The global demand for reliable network infrastructure has driven significant growth in the tools and equipment sector, particularly for Ethernet punch down tools—essential instruments in telecommunications and data cabling installations. According to Grand View Research, the global network cabling market was valued at USD 19.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030, fueled by increasing deployment of fiber optics, rising construction of smart buildings, and the proliferation of 5G and IoT technologies. Similarly, Mordor Intelligence projects steady growth in the structured cabling market, with a CAGR of approximately 6.8% over the forecast period (2023–2028), emphasizing the critical role of installation tools in maintaining high-performance networks. As data centers, enterprise networks, and broadband rollouts continue to scale, the need for precision, durability, and efficiency in termination tools has elevated the importance of leading manufacturers who combine innovation with reliability. In this competitive landscape, a select group of companies has emerged as top producers of Ethernet punch down tools, setting industry benchmarks in design, ergonomics, and performance.

Top 10 Ethernet Punch Down Tool Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Punchdown

Domain Est. 1995

Website: ecatalog.siemon.com

Key Highlights: The tool features an easy to hold, ergonomically designed handle that helps reduce fatigue when trimming wire or seating connecting blocks to the wiring base.Missing: ethernet man…

#2 Punch Down Installation Tool for Cat6/Cat5 Network Cable

Domain Est. 1996

Website: tripplite.eaton.com

Key Highlights: Rating 5.0 (4) This professional-grade, high-volume Punch-Down Cable Installation Tool, with adjustable impact, is the perfect multi-purpose tool for punching down Cat5/Cat6 ……

#3 Punchdown Tools

Domain Est. 1998

Website: jonard.com

Key Highlights: Free deliveryJonard Tools manufactures over 40 unique punchdown tools for the telecommunication, network and IT industry….

#4 Punchdown Tools

Domain Est. 1998

Website: kleintools.com

Key Highlights: Punchdown Tools ; VDV427300 Impact Punchdown Tool, 66/110 Blade Image. product number VDV427-300 VDV427-300 ; VDV427110 Extended Reach Blade for Impact Punchdown ……

#5 Punch Down and Termination Tools

Domain Est. 1999

Website: flukenetworks.com

Key Highlights: All-in-one wire crimping tool for fiber optics, ethernet cable and telephone wire plugs compatible with many 6- and 8- position modular telephone plugs….

#6 110 & 66 Block Punch Down Tools

Domain Est. 2002

Website: store.cablesplususa.com

Key Highlights: 4–11 day delivery 30-day returnsOur 110 & 66 Block Punch Down Tools are perfect for professionals who require an efficient and reliable tool for terminating and connecting wiring b…

#7 Introducing: trueIMPACT 110 Punch Down Tool

Domain Est. 2004

Website: truecable.com

Key Highlights: This blog will focus on our trueIMPACT 110 Impact punch down tool. There is a short video demonstration of the trueIMPACT tool below….

#8 Punchdown Tool, 66/110 Style

Domain Est. 2007

#9 High-Quality Punch Down Tools

Domain Est. 2013

Website: cableleader.com

Key Highlights: 5-day deliveryDiscover CableLeader’s range of punch down tools for 110 and 66 type applications. Adjustable impact force, interchangeable blades, and durable construction….

#10 VCELINK

Domain Est. 2017

Website: vcelink.com

Key Highlights: Enjoy “Buy More, Save More” offer at VCELINK, your go-to supplier for all Ethernet and low-voltage products. … Keystone Punch Down Tool VCELINK. $39.99 USD….

Expert Sourcing Insights for Ethernet Punch Down Tool

H2: 2026 Market Trends for Ethernet Punch Down Tools

The Ethernet punch down tool market is poised for notable evolution by 2026, driven by the expansion of high-speed network infrastructure, increased demand for reliable connectivity, and advancements in structured cabling systems. These tools, essential for terminating twisted-pair cables into punch down blocks, patch panels, and keystone jacks, are experiencing shifts influenced by technological innovation, labor efficiency demands, and global digital transformation.

1. Rising Demand from Data Centers and 5G Infrastructure

With the continued rollout of 5G networks and the exponential growth of cloud computing, data centers are expanding rapidly. This expansion demands high-density cabling installations, increasing the need for efficient punch down tools. By 2026, the demand for precision tools compatible with Cat6A, Cat7, and emerging Cat8 cabling standards will grow, particularly in regions like North America, Europe, and parts of Asia-Pacific.

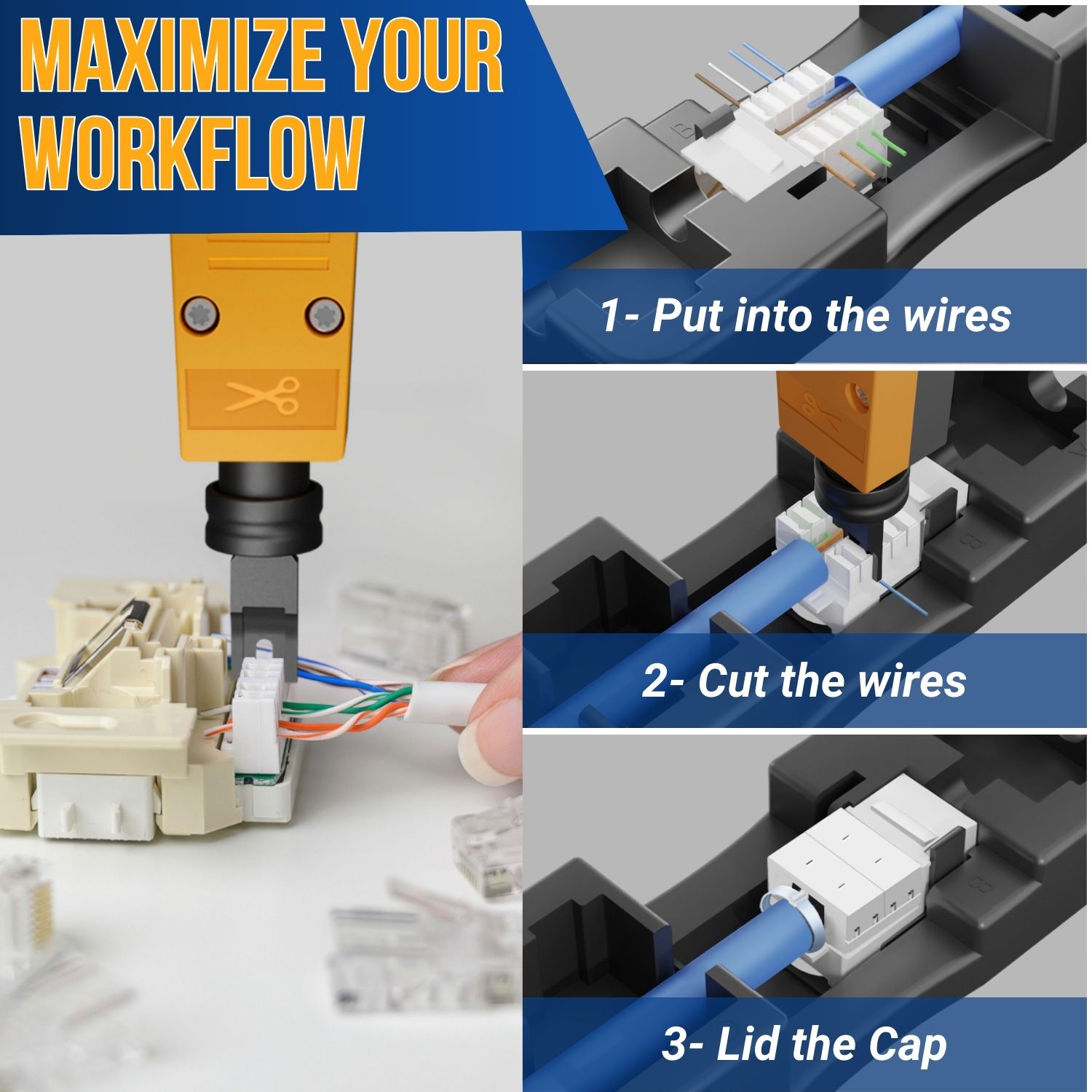

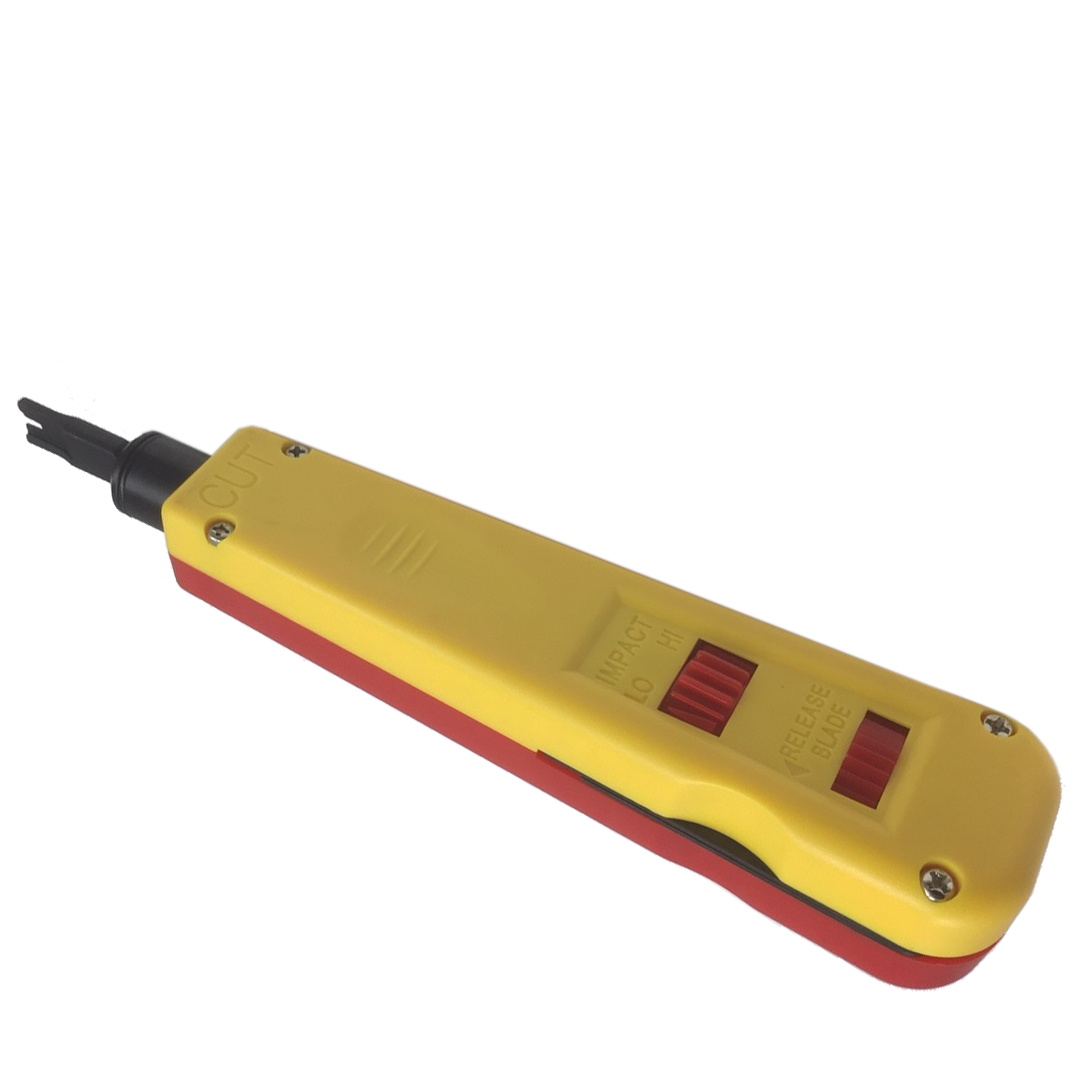

2. Automation and Ergonomic Design Innovations

Manufacturers are increasingly focusing on ergonomic, lightweight, and self-stripping punch down tools to reduce technician fatigue and improve installation speed. By 2026, expect wider adoption of tools with built-in wire cutters, interchangeable blades, and smart features such as force feedback or alignment guides. These enhancements aim to minimize human error and support faster deployment in large-scale installations.

3. Shift Toward Tool Kits and Bundled Solutions

Market players are responding to contractor preferences by offering comprehensive networking tool kits that include punch down tools, cable testers, crimpers, and strippers. This bundling strategy enhances value and convenience, especially for small and medium-sized enterprises (SMEs) and independent installers. By 2026, integrated solutions are expected to dominate procurement channels.

4. Sustainability and Durability Focus

As environmental regulations tighten, manufacturers are shifting toward recyclable materials and longer-lasting tool designs to reduce electronic and industrial waste. Durable, repairable tools made from high-grade steel or composite materials are gaining favor. This trend aligns with corporate sustainability goals and lifecycle cost considerations in enterprise deployments.

5. Regional Market Growth and Supply Chain Adaptations

Asia-Pacific is projected to be the fastest-growing market due to government-led smart city initiatives and broadband expansion in countries like India and Southeast Asian nations. Meanwhile, North America and Europe maintain strong demand driven by network upgrades and IoT integration. Supply chains are adapting to localized manufacturing and inventory resilience to mitigate disruptions, influencing tool availability and pricing.

6. Competitive Landscape and Brand Differentiation

The market remains competitive, with key players such as Fluke Networks, Klein Tools, Ideal Industries, and Panduit investing in R&D and brand differentiation. By 2026, success will depend on innovation, compatibility with emerging standards, and strong distribution networks. Emerging brands may leverage e-commerce platforms to gain market share, particularly in B2C and prosumer segments.

In summary, the 2026 Ethernet punch down tool market will reflect broader trends in network infrastructure development, emphasizing efficiency, precision, and sustainability. As connectivity demands intensify globally, punch down tools will remain a critical—but increasingly sophisticated—component of structured cabling ecosystems.

Common Pitfalls When Sourcing an Ethernet Punch Down Tool (Quality and IP)

Poor Build Quality Leading to Inconsistent Termination

Many low-cost punch down tools are constructed with substandard materials, such as brittle plastic housings or soft metal blades. This can result in inconsistent wire seating, damaged insulation, or incomplete connections, leading to network signal loss or intermittent connectivity. Users may also experience tool failure after minimal use, especially in high-volume installations.

Dull or Improperly Designed Blades

A frequent issue is receiving tools with dull or incorrectly shaped blades that don’t fully seat wires into IDC (Insulation Displacement Connector) terminals. This compromises termination reliability and can damage patch panel or jack contacts. Some tools lack interchangeable blades or are not compatible with standard 110 or Krone-style blocks, limiting their versatility.

Lack of Intellectual Property (IP) Compliance

Sourcing counterfeit or imitation tools that infringe on patented designs (e.g., those resembling知名品牌 like Fluke or Ideal) can expose buyers to legal risks. These knock-offs often bypass IP protections and may not meet safety or performance standards, undermining warranty validity and organizational compliance.

Inadequate Ergonomics and User Fatigue

Poorly designed tools with uncomfortable grips or excessive actuation force contribute to hand strain during prolonged use. This not only reduces work efficiency but may also lead to repetitive strain injuries, especially for technicians handling large-scale deployments.

Missing Safety and Certification Standards

Some imported punch down tools lack essential safety certifications (e.g., CE, RoHS, or UL recognition), indicating potential non-compliance with electrical and material safety regulations. This is particularly concerning in enterprise or industrial environments where tool reliability and user safety are critical.

Limited Compatibility with Modern Cabling Standards

Certain tools are not optimized for higher category cables (e.g., Cat 6A or Cat 7), which require precise punch-down techniques to maintain signal integrity. Tools without proper blade geometry or depth control can disrupt cable twist or damage shielding, resulting in failed certification tests.

Logistics & Compliance Guide for Ethernet Punch Down Tool

Product Overview

The Ethernet Punch Down Tool is a hand-held tool used in network cabling installations to terminate twisted-pair cables onto punch-down blocks, patch panels, and keystone jacks. This guide outlines the logistics and compliance requirements for the import, distribution, and use of such tools.

Classification & HS Code

- HS Code: 8205.40.00 (Hand tools not elsewhere specified, of base metal)

- Category: Hand Tools / Network Installation Equipment

- Note: Classification may vary slightly by country; verify with local customs authorities.

Import & Export Documentation

- Commercial Invoice: Must include product description, quantity, value, country of origin, and HS code.

- Packing List: Detailed list of contents per shipment.

- Bill of Lading/Air Waybill: Required for freight forwarding.

- Certificate of Origin: May be required for preferential tariff treatment under trade agreements.

- Import Permits: Typically not required for hand tools, but confirm with destination country.

Packaging & Labeling Requirements

- Packaging: Standard retail or bulk packaging; must be durable for shipping.

- Labeling:

- Product name and model number

- Manufacturer or brand name

- Country of origin

- Safety warnings (e.g., eye protection recommended)

- CE, UKCA, or other applicable marks (if present)

- Language: Labels and instructions must comply with local language requirements in target markets (e.g., English in the U.S., French in Canada, bilingual in EU countries).

Regulatory Compliance

United States

- OSHA: No specific OSHA regulation for punch down tools, but general hand tool safety guidelines apply.

- FCC: Not applicable — non-electrical tool.

- Cal/OSHA: Complies with general tool safety standards; no chemical emissions.

European Union

- CE Marking: Required. Must comply with:

- PPE Regulation (EU) 2016/425: If marketed as protective equipment (not typical).

- Machinery Directive 2006/42/EC: May not apply to simple hand tools.

- RoHS 2 (2011/65/EU): Applies if tool contains electrical components (not typical for basic punch down tools).

- REACH (EC 1907/2006): Ensure no restricted substances in materials (e.g., lead, cadmium).

- UKCA Marking: Required for sale in Great Britain (post-Brexit); similar requirements to CE.

Canada

- Health Canada: No specific regulations for hand tools.

- Labeling: Bilingual (English/French) required under the Consumer Packaging and Labelling Act.

Australia & New Zealand

- AS/NZS Standards: No specific standard for punch down tools; general tool safety applies.

- ACCC Compliance: Must meet general product safety requirements under the Australian Consumer Law.

Environmental & Safety Compliance

- WEEE (EU): Not applicable — not electrical/electronic equipment.

- Battery/Chemical Content: Standard punch down tools contain no batteries or hazardous chemicals.

- User Safety: Recommend including safety instructions (e.g., wear eye protection, proper handling).

Shipping & Handling

- Weight & Dimensions: Typically lightweight (<1 lb / 0.5 kg); small package.

- Shipping Modes: Air, sea, or ground freight acceptable.

- Hazardous Materials: Not classified as hazardous; no IATA/IMDG restrictions.

- Storage Conditions: Store in dry, temperature-controlled environments; avoid prolonged exposure to moisture.

Warranty & After-Sales Support

- Standard Warranty: Typically 1-year limited warranty against manufacturing defects.

- Compliance with Local Laws: Warranty terms must comply with consumer protection laws (e.g., EU Consumer Rights Directive, U.S. Magnuson-Moss Warranty Act).

Record Keeping & Traceability

- Maintain records of:

- Supplier certifications

- Product conformity documentation

- Test reports (if applicable)

- Batch/lot numbers for traceability

- Retention period: Minimum 5–10 years, depending on jurisdiction.

Summary

The Ethernet Punch Down Tool is a low-risk, non-electric hand tool with minimal regulatory barriers. Compliance primarily involves accurate HS coding, proper labeling, and adherence to general product safety and environmental regulations in target markets. Always verify requirements with local authorities prior to shipment.

In conclusion, sourcing the right Ethernet punch down tool is a critical step in ensuring efficient, reliable, and professional network installations. When selecting a punch down tool, key factors such as durability, ergonomics, compatibility with different connector types (e.g., 66, 110, Krone), and blade quality must be carefully evaluated. Whether opting for a basic manual tool or a more advanced interchangeable or impact model, the choice should align with the scale and frequency of the work. Sourcing from reputable suppliers or manufacturers ensures tool authenticity, consistent performance, and access to warranties or customer support. Ultimately, investing in a high-quality punch down tool enhances termination accuracy, reduces cable damage, and improves overall productivity—making it a worthwhile consideration for any network cabling professional.