- Provide technical data sheets (TDS) and installation guidelines to end users.

Environmental and Sustainability Considerations

- Recyclability: Expand Bolts made from steel are fully recyclable—highlight this in marketing and compliance reports.

- Packaging Waste: Minimize packaging materials and use recyclable or biodegradable options where possible.

- Carbon Footprint: Optimize shipping routes and consolidate shipments to reduce emissions.

Conclusion

Compliance with logistics and regulatory standards is essential for the successful global distribution of Expand Bolts. By following this guide, manufacturers and distributors can ensure product safety, avoid customs delays, and maintain market access across international borders. Always consult local regulatory authorities or a customs broker for jurisdiction-specific requirements.

Conclusion for Sourcing Expand Bolts:

In conclusion, sourcing expand bolts requires a careful evaluation of quality, material specifications, load requirements, and supplier reliability. It is essential to select expand bolts that meet industry standards (such as ISO, DIN, or ASTM) and are suitable for the intended application—whether in construction, machinery installation, or structural anchoring. Conducting supplier assessments, requesting product certifications, and performing sample testing can ensure performance and safety. Additionally, considering factors like corrosion resistance, ease of installation, and cost-efficiency contributes to a successful procurement strategy. By establishing strong supply chain partnerships and maintaining quality control throughout the sourcing process, organizations can secure durable, reliable expand bolts that support long-term structural integrity and project success.