The global epoxy adhesives market continues to gain momentum, driven by rising demand across industrial, automotive, and construction sectors, with ceramic manufacturers increasingly relying on high-performance bonding solutions. According to Mordor Intelligence, the epoxy adhesives market is projected to grow at a CAGR of over 6.2% from 2023 to 2028, fueled by advancements in material science and the need for durable, heat-resistant, and chemically stable adhesives—qualities essential in ceramic production and repair. As manufacturers prioritize product longevity and precision, selecting the right epoxy glue has become a critical factor in maintaining efficiency and quality. With ceramic materials widely used in electronics, sanitaryware, and architectural components, the demand for specialized epoxies that offer low shrinkage, high shear strength, and thermal resilience continues to rise. This list identifies the top nine epoxy glues tailored for ceramic manufacturers, evaluated through performance metrics, user reviews, and technical specifications to align with evolving industry standards.

Top 9 Epoxy Glue For Ceramic Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

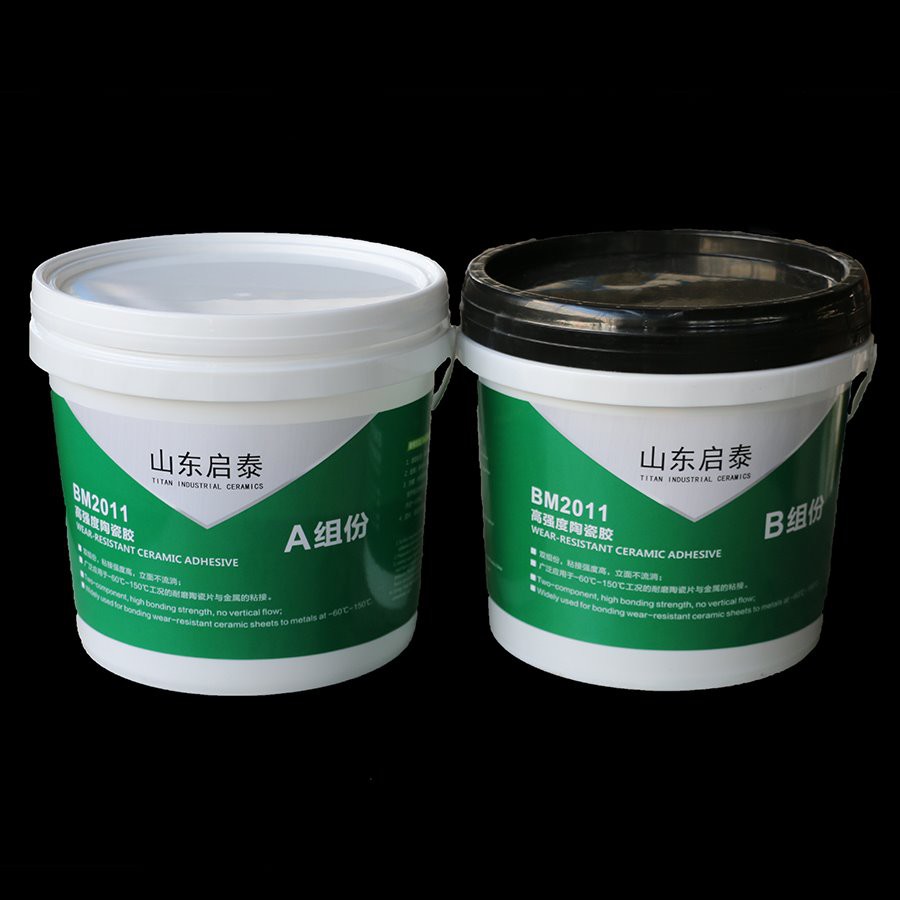

#1 Epoxy Bonding Agent For Ceramic Manufacturers, Suppliers, Factory

Domain Est. 2019

Website: wear-ceramic.com

Key Highlights: We’re professional epoxy bonding agent for ceramic manufacturers and suppliers in China, specialized in providing high quality ceramic materials….

#2 Permabond Adhesive

Domain Est. 1996

Website: permabond.com

Key Highlights: Manufacturer, Formulator, and Innovator of Adhesives. Permabond manufactures many … Single Part Epoxy Adhesives. Modified Epoxy & MS Polymer Adhesives….

#3 Cotronics

Domain Est. 1997

Website: cotronics.com

Key Highlights: Cotronics manufactures and distributes high temp adhesives, epoxies, ceramics, putties, sealants, conductive and insulating adhesives, insulation materials….

#4 Ceramic

Domain Est. 2013

Website: atomadhesives.com

Key Highlights: In stock Rating 4.8 (12) Ceramic-Bond 1 is an exceptional epoxy formulation recommended for lower temperature or wet industrial bonding applications where FAST CURING is required…

#5 Devcon Industrial Epoxy Adhesive

Domain Est. 2017

Website: itwperformancepolymers.com

Key Highlights: With the Devcon® structural adhesive, it is possible to bond a broad range of substrates such as rubber, ceramic, phenolic resin, steel, aluminum, pipe wrap, ……

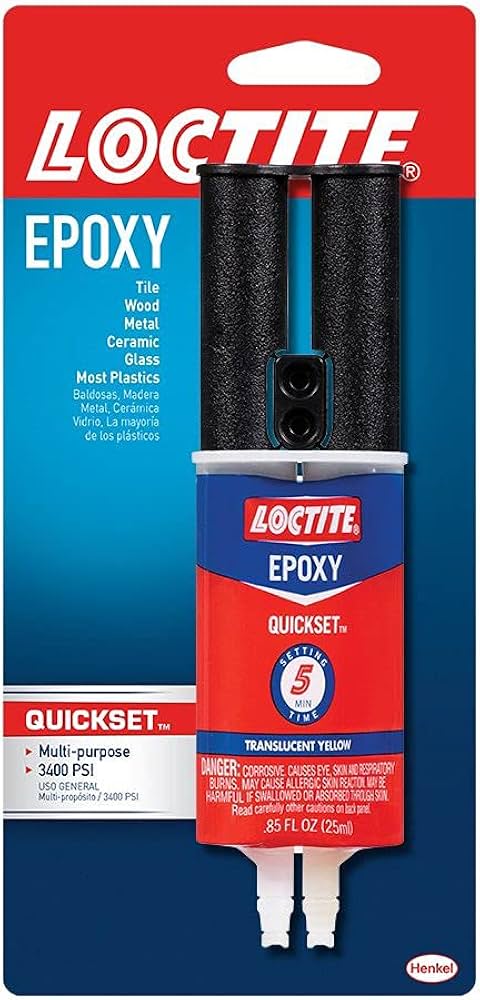

#6 Loctite Clear Epoxy

Domain Est. 1999

Website: loctiteproducts.com

Key Highlights: Loctite Epoxy Clear Multi-Purpose is a resilient, permanent two-part adhesive consisting of an epoxy resin and a hardener for large or multi-piece projects….

#7 Epoxy Adhesive

Domain Est. 1999

Website: sylmasta.com

Key Highlights: Epoxy Adhesive is a two-part super strong glue with a 5 minute cure time used to bond meta, plastic, ceramic, brick and other rigid substrates….

#8 Epoxy Resin Glue

Domain Est. 2002

Website: chemshun.com

Key Highlights: The epoxy resin glue is widely used for sticking ceramic on large range of materials surface in kind of conditions. Wear resistant ceramic linings using ……

#9 Stone Glue, Polyester Mastics, and Epoxy Resin Adhesives by …

Domain Est. 2013

Website: tenax4you.com

Key Highlights: A true 100% two-part epoxy glue, not water based, and is very easy to mix and spread. Use for bonding stone, hardwood, cement board, laminate and plywood….

Expert Sourcing Insights for Epoxy Glue For Ceramic

H2: 2026 Market Trends for Epoxy Glue for Ceramic

The global market for epoxy glue for ceramic is poised for steady growth through 2026, driven by increasing demand across industrial, consumer, and construction applications. Several key trends are expected to shape the market dynamics during this period.

1. Rising Demand in Construction and Home Improvement

The construction sector continues to be a major driver, with epoxy glues increasingly used for ceramic tile installations, repairs, and renovations. As urbanization expands and home improvement activities rise—especially in emerging economies—demand for durable, water-resistant bonding solutions like epoxy glue for ceramics is growing. DIY culture in North America and Europe further amplifies consumer demand for user-friendly, high-performance ceramic adhesives.

2. Technological Advancements and Product Innovation

Manufacturers are focusing on developing fast-curing, low-odor, and UV-resistant epoxy formulations tailored for ceramics. Innovations such as hybrid epoxy-polyurethane systems and nano-enhanced adhesives are improving bond strength and thermal stability. These advancements cater to both industrial users requiring precision and consumers seeking convenience and reliability.

3. Expansion in Industrial and Automotive Applications

Beyond traditional uses, epoxy glue for ceramics is finding new applications in electronics (e.g., bonding ceramic components in sensors and insulators) and the automotive industry (e.g., ceramic-based heat shields and exhaust systems). As electric vehicles (EVs) and advanced manufacturing grow, so does the need for high-temperature resistant adhesives—epoxy glues are well-positioned to meet these requirements.

4. Sustainability and Eco-Friendly Formulations

Environmental regulations are pushing manufacturers toward greener alternatives. By 2026, expect increased availability of bio-based epoxy resins and low-VOC (volatile organic compound) formulations. Brands emphasizing recyclability, reduced environmental impact, and safer handling will gain market share, particularly in environmentally conscious regions like Western Europe.

5. Regional Market Growth

Asia-Pacific is expected to dominate market growth due to rapid infrastructure development in China, India, and Southeast Asia. Latin America and the Middle East are also emerging as high-potential markets. Meanwhile, North America and Europe maintain steady demand, supported by renovation cycles and strict building codes requiring durable materials.

6. Competitive Landscape and Market Consolidation

The market is moderately fragmented, with key players such as 3M, Henkel (Loctite), Sika, and Permabond leading through R&D and strategic partnerships. Smaller regional brands are gaining traction by offering cost-effective solutions. By 2026, consolidation through mergers and acquisitions is anticipated, especially to expand distribution networks and enhance technical capabilities.

In summary, the epoxy glue for ceramic market in 2026 will be characterized by innovation, sustainability, and expanding applications. As performance requirements grow across sectors, epoxy adhesives will remain a preferred solution for ceramic bonding, supported by technological progress and evolving consumer needs.

Common Pitfalls When Sourcing Epoxy Glue for Ceramic: Quality and Intellectual Property Issues

Sourcing the right epoxy glue for ceramic applications requires careful consideration beyond price and availability. Overlooking quality and intellectual property (IP) aspects can lead to performance failures, legal risks, and reputational damage. Below are key pitfalls to avoid:

Poor Adhesive Quality and Inconsistent Performance

One of the most frequent issues when sourcing epoxy glue for ceramics is receiving products that fail to meet technical specifications. Low-quality epoxies may exhibit weak bond strength, poor heat or moisture resistance, or inconsistent curing behavior—especially critical when bonding ceramics used in high-temperature or humid environments. Suppliers from unverified sources may provide off-spec or expired batches, leading to product failure in end-use applications. Always request material data sheets (MSDS), performance test results, and batch certifications to validate adhesive performance.

Misrepresentation of Technical Properties

Some suppliers exaggerate or falsify product specifications such as tensile strength, cure time, or temperature resistance. This misrepresentation can mislead buyers into selecting an adhesive unsuitable for ceramic bonding, which often demands high rigidity and thermal stability. To avoid this, conduct independent lab testing on samples and verify claims through third-party certifications or accredited testing bodies.

Lack of Traceability and Batch-to-Batch Variability

Reputable epoxy manufacturers maintain strict quality control and provide traceability for raw materials and production batches. When sourcing from less-regulated suppliers, traceability is often absent, increasing the risk of batch inconsistencies. This variability can compromise bonding reliability, especially in industrial or medical ceramic applications where consistency is critical.

Intellectual Property Infringement Risks

Sourcing epoxy glue from unauthorized or gray-market suppliers can expose your business to intellectual property (IP) violations. Some manufacturers produce counterfeit versions of well-known branded epoxies, replicating packaging and labeling without licensing. Using such products may lead to legal liability, particularly in regulated industries. Always procure adhesives through authorized distributors and verify the supplier’s legitimacy with the original manufacturer.

Inadequate Regulatory Compliance

Many epoxy formulations are subject to regional regulations (e.g., REACH, RoHS, FDA). Low-cost suppliers may use restricted or hazardous substances to cut costs, making the adhesive non-compliant. For ceramics used in food-contact or medical devices, using non-compliant epoxy can result in regulatory penalties and recalls. Ensure the adhesive meets all relevant compliance standards for your target market.

Insufficient Technical Support and Documentation

High-quality epoxy suppliers provide comprehensive technical support, application guidance, and safety documentation. When sourcing from unreliable vendors, this support is often missing, leaving users without critical information on surface preparation, mixing ratios, or curing conditions—key factors for successful ceramic bonding. Lack of proper documentation also complicates quality audits and process validation.

By recognizing these common pitfalls, businesses can implement stronger sourcing strategies—such as vetting suppliers rigorously, demanding full compliance documentation, and testing samples—ensuring they obtain a high-quality, legally sound epoxy adhesive suitable for ceramic applications.

Logistics & Compliance Guide for Epoxy Glue for Ceramic

Overview

Epoxy glue for ceramic is a two-part adhesive system commonly used for bonding ceramics, porcelain, and other materials. Due to its chemical composition—typically containing epoxy resins, hardeners (such as amines), and fillers—it may be subject to various regulatory and logistical requirements during storage, transport, and handling. This guide outlines key logistics and compliance considerations to ensure safe and legal distribution and use.

Classification & Regulatory Status

Epoxy glue formulations may be classified as hazardous materials depending on their components. Common classifications include:

– UN Number: Typically UN 1866 (Corrosive liquid, organic, n.o.s.) or UN 3082 (Environmentally hazardous substance, liquid, n.o.s.), depending on formulation.

– Hazard Class: Often Class 8 (Corrosive Substances), and potentially Class 3 (Flammable Liquids) if solvent-based.

– GHS Classification: May include hazards such as:

– Skin corrosion/irritation (Category 1B)

– Serious eye damage/eye irritation (Category 1)

– Specific target organ toxicity (single exposure, Category 3 – respiratory irritation)

– Hazardous to the aquatic environment (acute, Category 2 or 3)

Always consult the Safety Data Sheet (SDS) to confirm classification.

Packaging Requirements

- Use UN-certified packaging appropriate for the hazard class and quantity.

- Ensure containers are leak-proof, tightly sealed, and resistant to chemical corrosion.

- Dual packaging (inner and outer containers) is recommended for added safety.

- Label packages with:

- Proper shipping name (e.g., “Corrosive liquid, organic, n.o.s.”)

- UN number

- Hazard class label (e.g., Class 8 corrosive)

- GHS pictograms and hazard statements

- Handling instructions (e.g., “Keep upright,” “Protect from heat”)

Transport Regulations

Road (ADR – Europe)

- Comply with ADR regulations for dangerous goods.

- Transport in approved vehicles with appropriate placards.

- Drivers must hold valid ADR training certificates.

- Required documentation: Transport document, SDS, and emergency instructions.

Air (IATA DGR)

- Subject to IATA Dangerous Goods Regulations.

- Quantity limits per package and per aircraft apply.

- Packages must pass vibration, drop, and leakage tests.

- Shipper must provide a completed Shipper’s Declaration for Dangerous Goods.

Sea (IMDG Code)

- Follow the International Maritime Dangerous Goods (IMDG) Code.

- Use marine pollutant markings if applicable.

- Ensure proper stowage and segregation from incompatible materials (e.g., oxidizers).

Storage Guidelines

- Store in a cool, dry, well-ventilated area away from direct sunlight and heat sources.

- Ideal temperature range: 15°C to 25°C (59°F to 77°F).

- Keep away from incompatible substances such as strong acids, oxidizers, and bases.

- Use secondary containment to prevent environmental contamination in case of leaks.

- Limit storage duration according to manufacturer’s shelf life (typically 12–24 months).

Labeling & Documentation

- Product Label: Must include:

- Product identifier

- Supplier information

- GHS pictograms

- Signal word (e.g., “Danger”)

- Hazard and precautionary statements

- First aid measures

- Safety Data Sheet (SDS): Must be provided in the local language(s) of destination countries and updated per GHS standards (e.g., REACH in EU, OSHA HazCom in US).

- Customs Documentation: Include accurate HS codes (e.g., 3506.91 for adhesives based on epoxies), commercial invoice, packing list, and certificates of origin if applicable.

Regulatory Compliance by Region

European Union (EU)

- Comply with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals).

- Ensure substances are registered with ECHA.

- Label per CLP Regulation (EC) No 1272/2008.

- May require SDS in all official EU languages upon request.

United States

- Comply with OSHA Hazard Communication Standard (29 CFR 1910.1200).

- Report to EPA under TSCA if new chemical substances are involved.

- Follow state regulations (e.g., California Prop 65 if containing listed chemicals).

Other Regions

- Canada: WHMIS 2015 compliance required; French/English labeling.

- China: GHS implementation under GB standards; registration via MEA may be required.

- Australia: Comply with HSIS and GHS under WHS Regulations; AICS inventory listing.

Environmental & Disposal Considerations

- Do not dispose of down drains or in regular trash.

- Follow local regulations for hazardous waste disposal.

- Empty containers should be rinsed and recycled or disposed of as hazardous waste.

- Report spills immediately; use absorbent materials and PPE during cleanup.

Training & Emergency Preparedness

- Train personnel in:

- Handling and storage procedures

- Use of PPE (gloves, goggles, respirators if needed)

- Emergency response (spill control, first aid)

- Maintain spill kits and eyewash stations in storage and handling areas.

- Ensure emergency contact information is accessible (e.g., poison control, fire department).

Conclusion

Proper logistics and compliance management for epoxy glue for ceramic ensures safety, regulatory adherence, and smooth international trade. Always verify classification through the SDS, follow regional regulations, and maintain accurate documentation throughout the supply chain. Regular audits and staff training are essential for ongoing compliance.

In conclusion, sourcing epoxy glue for ceramic applications requires careful consideration of factors such as bond strength, durability, resistance to temperature and moisture, ease of application, and curing time. Epoxy adhesives are highly effective for ceramics due to their strong, long-lasting bonds and ability to fill gaps, making them ideal for both structural repairs and decorative projects. When selecting an epoxy, prioritize formulations specifically designed for ceramics or multi-surface use, and ensure compatibility with the ceramic type (e.g., glazed, porous, or high-fired). Additionally, consider user-friendly options like two-part syringes or pre-mixed varieties for convenience. Sourcing from reputable suppliers or brands known for quality and consistency will ensure reliable performance and optimal results. By evaluating these factors, you can identify the best epoxy glue to achieve a durable, seamless, and aesthetically pleasing bond for your ceramic repair or assembly needs.