The global ethernet cable market is experiencing robust growth, driven by increasing demand for high-speed data transmission across data centers, enterprise networks, and smart infrastructure. According to a report by Mordor Intelligence, the global ethernet cable market was valued at USD 12.4 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of over 6.8% from 2024 to 2029. This expansion is fueled by the rising deployment of 5G networks, cloud computing, and the Internet of Things (IoT), all of which require reliable and high-performance connectivity solutions. As a critical component of ethernet cables, the quality and precision of cable ends—also known as connectors or RJ45 plugs—have become paramount in ensuring signal integrity and durability. This growing demand has spurred innovation and competition among manufacturers specializing in ethernet cable ends, with a select group of companies leading the market in terms of production volume, technological advancement, and global reach.

Top 10 Ethernet Cable End Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Panduit

Domain Est. 1994

Website: panduit.com

Key Highlights: Panduit develops smarter, scalable network infrastructure and industrial electrical wiring solutions that unlock the full potential of your business….

#2 Belden

Domain Est. 1997

Website: belden.com

Key Highlights: We design, manufacture and market networking, connectivity, cable products and solutions for industrial automation, smart buildings and broadcast markets….

#3 Industrial Ethernet

Domain Est. 2021

Website: amphenol-cs.com

Key Highlights: Amphenol has a full range of Industrial Ethernet connectors to reliably help carry the load. We offer a range of interconnect and cable assembly products….

#4 Cables

Domain Est. 1994

Website: commscope.com

Key Highlights: CommScope Cables for Superior Connectivity. CommScope offers an extensive range of high-performance cables to meet your connectivity needs….

#5 Ethernet connectors

Domain Est. 1996

Website: weidmuller.com

Key Highlights: Pre-assembled connectors for copper and fiber optic cables suitable for field assembly ensure reliable data transmission in your Ethernet networks….

#6 L

Domain Est. 1996

Website: l-com.com

Key Highlights: L-com’s cable configurator allows you to build custom cable assemblies with low or no minimum order quantities and fast turn-around times. Get Started. New ……

#7 PIC Wire & Cable

Domain Est. 1996

Website: picwire.com

Key Highlights: Premium interconnect cables designed for electronic RF, video, data, and high-frequency aerospace applications….

#8 cable management, ethernet cable management, network cable …

Domain Est. 2000

Website: patchsee.com

Key Highlights: The best cabling solution in the patching frames: PATCHSEE INTELLIGENT PATCH CORD, a unique innovation to trace your cables at the speed of light!…

#9 Cablesys: Pre

Domain Est. 2002

Website: cablesys.com

Key Highlights: Cablesys manufactures data center grade Ethernet cable and connectivity; pre-terminated patch panels, patch cables, CAT6, CAT6A, UTP, FTP, CMR, and CMP….

#10 List of RJ45 Connectors Models & Products

Domain Est. 1992

Website: te.com

Key Highlights: Our RJ45 connector portfolio offers multiple and single port connectors, ganged or stacked multiple port configuration, and shielded and unshielded connectors….

Expert Sourcing Insights for Ethernet Cable End

H2: 2026 Market Trends for Ethernet Cable Ends

The global market for Ethernet cable ends—comprising connectors, plugs, jacks, and termination components—is poised for significant evolution by 2026, driven by rapid advancements in networking infrastructure, increasing demand for high-speed data transmission, and the expansion of smart technologies. Several key trends are expected to shape this market over the next few years.

1. Rising Demand for High-Speed Connectivity

With the proliferation of bandwidth-intensive applications such as 4K/8K video streaming, cloud computing, virtual reality (VR), and online gaming, there is a growing need for Ethernet cables that support higher data rates. As a result, the demand for Ethernet cable ends compatible with Cat6A, Cat7, and Cat8 standards is increasing. By 2026, these high-performance connectors will dominate the market, especially in data centers and enterprise networks, where reliability and speed are critical.

2. Growth in Data Center Expansion

Hyperscale data centers and edge computing facilities are expanding rapidly to meet the demands of digital transformation and 5G rollout. This infrastructure growth is directly boosting the need for reliable Ethernet interconnects. Modular jacks and shielded connectors that reduce electromagnetic interference (EMI) and support Power over Ethernet (PoE++) are increasingly preferred, driving innovation and adoption in the Ethernet cable end segment.

3. Adoption of PoE and Smart Building Technologies

The integration of Power over Ethernet (PoE) in IP cameras, VoIP phones, smart lighting, and IoT devices is accelerating. By 2026, Ethernet cable ends designed to handle higher power loads (up to 90W with PoE++) will see robust market growth. The rise of smart homes and intelligent building systems will further fuel demand for durable, high-efficiency connectors capable of transmitting both data and power reliably.

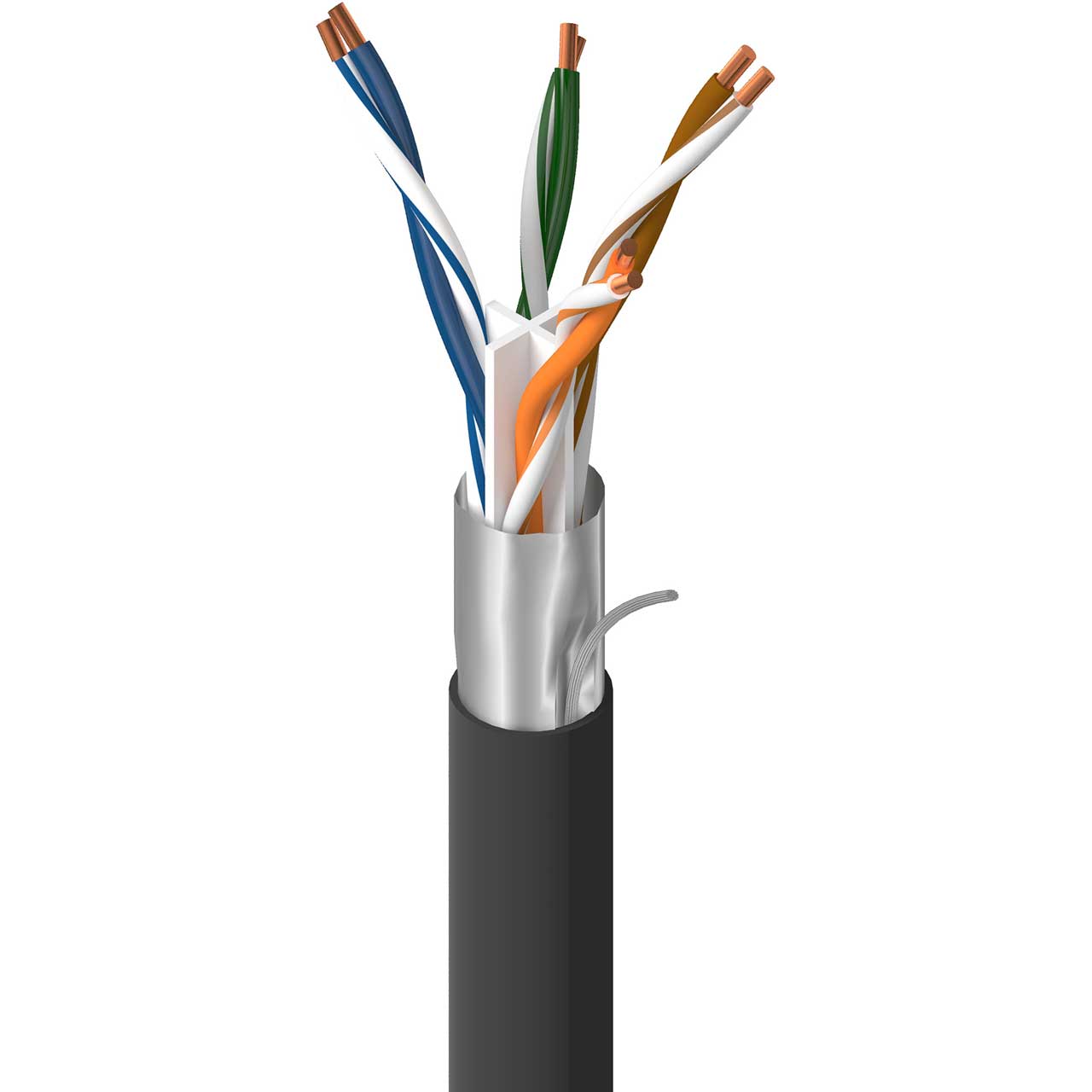

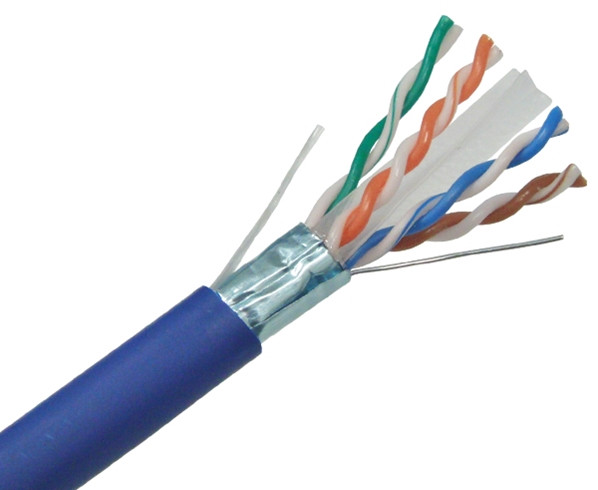

4. Increased Focus on Miniaturization and Reliability

As network devices become smaller and more compact, there is a trend toward miniaturized Ethernet connectors, such as compact RJ45 and magnetic jacks. Manufacturers are investing in designs that maintain signal integrity while reducing form factors. Additionally, ruggedized and industrial-grade Ethernet ends are gaining traction in harsh environments, including manufacturing, transportation, and outdoor installations.

5. Regional Market Dynamics and Supply Chain Shifts

Asia-Pacific is expected to lead market growth by 2026, driven by strong investments in telecommunications infrastructure in countries like China, India, and South Korea. North America and Europe will maintain steady growth due to data center buildouts and smart city initiatives. However, supply chain localization and efforts to reduce dependency on single-source suppliers may lead to increased regional manufacturing of Ethernet components.

6. Sustainability and Material Innovation

Environmental regulations and corporate sustainability goals are pushing manufacturers to develop Ethernet cable ends using recyclable materials and lead-free soldering processes. By 2026, eco-friendly production methods and longer product lifecycles will be key differentiators in the competitive landscape.

In conclusion, the Ethernet cable end market in 2026 will be shaped by the convergence of speed, power delivery, miniaturization, and sustainability. Stakeholders who innovate in high-performance, energy-efficient, and environmentally responsible connector solutions will be best positioned to capture market share in this evolving ecosystem.

Common Pitfalls When Sourcing Ethernet Cable Ends (Quality, IP)

When sourcing Ethernet cable ends—particularly for industrial or high-performance applications—overlooking key quality and IP (Ingress Protection) rating factors can lead to network failures, safety hazards, and costly downtime. Below are common pitfalls to avoid:

Poor Material Quality and Construction

Using low-grade materials in connectors, such as cheap plastics or substandard metal contacts, can result in poor conductivity, signal loss, and premature failure. Look for connectors made with gold-plated contacts and durable thermoplastic or metal housings to ensure longevity and reliable performance.

Inadequate IP Rating for Environment

Selecting connectors without appropriate IP ratings for the operating environment is a frequent mistake. For example, using an IP20-rated connector in outdoor or industrial settings exposes the connection to dust and moisture, leading to corrosion and short circuits. Always match the IP rating (e.g., IP67, IP68) to the environmental conditions—such as exposure to water, dust, or chemicals.

Mismatched Cable and Connector Specifications

Pairing connectors with incompatible cable types (e.g., Cat6a connector with Cat5e cable) can degrade network performance and fail to support required bandwidth. Ensure compatibility in terms of category rating, shielding (STP/UTP), and conductor size to maintain signal integrity and meet performance standards.

Lack of Strain Relief

Failing to include proper strain relief in the connector design puts stress on solder joints or crimp connections, increasing the risk of cable detachment. Choose connectors with built-in strain relief or ruggedized boots, especially in high-vibration environments like manufacturing or transportation.

Absence of EMI/RFI Shielding

In electrically noisy environments, unshielded connectors can lead to electromagnetic interference (EMI) or radio frequency interference (RFI), disrupting data transmission. Use shielded connectors (e.g., FTP or S/FTP compatible) with 360° shielding continuity to maintain signal quality in industrial or high-interference areas.

Non-Compliance with Industry Standards

Sourcing connectors that do not meet recognized standards (e.g., IEC 60512, TIA/EIA-568) can result in inconsistent performance and safety risks. Always verify compliance with relevant certifications to ensure reliability, interoperability, and regulatory acceptance.

Overlooking Mechanical Durability

Connectors used in harsh environments must withstand repeated mating cycles, impact, and temperature fluctuations. Avoid flimsy designs; instead, opt for ruggedized, locking (e.g., screw or push-pull) connectors that provide secure connections and resist accidental disengagement.

By addressing these pitfalls during the sourcing process, organizations can ensure reliable, long-lasting Ethernet connections that meet both performance and environmental demands.

Logistics & Compliance Guide for Ethernet Cable Ends

This guide outlines key logistics considerations and compliance requirements for the handling, transportation, and regulatory adherence of Ethernet cable ends—components used in network cabling systems such as RJ45 connectors, plugs, and terminations.

Regulatory Compliance

Ensure all Ethernet cable ends meet applicable international and regional standards to guarantee performance, safety, and environmental responsibility.

Electrical and Performance Standards

Ethernet cable ends must comply with recognized industry specifications to ensure interoperability and data transmission reliability. Key standards include:

– ANSI/TIA-568: Governs commercial building telecommunications cabling standards in the U.S.

– ISO/IEC 11801: International standard for structured cabling, including performance criteria for connectors.

– IEEE 802.3: Defines Ethernet protocol requirements, influencing connector design for data integrity.

Safety and Environmental Regulations

Manufacturers and distributors must adhere to safety and ecological directives, particularly when shipping globally.

– RoHS (Restriction of Hazardous Substances): Applies in the EU and other regions; restricts lead, mercury, cadmium, and other hazardous materials in electrical equipment.

– REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): Requires disclosure of substances of very high concern (SVHC) in products sold in the EU.

– WEEE (Waste Electrical and Electronic Equipment): Mandates proper disposal and recycling of electronic components, including cable ends.

Packaging and Labeling Requirements

Proper labeling supports compliance and efficient logistics:

– Include product specifications (e.g., Cat5e, Cat6, Cat6a), RoHS/REACH compliance marks, and manufacturer details.

– Use anti-static packaging where applicable to protect sensitive components during transit.

– Ensure multilingual labeling for international shipments, especially in EU and Asian markets.

Logistics Management

Efficient logistics ensure timely delivery while maintaining product integrity and minimizing costs.

Storage Conditions

Ethernet cable ends are generally non-sensitive but should be stored under controlled conditions:

– Maintain dry, temperature-stable environments (15°C to 30°C recommended).

– Avoid exposure to dust, moisture, and direct sunlight to prevent oxidation or material degradation.

– Store in original sealed packaging until use to preserve quality.

Transportation and Handling

- Use standard parcel or freight shipping methods depending on order volume.

- Implement ESD (electrostatic discharge) protection during bulk handling if required.

- Consolidate shipments where possible to reduce carbon footprint and shipping expenses.

- Track shipments using barcodes or RFID tags for inventory accuracy.

Import and Export Documentation

Cross-border shipments require proper documentation to avoid delays:

– Commercial invoice detailing product description, value, and harmonized system (HS) code (e.g., 8531.80 for electrical connectors).

– Certificate of conformity for regulated markets.

– Bill of lading or air waybill for freight tracking.

– Verify customs duties and import taxes based on destination country regulations.

Supplier and Quality Assurance

- Source from certified suppliers complying with ISO 9001 (Quality Management) and ISO 14001 (Environmental Management).

- Conduct periodic audits and sample testing to ensure ongoing compliance and performance.

By adhering to this logistics and compliance framework, businesses can ensure the reliable distribution of Ethernet cable ends while meeting global regulatory demands and maintaining supply chain efficiency.

Conclusion on Sourcing Ethernet Cable Ends (RJ45 Connectors):

Sourcing the right Ethernet cable ends, commonly known as RJ45 connectors, is a critical step in ensuring reliable and high-performance network connections. The choice of connector should align with the cable category (e.g., Cat5e, Cat6, Cat6a), shielding requirements, and termination method (solid vs. stranded conductors). High-quality connectors made from durable materials with gold-plated contacts help minimize signal loss, crosstalk, and corrosion, contributing to long-term network stability.

When sourcing, consider reputable manufacturers, compatibility with your crimping tools, and whether you need shielded (STP) or unshielded (UTP) versions for your environment. Bulk purchasing can reduce costs for large-scale deployments, but always prioritize quality over price to avoid connectivity issues. Additionally, ensuring compatibility with your chosen Ethernet standard (e.g., Gigabit or 10 Gigabit Ethernet) is essential for future-proofing your network infrastructure.

In summary, carefully selecting and sourcing the appropriate Ethernet cable ends enhances connection reliability, supports optimal data transmission speeds, and reduces the risk of network downtime—making it a vital consideration in any cabling project.