The global ESD (electrostatic discharge) flooring market is experiencing robust growth, driven by increasing demand across electronics manufacturing, healthcare, data centers, and cleanroom environments. According to Grand View Research, the global ESD flooring market was valued at USD 1.38 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2024 to 2030. This growth is fueled by stringent regulatory standards for static control and the rapid expansion of high-tech manufacturing facilities, particularly in Asia-Pacific. As industries prioritize precision and safety, the need for reliable ESD floor tiles has surged, prompting heightened competition among manufacturers to deliver innovative, durable, and compliant flooring solutions. In this evolving landscape, identifying the top performers in ESD floor tile manufacturing is critical for procurement teams and facility planners aiming to ensure operational integrity and regulatory compliance.

Top 10 Esd Floor Tiles Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

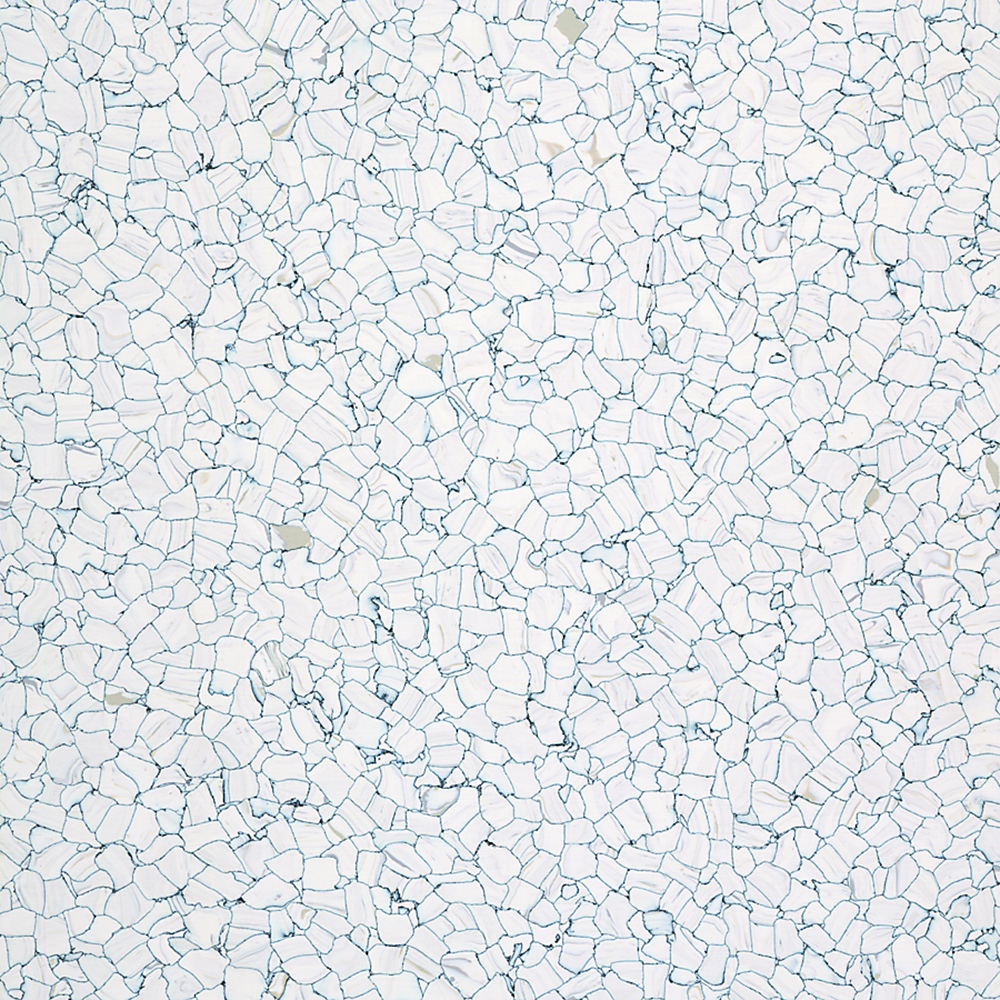

#1 Delane ESD Vinyl Tile

Domain Est. 2001

Website: flexcofloors.com

Key Highlights: As a leading manufacturer of ESD protection, Flexco flooring prevents and removes static charges, keeping people, equipment and environments safe from damage….

#2 ESD vinyl static control tile

Domain Est. 1996

Website: roppe.com

Key Highlights: Roppe ESD Vinyl Static Control Tile is a vinyl flooring product designed to prevent electrostatic discharge (ESD) related damage….

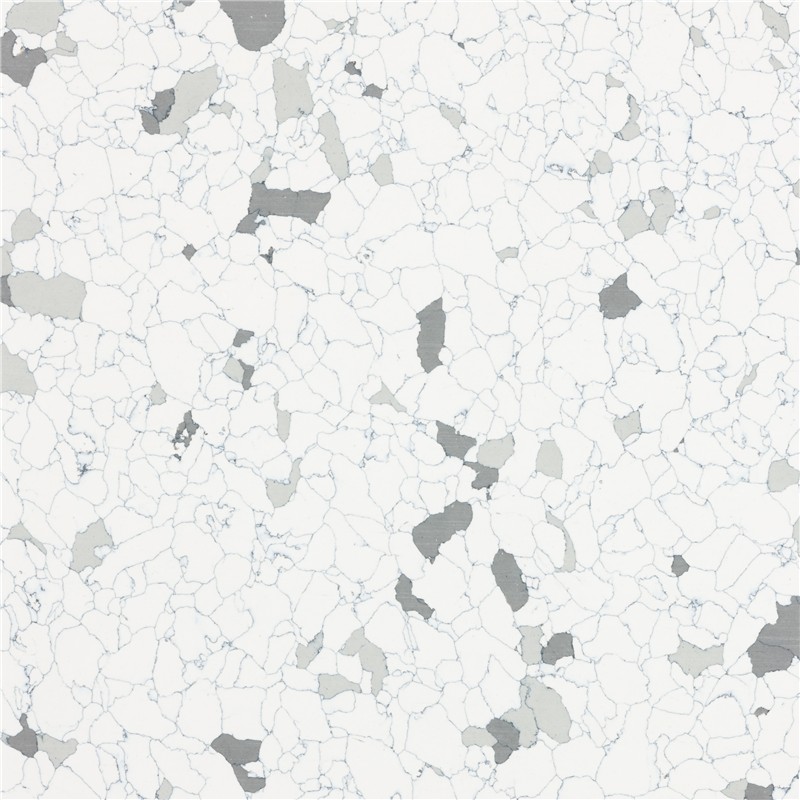

#3 ESD & Cleanroom Flooring

Domain Est. 1996

Website: forbo.com

Key Highlights: Forbo Flooring Systems is an international market leader with a wealth of experience in ESD and cleanroom flooring. We offer several flooring solutions….

#4 ESD Static Control Tile

Domain Est. 1997

Website: vpicorp.com

Key Highlights: VPI static control floors eliminate or reduce the amount of static electricity in an environment by “channeling” the static electricity away through the floor….

#5 ESD Vinyl Tile

Domain Est. 1998

Website: statguard.descoindustries.com

Key Highlights: $1 deliveryOur line of ESD Vinyl tiles includes both static dissipative and conductive tiles to meet your specific flooring application….

#6 esd Static Control Flooring

Domain Est. 1999

Website: armstrongflooring.com

Key Highlights: Electrostatic dissipative tile is designed to control static, protecting people and preventing damage to expensive equipment….

#7 ESD Flooring Solutions

Domain Est. 2001

Website: gerflorusa.com

Key Highlights: ESD flooring tiles provide a precise, modular solution that helps protect electronics with anti-static flooring options · Durable ESD flooring products for data ……

#8 ElectraTile Vinyl ESD Floor Tiles

Domain Est. 2003

Website: store.unitedesd.com

Key Highlights: In stock $24.06 deliveryElectraTile ESD flooring features a high rating for dimensional stability and compressive strength and is supplied in the static conductive range of <1.0E06...

#9 ESD Flooring For Any Industry

Domain Est. 2006

Website: staticstop.com

Key Highlights: We offer ESD Flooring Solutions in almost every form imaginable. From interlocking ESD floor tiles, to epoxy based ESD flooring….

#10 ESD Flooring

Domain Est. 2007

Website: cleanroomworld.com

Key Highlights: We have ESD tiles and ESD flooring that can be used in a variety of settings, including: cleanrooms, labs, manufacturing facilities, and other environments….

Expert Sourcing Insights for Esd Floor Tiles

H2: 2026 Market Trends for ESD Floor Tiles

The Electrostatic Discharge (ESD) floor tiles market is poised for significant transformation by 2026, driven by technological advancements, evolving industry standards, and shifting global manufacturing and data infrastructure demands. Key trends shaping the market include:

1. Surge in Demand from Electronics and Semiconductor Manufacturing

As global semiconductor production expands—spurred by the CHIPS Act in the U.S., EU semiconductor initiatives, and continued demand for advanced electronics—ESD flooring becomes mission-critical. Cleanroom environments require reliable static control, fueling demand for high-performance ESD tiles. By 2026, this segment will dominate market growth, especially in Asia-Pacific and North America.

2. Integration with Smart Building Technologies

The rise of Industry 4.0 and smart facilities is pushing ESD flooring to evolve beyond static control. By 2026, expect increased adoption of intelligent ESD tiles embedded with sensors to monitor foot traffic, environmental conditions, and electrical resistance in real time. These smart systems will integrate with building management systems (BMS) for predictive maintenance and enhanced operational efficiency.

3. Sustainability and Eco-Friendly Materials

Environmental regulations and corporate sustainability goals are driving innovation. Manufacturers are developing ESD tiles from recycled materials (e.g., post-consumer PVC, rubber) and bio-based polymers. Low-VOC (volatile organic compound) formulations and recyclable end-of-life solutions will become standard, aligning with green building certifications like LEED and BREEAM.

4. Growth in Data Centers and Server Farms

With exponential data growth and the rollout of AI infrastructure, hyperscale data centers require ESD protection to safeguard sensitive equipment. By 2026, ESD flooring will be increasingly specified in new and retrofitted data centers, especially in colocation facilities. Modular, easy-to-install tiles with high durability and thermal conductivity will be in demand.

5. Regional Market Shifts and Localization

While North America and Europe maintain high adoption due to stringent ESD standards (e.g., ANSI/ESD S20.20, IEC 61340), the Asia-Pacific region—particularly China, India, and Southeast Asia—will lead in market growth. Rising electronics manufacturing hubs and government investments in high-tech infrastructure will drive regional expansion, leading to localized production and supply chains.

6. Advancements in Material Performance and Design

Innovations in conductive additives (e.g., carbon nanotubes, graphene) are improving conductivity, durability, and aesthetic flexibility. By 2026, ESD tiles will offer better resistance to chemicals, abrasion, and heavy loads, while providing customizable colors and patterns to suit modern industrial and commercial interiors.

7. Standardization and Compliance Pressures

Global harmonization of ESD standards will increase, with more industries—such as healthcare, pharmaceuticals, and automotive—adopting ESD flooring to protect sensitive devices and processes. Certification and traceability of ESD performance will become critical purchasing factors, pushing manufacturers toward third-party testing and digital product passports.

In summary, the 2026 ESD floor tiles market will be characterized by smarter, greener, and more adaptable solutions, expanding beyond traditional industrial settings into high-tech commercial and data-centric environments. Companies that innovate in sustainability, digital integration, and regional customization will gain competitive advantage.

Common Pitfalls When Sourcing ESD Floor Tiles (Quality and IP)

Sourcing Electrostatic Discharge (ESD) floor tiles is critical for environments like data centers, electronics manufacturing, and laboratories where static control is essential. However, organizations often encounter significant challenges related to quality assurance and intellectual property (IP) protection. Understanding these pitfalls can help prevent costly mistakes and ensure long-term performance and compliance.

Poor Quality Control and Inconsistent Performance

One of the most frequent issues when sourcing ESD floor tiles is inconsistent product quality. Low-cost suppliers, especially those from less-regulated markets, may use substandard materials or inadequate manufacturing processes. This can result in tiles that fail to meet required electrical resistance specifications (typically 10^4 to 10^9 ohms), leading to ineffective static dissipation. Additionally, poor mechanical durability—such as susceptibility to cracking, delamination, or wear—reduces the tile’s lifespan and increases maintenance costs.

Lack of Certification and Compliance Verification

Many suppliers claim their ESD tiles meet international standards like ANSI/ESD S20.20, IEC 61340-5-1, or ISO 9001, but fail to provide verifiable test reports or third-party certifications. Without proper documentation, buyers risk installing non-compliant flooring that could compromise sensitive equipment or void equipment warranties. Always insist on up-to-date, accredited lab test results specific to the batch being supplied.

Misrepresentation of ESD Mechanism

ESD tiles can use different conductive mechanisms—carbon-based, metal-coated particles, or polymer-based additives. Some unscrupulous suppliers may misrepresent the technology used, claiming a more durable or reliable method than is actually implemented. For example, a tile advertised as “carbon-loaded throughout” may only have a conductive surface coating, which wears off over time, degrading ESD performance.

Intellectual Property (IP) Infringement Risks

When sourcing from overseas manufacturers, especially in regions with weak IP enforcement, there is a risk of purchasing counterfeit or copied products. Reputable ESD flooring brands invest heavily in R&D and design patents. Sourcing generic tiles that mimic patented patterns, compositions, or installation systems may expose your organization to legal liability, particularly if the flooring is part of a larger, IP-sensitive facility.

Inadequate Technical Support and Installation Guidance

Low-cost suppliers often lack the technical infrastructure to provide detailed installation protocols, maintenance guidelines, or on-site support. Improper installation—such as incorrect grounding, adhesive selection, or seam sealing—can nullify the ESD properties of even high-quality tiles. Without proper support, buyers face increased risk of system failure and costly rework.

Supply Chain and Long-Term Availability Issues

ESD flooring systems often require future expansions or replacements. Sourcing from suppliers without stable production or long-term product roadmaps can lead to mismatches in color, texture, or performance when additional tiles are needed years later. This inconsistency can compromise both aesthetics and functionality.

Hidden Costs from Short-Term Savings

While initial pricing may appear attractive, low-quality ESD tiles often lead to higher total cost of ownership due to premature replacement, downtime, or damage to sensitive equipment from electrostatic discharge. Cutting corners on quality can ultimately jeopardize operational integrity and safety.

To mitigate these risks, conduct thorough due diligence: verify certifications, request product samples for independent testing, audit supplier facilities when possible, and ensure IP compliance through legal review of product designs and documentation.

Logistics & Compliance Guide for ESD Floor Tiles

Product Overview and Handling Requirements

ESD (Electrostatic Discharge) floor tiles are specialized flooring systems designed to safely dissipate static electricity in environments such as data centers, laboratories, cleanrooms, and electronics manufacturing facilities. Due to their conductive or static-dissipative properties, these tiles require careful handling, storage, and installation to maintain performance integrity. Proper logistics planning ensures product efficacy and compliance with industry standards.

Packaging and Transportation Standards

ESD floor tiles are typically packaged in sturdy, moisture-resistant cartons or palletized with edge protection to prevent chipping or warping. Each package should be clearly labeled with:

– Product name and ESD classification (e.g., conductive, static-dissipative)

– Batch or lot number for traceability

– Handling symbols (e.g., “This Side Up,” “Do Not Stack”)

– Anti-static warning labels where applicable

During transportation, tiles must be protected from extreme temperatures, moisture, and direct sunlight. Vehicles should be enclosed and climate-controlled when possible, especially in humid or freezing conditions. Pallets must be secured to prevent shifting, and stacking should not exceed manufacturer-recommended limits.

Storage Conditions and Shelf Life

Store ESD floor tiles in a clean, dry, and temperature-controlled environment (typically 15°C to 25°C or 59°F to 77°F). Relative humidity should be maintained between 30% and 50% to prevent dimensional changes or adhesive degradation.

– Keep tiles elevated on pallets, away from direct floor contact

– Avoid storing near heat sources or electrical equipment

– Limit stack height to prevent deformation (usually no more than 10–12 layers)

– Rotate stock using FIFO (First In, First Out) to ensure freshness

Most ESD tiles have a shelf life of 12 to 24 months from manufacture date—verify this with the manufacturer’s technical data sheet.

Import/Export and Regulatory Compliance

When shipping ESD floor tiles internationally, ensure compliance with relevant regulations:

– REACH (EU): Confirm that materials are registered and do not contain restricted substances (e.g., certain phthalates)

– RoHS (EU/UK/China): Verify compliance with restrictions on hazardous substances

– TSCA (USA): Ensure chemical components comply with EPA standards

– Customs Documentation: Provide accurate HS codes (typically under 3918.10 or 3918.90 for plastic floor coverings), commercial invoices, and certificates of origin

Some countries may require additional certifications or conformity assessments—consult with a customs broker when necessary.

Safety and Environmental Compliance

- Material Safety Data Sheets (MSDS/SDS): Maintain up-to-date SDS for all tile components and adhesives used in installation

- VOC Emissions: Choose low-VOC or Greenguard-certified products to meet indoor air quality standards (e.g., LEED, WELL)

- Disposal and Recycling: Follow local regulations for disposal of off-cuts or unused tiles. Many ESD tiles are recyclable—check with the manufacturer for take-back programs

Installation and Site Compliance

Prior to installation, ensure the subfloor meets flatness and moisture requirements per ASTM F710 or equivalent. ESD flooring systems must be grounded properly using copper strips and verified with a resistance meter per:

– ANSI/ESD S20.20: Standard for protection of electrical and electronic parts

– IEC 61340-5-1: International standard for ESD control programs

Qualified personnel should perform continuity and resistance-to-ground tests after installation to validate compliance.

Documentation and Traceability

Maintain full documentation throughout the supply chain:

– Manufacturer’s certification of ESD performance (e.g., surface resistance, point-to-point resistance)

– Batch-specific test reports

– Installation records and test results

– Compliance declarations (RoHS, REACH, etc.)

This documentation supports audits, warranties, and regulatory inspections.

Summary

Effective logistics and compliance management for ESD floor tiles ensures product integrity, regulatory adherence, and operational safety. From proper handling and storage to international shipping and installation validation, each step must follow manufacturer guidelines and recognized standards to maintain performance in sensitive environments.

Conclusion for Sourcing ESD Floor Tiles

Sourcing ESD (Electrostatic Discharge) floor tiles requires a comprehensive evaluation of technical specifications, environmental conditions, compliance standards, and long-term performance requirements. The selection process should prioritize materials that offer consistent electrical conductivity or static dissipation, durability under expected foot and equipment traffic, and resistance to chemicals and abrasion. Compliance with industry standards such as ANSI/ESD S20.20, IEC 61340-5-1, and local building regulations is essential to ensure safety and functionality in sensitive environments like electronics manufacturing, cleanrooms, data centers, and laboratories.

Beyond technical performance, factors such as ease of installation, maintenance requirements, and total cost of ownership should be considered. Engaging reputable suppliers with a proven track record in ESD solutions, verified product testing, and certification documentation is crucial. Additionally, conducting site assessments and pilot installations can mitigate risks and validate performance before full-scale deployment.

In conclusion, a strategic, well-informed sourcing approach—balancing performance, compliance, and cost—ensures the selection of ESD floor tiles that effectively protect sensitive equipment, enhance workplace safety, and support operational continuity over time.