The global demand for EVA (ethylene-vinyl acetate) bags has surged in recent years, driven by their lightweight, waterproof, and durable properties—making them ideal for travel, sports, and outdoor activities. According to Grand View Research, the global EVA foam market size was valued at USD 11.4 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This expansion is fueled by rising consumer preference for eco-friendly and low-maintenance materials, as well as increasing demand in the packaging, footwear, and consumer goods sectors. As EVA bags become a staple in both retail and industrial applications, the manufacturing landscape has evolved to meet heightened quality and sustainability standards. Based on production capacity, export volume, innovation, and market presence, the following nine manufacturers have emerged as leaders in the global EVA bags industry.

Top 9 Eva Bags Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 EVA bags for carbon black

Domain Est. 2018

Website: zonpak.com

Key Highlights: EVA bags for carbon black Manufacturers, Factory, Suppliers From China, We will supply best quality, the most market competitive price, for every new and ……

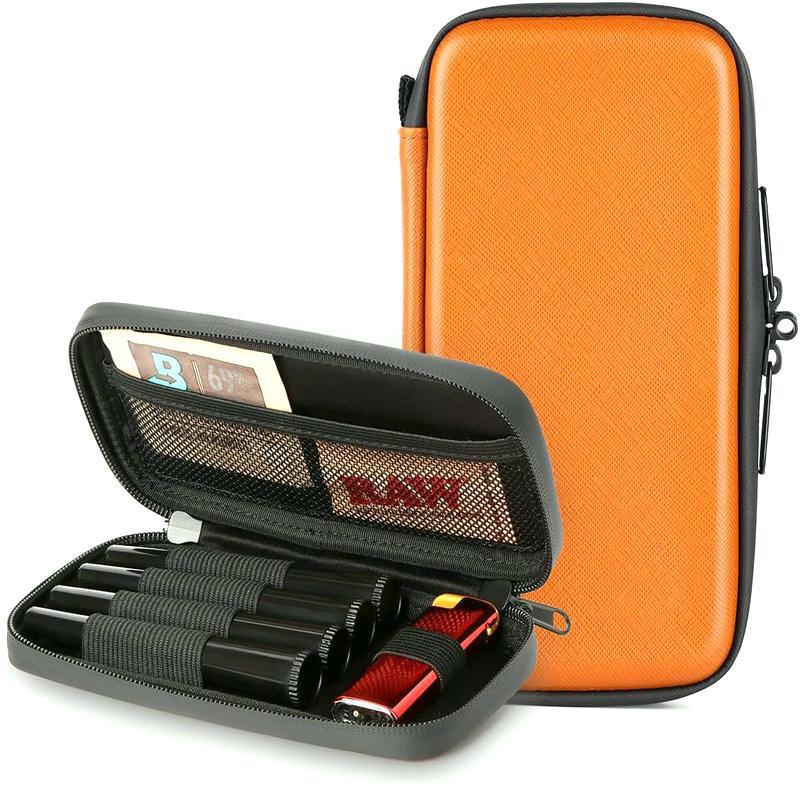

#2 Eva Case Manufacturer & Eva Hard Case

Domain Est. 2021

Website: casesbag.com

Key Highlights: Welcome to BaiYang Factory Products Catalog. We have more than 15 year’ experience to satisfy your EVA cases, Neoprene Sleeve, Bags and Luggage requirements….

#3 EVA low melt batch inclusion bag

Domain Est. 2000 | Founded: 1989

Website: wenwugang.com.cn

Key Highlights: Wenwugang Technology, established in 1989, has now developed three major product lines. One is the PE isolation film and EVA low melt batch inclusion bags….

#4 Dongguan EVA Case Manufacturer

Domain Est. 2014

Website: evacase.net

Key Highlights: We are one of top 10 professional heat compression foaming factories from China! We custom EVA case and related products for more than 15 years….

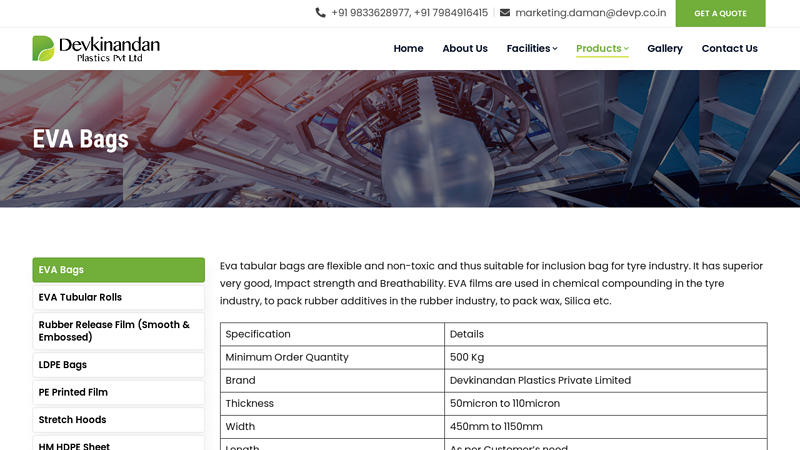

#5 EVA bags manufacturers in India.

Domain Est. 2019

Website: devkinandan.net

Key Highlights: Eva tabular bags are flexible and non-toxic and thus suitable for inclusion bag for tyre industry. It has superior very good, Impact strength and ……

#6 Medical EVA Bags

Domain Est. 1999

Website: gvs.com

Key Highlights: The medical EVA bags are plastic containers designed for compounding and storage of enteral and parenteral nutrition solutions, cell culture, ……

#7 EVA bags for blood derivatives and biopharmaceuticals

Domain Est. 1999

Website: technoflex.net

Key Highlights: Technoflex EVA bags suitable for blood derivatives, frozen plasma. They can be sterilized for parenteral nutrition solutions in hospitals….

#8 EVA Bags

Domain Est. 2020

Website: bplsource.com

Key Highlights: Ethyl Vinyl Acetate (EVA) bags are constructed from a copolymer, monolayer film PVC ports and tubing. This product is not made with natural rubber latex or DEHP ……

#9 Production and distribution of EVA products

Website: evacarbplast.hu

Key Highlights: EVA CarbPlast Kft. was established in the summer of 2021 with the aim of producing low-melting tube foil and bags in Hungary and Central Europe….

Expert Sourcing Insights for Eva Bags

H2 2026 Market Trends for Eva Bags

As we move deeper into 2026, the market for EVA (Ethylene-Vinyl Acetate) bags is experiencing significant transformation, driven by evolving consumer preferences, technological advancements, and intensified focus on sustainability. The H2 outlook reveals several key trends shaping the industry:

1. Sustainability & Circularity as Non-Negotiables:

Consumer and regulatory pressure is pushing EVA bag manufacturers beyond basic recyclability. H2 2026 sees a surge in demand for:

* Increased Recycled Content: Brands are actively sourcing EVA resins derived from post-consumer or post-industrial waste (rEVA), with transparency in sourcing becoming a key differentiator.

* Design for Disassembly & Recycling: Products are being engineered for easier material separation at end-of-life, facilitating mechanical recycling. Monomaterial constructions are gaining favor.

* Take-Back & Refurbishment Programs: Leading brands are launching or expanding programs to collect used EVA bags, refurbish them, or ensure proper recycling, strengthening brand loyalty and reducing waste.

2. Performance Innovation & Multifunctionality:

The “good enough” EVA bag is being replaced by high-performance, multi-use products:

* Enhanced Durability & Weather Resistance: Advanced EVA formulations offer improved resistance to UV degradation, extreme temperatures, and physical abrasion, extending product lifespan – a key sustainability driver.

* Smart Integration: H2 2026 sees early but growing adoption of integrated features like RFID blocking (for tech sleeves), minimalistic solar charging patches for small devices, or embedded tracking chips (using passive tech to avoid battery waste).

* Ergonomic & Adaptive Design: Focus on improved shoulder straps, back padding (for larger bags), and modular attachment systems (e.g., MOLLE-compatible webbing) for customization.

3. Premiumization & Brand Differentiation:

The market is bifurcating, with significant growth in the premium segment:

* Luxury & Fashion-Forward EVA: High-end brands and designers are embracing EVA’s moldability for unique, sculptural designs in fashion accessories (totes, clutches, footwear-integrated bags), moving beyond purely functional uses.

* Artisanal & Limited Editions: Collaborations with artists and designers for limited-run, collectible EVA bags are increasing, leveraging the material’s color vibrancy and formability.

* Focus on Aesthetics: Beyond utility, aesthetics are paramount. Expect sophisticated finishes (matte, soft-touch, textured), nuanced color palettes, and minimalist branding.

4. Supply Chain Resilience & Regionalization:

Geopolitical factors and cost volatility are impacting sourcing:

* Nearshoring/Reshoring: Some brands, particularly in North America and Europe, are shifting production closer to end markets to reduce lead times, transportation emissions, and supply chain risks.

* Vertical Integration: Larger players are investing in or securing long-term partnerships with EVA resin producers to ensure stable, ethically sourced, and potentially recycled material supply.

* Transparency & Traceability: Blockchain and digital product passports are being piloted to provide verifiable data on material origin, carbon footprint, and manufacturing conditions.

5. Niche Market Expansion:

EVA’s properties are unlocking new applications:

* Cold Chain & Medical Logistics: Growth in insulated EVA bags for last-mile delivery of pharmaceuticals, vaccines, and perishable goods, leveraging EVA’s excellent insulating properties.

* Specialized Sports & Outdoor: Beyond standard coolers, demand is rising for EVA bags designed for specific activities like e-bikes (integrated battery cases), drone transport (impact-resistant cases), and technical diving (dry bags with advanced seals).

* Eco-Tourism & Adventure Gear: Lightweight, durable, and waterproof EVA bags are becoming staples for travelers and outdoor enthusiasts, marketed heavily on durability and low environmental impact.

Conclusion for H2 2026:

The EVA bag market in H2 2026 is characterized by a powerful convergence of sustainability imperatives, technological refinement, and design innovation. Success will belong to brands that can authentically integrate recycled materials, extend product lifecycles, offer superior performance or unique design, and build transparent, resilient supply chains. The focus has decisively shifted from being merely “waterproof and lightweight” to being responsible, durable, intelligent, and desirable. Companies failing to adapt to these trends risk significant market share loss.

Common Pitfalls Sourcing Eva Bags: Quality and Intellectual Property Issues

Sourcing EVA (Ethylene-Vinyl Acetate) bags—popular for their durability, water resistance, and lightweight feel—can offer significant cost advantages, particularly when procuring from overseas manufacturers. However, buyers often encounter critical challenges related to quality consistency and intellectual property (IP) risks. Being aware of these common pitfalls is essential for protecting your brand, ensuring customer satisfaction, and avoiding legal complications.

Quality Inconsistencies

One of the most widespread issues when sourcing EVA bags is inconsistent product quality. Despite detailed specifications, many suppliers fail to deliver uniformly high standards across production batches.

-

Material Grade Variability: Not all EVA foam is created equal. Suppliers may use lower-grade EVA to cut costs, resulting in bags that are less durable, more prone to cracking, or with a cheaper tactile feel. Without strict material verification, the final product may fall short of expectations.

-

Poor Craftsmanship and Construction: Common defects include uneven seams, misaligned zippers, weak stitching, or glue overflow. These flaws not only affect aesthetics but also compromise functionality and longevity.

-

Color and Finish Discrepancies: Color variations between samples and bulk orders are frequent due to differences in dye lots or production conditions. Matte or glossy finishes may also differ, impacting brand presentation.

-

Lack of Rigorous Quality Control: Some factories lack standardized quality assurance processes. Without third-party inspections or clear acceptance criteria, defective units may slip through.

Best Practice: Require material certifications, conduct pre-production samples, perform in-line inspections, and schedule final random inspections before shipment.

Intellectual Property (IP) Risks

Sourcing EVA bags, especially custom designs, exposes businesses to significant IP vulnerabilities, particularly in regions with weaker IP enforcement.

-

Design Copying and Reverse Engineering: Suppliers may replicate your unique bag designs—shapes, logos, stitching patterns—and sell them to competitors or create knock-offs under different brands. Once a mold is created, it’s easy and cheap to reproduce.

-

Unauthorized Production (Overruns): Factories may produce additional units beyond your order quantity and sell them independently, diluting your brand and saturating the market.

-

Lack of Legal Protections: In many manufacturing countries, enforcement of IP laws is limited. Even with contracts, legal recourse can be slow, costly, or ineffective.

-

OEM/ODM Supplier Conflicts: If you engage an ODM (Original Design Manufacturer), there’s a risk they retain rights to the design or reuse it for other clients, undermining your exclusivity.

Best Practice: Protect your designs through patents or trademarks where possible. Use strong, jurisdiction-specific contracts with confidentiality clauses and audit rights. Work with trusted suppliers and consider using third-party IP protection services. Limit access to design files and molds.

By proactively addressing these quality and IP pitfalls, businesses can better safeguard their investments, maintain brand integrity, and ensure a reliable supply of high-performing EVA bags.

Logistics & Compliance Guide for Eva Bags

Overview

This guide outlines the essential logistics and compliance considerations for the manufacturing, distribution, and sale of Eva Bags—lightweight, durable bags made from ethylene-vinyl acetate (EVA) material. Adhering to these guidelines ensures efficient operations, regulatory compliance, and consumer safety across global markets.

Material Sourcing & Manufacturing Compliance

Ensure all EVA materials are sourced from reputable suppliers who provide certificates of compliance (C of C) for restricted substances. Confirm that EVA resins are free from hazardous chemicals such as phthalates, heavy metals (e.g., lead, cadmium), and other substances restricted under REACH (EU), CPSIA (USA), and other regional regulations. Implement a supplier audit program to verify environmental and labor standards.

Product Safety & Testing

All Eva Bags must undergo rigorous third-party testing to meet relevant safety standards, including:

– EN 71-3 (EU): Migration of certain elements in toy-related products (if applicable)

– CPSIA (USA): Lead and phthalate content limits

– Proposition 65 (California): Warning requirements for chemical exposure

– REACH SVHC: Compliance with Substances of Very High Concern

Maintain up-to-date test reports and technical documentation for each product line.

Packaging & Labeling Requirements

Product packaging must include:

– Manufacturer/importer name and address

– Country of origin

– Care instructions (if applicable)

– Compliance marks (e.g., CE mark for EU, FCC ID if electronics are integrated)

– Recycling symbols and material identification (e.g., “EVA” or “#7 Other”)

Ensure labels are durable, legible, and permanently affixed per local requirements.

Import & Export Regulations

Comply with customs regulations in both origin and destination countries:

– Secure accurate HS (Harmonized System) codes (e.g., 4202.92 for travel bags of plastic)

– Provide commercial invoices, packing lists, and certificates of origin

– Verify compliance with trade agreements (e.g., USMCA, RCEP) to benefit from reduced tariffs

– Monitor import restrictions or bans on certain plastics in target markets

Transportation & Logistics

Use protective packaging to prevent deformation or damage during transit. EVA bags are generally lightweight but can be sensitive to heat and pressure. Store and ship in climate-controlled environments when possible. Optimize packaging size and weight to reduce shipping costs and carbon footprint. Choose carriers with experience in consumer goods and reliable tracking systems.

Environmental & Sustainability Compliance

Adhere to Extended Producer Responsibility (EPR) regulations in applicable regions (e.g., packaging waste schemes in EU member states). Provide information on recyclability and encourage end-of-life return programs where possible. Avoid non-recyclable additives or laminates unless necessary. Explore use of recycled EVA content where feasible and certified.

Consumer Information & Warranties

Include clear user guidelines and warranty information with each product. Disclose care and maintenance instructions to prolong product life. Establish a process for handling customer complaints and product recalls in accordance with local consumer protection laws (e.g., Consumer Rights Act in UK, Magnuson-Moss Warranty Act in USA).

Recordkeeping & Documentation

Maintain comprehensive records for a minimum of 5 years, including:

– Test reports and compliance certifications

– Supplier agreements and audits

– Shipping and customs documentation

– Customer complaints and corrective actions

These records support regulatory audits and due diligence in case of product inquiries.

Conclusion

Effective logistics and strict compliance are critical to the successful global distribution of Eva Bags. By following this guide, manufacturers and distributors can ensure product safety, legal adherence, and operational efficiency while building consumer trust and brand integrity. Regularly review and update practices to align with evolving regulations and industry standards.

In conclusion, sourcing EVA (ethylene-vinyl acetate) bags requires a strategic approach that balances quality, cost, sustainability, and reliability. By identifying reputable suppliers, evaluating material safety and durability, considering environmental impact, and ensuring compliance with regulatory standards, businesses can secure high-quality EVA bags that meet both functional and ethical requirements. Additionally, leveraging bulk purchasing, establishing strong supplier relationships, and staying informed about market trends can enhance sourcing efficiency and long-term success. Ultimately, a well-structured sourcing strategy not only supports product excellence but also strengthens brand reputation and customer satisfaction in an increasingly competitive market.