The global screen printing market is experiencing steady growth, driven by rising demand in the textile, signage, and packaging industries. According to Mordor Intelligence, the screen printing market was valued at USD 7.48 billion in 2023 and is projected to reach USD 9.67 billion by 2029, growing at a CAGR of 4.42% during the forecast period. This expansion underscores the increasing need for reliable, high-performance equipment among silk screen printing manufacturers. As production scales and quality expectations rise, selecting the right machinery becomes critical to maintaining efficiency, precision, and competitiveness. From automatic presses to advanced drying systems, the following list highlights the top 10 essential pieces of equipment that modern silk screen printing operations rely on to meet market demands and sustain growth.

Top 10 Equipment For Silk Screen Printing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 AWT World Trade, Inc.

Domain Est. 1997

Website: awt-gpi.com

Key Highlights: AWT, leading manufacturer of silk screen printing equipment, graphic and textile screen printing machines, manual t-shirt printing presses, ……

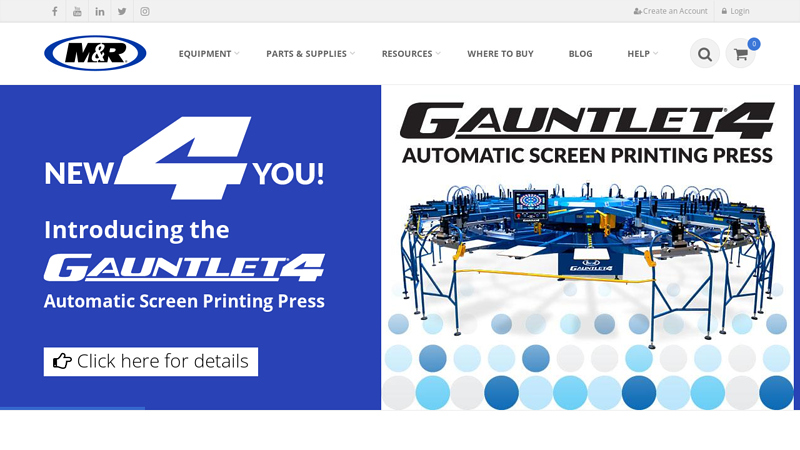

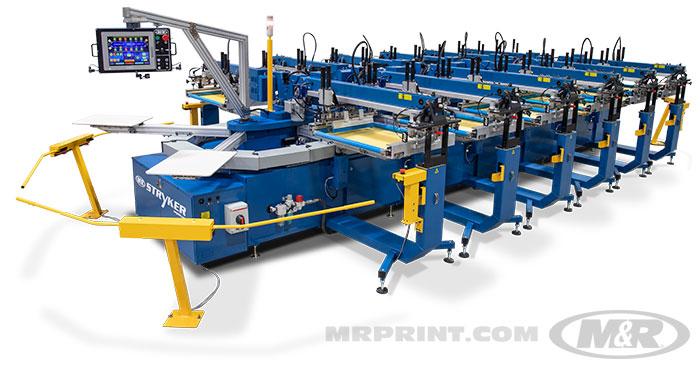

#2 M&R Printing Equipment Inc. :: DTF

Domain Est. 1996

Website: mrprint.com

Key Highlights: M&R makes a wide range of textile printing equipment, including Direct to Film (DTF), Direct to Garment, (DTG), Hybrid Digital Printing, manual & automatic ……

#3 Workhorse Products Screen Printing Equipment Manufacturer

Domain Est. 1997

Website: workhorseproducts.com

Key Highlights: Workhorse Products Screen Printing Equipment Manufacturer. Automatic and Manual Screen Printing Equipment, Dryers, Flash Cure Units & Support Equipment….

#4 ROQ International

Domain Est. 2014

Website: roqinternational.com

Key Highlights: ROQ is a European industrial company producing silkscreen and digital printing, folding and packaging machines for textile and other industries….

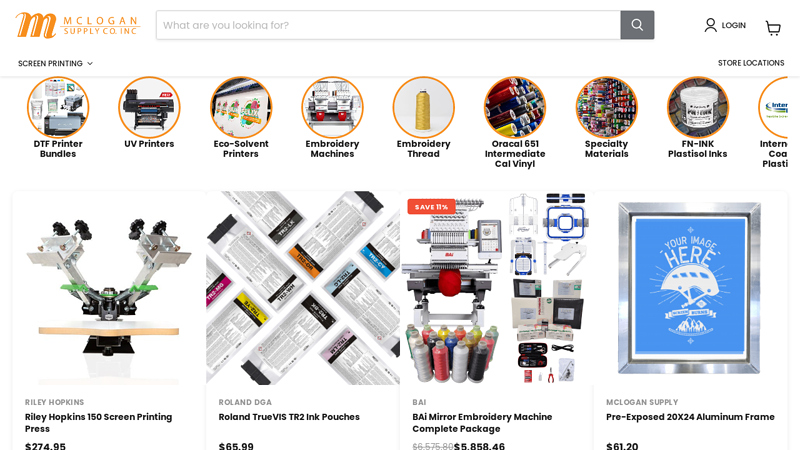

#5 Screen Printing, Heat Transfer, and DTG Supplies & Equipment

Domain Est. 1998

Website: mclogan.com

Key Highlights: Free delivery over $250 20-day returnsOct 8, 2025 · Riley Hopkins 150 Screen Printing Press. $274.95 ; Roland TrueVIS TR2 Ink Pouches. $65.99 ; BAi Mirror Embroidery Machine Comple…

#6 Anatol Equipment

Domain Est. 1998

Website: anatol.com

Key Highlights: Anatol Equipment offers high-quality automatic screen printing presses for textile businesses worldwide. Discover our innovative solutions today….

#7 High

Domain Est. 1998

Website: vastex.com

Key Highlights: Vastex manufactures high-performance screen printing, DTF & DTG equipment including presses, dryers, flash units, and training to help you build your ……

#8 Screen Printing Presses

Domain Est. 1999

Website: rileyhopkins.com

Key Highlights: 30-day returnsRiley Hopkins offers a wide selection of equipment that’ll fuel any shop. The 150 press is perfect for novices, the 250 press is great for printers looking ……

#9 Screen Printing Equipment, Inks, and Supplies

Domain Est. 2002

Website: screenprintingsupply.com

Key Highlights: Get custom PMS Mixes in Pint and Quart Sizes at Flat-Rate Prices. Free Shipping on in-stock supply orders of $299 (website orders only). 5 Locations….

#10 Ryonet Corporation

Domain Est. 2006

Website: ryonet.com

Key Highlights: SCREENPRINTING.COM. Education, equipment, and supplies for the screen printing community….

Expert Sourcing Insights for Equipment For Silk Screen Printing

2026 Market Trends for Equipment for Silk Screen Printing

The market for silk screen printing equipment is poised for significant transformation by 2026, driven by technological innovation, shifting consumer demands, and evolving industry applications. Key trends shaping the landscape include:

Automation and Smart Manufacturing Integration

By 2026, automation will be a cornerstone of competitive silk screen printing operations. Printers are increasingly investing in semi-automated and fully automated presses, automatic ink mixing systems, and robotic pallet loaders to reduce labor costs, improve consistency, and increase throughput. Integration with Industry 4.0 principles—such as IoT-enabled machines that provide real-time performance analytics, predictive maintenance alerts, and centralized control via cloud platforms—will become standard in mid- to high-end equipment, enabling smarter production planning and reduced downtime.

Demand for Hybrid and Multi-Process Systems

As customization and short-run orders grow, especially in apparel and promotional goods, manufacturers are gravitating toward hybrid systems that combine screen printing with digital or direct-to-garment (DTG) technologies. By 2026, equipment that supports seamless transitions between screen and digital printing within the same workflow will gain traction. These hybrid solutions allow print shops to efficiently handle both high-volume solid-color jobs (ideal for screen printing) and variable, full-color designs (better suited for digital), maximizing flexibility and profitability.

Sustainability-Driven Equipment Design

Environmental regulations and consumer pressure are pushing equipment manufacturers to prioritize sustainability. In 2026, expect wider adoption of water-based and eco-solvent inks, supported by screen printing machines designed for easier cleaning with low-VOC solutions. Equipment with closed-loop ink recirculation systems, reduced water consumption in washout processes, and energy-efficient curing units (such as LED-UV dryers) will be increasingly favored. Machines made with recyclable materials and modular designs for repairability will also align with circular economy principles.

Growth in Niche and High-Precision Applications

Beyond traditional textiles, screen printing is expanding into electronics (e.g., printed sensors, circuit boards), solar panels, and medical devices. This shift is fueling demand for high-precision flatbed and rotary screen printing equipment capable of micron-level accuracy and compatible with specialized inks like conductive, ceramic, or bio-inks. By 2026, these industrial applications will represent a growing segment of the equipment market, with suppliers offering tailored solutions for fine-line printing, multi-layer deposition, and compatibility with cleanroom environments.

Regional Market Diversification and Localization

While Asia-Pacific remains a dominant hub for both production and consumption, North America and Europe are seeing a resurgence in local manufacturing, driven by nearshoring trends and demand for fast-turnaround custom goods. This shift supports the growth of compact, user-friendly screen printing equipment suited for small to medium enterprises (SMEs) and on-demand print shops. By 2026, equipment suppliers will increasingly offer localized support, modular entry-level systems, and digital integration tools to empower regional businesses.

In summary, the 2026 silk screen printing equipment market will be defined by smarter, more sustainable, and versatile technologies that cater to both traditional and emerging applications. Success will depend on adaptability, integration capabilities, and alignment with broader industrial and environmental trends.

Common Pitfalls When Sourcing Equipment for Silk Screen Printing (Quality and IP)

Sourcing equipment for silk screen printing involves navigating a complex landscape where quality inconsistencies and intellectual property (IP) concerns can significantly impact your operations and brand integrity. Overlooking these pitfalls may lead to production delays, subpar output, legal issues, or even reputational damage. Below are key challenges to watch for:

Poor Equipment Quality and Performance

One of the most frequent issues when sourcing screen printing equipment—especially from low-cost or international suppliers—is receiving machinery that fails to meet expected quality standards. This includes inconsistent print registration, unreliable drying or curing units, and frames or squeegees that wear out prematurely. Low-quality exposure units may not deliver uniform UV light, resulting in poorly exposed screens and blurred prints. Investing in equipment that appears cost-effective upfront can lead to higher long-term costs due to maintenance, reprints, and downtime.

Lack of After-Sales Support and Spare Parts Availability

Many budget equipment suppliers, particularly those overseas, offer little to no local technical support, training, or access to replacement parts. When a critical component breaks, waiting weeks for a spare part from abroad can halt production. This lack of service infrastructure undermines operational efficiency and increases total cost of ownership, even if the initial purchase price was low.

Inaccurate or Misrepresented Technical Specifications

Some suppliers may exaggerate the capabilities of their equipment—such as print speed, resolution, or material compatibility. This misrepresentation can result in the machine being incompatible with your production needs. Always verify specifications through third-party reviews, on-site demonstrations, or references from existing customers before purchasing.

Intellectual Property (IP) Risks with Clone or Counterfeit Machines

A significant, often overlooked risk is sourcing equipment that infringes on patented designs or technologies. Some manufacturers, particularly in regions with lax IP enforcement, produce “clone” versions of popular screen printing machines that mimic branded models. Using such equipment can expose your business to legal liability, especially if the original IP holder takes action against downstream users or distributors. Additionally, cloned machines often lack the engineering precision and quality control of genuine models, further compromising print quality and durability.

Inadequate Compliance with Safety and Environmental Standards

Certain imported printing equipment may not comply with regional safety, electrical, or emissions regulations (e.g., CE, UL, or OSHA standards). Non-compliant curing units, for example, might emit unsafe levels of UV radiation or volatile organic compounds (VOCs), posing health risks and potential legal consequences. Always confirm that equipment meets the regulatory requirements of your operating region.

Hidden Costs from Integration and Setup Challenges

Equipment that isn’t designed for easy integration with your existing workflow—including software compatibility, space requirements, or utility needs (e.g., compressed air, electrical load)—can lead to unexpected setup costs. Automation interfaces or digital control systems may require additional investment in training or middleware to function properly.

Conclusion

To mitigate these risks, conduct thorough due diligence: request product demonstrations, verify supplier credentials, check for IP compliance, and prioritize vendors with strong service networks. Investing in high-quality, legally compliant equipment from reputable sources protects both your print quality and your business from avoidable legal and operational setbacks.

Logistics & Compliance Guide for Equipment for Silk Screen Printing

Overview

Silk screen printing equipment includes machines such as screen printing presses (manual, semi-automatic, automatic), exposure units, flash dryers, conveyor dryers, washout booths, and associated parts. Proper logistics planning and adherence to compliance regulations are essential for the safe, legal, and efficient import, export, distribution, and operation of this equipment globally.

Classification and HS Codes

Correct classification of silk screen printing equipment under the Harmonized System (HS) is critical for customs clearance and duty assessment. Typical HS codes include:

- 8442.30: Printing machinery used for screen, block, or stencil printing.

- 8514.40: Industrial electro-thermic appliances such as infrared or conveyor dryers.

- 8479.89: Other machines and mechanical appliances having individual functions, which may cover auxiliary screen printing units.

Note: HS codes may vary by country. Confirm with local customs authorities or a licensed customs broker.

Import/Export Regulations

- Export Controls: Most silk screen printing equipment is not subject to strict export controls (e.g., ITAR or EAR). However, advanced automation systems or integrated software may require review.

- Import Requirements: Importers must provide accurate commercial invoices, packing lists, and bills of lading. Some countries require certificates of origin or conformity.

- Restricted Countries: Be aware of trade sanctions. Exporting to embargoed regions (e.g., Iran, North Korea) may be prohibited.

Packaging and Handling

- Fragile Components: Exposure units and dryer electronics are sensitive to shock and moisture. Use wooden crates with foam padding.

- Weight and Dimensions: Large automatic presses can exceed 500 kg. Confirm freight class, pallet size (standard: 48″x40″), and forklift access.

- Labeling: Include handling labels (“Fragile,” “This Side Up,” “Do Not Stack”) and contact information.

Shipping and Transportation

- Mode of Transport: Ocean freight is cost-effective for heavy machinery. Air freight is faster but expensive.

- Incoterms: Clearly define responsibilities using standard terms (e.g., FOB, CIF, DDP). FOB is common for exporter-managed loading; DDP for full turnkey delivery.

- Insurance: Obtain all-risk cargo insurance covering damage, theft, and delays.

Customs Clearance

- Documentation: Prepare:

- Commercial invoice (with detailed description and value)

- Bill of lading or air waybill

- Packing list

- Certificate of origin (if claiming preferential tariffs)

- Import license (if required by destination country)

- Duties and Taxes: Tariff rates vary by country (typically 0–10% for printing machinery). VAT or GST may apply upon import.

Safety and Compliance Standards

Ensure equipment meets safety and environmental standards in the destination market:

– CE Marking (EU): Required under Machinery Directive 2006/42/EC and Low Voltage Directive 2014/35/EU.

– UL/CSA (USA/Canada): Electrical components must be certified by a Nationally Recognized Testing Laboratory (NRTL).

– RoHS and REACH (EU): Restrict hazardous substances in electrical equipment and chemical components.

– Energy Efficiency: Conveyor dryers must comply with local energy standards (e.g., ERP in EU).

Installation and Operational Compliance

- Electrical Requirements: Verify voltage (110V vs. 220–240V), phase (single vs. three-phase), and plug types.

- Ventilation and Emissions: Washout booths and dryers may require fume extraction systems to meet OSHA (USA) or COSHH (UK) standards.

- Workplace Safety: Guard moving parts, install emergency stops, and provide operator training per local labor laws.

After-Sales and Service Logistics

- Spare Parts Inventory: Maintain key spare parts (squeegees, platens, belts) locally to minimize downtime.

- Technical Support: Provide manuals in local language and remote/onsite support options.

- Warranty Compliance: Honor international warranty terms and document service activities.

Environmental and Disposal Regulations

- Waste Management: Used screens, emulsion, and solvents must be disposed of per local hazardous waste laws (e.g., EPA in USA, WEEE in EU).

- End-of-Life Equipment: Recycle metal components and properly dispose of electronic control units under e-waste regulations.

Conclusion

Successful logistics and compliance for silk screen printing equipment require attention to classification, transport, customs, safety standards, and local regulations. Partnering with experienced freight forwarders, customs brokers, and compliance consultants ensures smooth international operations and minimizes risks.

In conclusion, sourcing equipment for screen printing requires careful consideration of several key factors to ensure efficiency, quality, and long-term viability of your printing operation. It is essential to assess your specific production needs—such as volume, print complexity, and substrate types—before selecting equipment. Investing in high-quality, durable machinery like exposure units, screen printing presses, dryers, and washing stations from reputable suppliers can significantly enhance print consistency and operational productivity. Additionally, factoring in maintenance requirements, space availability, and budget constraints will help in making cost-effective decisions. Exploring both new and refurbished equipment options can provide flexibility and value. Ultimately, well-researched sourcing of screen printing equipment lays the foundation for a scalable, professional, and competitive printing business capable of delivering high-quality results consistently.