The global evaporative emissions (evap) canister market is experiencing steady expansion, driven by increasingly stringent vehicle emissions regulations and the global push toward cleaner transportation. According to Mordor Intelligence, the evap canister market was valued at approximately USD 1.8 billion in 2023 and is projected to grow at a CAGR of over 4.5% through 2029. This growth is fueled by rising automotive production, especially in emerging economies, and the integration of advanced emission control systems in both internal combustion engine (ICE) and hybrid vehicles. As environmental standards such as Euro 7, China 6, and EPA Tier 3 continue to tighten, manufacturers are investing in high-efficiency evap canisters that effectively capture fuel vapors and reduce volatile organic compound (VOC) emissions. In this evolving landscape, a select group of suppliers has emerged as leaders through innovation, global reach, and compliance with next-generation emission requirements. The following overview highlights the top 8 evap canister manufacturers shaping the industry’s future.

Top 8 Evap Canisters Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Fuel Vapor Carbon Canister

Domain Est. 1999

#2 PHINIA

Domain Est. 2022

Website: phinia.com

Key Highlights: Discover our selection of high-quality carbon canisters designed to meet the packaging needs of automotive and non-automotive manufacturers worldwide….

#3 EVAP & Carbon Canister Modeling

Domain Est. 1997

Website: gtisoft.com

Key Highlights: An activated carbon canister is used to capture hydrocarbon vapor emissions from the fuel tank as part of an EVAP system. The user has full control over ……

#4 Fuel Vapor Canisters

Domain Est. 2000

Website: standardbrand.com

Key Highlights: A fuel vapor canister, part of the EVAP system, captures fuel vapors before they become emissions that pollute the atmosphere….

#5 Vapor Canisters

Domain Est. 2002

Website: motorad.com

Key Highlights: The vapor canister is a key element in a vehicle’s evaporative emissions control (EVAP) system, designed to capture and store fuel vapors from the gas tank….

#6 Vapor Canister

Domain Est. 2010

Website: wellsve.com

Key Highlights: Wells Vapor Canisters are engineered and tested to match OE parts in fit, form and function and are compatible with both domestic and imported vehicles. ……

#7 Carbon Canisters and EVAP Emission Control Systems

Domain Est. 2016

Website: vexagroup.net

Key Highlights: Understand the function of EVAP emission control systems and how they help in achieving zero evaporative emissions in vehicles….

#8 Vapor Canister

Domain Est. 2023

Website: vaporcanister.com

Key Highlights: The Vapor Trapper is a charcoal fuel vapor canister designed to be easily retrofitted into your vintage car or truck, or boat….

Expert Sourcing Insights for Evap Canisters

H2: Projected 2026 Market Trends for Evaporative Emission (Evap) Canisters

The global evaporative emission (evap) canister market is poised for significant transformation by 2026, driven by tightening environmental regulations, advancements in vehicle technologies, and the ongoing shift toward electrification. Evap canisters, which capture fuel vapors from a vehicle’s fuel system to prevent hydrocarbon emissions, remain a critical component in internal combustion engine (ICE) and hybrid vehicles. The following analysis outlines key trends expected to shape the evap canister market in 2026.

-

Stricter Emission Regulations Driving Demand

Governments worldwide, particularly in North America, Europe, and China, continue to enforce stringent vehicle emission standards. Regulations such as Euro 7 in Europe and Tier 4 standards in the U.S. are expected to mandate lower evaporative emissions, increasing the need for high-efficiency evap canisters with enhanced vapor storage capacity and better purge control. This regulatory push will sustain demand for advanced canister systems, even as ICE vehicle production declines. -

Hybrid Vehicles Sustaining Evap Canister Relevance

While the rise of battery electric vehicles (BEVs) reduces the need for evap canisters, hybrid electric vehicles (HEVs and PHEVs) still rely on internal combustion engines and fuel systems. As automakers expand their hybrid offerings to bridge the transition to full electrification, the demand for evap canisters will remain robust through 2026. Automakers are investing in compact, lightweight, and high-capacity canisters optimized for hybrid platforms. -

Technological Innovation and Material Advancements

By 2026, evap canister design is expected to evolve with new activated carbon formulations that offer higher adsorption efficiency and longer service life. Innovations such as dual-bed canisters, integrated sensors, and smart purge valve systems will improve real-world emission control. Additionally, manufacturers are exploring recyclable and bio-based materials to meet sustainability goals and reduce the environmental footprint of canister production. -

Regional Market Dynamics

Asia-Pacific, led by China and India, will remain the largest market for evap canisters due to high vehicle production and urbanization. Europe and North America will see steady demand driven by regulatory compliance and hybrid vehicle adoption. Emerging markets in Southeast Asia and Latin America will also contribute to growth as vehicle ownership increases and emission norms are adopted. -

Consolidation and Strategic Partnerships

The evap canister supply chain is likely to see increased consolidation as Tier 1 suppliers such as Denso, Continental, and BorgWarner acquire niche players or form joint ventures to enhance R&D capabilities. Partnerships between canister manufacturers and automakers will focus on co-developing integrated fuel vapor management systems tailored to next-generation powertrains. -

Impact of Fuel Type and Infrastructure

The prevalence of gasoline-powered vehicles will continue to support evap canister demand. However, the growing use of ethanol-blended fuels and alternative fuels like methanol may require canisters with modified carbon media to handle different vapor compositions. Infrastructure development for alternative fuels will influence regional canister specifications.

In conclusion, while the long-term outlook for evap canisters may be challenged by the rise of BEVs, the 2026 market will remain strong due to regulatory mandates, hybrid vehicle growth, and technological innovation. Manufacturers who invest in advanced, adaptable, and sustainable canister solutions will be best positioned to capture market share in this evolving landscape.

Common Pitfalls When Sourcing Evap Canisters: Quality and IP Risks

Sourcing evaporative emissions (Evap) canisters—critical components in vehicle fuel vapor management systems—exposes procurement teams and manufacturers to several risks, particularly concerning quality consistency and intellectual property (IP) protection. Overlooking these pitfalls can lead to non-compliance, costly recalls, and legal disputes.

Quality-Related Pitfalls

Inconsistent Adsorption Performance

Evap canisters rely on activated carbon to absorb fuel vapors. Sourced units may use lower-grade or improperly treated carbon, leading to reduced vapor retention capacity. This can result in elevated hydrocarbon emissions, failing emissions tests (e.g., FTP-75), and violations of EPA or Euro 6/7 standards.

Poor Seal and Structural Integrity

Substandard manufacturing can introduce weak welds, porous housings, or inadequate valve sealing. These flaws may cause vacuum leaks, canister saturation, or even structural collapse under pressure, compromising evaporative system integrity and triggering EVAP fault codes (e.g., P0440–P0459).

Inadequate Environmental Resistance

Low-quality canisters may degrade prematurely when exposed to road salts, high underhood temperatures, or moisture. This leads to premature failure, especially in harsh climates, increasing warranty claims and field failures.

Non-Compliance with OEM Specifications

Sourcing from non-approved or generic suppliers often results in canisters that do not meet dimensional, flow, or purge rate requirements. Even minor deviations can disrupt engine management systems calibrated to specific OEM parameters.

Intellectual Property Risks

Unauthorized Reverse Engineering

Many Evap canister designs are protected by patents covering unique geometries, valve mechanisms, or carbon bed configurations. Sourcing from suppliers using reverse-engineered designs exposes the buyer to litigation for contributory patent infringement, even if unintentional.

Use of Copycat Components

Some suppliers offer “compatible” canisters that mimic branded OEM designs. While marketed as replacements, these may infringe design patents or utility patents, creating legal exposure during audits or in international markets with strict IP enforcement (e.g., EU, USA).

Lack of IP Documentation and Traceability

Suppliers may fail to provide freedom-to-operate (FTO) opinions, patent licenses, or design validation reports. Without proper documentation, OEMs assume liability for any IP violations, especially when integrating components into final vehicle assemblies.

Grey Market and Counterfeit Components

Purchasing through unauthorized distributors increases the risk of receiving counterfeit or surplus canisters. These may lack proper certification, contain recycled or degraded carbon, and bear falsified markings—posing both quality and IP risks.

Mitigation Strategies

- Pre-Qualify Suppliers: Use OEM-approved vendor lists and conduct on-site audits focusing on material sourcing and process controls.

- Require Full IP Assurance: Obtain written confirmation of patent licenses and FTO documentation before production.

- Enforce Rigorous Testing: Validate performance through burst pressure, hydrocarbon breakthrough, and environmental durability tests.

- Secure Contracts with IP Indemnification: Ensure sourcing agreements hold suppliers liable for IP infringement claims.

Avoiding these pitfalls ensures regulatory compliance, protects brand reputation, and reduces long-term liability in Evap canister procurement.

Logistics & Compliance Guide for Evap Canisters

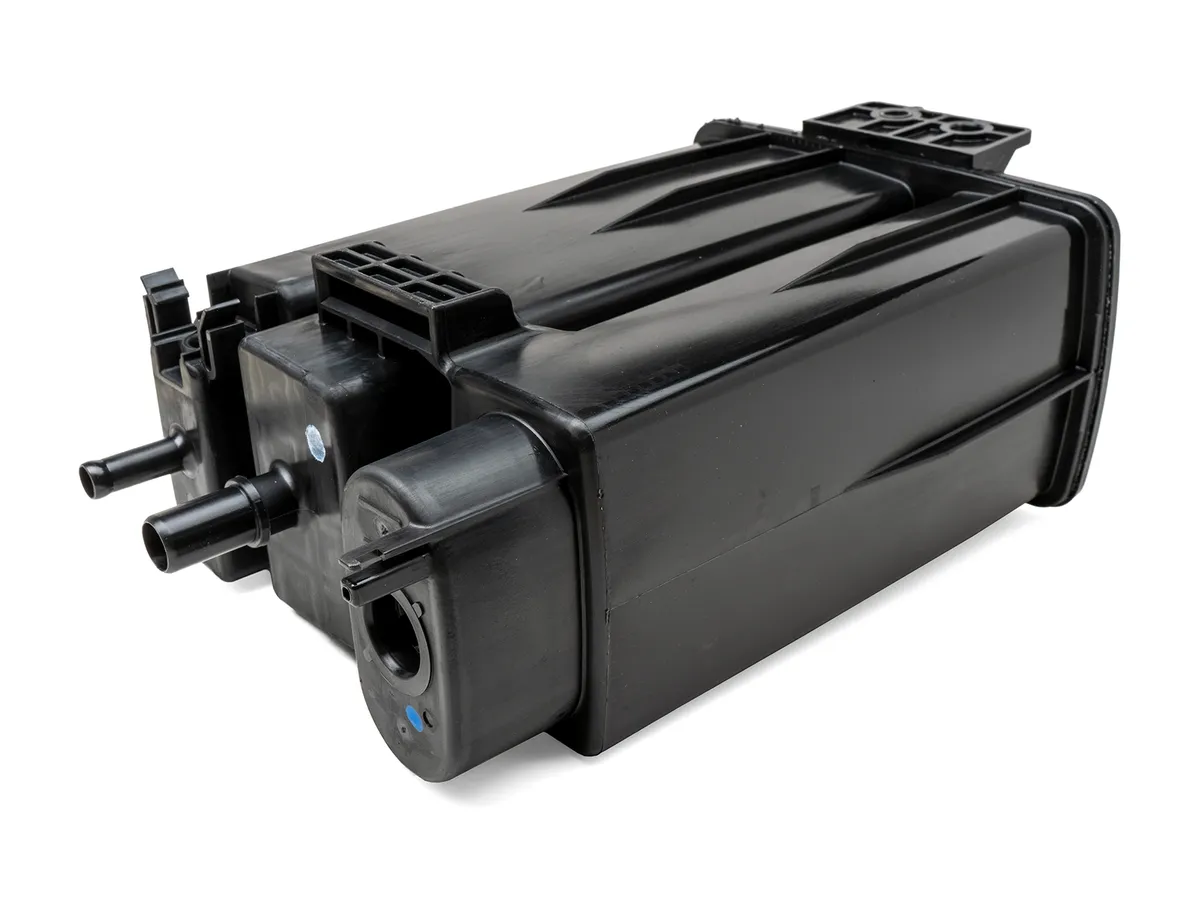

Overview of Evaporative Emission (Evap) Canisters

Evaporative Emission (Evap) canisters are essential components in automotive emission control systems designed to capture fuel vapors from the fuel tank and prevent their release into the atmosphere. These canisters contain activated carbon that absorbs hydrocarbons and are later purged into the engine for combustion. Due to their design and function, Evap canisters may contain trace amounts of fuel residues, which can trigger regulatory scrutiny during transportation, storage, and disposal.

Regulatory Classification and Compliance Requirements

Environmental Protection Agency (EPA) Regulations

Under the U.S. Environmental Protection Agency (EPA), Evap canisters may be classified as hazardous waste under the Resource Conservation and Recovery Act (RCRA) if they exhibit characteristics of ignitability (D001) due to residual hydrocarbons. Generators must evaluate whether used Evap canisters are hazardous waste by conducting a waste determination. Non-compliant handling can result in significant fines.

Department of Transportation (DOT) – Hazardous Materials Regulations (HMR)

The DOT regulates the transportation of hazardous materials, including potentially contaminated Evap canisters. If canisters contain free liquid or emit flammable vapors exceeding safety thresholds, they may be subject to 49 CFR regulations. Proper packaging, labeling, shipping papers, and training are required for hazardous materials transport. Empty containers may still require compliance if not properly purged.

International Air Transport Association (IATA) & International Maritime Organization (IMO)

For international shipments, IATA Dangerous Goods Regulations (air) and IMDG Code (sea) apply. Evap canisters with residual fuel vapors may fall under UN1203 (Gasoline) or UN1268 (Naphtha) with proper hazard class (Class 3, Flammable Liquid) and packing group designation. Accurate classification, packaging, marking, and documentation are mandatory.

Handling and Storage Best Practices

Pre-Shipment Evaluation

- Conduct a waste determination to assess whether the Evap canister is hazardous.

- Ensure canisters are drained of free liquids and purged of vapors where possible.

- Use vapor-tight containers or sealed bags for storage if residues are present.

Labeling and Documentation

- Clearly label containers with contents, date, and hazard warnings if applicable.

- Maintain manifests and shipping records for traceability.

- Provide Safety Data Sheets (SDS) if requested or if classified as hazardous.

Storage Conditions

- Store in a well-ventilated, fire-resistant area away from ignition sources.

- Segregate from incompatible materials (e.g., oxidizers).

- Limit storage time in accordance with local and federal regulations.

Transportation Guidelines

Domestic Shipments (U.S.)

- Determine hazard class using DOT criteria (e.g., vapor pressure testing).

- Use UN-rated packaging if shipping as hazardous material.

- Ensure drivers and handlers are trained under 49 CFR 172 Subpart H.

- Include proper shipping name, UN number, hazard class, and placards as required.

International Shipments

- Classify under IATA or IMDG based on vapor content and flammability.

- Use certified packaging with correct markings and labels (e.g., Class 3 flammable liquid).

- Complete dangerous goods declaration and ensure crew awareness.

- Comply with country-specific import restrictions (e.g., some nations restrict used automotive parts).

Disposal and Recycling Compliance

Recycling Options

- Partner with certified recyclers experienced in handling automotive emissions components.

- Recyclers may reclaim activated carbon or safely process residual hydrocarbons.

- Obtain certificates of recycling or destruction for audit and compliance purposes.

Landfill Disposal

- Only permitted if canisters pass TCLP (Toxicity Characteristic Leaching Procedure) testing and are non-hazardous.

- Never dispose of in regular trash if contaminated or untested.

Recordkeeping and Audits

- Maintain records of waste determinations, shipping manifests, training certifications, and disposal receipts for at least three years (or as required by jurisdiction).

- Conduct periodic compliance audits to ensure adherence to EPA, DOT, IATA, and local regulations.

Conclusion

Proper logistics and compliance for Evap canisters require careful evaluation of their contents, adherence to environmental and transportation regulations, and implementation of safe handling procedures. Misclassification or improper handling can result in regulatory penalties, environmental harm, and safety risks. Always consult with environmental and transportation compliance experts when in doubt.

Conclusion for Sourcing Evap Canisters:

In conclusion, sourcing evaporative (EVAP) canisters requires a strategic approach that balances component quality, supplier reliability, cost efficiency, and compliance with environmental and automotive industry standards. As emissions regulations continue to tighten globally, selecting EVAP canisters that meet or exceed OEM specifications is critical to ensuring vehicle performance, regulatory compliance, and environmental responsibility.

A thorough evaluation of potential suppliers should include an assessment of technical capabilities, manufacturing consistency, material quality, and after-sales support. Establishing long-term partnerships with reputable suppliers can lead to improved supply chain resilience, reduced lead times, and better cost control. Additionally, consideration of sustainability aspects—such as recyclability and low-emission production processes—aligns with broader corporate environmental goals.

In summary, effective sourcing of EVAP canisters not only supports vehicle emissions control but also contributes to long-term operational efficiency, regulatory compliance, and brand integrity in the competitive automotive market.