The global excavator attachments market is experiencing robust growth, driven by rising infrastructure development, urbanization, and demand for specialized excavation equipment. According to Grand View Research, the global construction machinery attachments market size was valued at USD 10.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.6% from 2023 to 2030. A key contributor to this expansion is the increasing adoption of versatile tools like rotating grapples, which enhance the functionality of excavators in applications ranging from demolition and forestry to waste management and recycling. As demand for precision, efficiency, and multi-functionality rises, manufacturers of excavator rotating grapples are scaling innovation and production to meet evolving needs. This growing momentum underscores the importance of identifying the top nine manufacturers leading advancements in performance, durability, and hydraulic integration in this competitive landscape.

Top 9 Excavator Rotating Grapple Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Rotobec

Domain Est. 1996

Website: rotobec.com

Key Highlights: Rotobec’s tough loaders and equipment attachments are used in over 50 countries. Use them for forestry, scrap & waste handling, rail, construction and more….

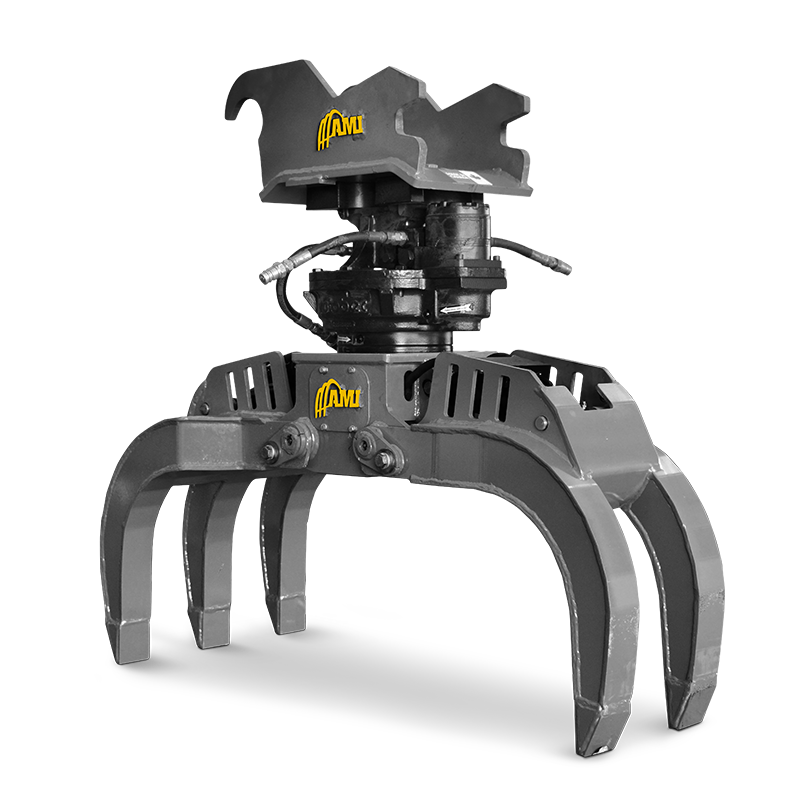

#2 AMI Attachments®

Domain Est. 2006

Website: amiattachments.com

Key Highlights: AMI Attachments is an innovative industry-leading manufacturer of quality, reliable attachments for excavators, backhoes, wheel loaders, motor graders and ……

#3

Domain Est. 2014 | Founded: 1978

Website: pembertonattachments.com

Key Highlights: Pemberton, Inc. was founded in 1978 by brothers Todd and Bruce Pemberton as a manufacturing company building hydraulic equipment loading ramps for trailers….

#4 Hydraulic Rotating Log Grapple Attachment

Domain Est. 1997

Website: bobcat.com

Key Highlights: The Bobcat® hydraulic rotating log grapple uses powerful hydraulics to open and close the jaws while a built-in rotator spins the grapple a full 360 degrees….

#5 Excavator grapple attachments

Domain Est. 2017

Website: epiroc.com

Key Highlights: Our MG hydraulic grapples are suitable for sorting and loading of demolished material, as well as for demolishing light buildings like masonry or wooden ……

#6 Excavator Rotating Log Grapple

Domain Est. 2019

Website: solarisattachments.com

Key Highlights: At Solaris Attachments, we offer a complete lineup of rotating excavator log and brush grapples from four leading brands—FARMA, KRPAN, Klou, ……

#7 Excavator Rotating Grapple Usage Including Skid Steer

Domain Est. 2021

Website: hawkexcavator.com

Key Highlights: This versatile attachment offers 360-degree rotation, enabling precise handling of materials, even in tight spaces, and enhances the performance of standard ……

#8 Excavator Rotating Grapple From BSGHGranulator

Domain Est. 2022

Website: bsghgranulator.com

Key Highlights: Excavator rotating grapple is a kind of front-end attachment specially used for grabbing scrap materials used with excavator….

#9 Excavator Rotating Grapple: A Complete Guide

Domain Est. 2021

Website: wilcomfg.com

Key Highlights: Discover how an excavator rotating grapple boosts project efficiency. This guide covers its mechanics, core applications, and how to select the right model….

Expert Sourcing Insights for Excavator Rotating Grapple

H2: 2026 Market Trends for Excavator Rotating Grapple

The global market for excavator rotating grapples is poised for steady growth through 2026, driven by rising demand in construction, demolition, waste management, and forestry sectors. These hydraulic attachments, known for their 360-degree rotation and enhanced material handling capabilities, are becoming essential tools for improving operational efficiency and safety on job sites.

One of the key drivers shaping the 2026 market landscape is the increasing adoption of compact and mini excavators in urban construction and infrastructure development. As cities expand and renovation projects multiply, the need for versatile, maneuverable equipment intensifies. Rotating grapples, compatible with a wide range of excavator sizes, offer contractors flexibility in handling debris, sorting recyclable materials, and managing green waste—making them indispensable in confined urban environments.

Additionally, growing emphasis on sustainability and waste recycling is accelerating demand. In Europe and North America, stringent environmental regulations are pushing contractors to adopt equipment that supports material segregation and efficient waste processing. Rotating grapples, especially those integrated with tilt or multi-function capabilities, enable precise sorting and reduce landfill dependency, aligning with circular economy goals.

Technological advancements are also a major trend. By 2026, manufacturers are focusing on smart attachments equipped with sensors and telematics to monitor performance, detect wear, and optimize maintenance schedules. These innovations enhance durability and reduce downtime, appealing to large-scale operators prioritizing fleet efficiency.

Regionally, Asia-Pacific is expected to witness the fastest growth due to rapid industrialization, infrastructure investments in countries like India and Vietnam, and expanding mining activities. Meanwhile, North America and Europe will maintain strong demand, supported by aging infrastructure renewal and green energy projects such as biomass handling and solar farm site preparation.

In summary, the 2026 market for excavator rotating grapples will be characterized by technological innovation, regulatory influence, and sector diversification. As construction and environmental priorities evolve, rotating grapples will continue to play a critical role in modernizing material handling across industries.

Common Pitfalls When Sourcing an Excavator Rotating Grapple (Quality and Intellectual Property)

Sourcing an excavator rotating grapple—especially from international suppliers—can be cost-effective, but it comes with several risks related to quality and intellectual property (IP). Being aware of these pitfalls helps ensure you get a reliable, durable, and legally compliant product.

Poor Build Quality and Material Selection

One of the most frequent issues when sourcing rotating grapples is substandard build quality. Low-cost manufacturers may use inferior steel, inadequate welding techniques, or imprecise machining. This leads to:

- Reduced durability under heavy use

- Increased risk of mechanical failure

- Shorter service life, requiring frequent replacements

Always request material certifications (e.g., mill test reports) and inspect welding standards (e.g., ISO 3834 compliance).

Lack of Proper Testing and Certification

Many suppliers, especially from emerging markets, do not conduct proper load testing or performance validation. Without third-party certification (e.g., CE, TÜV), there is no assurance that the grapple meets safety and performance standards.

Verify that the grapple has undergone:

– Load testing at 1.5x working load limit

– Rotation mechanism endurance testing

– Compatibility testing with your excavator model

Inadequate IP Protection and Design Copying

Rotating grapples often incorporate patented designs, especially in jaw geometry, rotation mechanisms, and hydraulic systems. Sourcing from unverified suppliers increases the risk of:

- Purchasing counterfeit or cloned products

- Infringing on existing patents, leading to legal liability

- Reputational damage if caught using IP-violating equipment

Always vet suppliers for original equipment manufacturer (OEM) authorization or design licenses.

Hidden Costs from Poor After-Sales Support

Low initial pricing can be misleading. Many budget suppliers offer minimal or no after-sales support, including:

- Lack of spare parts availability

- No technical documentation or manuals

- Inability to provide on-site service or troubleshooting

Ensure the supplier offers a warranty, spare parts inventory, and accessible customer support before finalizing the purchase.

Misrepresentation of Compatibility and Performance

Some suppliers exaggerate grapple performance (e.g., rotation speed, gripping force) or claim compatibility with a wide range of excavators without verification. This can lead to:

- Poor integration with your machine

- Hydraulic system incompatibility

- Reduced efficiency and operator frustration

Request performance data sheets and compatibility matrices specific to your excavator model.

Risks of Unauthorized Production Using Stolen IP

In some cases, factories produce grapples using CAD files or designs stolen from established brands. While these replicas may look identical, they often lack quality control and expose buyers to:

- Legal action if used commercially

- Warranty voids from original equipment manufacturers

- Safety risks due to unverified engineering

Conduct due diligence: visit the factory, audit their design and production processes, and request proof of IP ownership or licensing.

Conclusion

To avoid these pitfalls, work with reputable suppliers, conduct third-party inspections, and prioritize transparency in design and manufacturing. Investing time upfront to verify quality and IP compliance saves significant cost and risk in the long term.

Logistics & Compliance Guide for Excavator Rotating Grapple

Overview

An excavator rotating grapple is a specialized attachment designed to handle, sort, and manipulate materials such as scrap metal, demolition debris, logs, and waste. Due to its mechanical nature and use in industrial environments, proper logistics planning and regulatory compliance are essential for safe and legal transport, operation, and maintenance.

Transportation & Logistics

Packaging and Securing

Rotating grapples must be securely fastened to transport vehicles using appropriate tie-downs, chains, or brackets. Ensure that rotating components are locked in place to prevent movement during transit. Use protective covers on hydraulic connectors and pivot points to prevent damage and contamination.

Weight and Dimensions

Verify the grapple’s weight and dimensions before shipment. Confirm compatibility with transport vehicle capacity and compliance with road regulations regarding load size, weight distribution, and overhang. Oversized loads may require special permits and escort vehicles.

Handling Equipment

Use forklifts, cranes, or telehandlers with adequate lifting capacity when loading and unloading. Always attach lifting points as specified by the manufacturer. Never lift the grapple by hydraulic hoses or moving components.

Documentation

Include a detailed packing list, bill of lading, and equipment specifications (weight, dimensions, model number) with each shipment. For international shipments, provide commercial invoices, certificates of origin, and any required export documentation.

Regulatory Compliance

Machinery Safety Standards

Ensure the rotating grapple meets relevant safety standards such as ISO 12100 (Risk Assessment), ISO 4254 (Safety of Machinery), and applicable national regulations like the EU Machinery Directive (2006/42/EC) or OSHA standards in the United States. Look for CE, UKCA, or other applicable conformity markings.

Hydraulic System Compliance

Hydraulic components must comply with pressure safety standards (e.g., ISO 4413). All hoses and fittings should be rated for the system’s maximum operating pressure and include safety shields where required.

Environmental Regulations

Dispose of packaging materials, hydraulic fluids, and any contaminated components in accordance with local environmental laws. Avoid leakage during transport by sealing hydraulic ports and using drip trays if necessary.

Import/Export Regulations

For cross-border transport, verify customs requirements, tariff classifications (e.g., HS Code 8431.43 for parts of excavators), and any restrictions on machinery or hydraulic equipment. Some countries may require conformity assessments or inspections upon entry.

Installation & Operational Compliance

Operator Training

Only trained and authorized personnel should install and operate the rotating grapple. Operators must be familiar with the excavator’s hydraulic system, grapple controls, and emergency shutdown procedures.

Compatibility Verification

Confirm that the grapple is compatible with the host excavator’s hydraulic flow (GPM), pressure (PSI/Bar), and quick coupler system. Use manufacturer-provided compatibility charts to avoid damage or performance issues.

Routine Inspections

Implement a maintenance schedule that includes daily or pre-shift inspections of pins, bushings, hydraulic hoses, and locking mechanisms. Document all inspections and repairs in accordance with workplace safety regulations.

Certifications & Documentation

Declaration of Conformity

Retain the manufacturer’s Declaration of Conformity (DoC) to demonstrate compliance with applicable directives and standards. This document is critical for audits, customs clearance, and workplace safety inspections.

Maintenance Records

Keep detailed logs of all maintenance, repairs, and part replacements. These records support warranty claims and demonstrate due diligence in equipment safety.

Operator Manuals

Ensure up-to-date operator and maintenance manuals are available on-site. Manuals should include safety warnings, installation instructions, troubleshooting guides, and exploded diagrams.

Conclusion

Proper logistics and compliance practices are vital for the safe and efficient use of excavator rotating grapples. Adhering to transportation guidelines, regulatory standards, and documentation requirements minimizes risk, ensures legal operation, and extends equipment lifespan. Always consult manufacturer specifications and local regulations when planning logistics or deployment.

Conclusion: Sourcing an Excavator Rotating Grapple

Sourcing an excavator rotating grapple requires careful consideration of equipment compatibility, application requirements, build quality, and supplier reliability. A rotating grapple significantly enhances productivity and versatility in applications such as demolition, forestry, scrap handling, and site cleanup by allowing 360-degree rotation and precise material manipulation.

It is essential to match the grapple’s specifications—including jaw type, hydraulic flow requirements, and mounting compatibility—with the excavator model and job demands. Evaluating reputable suppliers, warranty terms, after-sales support, and total cost of ownership ensures long-term performance and return on investment. Additionally, prioritizing durability, ease of maintenance, and safety features contributes to efficient and safe operations.

In conclusion, a well-researched procurement process focused on quality, suitability, and support will lead to the successful integration of a rotating grapple, improving operational efficiency and expanding the capabilities of your excavation equipment.