The global essential oils market is experiencing robust growth, driven by rising consumer demand for natural and organic products across personal care, aromatherapy, and wellness industries. According to Grand View Research, the market was valued at USD 14.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 8.1% from 2023 to 2030. Similarly, Mordor Intelligence forecasts a CAGR of approximately 7.5% over the 2024–2029 period, citing increasing awareness of holistic health and the expansion of e-commerce platforms as key growth accelerators. As demand for high-purity essential oils surges, the role of reliable distillation equipment becomes critical. This has elevated the importance of advanced essential oil distillers capable of ensuring consistent yield, purity, and scalability. Below are the top 9 essential oil distiller manufacturers leading innovation and quality in this expanding sector.

Top 9 Essential Oil Distillers Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Young Living Farms

Domain Est. 1996

Website: youngliving.com

Key Highlights: Young Living is known as a pioneering force in the essential oil industry, and our legacy of research on essential oil production and use is integral to our ……

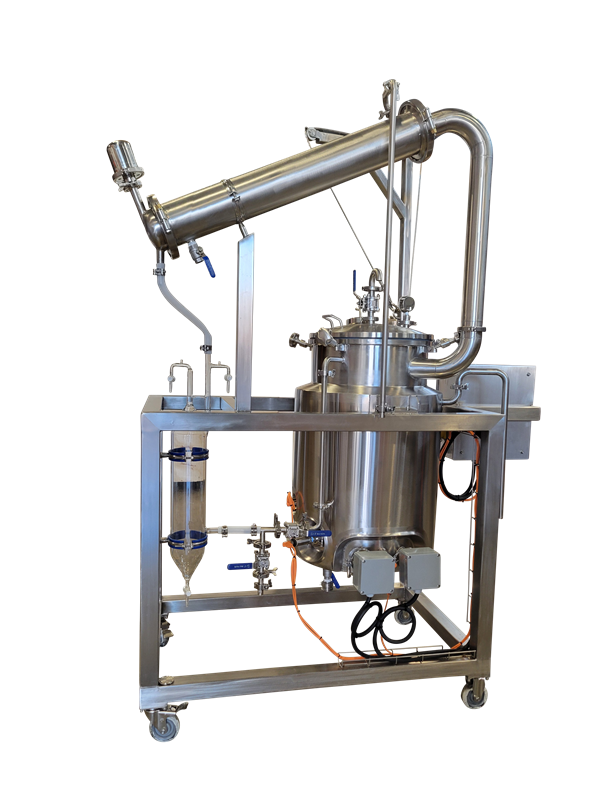

#2 Essential Oil Distillation

Domain Est. 1999

Website: newhouse-mfg.com

Key Highlights: Newhouse manufactures essential oil distillation equipment for commercial and home use. Ideal for aromatherapy, our food-grade stainless steel stills are ……

#3 Essential Oil Distillation, Extraction, Production Company

Domain Est. 2003

Website: hreynaud.com

Key Highlights: Reynaud & Fils, we have been distilling and selecting essential oils for over 120 years. Each essence is the result of expertise passed down from generation to ……

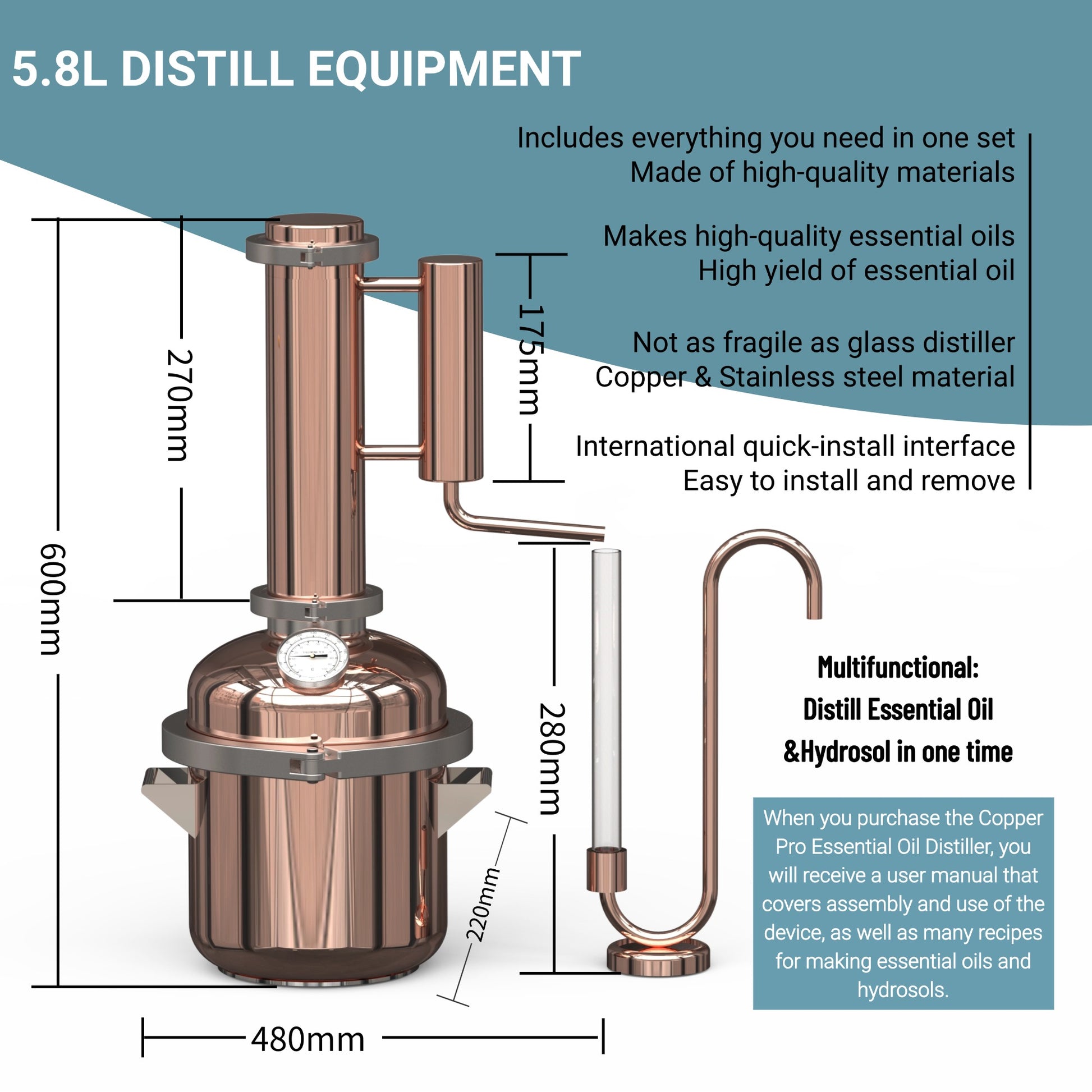

#4 Essential Oil & Hydrosol Distillation Kits

Domain Est. 2004

Website: copper-alembic.com

Key Highlights: Distillation Kits used to make steam distillation and hydrodistillation to collect both Essential Oils & Hydrosols….

#5 French laboratory for plants distillation

Domain Est. 2016

Website: laboratoire-helpac.com

Key Highlights: We transform more than 200 aromatic plants into essential oils, floral waters, oily macerates, vegetable oils and buds macerates….

#6 Hooloo Distillery Supply

Domain Est. 2017

Website: hooloodistill.com

Key Highlights: 7–15 day delivery 30-day returnsHooLoo is specialized in designing, producing and providing equipment including brewhouse, fermenter, bright beer tank, distillers, and etc….

#7 Distillery and Distiller Accessories

Domain Est. 2020

#8 Distillery – Eschgfeller

Website: eschgfeller.eu

Key Highlights: This is where the Eschgfeller family has been distilling valuable essential oils using steam distillation for more than five decades. Our manufacturing process ……

#9 Dolby Essential Stills

Domain Est. 2020 | Founded: 1995

Website: essentialstills.com

Key Highlights: Dolby Essential Stills has been manufacturing essential oil equipment since 1995. We now manufacture fully in-house at our factory in the Garden of England ……

Expert Sourcing Insights for Essential Oil Distillers

H2: 2026 Market Trends for Essential Oil Distillers

The global essential oil distillers market is poised for significant transformation by 2026, driven by evolving consumer preferences, technological advancements, and growing demand for natural and sustainable products. Key trends shaping the industry include:

-

Rising Demand in Aromatherapy and Wellness

The wellness industry continues to expand, with aromatherapy playing a central role. Consumers are increasingly adopting essential oils for stress relief, sleep improvement, and mental clarity. This trend is pushing distillers to scale production while maintaining high purity standards, particularly for oils like lavender, eucalyptus, and tea tree. -

Emphasis on Sustainable and Ethical Sourcing

Environmental concerns are influencing both producers and consumers. By 2026, distillers are expected to prioritize sustainable farming practices, fair trade sourcing, and eco-friendly distillation methods. Certifications such as organic, non-GMO, and carbon-neutral are becoming competitive advantages in the marketplace. -

Technological Innovation in Extraction Processes

Advancements in distillation technology—such as low-pressure steam distillation, hydro-diffusion systems, and integration with IoT for real-time monitoring—are improving yield efficiency and oil quality. Automated and modular distillers are gaining traction, especially among small to mid-sized producers aiming for scalability and consistency. -

Growth in DIY and Home-Based Distillation

The rise of the home wellness movement has fueled demand for compact, user-friendly essential oil distillers. By 2026, the consumer-grade distiller market is projected to grow significantly, with manufacturers focusing on affordability, safety, and ease of use for home herbalists and hobbyists. -

Expansion in Emerging Markets

Asia-Pacific and Latin America are emerging as high-growth regions due to increasing disposable incomes and traditional medicine integration. Countries like India, China, and Brazil are investing in local distillation infrastructure to support domestic and export demand, creating new opportunities for distiller manufacturers. -

Regulatory Scrutiny and Quality Standards

Regulatory bodies are tightening standards around labeling, adulteration, and safety. Distillers who can provide verifiable traceability—from plant source to final product—are likely to gain consumer trust and market share. Blockchain and QR-code tracking are being adopted to enhance transparency. -

Diversification into Niche and Rare Oils

As mainstream oils become commoditized, distillers are exploring high-value niche products such as blue tansy, spikenard, and champaca. These rare oils cater to premium skincare and luxury fragrance markets, offering higher margins and differentiation.

In summary, by 2026, essential oil distillers will need to balance innovation, sustainability, and quality to remain competitive. The convergence of wellness trends, technological progress, and global market expansion will define the future landscape of the industry.

Common Pitfalls When Sourcing Essential Oil Distillers: Quality and Intellectual Property Risks

Sourcing essential oil distillers requires careful due diligence, particularly concerning product quality and intellectual property (IP) protection. Overlooking these areas can lead to significant operational, legal, and reputational risks.

Quality-Related Pitfalls

Inconsistent or Substandard Product Quality

Many distillers, especially smaller or less experienced ones, may lack standardized processes, leading to batch-to-batch variability in chemical composition, aroma, and potency. Factors such as plant sourcing, distillation time, temperature control, and equipment cleanliness greatly influence quality. Without stringent quality control (QC) protocols and third-party testing (e.g., GC/MS analysis), buyers risk receiving adulterated or ineffective oils.

Lack of Transparency in Sourcing and Processing

Some suppliers obscure the origin of raw botanicals or use unsustainable harvesting practices. This opacity can result in contaminated or low-yield materials. Additionally, undisclosed use of solvents, synthetic additives, or re-distillation with fillers undermines product integrity and can violate regulatory standards for natural or organic labeling.

Absence of Certifications and Documentation

Reputable distillers typically hold certifications such as ISO, organic (e.g., USDA, ECOCERT), or fair trade. Sourcing from distillers without verifiable certifications increases the risk of non-compliance and exposes buyers to supply chain vulnerabilities, especially in regulated markets like cosmetics or aromatherapy.

Intellectual Property-Related Pitfalls

Unauthorized Use of Proprietary Blends or Formulations

If a buyer shares a custom essential oil blend or formulation with a distiller, there’s a risk the distiller may replicate or resell it to competitors without consent. Without a clear confidentiality agreement (NDA) or IP ownership clause in contracts, the buyer may lose exclusive rights to their innovation.

Lack of Clarity on IP Ownership in Co-Developed Products

In collaborative development scenarios, failure to define IP ownership upfront can lead to disputes. For instance, if a distiller contributes to refining a unique extraction method, conflicting claims over patents or trade secrets may arise unless contractual terms explicitly assign rights.

Exposure to Counterfeit or Pirated Processes

Some distillers may use patented distillation technologies or methods without proper licensing. Sourcing from such suppliers can inadvertently involve the buyer in IP infringement, leading to legal liability, especially if the final product enters markets with strong IP enforcement.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Conduct on-site audits and request full batch testing reports.

– Require legally binding NDAs and clear IP assignment agreements.

– Prioritize distillers with recognized certifications and transparent supply chains.

– Include quality specifications and IP protections in procurement contracts.

Proactive management of quality and IP concerns ensures a reliable, ethical, and legally sound supply of essential oils.

Logistics & Compliance Guide for Essential Oil Distillers

Understanding Essential Oil Regulations

Essential oil distillers must comply with a range of local, national, and international regulations. These include food, drug, cosmetic, and environmental safety standards. In the United States, the Food and Drug Administration (FDA) regulates essential oils based on their intended use—whether as cosmetics, dietary supplements, or therapeutic agents. The Environmental Protection Agency (EPA) may also regulate certain essential oils if marketed as pesticides. In the European Union, essential oils are governed by the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation and the EU Cosmetics Regulation (EC) No 1223/2009.

Distillers should classify their products accurately and ensure that labeling and claims comply with jurisdictional requirements. Mislabeling or making unsubstantiated health claims can result in regulatory penalties.

Sourcing Raw Materials Responsibly

Sustainable and ethical sourcing of botanical materials is critical for compliance and brand integrity. Distillers must verify the origin of plant material and ensure it is harvested in accordance with environmental and labor laws. Certification programs such as Fair Trade, USDA Organic, and Forest Stewardship Council (FSC) can help demonstrate responsible sourcing practices.

Documentation such as Certificates of Origin, Organic Certifications, and CITES (Convention on International Trade in Endangered Species) permits are often required, especially when importing plant material from other countries. Proper recordkeeping supports traceability and regulatory compliance.

Distillation Process Safety and Standards

Essential oil distillation involves high-pressure steam and flammable plant materials, requiring strict safety protocols. Distillers must comply with Occupational Safety and Health Administration (OSHA) standards in the U.S., or equivalent workplace safety regulations in other countries. Equipment should be regularly maintained and inspected to prevent accidents.

Good Manufacturing Practices (GMP) should be followed to ensure product consistency, purity, and safety. This includes maintaining clean workspaces, using food-grade or pharmaceutical-grade equipment, and documenting all processing steps.

Product Testing and Quality Assurance

All essential oils must undergo rigorous quality testing before distribution. Common tests include Gas Chromatography-Mass Spectrometry (GC-MS) to verify chemical composition, microbial testing to ensure safety, and heavy metal screening where applicable. Testing ensures that products meet international standards such as ISO 9841 (for lavender oil) or ISO 4730 (for tea tree oil).

Certificates of Analysis (CoA) should accompany every batch and be made available to customers and regulators upon request. Third-party lab testing enhances credibility and consumer trust.

Labeling and Packaging Compliance

Labels must be accurate and compliant with regional regulations. In the U.S., the Fair Packaging and Labeling Act (FPLA) requires the identity of the product, name and place of business, and net quantity. If marketed as a cosmetic, the FDA requires ingredient listing using International Nomenclature of Cosmetic Ingredients (INCI) names.

In the EU, labeling must include product function, list of allergens (if applicable), and a responsible person within the EU. Packaging must be child-resistant where required and made from recyclable or sustainable materials when possible.

Transport and Storage Logistics

Essential oils are often classified as hazardous materials due to their flammability and potential environmental impact. Transport regulations such as the Department of Transportation (DOT) in the U.S. or ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road) in Europe must be followed.

Proper packaging, hazard labeling, and shipping documentation (e.g., Safety Data Sheets or SDS) are mandatory. Oils should be stored in amber or UV-protected glass bottles, in cool, dry conditions away from direct sunlight to preserve quality.

Import and Export Considerations

Cross-border trade requires compliance with customs and import regulations. Essential oils may be subject to tariffs, import permits, or restrictions based on the plant species or country of origin. CITES-listed species (e.g., sandalwood, rosewood) require export and import permits.

Distillers must prepare accurate commercial invoices, packing lists, and certificates of origin. Harmonized System (HS) codes must be correctly assigned to facilitate customs clearance.

Recordkeeping and Traceability

Maintaining detailed records is essential for compliance audits and product recalls. Distillers should track batch numbers, raw material sources, processing parameters, test results, and distribution logs. A robust traceability system enables rapid response to quality issues and supports regulatory compliance.

Digital inventory and batch tracking systems can enhance efficiency and accuracy in recordkeeping.

Sustainability and Environmental Compliance

Distillation produces plant waste (spent biomass) and wastewater that must be managed responsibly. Compliance with local environmental regulations regarding disposal or reuse of byproducts is required. Composting spent plant material or repurposing it for biomass energy are sustainable options.

Water usage and energy consumption should be minimized, and distillers are encouraged to adopt eco-friendly practices such as solar-powered distillation or rainwater harvesting to reduce environmental impact.

Conclusion

Compliance in essential oil distillation involves navigating complex regulatory landscapes while maintaining high standards of quality, safety, and sustainability. By adhering to logistics and compliance best practices, distillers can ensure product integrity, protect consumer health, and support long-term business success.

In conclusion, sourcing essential oil distillers requires a strategic approach that balances quality, sustainability, cost, and scalability. It is essential to thoroughly evaluate potential suppliers based on their distillation methods, equipment quality, compliance with industry standards, and commitment to sustainable and ethical practices. Whether sourcing artisanal batch stills or industrial-scale systems, clear communication of technical specifications, after-sales support, and supply chain reliability are critical to ensuring long-term success. Additionally, building strong relationships with reputable manufacturers—locally or internationally—can enhance innovation, reduce lead times, and support consistent production of high-quality essential oils. Ultimately, the right distiller partnership will not only meet current operational needs but also provide the flexibility and support necessary for future growth and market competitiveness.