The global epoxy resin market, a key enabler for high-performance epoxy countertop solutions, is projected to grow at a CAGR of 6.1% from 2023 to 2028, according to Mordor Intelligence. This growth is driven by rising demand for durable, aesthetically versatile surfacing materials in residential and commercial kitchens. As homeowners increasingly prioritize seamless finishes, chemical resistance, and custom design capabilities, epoxy countertops have emerged as a preferred alternative to traditional materials like granite and quartz. Fueled by advancements in formulation technology and expanding DIY accessibility, the kitchen epoxy market segment is gaining traction among both professional fabricators and design-savvy consumers. In this evolving landscape, a select group of manufacturers are leading innovation in UV stability, low-VOC emissions, and rapid-cure systems—setting new benchmarks for performance and sustainability. Based on market presence, product breadth, technical specifications, and customer reviews, here are the top 9 epoxy countertop kitchen manufacturers shaping the industry today.

Top 9 Epoxy Countertop Kitchen Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Durcon Worksurfaces for Laboratories and Industrial Use

Domain Est. 1998

Website: durcon.com

Key Highlights: Durcon Epoxy products are a complete system of durable, high-performance, heat- and chemical-resistant worksurfaces, sinks, and accessories….

#2 NEOLITH – Kitchens

Domain Est. 2010

Website: neolith.com

Key Highlights: Neolith is a world leader in the design and manufacture of sintered stone surfaces … Kitchen countertops · Kitchen sinks · Kitchen claddings · Bathrooms….

#3 Countertop Epoxy

Domain Est. 2012

Website: countertopepoxy.com

Key Highlights: $27 delivery 30-day returnsPremium 100%-solids, zero-VOC epoxy kits for countertops, floors, showers, walls, and tubs —plus pigments and how-to videos. Installer-grade results at h…

#4 UltraClear Epoxy

Domain Est. 2012

Website: bestbartopepoxy.com

Key Highlights: Free deliveryPremium bar and table top epoxy. Scratch resistant. Heat resistant. Food Safe. Zero VOC. Made in USA. Receive FREE same-day shipping. Order today!…

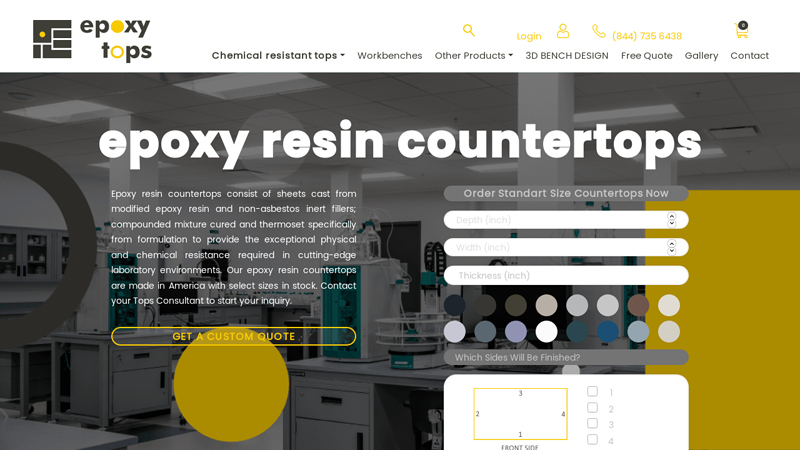

#5 Epoxy Resin Countertops

Domain Est. 2015

Website: epoxytops.com

Key Highlights: Our epoxy and phenolic resin countertops provide heavy-duty chemical resistance for any wet lab environment at a low price. Call today!…

#6 Bar & Table Top Epoxy Resin

Domain Est. 2017

Website: primaloc.com

Key Highlights: In stock Free delivery over $50Primaloc Epoxy specializes in crystal-clear epoxy solutions for bar tops, table tops, and countertops. Made 100% in the USA, our epoxy is designed to…

#7 Metallic Epoxy Countertop

Domain Est. 2019

Website: metallicepoxy.sg

Key Highlights: Metallic Epoxy surfaces are highly heat resistant and withstand temperatures up to 200°C. This property allows for safe and durable use in your kitchens….

#8

Domain Est. 2020

Website: epoxyresindesigns.com

Key Highlights: We are specialists in creating stunning designs on your existing countertops in durable epoxy resin. We can mimic marble, granite and many other custom ……

#9 Epoxy Countertops & Tabletops by Counter Intelligence

Domain Est. 2021

Website: counteri.com

Key Highlights: Discover Counter Intelligence for custom epoxy countertops and tabletops. Contact a Counteri dealer near you today to get started….

Expert Sourcing Insights for Epoxy Countertop Kitchen

2026 Market Trends for Epoxy Countertop Kitchens

Rising Demand for Customization and Unique Aesthetics

In 2026, consumers are increasingly prioritizing personalized, one-of-a-kind kitchen designs. Epoxy countertops meet this demand by offering unparalleled customization. Homeowners can select from a vast array of colors, embed decorative elements like metallic flakes, stones, or even recycled materials, and create seamless, waterfall-edge designs. The growing popularity of social media platforms like Pinterest and Instagram continues to fuel interest in visually striking, Instagram-worthy kitchens—making epoxy a preferred choice for those seeking standout aesthetics over conventional materials.

Increased Focus on Durable, Low-Maintenance Surfaces

As lifestyles become busier, durability and ease of maintenance are key decision factors in kitchen renovations. Epoxy countertops offer high resistance to scratches, stains, heat, and moisture when properly installed and sealed. By 2026, advancements in epoxy formulations have led to improved UV stability and reduced yellowing, enhancing long-term performance. These attributes position epoxy as a practical alternative to natural stone or laminate, especially in high-traffic households and modern urban kitchens.

Growth in DIY and Prosumer Markets

The availability of high-quality, user-friendly epoxy kits has democratized access to professional-looking finishes. In 2026, the DIY segment continues to expand, supported by online tutorials, YouTube channels, and e-commerce platforms offering comprehensive epoxy systems. While professional installations remain prevalent for complex designs, the prosumer market—consumers with intermediate skill levels undertaking semi-professional projects—is gaining traction, driving overall market growth.

Sustainability and Eco-Conscious Innovations

Environmental concerns are shaping material choices in home design. In response, epoxy manufacturers are developing more sustainable formulations, including bio-based resins and low-VOC (volatile organic compound) options. By 2026, eco-certified epoxy products are becoming standard offerings, appealing to environmentally conscious homeowners. Additionally, the ability to refinish existing countertops with epoxy—rather than replacing them—supports circular economy principles by reducing construction waste.

Integration with Smart Kitchen Trends

Smart kitchens are on the rise, and epoxy countertops are evolving to complement this trend. Some innovators are experimenting with embedding LED lighting or conductive elements beneath epoxy surfaces for interactive features. While still niche, these integrations signal a move toward multifunctional surfaces. In 2026, the seamless, non-porous nature of epoxy makes it an ideal base for future smart kitchen technologies, such as wireless charging zones or touch-sensitive controls.

Competitive Pricing and Market Expansion

Compared to premium materials like quartz or marble, epoxy remains a cost-effective option—particularly for large or custom installations. As skilled applicators become more widespread and supply chains stabilize, installation costs are expected to become more competitive by 2026. This affordability, combined with aesthetic flexibility, is expanding epoxy’s appeal beyond niche or industrial-style homes into mainstream suburban and mid-range renovations.

Challenges in Perception and Quality Control

Despite its benefits, the epoxy countertop market faces challenges related to inconsistent DIY results and lingering perceptions of fragility or yellowing. In 2026, industry leaders are addressing these concerns through certification programs for installers, clearer product labeling, and extended warranties. Consumer education remains critical to distinguishing high-performance epoxy from inferior products, ensuring long-term market credibility.

In summary, the 2026 market for epoxy kitchen countertops is characterized by innovation, personalization, and growing consumer trust. Driven by aesthetic appeal, durability, and evolving sustainability standards, epoxy is solidifying its position as a versatile and forward-looking choice in modern kitchen design.

Common Pitfalls When Sourcing Epoxy Countertop Kits for Kitchen Use (Quality and Intellectual Property)

Sourcing epoxy countertop kits for kitchen applications involves navigating a range of quality concerns and potential intellectual property (IP) issues. Avoiding these pitfalls is crucial for both DIYers and professionals aiming for durable, safe, and legally compliant results.

1. Compromised Material Quality

One of the most common issues is purchasing low-grade epoxy resin. Inferior formulations may contain excessive fillers, inconsistent curing agents, or non-food-safe additives. These can lead to poor adhesion, yellowing, cracking, or off-gassing harmful volatile organic compounds (VOCs), especially under heat or UV exposure common in kitchens.

2. Misleading Food-Safety Claims

Many epoxy products are marketed as “food-safe” without proper certification. True food-safe epoxy must comply with FDA 21 CFR 175.300 or equivalent standards. Failing to verify these certifications can result in using a product unsuitable for kitchen countertops, posing health risks.

3. Inadequate Heat and Scratch Resistance

Not all epoxy formulations are engineered to withstand kitchen conditions. Some kits fail under routine exposure to hot cookware or sharp utensils, leading to premature damage. Always check technical data sheets for heat deflection temperature and Shore D hardness ratings.

4. Poor UV Stability Leading to Yellowing

Epoxy exposed to sunlight or strong indoor lighting may yellow over time if it lacks adequate UV stabilizers. This is especially problematic in kitchens with natural light. Low-cost kits often omit these stabilizers to cut costs.

5. Inconsistent Mixing Ratios and Curing Issues

Low-quality kits may have imprecise mixing ratios or inconsistent viscosity, leading to incomplete curing, sticky surfaces, or bubbling. Reliable brands provide accurate volume or weight measurements and detailed instructions.

6. Intellectual Property Infringement in Design Kits

Some epoxy countertop kits include molds, patterns, or decorative elements that may infringe on copyrighted or patented designs. Sourcing from vendors that use stolen or unlicensed artwork can expose users to legal liability, especially for commercial projects.

7. Counterfeit or Rebranded Products

Many kits are rebranded versions of generic resins, sometimes misrepresented as premium or proprietary formulas. These may lack traceability, batch consistency, or technical support. Always verify the manufacturer and check for genuine reviews and certifications.

8. Lack of Technical Support and Warranty

Reputable suppliers offer customer support, troubleshooting guides, and product warranties. Sourcing from obscure or offshore suppliers often means limited or no support, increasing the risk of a failed installation.

9. Environmental and Regulatory Non-Compliance

Some epoxy products do not meet regional environmental regulations (e.g., VOC limits in California or REACH in the EU). Using non-compliant products can lead to legal issues or failed inspections, particularly in commercial kitchens.

10. Overlooking Proper Curing Time and Conditions

Many users rush the curing process due to misleading claims of “fast-cure” kits. Incomplete curing compromises durability and safety. Always follow manufacturer guidelines for temperature, humidity, and cure duration.

By being aware of these pitfalls—especially around material quality, safety certifications, and IP integrity—buyers can make informed decisions and achieve professional, long-lasting epoxy kitchen countertops.

Logistics & Compliance Guide for Epoxy Countertop Kitchen Projects

Product Sourcing and Material Handling

When sourcing epoxy resins and related materials for kitchen countertop applications, ensure suppliers provide detailed technical data sheets (TDS) and safety data sheets (SDS). Select food-safe, NSF-certified epoxy formulations that comply with FDA 21 CFR §175.300 for indirect food contact. Verify that all materials are stored in temperature-controlled environments (typically 65–80°F or 18–27°C) and kept sealed to prevent moisture contamination, which can affect curing.

Transportation and Storage Requirements

Transport epoxy components in approved, leak-proof containers, clearly labeled with hazard communication (GHS) pictograms. Avoid exposure to direct sunlight and extreme temperatures during transit. Upon receipt, store resins and hardeners upright in a dry, well-ventilated area away from ignition sources. Keep out of reach of children and pets. Segregate flammable liquids according to local fire codes (e.g., NFPA 30).

Workplace Safety and PPE Compliance

Adhere to OSHA regulations by ensuring all applicators wear appropriate personal protective equipment (PPE), including nitrile gloves, chemical-resistant aprons, safety goggles, and NIOSH-approved respirators with organic vapor cartridges. Maintain adequate ventilation using exhaust fans or air filtration systems to keep vapor concentrations below permissible exposure limits (PELs). Provide spill response kits and ensure staff are trained in handling chemical emergencies.

Environmental Regulations and Waste Disposal

Comply with EPA and local environmental regulations when disposing of uncured epoxy waste, mixing containers, and cleaning solvents. Uncured resin and hardener are typically classified as hazardous waste and must be disposed of through licensed hazardous waste handlers. Never pour leftover epoxy down drains or into soil. Follow RCRA guidelines for waste classification, labeling, and manifesting.

Installation and Curing Standards

Follow manufacturer-recommended mixing ratios and pot life guidelines precisely to ensure full polymerization and structural integrity. Maintain a controlled ambient temperature and humidity level during application and curing (usually 70–75°F and 40–60% RH). Allow sufficient cure time—typically 5–7 days—before subjecting countertops to heat or food contact. Document curing conditions and timelines for quality assurance.

Food Safety and Regulatory Certification

Only use epoxy systems explicitly certified for food-contact surfaces. Verify compliance with FDA 21 CFR §175.300 and, if applicable, NSF/ANSI Standard 51 for food equipment materials. Clearly label finished countertops with compliance information and provide end-users with care instructions to maintain food-safe integrity.

Documentation and Recordkeeping

Maintain detailed records of material purchases, SDS/TDS, batch numbers, application logs, and safety training certifications. These documents support regulatory compliance during inspections and are essential for warranty validation and liability protection. Store records for a minimum of five years or as required by local jurisdiction.

In conclusion, sourcing an epoxy countertop for your kitchen offers a unique combination of durability, aesthetic versatility, and long-term value when done correctly. By carefully selecting high-quality materials, choosing a reputable supplier or installer, and ensuring proper surface preparation and application, you can achieve a stunning, seamless finish that enhances both the functionality and visual appeal of your kitchen. While the initial investment may be higher than some alternatives, the resilience to heat, scratches, and stains—along with the ability to customize colors, patterns, and finishes—makes epoxy a compelling choice for modern kitchen designs. Ultimately, thoughtful sourcing and professional execution will ensure your epoxy countertop remains a durable and beautiful centerpiece for years to come.