The global foam roller market, prominently featuring EVA (ethylene-vinyl acetate) rollers, has experienced steady expansion driven by rising health and fitness awareness, increased home workout adoption, and demand for affordable recovery tools. According to Grand View Research, the global foam rollers market was valued at USD 1.1 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 7.3% from 2024 to 2030. This growth is fueled by expanding gym infrastructure, rising sports participation, and the growing popularity of self-myofascial release techniques among athletes and casual users alike. As a lightweight, durable, and cost-effective material, EVA has become a preferred choice for foam roller manufacturing, capturing a significant share of the market. With increasing competition and innovation, several manufacturers have emerged as leaders in producing high-quality, performance-driven EVA rollers. Based on production capacity, market presence, product innovation, and customer ratings, here are the top 9 EVA roller manufacturers shaping the industry today.

Top 9 Eva Roller Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wholesale Foam Roller

Domain Est. 2005

Website: wavar.com

Key Highlights: EVA Foam Roller has a very slight sponge feeling, which is very suitable for beginners who just get into the field and people who do not need solid Foam Roller….

#2 Reliable Foam Roller Manufacturers

Domain Est. 2006

Website: aplus88.com

Key Highlights: With rich experience in making EVA exercise roller field, Elysian becomes a leading brand of foam roller manufacturers. We insist to offer the best EVA foam ……

#3 Recycled EVA Foam Roller

Domain Est. 2012

Website: successfulmat.com

Key Highlights: Our recycled EVA roller contains recycled materials are made by incorporating crushed NG foam waste or discarded EVA foam products during the production process ……

#4 30 Global Foam Roller Manufacturers You Can Trust

Domain Est. 2015

Website: yanrefitness.com

Key Highlights: Fab-Ent is a manufacturer that focuses on foam rollers, massage tools, and other recovery equipment for gyms and fitness suppliers. They are known for their ……

#5 Wholesale Foam Rollers

Domain Est. 2021

Website: shengde-yoga.com

Key Highlights: Wholesale high-quality foam rollers including EVA, Cork, EPP, and EPE types. As a factory, we offer B2B supply, custom options, and fast global delivery….

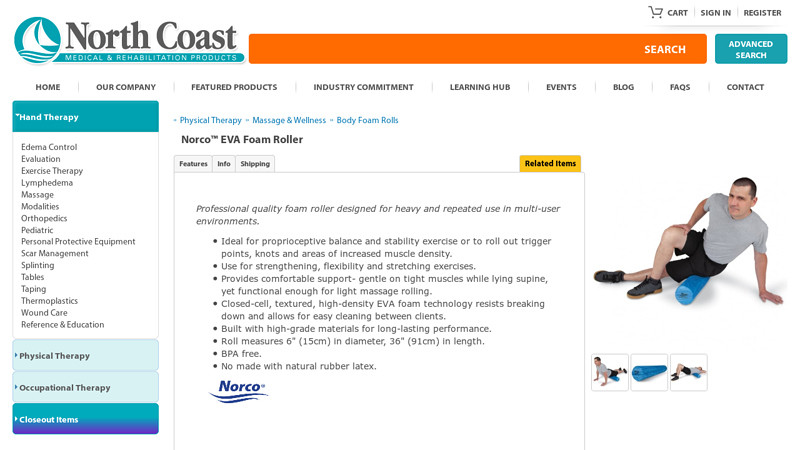

#6 Norco EVA Foam Roller

Domain Est. 1996

Website: ncmedical.com

Key Highlights: Professional quality foam roller designed for heavy and repeated use in multi-user environments. Ideal for proprioceptive balance and stability exercise or……

#7 Eva Foam Roller (18″ X 6″)

Domain Est. 1997

Website: bsnsports.com

Key Highlights: Help develop balance, postural alignment and flexibility. Ideal for self-myofascial release and massage therapy. 18” L x 6” diameter; round. Warranty….

#8 Power Systems Premium EVA Foam Roller

Domain Est. 2002

Website: anthem-sports.com

Key Highlights: Free delivery 30-day returnsThis roller is durable, yet soft to the touch, and built for heavy use. This is a great tool to stimulate blood flow, improve circulation, and loosen kn…

#9 Foam Roller Eva

Domain Est. 2018

Website: sideaita.net

Key Highlights: Foam rollers are versatile and multifunctional cylindrical tools that, can be used for self-massage, stretching and flexibility exercises….

Expert Sourcing Insights for Eva Roller

H2 2026 Market Trends Analysis for Eva Roller

As we look toward the second half of 2026, the market environment for Eva Roller—presumably a company operating in the personal care, beauty, or wellness sector (potentially known for facial rollers, skincare tools, or related products)—is poised for evolution driven by shifting consumer behaviors, technological advancements, and sustainability imperatives. Below is an analysis of key H2 2026 market trends likely to impact Eva Roller’s performance and strategic positioning.

1. Sustainability as a Non-Negotiable Standard

By H2 2026, eco-consciousness will no longer be a niche concern but a baseline expectation. Consumers will demand full transparency in sourcing, packaging, and lifecycle impact. Eva Roller must ensure:

– Use of biodegradable, recycled, or compostable packaging.

– Ethical sourcing of materials (e.g., certified jade, rose quartz, or sustainable EVA foam alternatives).

– Carbon-neutral shipping and manufacturing processes.

Opportunity: Brands that proactively communicate their sustainability efforts through certifications (e.g., B Corp, Climate Neutral) will gain loyalty and command premium pricing.

2. Personalization and Smart Skincare Integration

The convergence of beauty and tech will accelerate. Consumers will expect tools that integrate with digital skincare regimens. Key trends include:

– Demand for smart rollers with embedded sensors (e.g., tracking pressure, frequency, or skin temperature).

– Compatibility with AI skincare apps for personalized routines.

– Customizable designs (engraving, adjustable cooling/heating features).

Implication: Eva Roller should consider launching a connected product line or partnering with skincare tech platforms to remain competitive.

3. Holistic Wellness and Mental Health Focus

Skincare tools are increasingly seen as part of a broader self-care and mental wellness ritual. By H2 2026:

– Marketing will emphasize mindfulness, stress reduction, and emotional well-being.

– Ritual-based usage (e.g., morning calming routines, evening wind-downs) will be central to brand messaging.

– Partnerships with wellness influencers and mental health advocates will grow in importance.

Strategy: Eva Roller can differentiate by promoting the meditative benefits of facial rolling, supported by content on breathwork and mindfulness.

4. Rise of Niche and Inclusive Marketing

Diversity and inclusion will extend beyond representation to product design and accessibility:

– Expansion into underrepresented skin types, tones, and gender identities.

– Products tailored for sensitive skin, mature skin, or specific dermatological needs.

– Marketing campaigns featuring diverse age groups, abilities, and cultural backgrounds.

Action Item: Eva Roller should audit its product line and messaging for inclusivity gaps and develop targeted offerings.

5. Direct-to-Consumer (DTC) Evolution and Omnichannel Growth

While DTC remains strong, pure-play online brands face increasing competition. Success in H2 2026 will depend on:

– Seamless omnichannel experiences (e.g., online purchase with in-store pickup via retail partnerships).

– Subscription models for roller maintenance kits or complementary serums.

– Enhanced post-purchase engagement (e.g., virtual consultations, loyalty rewards).

Recommendation: Eva Roller should explore strategic retail partnerships (e.g., Sephora, Credo Beauty) while maintaining brand control through owned channels.

6. Regulatory and Ingredient Scrutiny

Global regulatory bodies will tighten rules around cosmetic tools and claims. Trends include:

– Stricter labeling requirements for materials and manufacturing origin.

– Bans on misleading “detox” or “lymphatic drainage” claims without clinical backing.

– Increased consumer skepticism toward unverified benefits.

Preparation: Eva Roller must ensure compliance and invest in third-party testing to validate product efficacy and safety.

Conclusion

H2 2026 presents both challenges and opportunities for Eva Roller. To thrive, the brand must embed sustainability at its core, embrace personalization through technology, and align with the growing wellness movement. By staying agile, consumer-centric, and transparent, Eva Roller can strengthen its market position and build lasting loyalty in an increasingly discerning beauty landscape.

Common Pitfalls When Sourcing Eva Rollers (Quality, IP)

Sourcing Eva rollers—commonly used in applications such as foam rollers, packaging, and industrial equipment—can present several challenges, particularly in ensuring quality consistency and protecting intellectual property (IP). Being aware of these pitfalls helps mitigate risks and ensures a reliable supply chain.

Quality Inconsistencies

One of the most frequent issues when sourcing Eva rollers is inconsistent product quality. Variations can occur in material density, surface finish, dimensional accuracy, and durability. These inconsistencies may stem from differences in raw material batches, manufacturing processes, or lack of stringent quality control at the supplier’s end. Low-quality Eva foam may degrade quickly, lack resilience, or fail to meet performance standards, leading to customer dissatisfaction and increased returns.

Lack of Material Certification

Many suppliers may not provide proper certifications for the EVA (ethylene-vinyl acetate) material used, such as RoHS, REACH, or FDA compliance, especially when sourcing from low-cost regions. Without these certifications, businesses risk regulatory non-compliance, particularly in industries like healthcare, child products, or food packaging where material safety is critical.

Inadequate Testing and Validation

Some suppliers may not conduct rigorous performance testing—such as compression resistance, UV stability, or abrasion resistance—resulting in rollers that underperform in real-world conditions. Relying solely on supplier claims without independent testing increases the risk of product failure post-production.

Intellectual Property (IP) Risks

When sourcing Eva rollers, especially custom-designed ones, there is a significant risk of IP theft or unauthorized replication. Suppliers in certain regions may duplicate designs or share proprietary specifications with third parties. Without proper legal safeguards—such as non-disclosure agreements (NDAs), IP ownership clauses in contracts, or patent protections—businesses may lose control over their innovations.

Weak Contractual Protections

A common oversight is entering into sourcing agreements without clear terms regarding quality standards, IP ownership, and liability for non-compliance. Vague or missing clauses can make it difficult to enforce accountability if the supplier delivers substandard products or breaches IP terms.

Supply Chain Transparency Issues

Limited visibility into the supplier’s manufacturing process and subcontracting practices can hide risks such as the use of unauthorized materials or secondary sourcing. This lack of transparency complicates quality assurance and traceability efforts, especially in regulated industries.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Conduct thorough supplier audits and request material test reports.

– Require third-party certifications relevant to the application.

– Implement robust NDAs and IP assignment agreements.

– Include specific quality metrics and penalties for non-compliance in contracts.

– Perform pilot runs and independent product testing before full-scale production.

Proactively addressing these risks ensures that sourced Eva rollers meet both performance expectations and legal requirements.

Logistics & Compliance Guide for Eva Roller

This guide outlines the essential logistics and compliance considerations for Eva Roller, ensuring smooth operations, regulatory adherence, and customer satisfaction. All departments must follow these guidelines to maintain efficiency and legal compliance.

Supply Chain Management

Eva Roller relies on a tightly coordinated supply chain to deliver high-quality roller products to customers worldwide. Key components include:

- Supplier Vetting: Only pre-approved suppliers meeting ISO and environmental standards may be used.

- Inventory Management: Utilize just-in-time (JIT) principles to minimize overstock while ensuring product availability.

- Lead Time Monitoring: Track supplier delivery performance monthly and address delays promptly.

International Shipping & Documentation

Compliance with international trade regulations is mandatory for all export shipments.

- Customs Documentation: Ensure all shipments include a commercial invoice, packing list, bill of lading/airway bill, and any required certificates of origin.

- HS Code Accuracy: Assign correct Harmonized System (HS) codes for each product to avoid customs delays or penalties.

- Export Controls: Verify that shipments comply with export regulations in both the origin and destination countries, including any restrictions on dual-use items.

Product Compliance & Certification

All Eva Roller products must meet regional safety and environmental standards.

- CE Marking: Required for all products sold in the European Economic Area (EEA), indicating conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Confirm all electrical components are free from restricted hazardous substances (e.g., lead, cadmium).

- REACH Regulations: Register and disclose all chemical substances used in production as required in the EU.

- FDA Registration: Applicable for products used in food processing or medical environments (if applicable).

Packaging & Labeling Standards

Proper packaging and labeling ensure product integrity and regulatory compliance.

- Labeling Requirements: Include product name, model number, serial number, country of origin, manufacturer details, and compliance marks (e.g., CE, RoHS).

- Multilingual Labels: For EU and global markets, provide safety and handling instructions in local languages.

- Sustainable Packaging: Use recyclable or biodegradable materials where possible, in line with corporate sustainability goals.

Transportation & Carrier Compliance

Select and manage carriers based on performance, reliability, and regulatory compliance.

- Carrier Qualification: Only work with carriers that maintain valid insurance and comply with international transport regulations (e.g., ADR for hazardous goods).

- Temperature Control: For sensitive components, use climate-controlled transport and monitor conditions during transit.

- Tracking & Visibility: All shipments must be trackable in real time using integrated logistics platforms.

Returns & Reverse Logistics

Establish clear procedures for handling product returns while remaining compliant.

- Return Authorization (RMA): Require customers to obtain an RMA number before returning any product.

- Inspection & Disposition: Inspect returned items for damage or non-compliance and document findings.

- Waste Disposal: Recycle or dispose of defective products according to local environmental regulations (e.g., WEEE in the EU).

Recordkeeping & Audits

Maintain accurate records to support compliance and operational transparency.

- Document Retention: Store shipping records, compliance certificates, and supplier agreements for a minimum of 7 years.

- Internal Audits: Conduct quarterly audits of logistics and compliance processes.

- Regulatory Updates: Assign a compliance officer to monitor changes in international trade laws and adjust procedures accordingly.

Training & Accountability

Ensure all staff involved in logistics and compliance are properly trained.

- Compliance Training: Provide annual training on export controls, product safety, and documentation requirements.

- Designated Contacts: Appoint logistics and compliance leads in each region to serve as points of contact.

- Incident Reporting: Establish a system for reporting and resolving compliance violations or shipping errors.

Adherence to this guide ensures Eva Roller maintains operational excellence, legal compliance, and a strong reputation in global markets.

Conclusion for Sourcing EVA Roller

Sourcing EVA rollers requires a strategic approach that balances quality, cost, and reliability. After evaluating potential suppliers, technical specifications, material composition, and manufacturing capabilities, it is evident that selecting the right EVA roller supplier is critical to ensuring consistent product performance, particularly in applications such as printing, lamination, and material handling.

Key factors such as roller hardness (durometer), cell structure density, durability, and resistance to heat and wear should guide the selection process. Additionally, vetting suppliers based on certifications, production capacity, lead times, and after-sales support enhances supply chain stability. Opting for manufacturers with proven expertise in EVA foam processing and custom roll fabrication can provide a competitive advantage.

In conclusion, successful sourcing of EVA rollers involves thorough due diligence, clear communication of technical requirements, and establishing long-term partnerships with reliable suppliers. By prioritizing quality and performance, businesses can ensure optimal functionality of EVA rollers in their operations, ultimately improving efficiency and reducing maintenance costs.