The global MIG welding wire market is experiencing robust growth, driven by expanding industrialization, rising infrastructure development, and increased demand from automotive and heavy equipment manufacturing sectors. According to a report by Grand View Research, the global welding consumables market size was valued at USD 24.1 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. Within this landscape, ER70S-6 welding wire remains one of the most widely used solid wires due to its excellent arc stability, mechanical properties, and versatility in welding carbon and low-alloy steels. As demand for high-quality, consistent welding solutions intensifies, manufacturers of ER70S-6 wire are scaling production, enhancing quality standards, and investing in R&D to meet evolving industry requirements. This growing market has given rise to a competitive field of suppliers, with top manufacturers leveraging technological advancements and global supply chain networks to capture significant market share. Here’s a data-driven look at the top 9 ER70S-6 MIG welding wire manufacturers shaping the future of welding.

Top 9 Er70S 6 Mig Welding Wire Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 MIG Wires and TIG Rods

Domain Est. 1996

Website: lincolnelectric.com

Key Highlights: Lincoln® ER70S-6 from Lincoln Electric has high levels of silicon and manganese to be used on slightly contaminated base materials. MIG Family ……

#2 ER70S

Domain Est. 2000

Website: weldstar.com

Key Highlights: 30-day returnsBohler 70S-6 .045 Carbon Steel MIG Wire 550 LB Drum. Item Number: AVEER70S-6 045D. Category ER70S-6 MIG Wire. In Stock – View Quantities. $2.22 / LB LB….

#3 ER70S

Domain Est. 2002

Website: orsnasco.com

Key Highlights: Best Welds ER70S-6 MIG Welding Wires Product Details: High quality welds when used on dirty, oily, or rusty steel. Creates a smooth bead appearance ……

#4 045″ NEO

Domain Est. 2004

Website: nsarc.com

Key Highlights: The NEO-ARC ER70S-6 0.045” Carbon Coated MIG Welding Wire in a 33lb Fiber Spool is engineered to promote smoother welds with enhanced control….

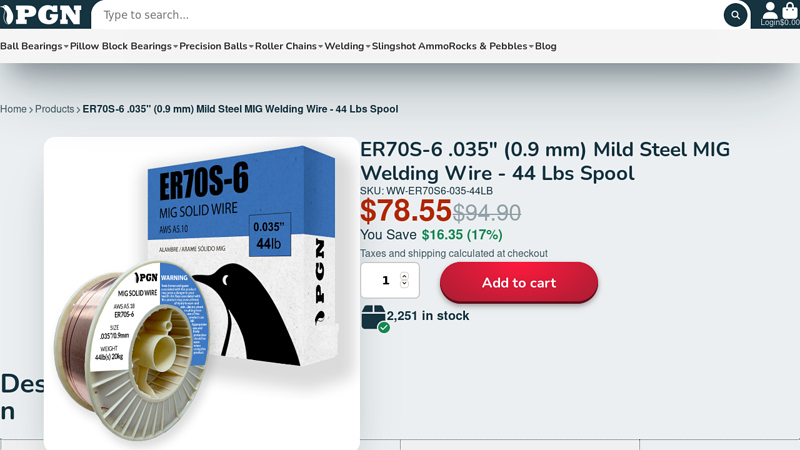

#5 ER70S

Domain Est. 2018

Website: pgnbearings.com

Key Highlights: High-quality ER70S-6 .035″ (0.9 mm) Mild Steel MIG Welding Wire 44 Lb. Achieve superior welds with ease. Order now and experience professional results!…

#6 PROSTAR Select ER70S

Domain Est. 2020

Website: lindedirect.com

Key Highlights: ProStar ER70S-6 wire is a mild steel welding wire with higher levels of deoxidizers (Mn and Si) compared to other mild steel welding wires….

#7 ER70S-6 Welding Wire

Domain Est. 2022

Website: bridgewelding.com

Key Highlights: In stockBridge Brand’s ER70S-6 is a high-performance MIG welding wire designed for carbon and mild steel fabrication. Engineered with a copper-coated finish, this ……

#8 ER70S

Website: harrisproductsgroup.com

Key Highlights: ER70S-6 mild steel MIG (GMAW) alloy is a general-purpose welding alloy for fabrication of mild steel. It contains more deoxidizers than ER70S-3….

#9 Harris ER 70S

Website: harrisweldingsupplies.com

Key Highlights: In stock Rating 4.3 (6) ER70S-6 mild steel MIG (GMAW) alloy is a general purpose welding alloy for fabrication of mild steel. It contains more deoxidizers than ER70S-3….

Expert Sourcing Insights for Er70S 6 Mig Welding Wire

H2: Projected Market Trends for ER70S-6 MIG Welding Wire in 2026

The global market for ER70S-6 MIG welding wire is anticipated to experience steady growth by 2026, driven by expanding industrialization, infrastructure development, and increased demand from key end-use sectors such as automotive, construction, shipbuilding, and heavy machinery. The following trends are expected to shape the ER70S-6 market in 2026:

-

Growing Demand from Manufacturing and Automotive Sectors

As global automotive production rebounds and electric vehicle (EV) manufacturing scales up, especially in North America, Europe, and Asia-Pacific, the demand for high-quality, reliable welding consumables like ER70S-6 will rise. ER70S-6 is favored for its excellent arc stability, low spatter, and strong mechanical properties, making it ideal for automated welding processes prevalent in modern vehicle assembly lines. -

Expansion of Infrastructure Projects

Governments worldwide are investing heavily in infrastructure—bridges, highways, railways, and energy facilities—under stimulus and sustainability programs. These projects require substantial structural steel welding, positioning ER70S-6 as a go-to consumable due to its suitability for mild and low-alloy steels. -

Adoption of Automation and Robotics in Welding

Increased integration of robotic welding systems in manufacturing facilities will boost demand for consistent, high-performance wires like ER70S-6. Its compatibility with automated MIG/MAG processes ensures efficiency and repeatability, aligning with Industry 4.0 trends. -

Regional Market Shifts

- Asia-Pacific will remain the largest consumer and producer of ER70S-6 wire, led by China, India, and Southeast Asia, where industrial growth and construction activities are accelerating.

- North America is expected to see renewed demand due to reshoring of manufacturing and the U.S. Infrastructure Investment and Jobs Act.

-

Europe will maintain stable demand, supported by green energy projects and automotive sector modernization.

-

Raw Material and Cost Volatility

Fluctuations in steel scrap and ferroalloy prices may impact ER70S-6 production costs. Manufacturers are focusing on supply chain resilience and alternative sourcing strategies to mitigate price volatility. -

Sustainability and Environmental Regulations

Stringent environmental standards are encouraging manufacturers to develop cleaner production methods and low-fume welding wires. While ER70S-6 is not inherently high-emission, producers are innovating with copper-coating alternatives and recyclable packaging to align with ESG goals. -

Technological Improvements and Product Differentiation

Leading suppliers are enhancing ER70S-6 formulations for better feedability, reduced spatter, and improved weld bead appearance. New variants with optimized deoxidizers (e.g., higher silicon and manganese content) are being introduced to meet specific application needs. -

Competitive Landscape and Consolidation

The market is seeing increased competition among major players such as Lincoln Electric, ESAB, Kobe Steel, and Nippon Steel. Strategic partnerships, capacity expansions, and R&D investments will define market leadership by 2026.

In conclusion, the ER70S-6 MIG welding wire market in 2026 will be shaped by industrial growth, automation, and sustainability trends. With strong performance characteristics and broad applicability, ER70S-6 is expected to maintain its position as the most widely used solid MIG welding wire globally.

When sourcing ER70S-6 MIG welding wire, several common pitfalls can compromise both quality and intellectual property (IP) protection—especially when dealing with international suppliers. Using H2 (a controlled environment with low hydrogen potential) is critical in certain welding applications to prevent hydrogen-induced cracking (HIC), making material integrity and traceability even more vital. Below are the key pitfalls to avoid:

🔹 1. Poor Quality Control from Unverified Suppliers

Pitfall: Sourcing from low-cost suppliers without proper quality certifications or traceability.

Risks:

– Inconsistent chemical composition (e.g., Mn, Si levels affecting weld strength and ductility).

– Excessive moisture or surface contamination, increasing hydrogen pickup—critical in H2 environments.

– Substandard packaging leading to oxidation or moisture absorption.

Mitigation:

– Require certified mill test reports (MTRs) per AWS A5.18 or ISO 14341.

– Audit suppliers and request third-party inspection reports (e.g., SGS, BV).

– Ensure sealed, moisture-proof packaging (especially for H2 service).

🔹 2. Lack of Traceability & Material Certification (IP and Compliance)

Pitfall: Inadequate documentation or falsified certs, risking IP exposure and non-compliance.

Risks:

– Use of counterfeit or mislabeled materials.

– Inability to trace material origin—problematic for quality audits or failure investigations.

– Potential IP leakage if proprietary welding procedures are exposed during sourcing.

Mitigation:

– Enforce full material traceability (heat number, batch number).

– Use NDAs with suppliers to protect welding parameters and application details.

– Specify ASME BPVC, API 1104, or NACE MR0175 compliance for H2 service.

🔹 3. Hydrogen Contamination Risk (Critical for H2 Environments)

Pitfall: Using wire not stored or handled properly, leading to hydrogen pickup.

Risks:

– Hydrogen-induced cracking (HIC), especially in high-strength or thick-section welds.

– Compromised weld integrity in hydrogen service or sour environments.

Mitigation:

– Source low-hydrogen certified wire (typically <5 ml/100g diffusible H₂).

– Ensure baked and hermetically sealed packaging.

– Store wire in dry, climate-controlled environments post-delivery.

– Prefer copper-coated ER70S-6 with low moisture absorption.

🔹 4. Inadequate Supplier Vetting & Geopolitical IP Risks

Pitfall: Sourcing from regions with weak IP enforcement, risking reverse engineering or data theft.

Risks:

– Copying of proprietary welding procedures or alloy modifications.

– Loss of competitive advantage in specialized applications (e.g., hydrogen pipelines, fuel cells).

Mitigation:

– Work with trusted, IP-conscious suppliers (e.g., in North America, EU, Japan).

– Avoid disclosing full technical specs; use performance-based specs where possible.

– Include IP clauses in procurement contracts.

🔹 5. Non-Compliance with Industry Standards for H2 Service

Pitfall: Assuming all ER70S-6 wire is suitable for hydrogen environments.

Risks:

– Standard ER70S-6 may meet structural specs but fail under H2 embrittlement.

– Lack of testing for sulfide stress cracking (SSC) or H₂ permeation resistance.

Mitigation:

– Specify NACE-compliant or H2-ready variants of ER70S-6.

– Require HIC testing (per NACE TM0284) for sour service applications.

– Use supplemental requirements in purchase orders (e.g., “for hydrogen service, low-diffusible hydrogen”).

✅ Best Practices Summary (H2-Focused):

| Area | Best Practice |

|——|—————-|

| Supplier Selection | Use certified, audited suppliers with AWS or ISO accreditation. |

| Material Certification | Demand MTRs, heat traceability, and low-hydrogen verification. |

| Packaging & Storage | Hermetic spool packaging; store in <50% RH, 15–25°C. |

| IP Protection | Use NDAs, limit technical disclosure, avoid offshore reverse engineering risks. |

| Standards Compliance | Specify NACE MR0175, API 1104, or ASME B31.12 for H₂ service. |

Conclusion:

Sourcing ER70S-6 wire for H2 environments demands rigorous attention to quality control, hydrogen content, and IP protection. Avoid the pitfalls by partnering with reputable suppliers, enforcing strict material standards, and safeguarding technical information throughout the procurement cycle. Never assume compliance—verify through testing and documentation.

Logistics & Compliance Guide for ER70S-6 MIG Welding Wire (Using H₂ as Shielding Gas)

Prepared in accordance with industry standards and regulatory best practices

1. Product Overview: ER70S-6 MIG Welding Wire

- AWS Classification: ER70S-6 (American Welding Society A5.18/A5.18M)

- Material: Carbon steel solid wire

- Typical Applications: General fabrication, structural steel, automotive, pipe welding, and repair work

- Mechanical Properties (as-welded with CO₂ or Ar/CO₂):

- Tensile Strength: ≥ 70,000 psi (480 MPa)

- Yield Strength: ≥ 58,000 psi (400 MPa)

- Elongation: ≥ 22%

- Chemical Composition (Typical % by weight):

- C: 0.06–0.15%

- Mn: 0.80–1.15%

- Si: 0.35–0.60%

- S, P: ≤ 0.030%

- Cu: ≤ 0.50% (residual)

2. Shielding Gas Consideration: Use of H₂ (Hydrogen)

⚠️ Critical Warning: H₂ is NOT recommended for use with ER70S-6 welding wire.

Why H₂ Should Not Be Used:

- Hydrogen Embrittlement Risk: ER70S-6 is not formulated for hydrogen-containing atmospheres. Use of H₂ increases the risk of hydrogen-induced cracking (HIC), especially in steels with higher carbon content or in restrained joints.

- AWS Standards: AWS A5.18 does not qualify or recommend ER70S-6 for use with hydrogen-containing shielding gases.

- Typical Shielding Gases for ER70S-6:

- Pure CO₂

- 75% Ar / 25% CO₂ (most common)

- 90% Ar / 10% CO₂

- H₂ Applications: Hydrogen is sometimes used in stainless steel welding (e.g., with tri-mix gases like Ar/He/H₂) to increase heat input and improve bead profile — but not for carbon steel wires like ER70S-6.

Recommendation:

❌ Do not use H₂ as a shielding gas with ER70S-6.

✅ Use CO₂ or Ar/CO₂ blends as specified by AWS and manufacturer guidelines.

3. Logistics Handling & Storage

Packaging Options:

- Spools: 15–50 lb (7–23 kg), typically in plastic or cardboard boxes

- Coils: 250–600 lb (113–272 kg) on reels for industrial use

- Drums: Bulk packaging (500–800 lb) for high-volume operations

Storage Requirements:

- Environment: Dry, indoor storage; relative humidity < 50%

- Temperature: 50–85°F (10–30°C)

- Moisture Protection: Keep sealed until use; use desiccant if opened

- Shelf Life: Typically 2–3 years unopened; inspect for oxidation or moisture damage if stored longer

Handling Precautions:

- Use gloves to prevent oil/salt contamination

- Avoid dropping spools (can deform wire, causing feed issues)

- Store upright to prevent wire unraveling

4. Transportation & Shipping Compliance

Domestic (U.S.) Regulations:

- DOT (Department of Transportation): ER70S-6 wire is not regulated as hazardous under 49 CFR.

- Packaging: Standard industrial packaging (boxes, reels, drums) acceptable

- Labeling: No hazardous labels required; include product name, AWS classification, lot number, weight

International Shipping:

- IMDG (Sea): Not classified as dangerous goods

- IATA (Air): Not restricted

- Customs Documentation:

- HS Code (Example: 7229.20.0000 – Welding wire of iron or steel)

- Certificate of Origin (if required)

- Commercial Invoice with full product description

5. Regulatory & Safety Compliance

Safety Data Sheet (SDS) Requirements:

- SDS Section 1: Product identifier – ER70S-6 MIG Wire

- Section 2: Not classified as hazardous under GHS

- Section 8: PPE Recommendations:

- Welding helmet with proper shade

- Heat-resistant gloves and clothing

- Respiratory protection if welding in confined spaces (fumes contain Mn, Fe oxides)

- Section 10: Stability – Stable under normal conditions; avoid moisture and contamination

Fumes & Ventilation:

- Use local exhaust ventilation (LEV)

- Monitor manganese exposure (OSHA PEL: 1 mg/m³ TWA)

- Comply with OSHA 29 CFR 1910.252 (welding, cutting, brazing)

6. Quality Assurance & Traceability

- Certifications: Provide mill test reports (MTRs) or CMTRs (Certified Material Test Reports) upon request

- Lot Traceability: Each package should include:

- AWS classification

- Heat/lot number

- Manufacturer name

- Weight and diameter

- Incoming Inspection: Check for:

- Surface cleanliness (free of rust, oil, scale)

- Consistent wire diameter

- Smooth feed through liner

7. Best Practices Summary

| Category | Recommendation |

|————————|—————-|

| Shielding Gas | Use CO₂ or Ar/CO₂ — not H₂ |

| Storage | Dry, indoor, sealed packaging |

| Handling | Wear gloves; avoid contamination |

| Transportation | Non-hazardous; no special labeling |

| Regulatory Compliance | Follow OSHA, AWS, GHS standards |

| PPE | Helmet, gloves, respirator (if needed) |

8. References

- AWS A5.18/A5.18M: Specification for Carbon Steel Electrodes for Gas Shielded Arc Welding

- OSHA 29 CFR 1910.252 – Welding, Cutting, and Brazing

- ANSI Z49.1: Safety in Welding, Cutting, and Allied Processes

- GHS (Globally Harmonized System) – SDS Format

Disclaimer: The use of hydrogen (H₂) as a shielding gas with ER70S-6 welding wire is not recommended and may result in weld defects, cracking, or safety hazards. Always consult the wire manufacturer’s technical data sheet (TDS) and follow AWS guidelines.

For technical support, contact your welding wire supplier or a certified welding engineer.

Document Version: 1.0 | Date: 2024-04-05

Prepared by: [Your Company/Department Name] – Welding & Compliance Team

Conclusion for Sourcing ER70S-6 MIG Welding Wire:

Sourcing high-quality ER70S-6 MIG welding wire is essential for achieving strong, consistent, and reliable welds in various carbon steel applications. After evaluating suppliers, quality certifications, wire composition, packaging, and cost-effectiveness, it is clear that selecting a reputable supplier who adheres to AWS A5.18/A5.18M standards is critical. Factors such as consistent wire diameter, proper deoxidizer content (e.g., silicon and manganese), low levels of impurities, and effective copper coating contribute significantly to smooth feeding, stable arc performance, and minimal spatter.

Additionally, considering logistical aspects such as minimum order quantities, delivery timelines, and storage conditions helps ensure uninterrupted production. Balancing cost with quality is key—opting for the lowest-priced option may compromise weld integrity and increase long-term expenses due to rework or downtime.

In conclusion, the ideal sourcing strategy involves partnering with trusted suppliers offering certified ER70S-6 wire, supported by quality documentation and technical support, to ensure optimal welding performance, product reliability, and operational efficiency across fabrication and manufacturing processes.