The global expanded polypropylene (EPP) materials market is experiencing robust growth, driven by increasing demand for lightweight, durable, and sustainable packaging and insulation solutions across industries such as automotive, consumer goods, and healthcare. According to Grand View Research, the global EPP market was valued at USD 2.1 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030, fueled by stringent regulations favoring recyclable materials and advancements in material performance. Similarly, Mordor Intelligence projects a CAGR of over 6% during the forecast period 2023–2028, citing growing adoption in electric vehicle (EV) battery protection systems and cold chain logistics as key growth drivers. With rising environmental awareness and continued innovation in foam technology, EPP has emerged as a preferred alternative to traditional foams like EPS and PU. As demand surges, a select group of manufacturers are leading the charge in production capacity, technological development, and global reach—shaping the future of thermoplastic foams. Here’s a data-driven look at the top 10 EPP material manufacturers at the forefront of this expanding market.

Top 10 Epp Material Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Modern Polymers, Inc.

Domain Est. 2000

Website: modernpolymers.com

Key Highlights: Modern Polymers · The manufacturer of choice for Automotive, Aerospace and Packaging molded EPS and EPP foam products. · Recognized Nationally · POLYMER AUTOMOTIVE…

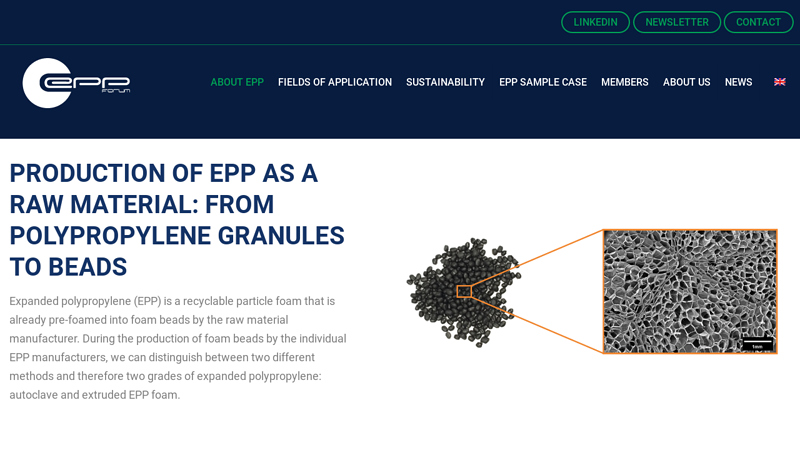

#2 Raw material production

Domain Est. 2006

Website: epp-forum.com

Key Highlights: Expanded polypropylene (EPP) is a recyclable particle foam that is already pre-foamed into foam beads by the raw material manufacturer….

#3 Manufacturer of GRP/FRP Pipe & Chemical Equipment by EPP …

Domain Est. 2015 | Founded: 1986

Website: eppcomposites.com

Key Highlights: Established in 1986, EPP Composites is a globally renowned FRP/GRP manufacturer, providing turnkey solutions across diverse industries. With a 1.45 million sq….

#4 EPP Material

Domain Est. 2023

Website: eppmaterials.com

Key Highlights: Buy good quality EPP Material from EPP Material manufacturer, We provide low priced EPP Material from China….

#5 China EPP Material & EPP Packaging factories

Domain Est. 2023

Website: m.eppmaterials.com

Key Highlights: Good quality EPP Material from China, EPP Packaging factories of Weihai Hanwell New Material Co., Ltd…..

#6 EPP information

Domain Est. 1999

Website: epp.co.kr

Key Highlights: EPP is an initialism for Expanded Polypropylene, referring to foam beads of spherical form which expanded Polypropylene (PP) physically (ie non-crosslinking)…

#7 ARPRO, the market leading Expanded Polypropylene (EPP) material

Domain Est. 2004

Website: arpro.com

Key Highlights: ARPRO Expanded Polypropylene is a 3D engineering material that delivers energy absorption with structural strength at very low weight….

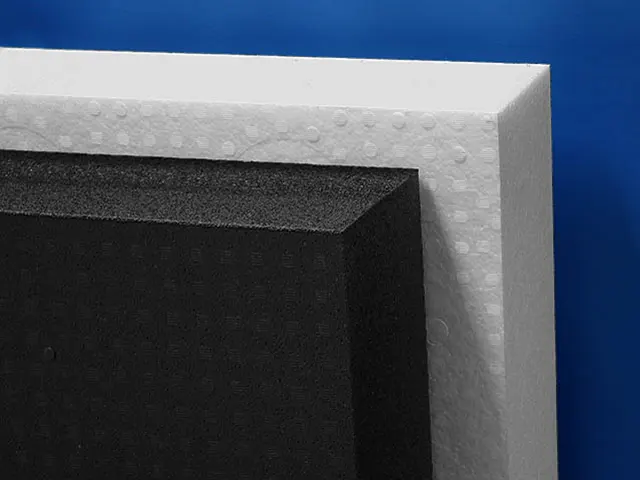

#8 Expanded Polypropylene

Domain Est. 2006

Website: knauf-industries.com

Key Highlights: Expanded polypropylene (EPP) is a material with many unique properties. Its light weight, exceptional strength and resilience make it an ideal choice in a ……

#9 Foam For Automotive

Domain Est. 2019

Website: engineeredfoamproducts.com

Key Highlights: Expanded Polypropylene (EPP) offers superb impact absorption performance to improve road safety for drivers, passengers and pedestrians….

#10 Expanded Polypropylene

Domain Est. 2022

Website: creativefoamusa.com

Key Highlights: We manufacture expanded polypropylene (EPP) products. EPP is a lightweight, flexible, and impact-resistant foam material for use in higher performance ……

Expert Sourcing Insights for Epp Material

H2: 2026 Market Trends for EPP Material

Expanded Polypropylene (EPP) is poised for significant market expansion and transformation by 2026, driven by growing demand across key industries, sustainability imperatives, and technological advancements. As global economies continue to prioritize lightweight, recyclable, and high-performance materials, EPP is emerging as a material of choice in automotive, packaging, consumer goods, and construction sectors. Below are the key market trends shaping the EPP landscape in 2026:

1. Rising Demand in the Automotive Industry

The automotive sector remains the largest consumer of EPP, accounting for over 50% of global demand. By 2026, EPP’s use in electric vehicles (EVs) will accelerate due to its excellent energy absorption, thermal insulation, and lightweight properties—critical for improving battery protection and vehicle efficiency. Components such as bumpers, interior trims, battery housings, and under-the-hood insulation increasingly incorporate EPP to meet safety and fuel economy standards.

2. Sustainability and Circular Economy Initiatives

Environmental regulations and consumer preferences are pushing manufacturers toward recyclable and bio-based materials. EPP is 100% recyclable, has a low carbon footprint during production, and can be reprocessed multiple times without significant degradation. By 2026, leading EPP producers are expected to expand closed-loop recycling systems and introduce EPP grades derived from renewable feedstocks, aligning with EU Green Deal and global net-zero targets.

3. Growth in Protective and Industrial Packaging

The e-commerce boom and need for durable, lightweight packaging are boosting EPP adoption in logistics and industrial applications. EPP’s shock absorption and thermal insulation properties make it ideal for shipping temperature-sensitive goods (e.g., pharmaceuticals, food) and high-value electronics. Innovations in design and molding technology are enabling cost-effective, customized packaging solutions, further driving market penetration.

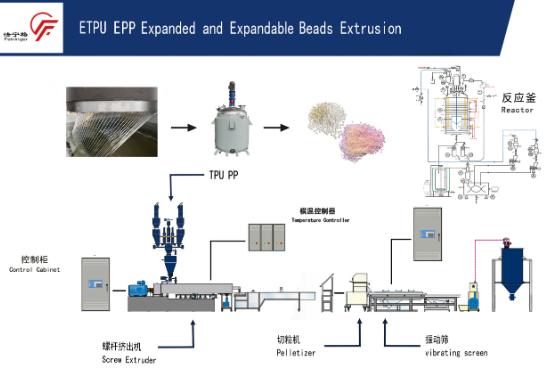

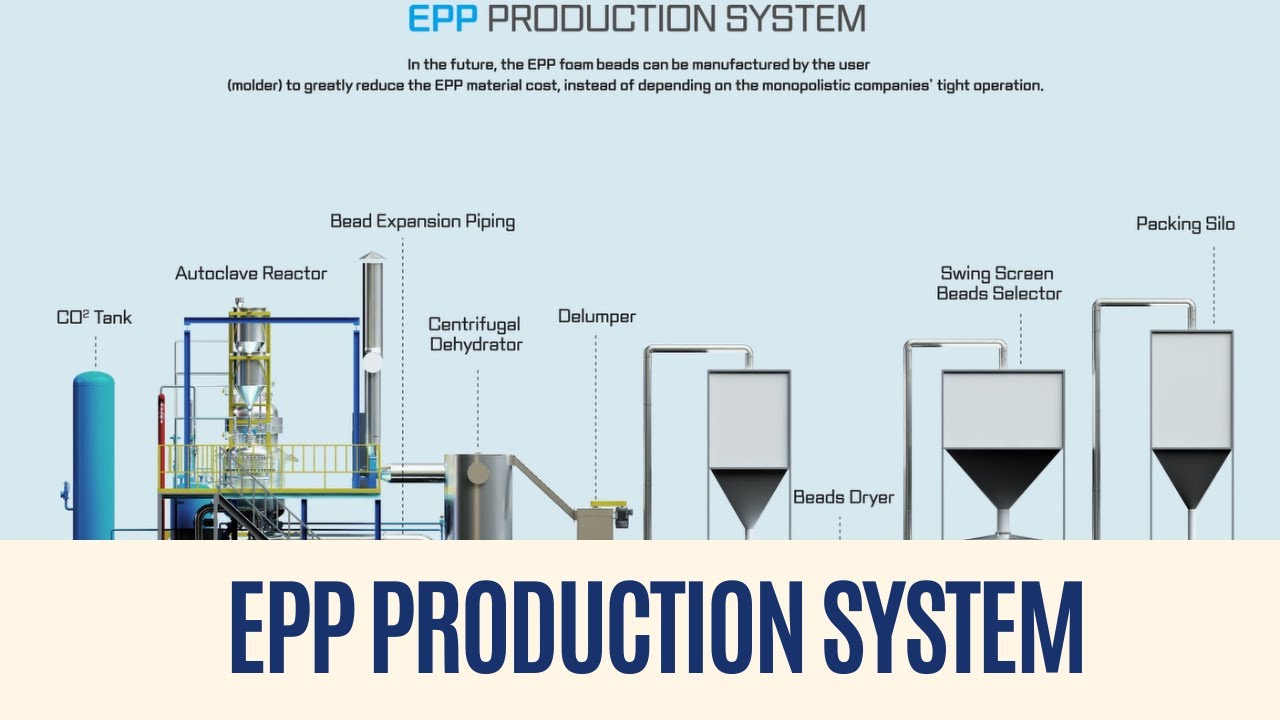

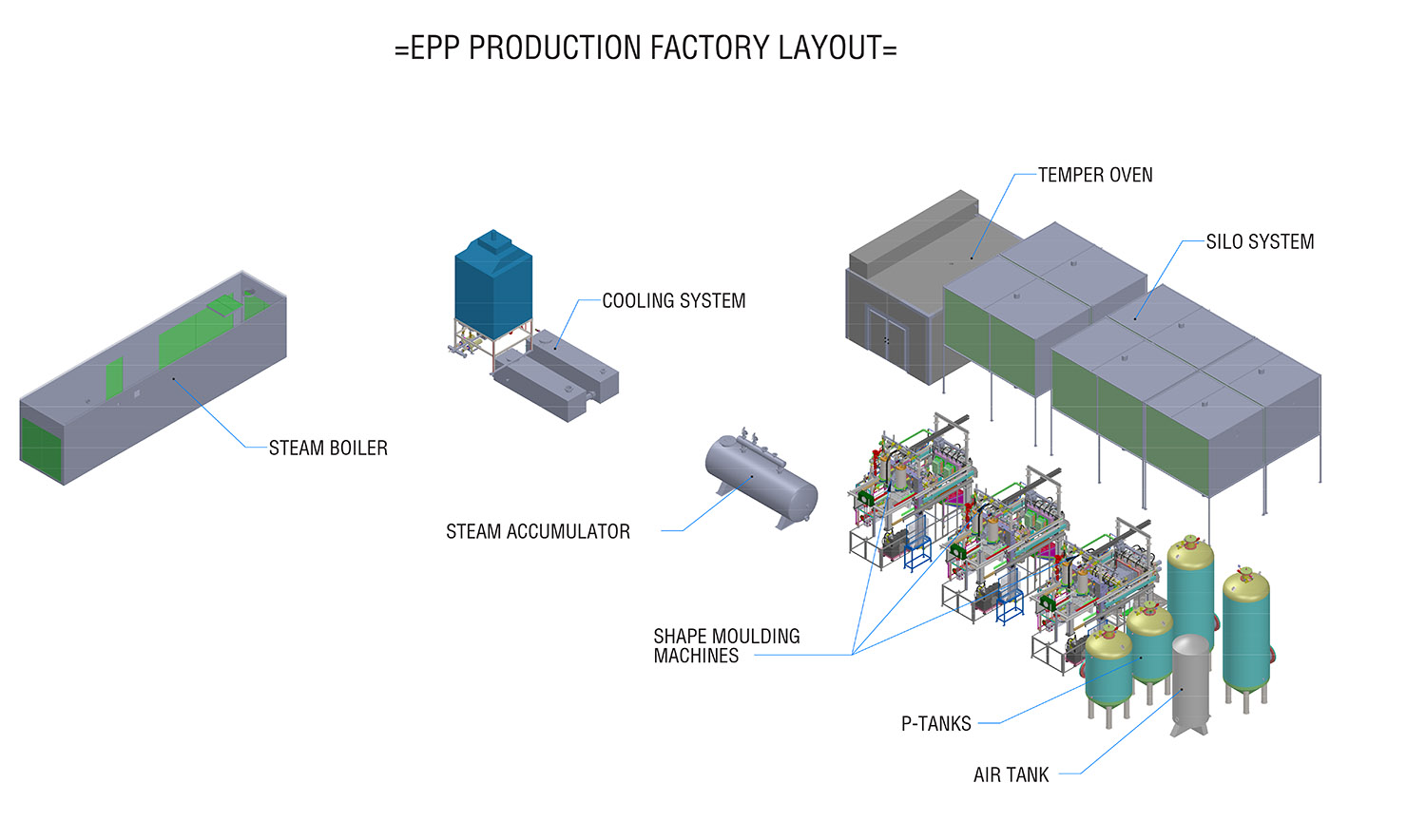

4. Technological Advancements in Processing and Design

Manufacturers are investing in advanced molding techniques such as steam-chest molding and digital simulation tools to improve precision, reduce cycle times, and minimize material waste. By 2026, integration with Industry 4.0 practices—like AI-driven quality control and IoT-enabled production lines—will enhance scalability and customization capabilities, allowing EPP producers to meet complex design requirements across sectors.

5. Expansion in Construction and Consumer Applications

EPP is gaining traction in construction for insulation panels and lightweight structural components due to its thermal efficiency and moisture resistance. Additionally, consumer products such as sports equipment, furniture, and child safety gear are increasingly utilizing EPP for its durability and comfort. These niche applications are expected to grow at a CAGR above 7% through 2026.

6. Regional Market Dynamics

Europe leads in EPP adoption, driven by stringent automotive safety and environmental regulations. Asia-Pacific, particularly China and India, is the fastest-growing region due to rising automotive production and urbanization. North America is witnessing increased demand in EVs and sustainable packaging. Strategic partnerships and capacity expansions by key players (e.g., BASF, BEWI, JSP) are expected to strengthen regional supply chains.

7. Price Volatility and Raw Material Challenges

Despite positive trends, EPP markets may face headwinds from fluctuating polypropylene feedstock prices linked to crude oil markets. However, long-term contracts, investment in alternative feedstocks, and improved recycling infrastructure are expected to mitigate these risks by 2026.

Conclusion

By 2026, the EPP material market is projected to exceed USD 3.5 billion, growing at a CAGR of approximately 6.5% from 2021. The confluence of sustainability, performance advantages, and innovation positions EPP as a critical enabler of green manufacturing and advanced design across industries. Companies that invest in recycling, R&D, and regional diversification will be best positioned to capitalize on emerging opportunities in the evolving EPP landscape.

Common Pitfalls When Sourcing EPP Material (Quality, IP)

Sourcing Expanded Polypropylene (EPP) material can present several challenges, particularly concerning material quality and intellectual property (IP) protection. Overlooking these aspects can lead to production delays, compromised product performance, legal disputes, and reputational damage. Below are key pitfalls to avoid:

Inadequate Quality Control and Material Consistency

One of the most frequent issues is receiving EPP batches with inconsistent density, cell structure, or mechanical properties. Suppliers may use recycled content or substandard raw materials without proper disclosure, leading to variations in impact resistance, thermal insulation, and dimensional stability. Always verify the supplier’s quality management systems (e.g., ISO 9001), request material test reports (MTRs), and conduct incoming inspections or third-party testing.

Lack of Traceability and Certification

EPP used in regulated industries (e.g., automotive, medical, food contact) must meet specific safety and compliance standards. Sourcing without proper documentation—such as FDA compliance, REACH, RoHS, or UL certifications—can result in non-compliance. Ensure the supplier provides full traceability from raw material to finished bead, including batch numbers and test data, to mitigate regulatory risks.

Insufficient Intellectual Property Agreements

When developing custom EPP molds or formulations, IP ownership can become a major concern. Many suppliers claim partial or full rights to tooling, designs, or material blends created during collaboration. Without clear contractual agreements (e.g., work-for-hire clauses, IP assignment), companies risk losing exclusive rights to their innovations or facing costly litigation. Always define IP ownership upfront in supplier contracts.

Tooling Ownership and Access Disputes

Molded EPP parts require expensive, custom tooling. Some suppliers retain physical or legal control over molds, restricting your ability to switch manufacturers or scale production. This creates vendor lock-in and limits negotiation power. Ensure contracts explicitly state that your company owns the tooling and has unfettered access, including digital design files (e.g., CAD).

Hidden Costs and Minimum Order Quantities (MOQs)

Suppliers may quote low per-unit prices but impose high MOQs or charge exorbitant setup fees. Additionally, costs can escalate due to hidden charges for storage, color changes, or small batch runs. Evaluate total cost of ownership and negotiate flexible terms, especially for prototyping or low-volume production.

Geographic and Logistical Risks

Sourcing EPP from distant suppliers introduces supply chain vulnerabilities, including shipping delays, import tariffs, and communication barriers. These factors can affect lead times and increase costs. Consider dual sourcing or regional suppliers to mitigate disruption risks.

Environmental and Sustainability Misrepresentation

With growing emphasis on sustainability, some suppliers may misrepresent the recyclability or recycled content of their EPP. Verify environmental claims through third-party audits or certifications (e.g., EPDs, recyclability logs) to avoid greenwashing and ensure alignment with corporate sustainability goals.

By proactively addressing these pitfalls—through due diligence, clear contracts, and robust supplier qualification—companies can secure reliable, high-quality EPP material while protecting their intellectual property and long-term business interests.

Logistics & Compliance Guide for EPP Material

Expanded Polypropylene (EPP) is a lightweight, durable, and recyclable foam material widely used in packaging, automotive components, and consumer goods. Ensuring proper logistics handling and regulatory compliance is essential for safe, efficient, and environmentally responsible operations.

Material Properties and Handling

EPP is known for its shock absorption, thermal insulation, and chemical resistance. Due to its low density, it occupies significant volume relative to weight. Handle EPP with care to avoid excessive compression or punctures that may compromise structural integrity. Store in a clean, dry area away from direct sunlight and extreme temperatures to prevent degradation. Avoid stacking heavy loads on EPP packaging components unless designed for such use.

Packaging and Transportation

When shipping EPP parts or products, use protective outer packaging such as corrugated cardboard or reusable containers to prevent damage during transit. Consolidate shipments efficiently to optimize space and reduce transport costs. EPP is generally non-hazardous and can be transported via standard freight methods (road, rail, air, sea). Ensure proper labeling and secure loading to prevent shifting. For international shipments, verify dimensional weight policies with carriers, as EPP’s volume may impact shipping costs.

Regulatory Compliance

EPP material typically complies with major international safety and environmental standards. Confirm that your EPP supplier provides documentation showing compliance with REACH (EU), RoHS (EU), and FDA (for food-contact applications, if applicable). EPP does not contain CFCs or HCFCs and has zero ozone depletion potential (ODP), making it compliant with Montreal Protocol standards. For automotive or construction applications, ensure adherence to specific industry standards (e.g., FMVSS, EN 13501 for fire safety).

Recycling and Environmental Responsibility

EPP is 100% recyclable and can be processed through mechanical recycling methods. Encourage end-of-life collection programs and partner with certified recycling facilities. Avoid contamination with non-recyclable materials. Document recycling efforts to support environmental reporting and sustainability goals. EPP’s long service life and recyclability contribute positively to circular economy initiatives.

Documentation and Traceability

Maintain detailed records including material safety data sheets (MSDS/SDS), certificates of compliance, batch numbers, and supplier information. This ensures traceability and simplifies audits or regulatory inquiries. For global supply chains, ensure all documentation meets local language and regulatory requirements in destination markets.

Training and Safety

Train logistics and warehouse staff on proper EPP handling, storage, and emergency procedures. While EPP is non-toxic and non-irritant, standard workplace safety practices should be followed. In case of fire, EPP will melt and burn, producing carbon monoxide and hydrocarbons—ensure appropriate fire suppression systems are in place.

By adhering to this guide, organizations can ensure the safe, compliant, and sustainable logistics management of EPP materials across the supply chain.

Conclusion on Sourcing EPP Material

In conclusion, sourcing Expanded Polypropylene (EPP) material requires a strategic approach that balances quality, cost, sustainability, and supply chain reliability. EPP’s excellent energy absorption, lightweight nature, and recyclability make it a preferred choice across industries such as automotive, packaging, consumer goods, and construction. When sourcing EPP, it is essential to partner with reputable suppliers who adhere to international quality standards, offer material traceability, and support environmental goals through responsible production practices.

Evaluating suppliers based on material consistency, customization capabilities, technical support, and logistical efficiency ensures a reliable supply chain and optimal product performance. Additionally, considering regional availability, regulatory compliance, and long-term cost implications—such as recyclability and lifecycle benefits—can lead to more sustainable and economically sound decisions.

Ultimately, a well-planned sourcing strategy for EPP not only enhances product performance and environmental footprint but also strengthens competitiveness and innovation in the market.