The global epoxy resin market is experiencing robust growth, driven by increasing demand across construction, automotive, and industrial sectors. According to a 2023 report by Mordor Intelligence, the market was valued at USD 10.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2028. A significant portion of this demand stems from the building and construction industry, where epoxy resins are valued for their durability, chemical resistance, and seamless finish—qualities that make them particularly suitable for high-moisture environments like shower floors. As bathroom renovation and waterproofing solutions gain prominence in both residential and commercial spaces, manufacturers specializing in epoxy resin shower flooring are emerging as key players in the niche surfacing market. This growing adoption, supported by advancements in UV-stable and low-VOC formulations, has intensified competition among producers to deliver high-performance, aesthetically versatile flooring solutions. Below, we highlight the top 10 manufacturers leading innovation and quality in epoxy resin shower floor systems.

Top 10 Epoxy Resin Shower Floor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

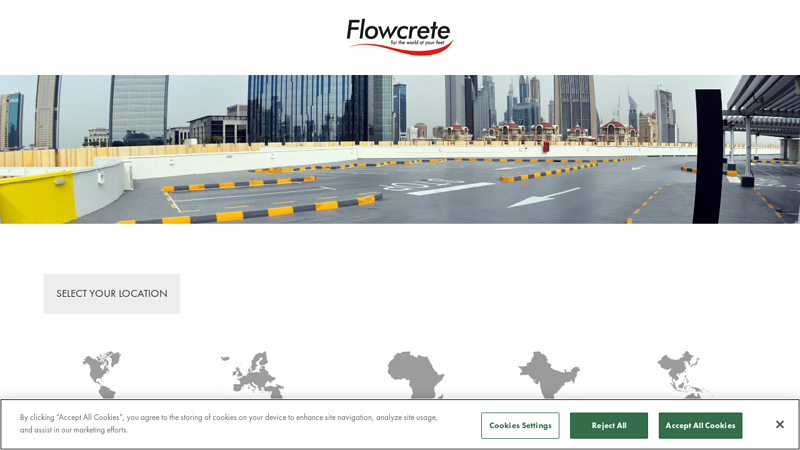

#1 World Leading Manufacturer of High Performance Seamless Resin …

Domain Est. 1996

Website: flowcrete.com

Key Highlights: World Leading Manufacturer of High Performance Seamless Resin Flooring Solutions | Flowcrete | Epoxy, Polyurethane & MMA Resin Flooring….

#2 High Performance Flooring

Domain Est. 1998

Website: industrial.sherwin-williams.com

Key Highlights: Sherwin-Williams High Performance Flooring offers durable, seamless resinous systems for commercial and industrial applications. Get in touch with us today!…

#3 Restroom Epoxy

Domain Est. 1998

Website: armorpoxy.com

Key Highlights: ArmorPoxy carries innovative restroom and bathroom floor coatings such as epoxy, polyaspartic, nano technology based sealers, and topcoats….

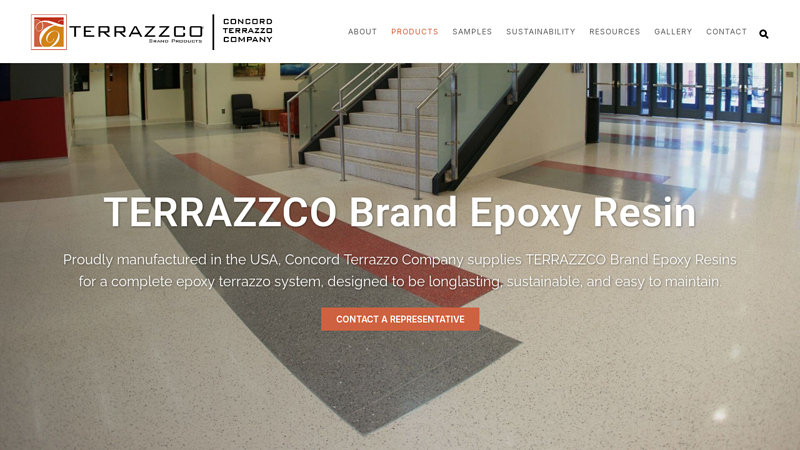

#4 Epoxy Resin

Domain Est. 2005

Website: terrazzco.com

Key Highlights: TERRAZZCO Brand Epoxy Resin is a decorative terrazzo flooring system designed for institutional, commercial, and industrial building projects….

#5 Tile Redi

Domain Est. 1996

Website: tileredi.com

Key Highlights: Tile Redi offers shower pans & bases, shower shelves, tile trim, benches, shower walls and many other shower waterproofing products and accessories….

#6 MAPEI

Domain Est. 1996

Website: mapei.com

Key Highlights: MAPEI is the leading company in the building industry, with over 80 years of experience, in the field of adhesives, sealants & chemical products for ……

#7 CUSTOM Building Products

Domain Est. 1997 | Founded: 1964

Website: custombuildingproducts.com

Key Highlights: CustomTech from Custom Building Products — the brand flooring contractors have trusted since 1964. Engineered to exceed the most stringent requirements, ……

#8 Homepage

Domain Est. 2005

Website: wedicorp.com

Key Highlights: wedi Waterproof Shower Systems offer reliable, cost-efficient solutions for constructing 100% waterproof and mold-proof showers, and are easy to install….

#9 Everlast Epoxy for Shower Floors and Walls

Domain Est. 2006

Website: everlastepoxy.com

Key Highlights: Discover durable, waterproof epoxy shower floors that prevent mold and cracks. Easy to clean, seamless, and built to last—perfect for any bathroom….

#10 Metallic Epoxy Bathroom

Domain Est. 2019

Website: metallicepoxy.sg

Key Highlights: Our Metallic Epoxy is highly heat resistant and withstands temperatures up to 200°C. With its anti-skid properties on the floor, it can allow for safe and ……

Expert Sourcing Insights for Epoxy Resin Shower Floor

H2: Projected 2026 Market Trends for Epoxy Resin Shower Floors

The market for epoxy resin shower floors is poised for significant evolution by 2026, driven by advancements in material science, shifting consumer preferences toward durable and aesthetically flexible bathroom solutions, and increasing demand for low-maintenance home renovation products. Key trends shaping the 2026 outlook include growing adoption in both residential and commercial sectors, innovation in eco-friendly formulations, and rising integration with smart home design.

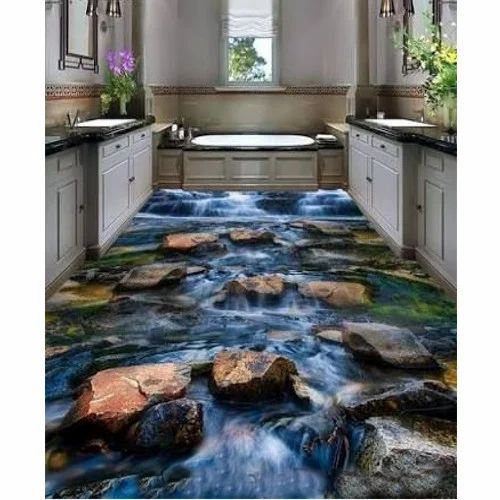

One of the dominant drivers will be the expanding preference for seamless, waterproof flooring systems in wet areas. Epoxy resin shower floors offer a completely watertight surface with minimal grout lines, reducing mold and mildew risks—critical factors for health-conscious consumers. As bathroom design trends lean toward minimalist, spa-like aesthetics, the high-gloss finish and customizable color options of epoxy resins align well with modern interior themes.

Technological advancements are expected to enhance product performance. By 2026, manufacturers are likely to introduce faster-curing, UV-stable, and slip-resistant epoxy formulations tailored specifically for shower environments. These innovations will address longstanding concerns about longevity and safety, particularly in high-humidity zones.

Sustainability will also play a pivotal role. With increasing regulatory pressure and consumer demand for green building materials, epoxy producers are investing in bio-based resins and low-VOC (volatile organic compound) systems. These eco-conscious variants are projected to capture a growing share of the market, particularly in North America and Western Europe.

Additionally, the DIY renovation movement is fueling demand for user-friendly epoxy kits. By 2026, pre-measured, easy-application epoxy systems with augmented reality (AR) guidance or app-based tutorials are expected to gain popularity, enabling homeowners to install professional-quality shower floors without specialized labor.

Regionally, the North American and Asia-Pacific markets are anticipated to lead growth. In the U.S., aging housing stock and remodeling activity will drive demand, while in countries like China and India, rising disposable incomes and urbanization will boost adoption in new construction projects.

In conclusion, the 2026 epoxy resin shower floor market will be defined by innovation, sustainability, and design versatility. As the product matures and overcomes traditional barriers such as complexity of installation and environmental concerns, it is set to become a mainstream choice in modern bathroom design.

Common Pitfalls When Sourcing Epoxy Resin Shower Floors (Quality & Intellectual Property)

Sourcing epoxy resin shower floors—whether pre-fabricated or custom systems—requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these areas can lead to product failure, legal disputes, or reputational damage. Below are key pitfalls to avoid:

Poor Material Quality and Performance

1. Substandard Resin Formulation

Many suppliers cut costs by using low-grade epoxy resins or incorrect hardener ratios. This results in inadequate chemical resistance, poor adhesion, and premature degradation when exposed to constant moisture and cleaning agents. Always verify technical data sheets (TDS) and request third-party test reports for water absorption, tensile strength, and chemical resistance.

2. Inadequate UV and Yellowing Resistance

Standard epoxy yellows over time when exposed to UV light—even indoor bathroom lighting can trigger this. Sourcing a formulation without UV stabilizers leads to unsightly discoloration. Ensure the product includes aliphatic or UV-resistant additives if appearance longevity is critical.

3. Insufficient Slip Resistance

A smooth epoxy finish in a wet environment poses a serious safety hazard. Some suppliers provide glossy, non-textured surfaces unsuitable for shower use. Confirm that the product includes anti-slip additives (e.g., silica or aluminum oxide) and meets safety standards like DIN 51130 (R10 or higher for wet areas).

4. Poor Curing Conditions and Application Requirements

Epoxy performance heavily depends on correct mixing ratios, ambient temperature, and humidity during curing. Suppliers from unregulated markets may not provide clear installation guidelines or training, leading to improper curing, bubbling, or delamination. Verify that the supplier offers comprehensive installation support and environmental specifications.

5. Lack of Certification and Compliance

Reputable epoxy systems should meet health and safety standards such as NSF/ANSI 61 (drinking water safety), LEED compliance, or VOC regulations (e.g., EU REACH, California 01350). Sourcing non-certified products risks health hazards and non-compliance with building codes.

Intellectual Property and Branding Risks

1. Copycat or Counterfeit Products

The popularity of seamless epoxy shower floors has led to widespread replication. Some suppliers offer near-identical designs or formulations that infringe on patented systems or trade-dress rights. Sourcing such products can expose you to legal liability, especially in commercial projects or branded developments.

2. Unlicensed Use of Proprietary Systems

Certain high-performance epoxy systems (e.g., specific multi-layer waterproofing systems) are protected by patents or exclusive licensing agreements. Suppliers may claim compatibility or equivalence but fail to deliver the same performance. Always verify whether the supplier is an authorized distributor or holds proper licensing for branded technologies.

3. Misrepresentation of Origin and Innovation

Some suppliers falsely claim their epoxy formula is “patent-pending” or “exclusive” when it is not. This misleads buyers into believing they are acquiring a unique, protected product. Conduct due diligence by checking patent databases (e.g., USPTO, EPO) and requesting proof of IP ownership or registration.

4. Design Copyright Infringement

Custom aesthetic finishes—such as colored aggregates, metallic effects, or patterned inlays—may be protected by design copyrights or industrial design registrations. Reproducing these without permission, even unintentionally, can lead to IP litigation. Ensure your supplier can prove rights to any decorative elements used.

5. Inadequate Contractual IP Protections

When sourcing custom-designed epoxy floors, contracts often fail to clarify IP ownership of the final product or design. This can result in disputes over usage rights, especially if the same design is sold to competitors. Always include IP assignment or exclusivity clauses in procurement agreements.

Conclusion

To mitigate risks, work with reputable suppliers who provide full transparency on material composition, certifications, and intellectual property status. Request samples, review legal disclaimers, and consult with technical and legal experts when scaling procurement. Prioritizing quality and IP integrity ensures long-term performance, safety, and legal compliance in your epoxy resin shower floor projects.

Logistics & Compliance Guide for Epoxy Resin Shower Floor Installation

Product Handling and Storage

Ensure epoxy resin components (resin, hardener, additives) are stored in a cool, dry, and well-ventilated area, away from direct sunlight and heat sources. Maintain storage temperatures between 60°F and 80°F (15°C–27°C) to preserve product stability and shelf life. Keep containers tightly sealed when not in use to prevent moisture contamination and premature curing. Store out of reach of children and pets, and separate from incompatible materials such as oxidizers or flammable substances.

Transportation Requirements

Transport epoxy resin systems in original, UN-rated containers with secure closures to prevent leaks. Vehicles must be well-ventilated and protected from extreme temperatures during transit. Follow Department of Transportation (DOT) regulations for hazardous materials if applicable—check Safety Data Sheet (SDS) for classification. Most epoxy resins are classified as ORM-D (Other Regulated Material – Domestic) or fall under Class 3 Flammable Liquids if flash point is below 140°F (60°C). Proper labeling, spill kits, and documentation are required when transporting in regulated quantities.

Job Site Preparation and Safety

Prior to installation, ensure the shower substrate is clean, structurally sound, and free of dust, oil, or moisture. Use mechanical abrasion (e.g., grinding) to create proper surface profile for adhesion. Provide adequate ventilation at the job site—use exhaust fans or open windows to minimize vapor buildup. Prohibit smoking and open flames due to flammable vapors during application and cure.

Personal Protective Equipment (PPE)

All personnel must wear appropriate PPE during handling and installation, including:

– Nitrile gloves (double-gloving recommended)

– Chemical-resistant apron or coveralls

– Safety goggles or full-face shield

– NIOSH-approved respirator with organic vapor cartridges

Failure to use proper PPE may result in skin irritation, respiratory issues, or sensitization.

Mixing and Application Compliance

Follow manufacturer’s specified mix ratio precisely—typically a 1:1 or 2:1 resin-to-hardener ratio by volume or weight. Use calibrated measuring tools and mix thoroughly for 2–3 minutes to ensure complete homogenization. Avoid introducing air during mixing; roll or skim with a notched trowel or squeegee as directed. Apply within the pot life window and adhere to ambient temperature and humidity limits (typically 50°F–90°F and <85% RH).

Curing and Drying Conditions

Allow for a minimum 24-hour cure time before light foot traffic and 72 hours before full water exposure, unless specified otherwise by the manufacturer. Maintain stable temperatures during cure—avoid cold drafts or rapid temperature changes which may cause incomplete curing or cracking. Do not expose to standing water or cleaning agents before full cure.

Waste Disposal and Environmental Compliance

Dispose of unused epoxy, mixing containers, and application tools as hazardous waste in accordance with local, state, and federal regulations (e.g., EPA, RCRA). Never pour epoxy resin or solvent cleaners down drains. Use absorbent materials for spills and dispose of contaminated materials at approved hazardous waste facilities. Consult SDS Section 13 for specific disposal recommendations.

Regulatory and Certification Standards

Ensure the epoxy resin system complies with relevant standards, including:

– ASTM D4258 / D4259 for surface preparation

– ANSI A118.10 for high-performance bonding mortars (if underlayment is used)

– VOC compliance per EPA Method 24 or SCAQMD Rule 1113 (Volatile Organic Compounds)

– NSF/ANSI 61 or NSF/ANSI 51 for potable water contact (if applicable for shower use)

Verify product certification and obtain documentation from the manufacturer for code compliance.

Documentation and Recordkeeping

Maintain records of Safety Data Sheets (SDS), product warranties, batch numbers, mix logs, and application conditions (temperature, humidity, substrate prep). These records support compliance audits, warranty claims, and liability protection. Provide homeowners or building managers with care and maintenance instructions post-installation.

In conclusion, sourcing epoxy resin for a shower floor requires careful consideration of product quality, waterproofing capabilities, durability, and safety for wet environments. It is essential to select a 100% solids, non-yellowing, and mold/mildew-resistant epoxy specifically formulated for bathroom or shower applications. Proper surface preparation, accurate mixing ratios, and following manufacturer instructions are critical to ensure a long-lasting, seamless, and waterproof finish. Additionally, sourcing from reputable suppliers ensures authenticity and access to technical support. When done correctly, an epoxy resin shower floor offers a modern, low-maintenance, and highly durable solution that combines aesthetic appeal with functional performance.