The global engine shaft coupling market is experiencing robust growth, driven by increasing demand from industries such as power generation, oil & gas, marine, and heavy manufacturing. According to a report by Mordor Intelligence, the global shaft coupling market was valued at USD 6.2 billion in 2023 and is projected to grow at a CAGR of over 6.8% during the forecast period 2024–2029. This expansion is fueled by rising industrial automation, the need for high-efficiency power transmission systems, and ongoing infrastructure development across emerging economies. Additionally, Grand View Research highlights a growing shift toward precision-engineered and maintenance-free couplings, particularly in applications requiring reliability under high torque and variable speeds. As industries prioritize energy efficiency and operational uptime, the demand for advanced engine shaft couplings continues to rise—setting the stage for innovation and competition among leading manufacturers worldwide.

Top 10 Engine Shaft Coupling Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

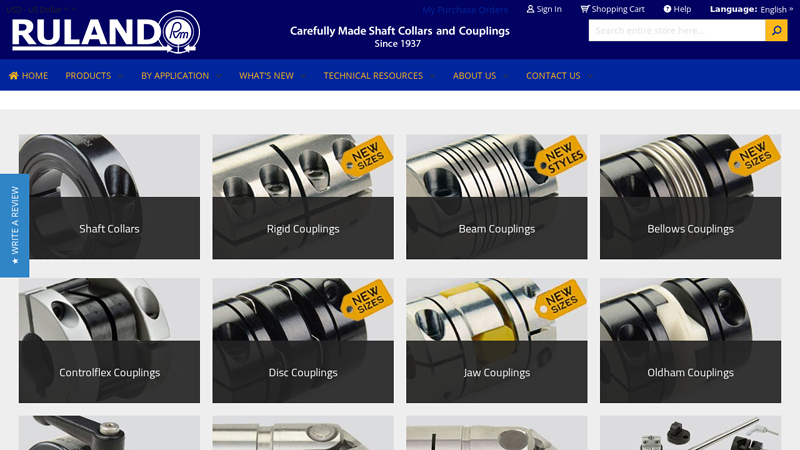

#1 Shaft Collar, Rigid Coupling & Flexible Shaft Coupling Manufacturer …

Domain Est. 1996 | Founded: 1937

Website: ruland.com

Key Highlights: Established in 1937, Ruland focuses on the design and manufacturing of high performing shaft collars and couplings. All products are carefully manufactured….

#2 Ameridrives Gear Couplings, Disc Couplings & Mill Spindles

Domain Est. 1997

Website: ameridrives.com

Key Highlights: Ameridrives is a pioneering global leader in the design and manufacture of highly-engineered industrial couplings and universal joints….

#3 Coupling Corporation of America

Domain Est. 1996

Website: couplingcorp.com

Key Highlights: Coupling Corporation boasts over 40 years of experience building longlasting, reliable, high performance couplings and shaft hubs….

#4

Domain Est. 1996 | Founded: 1956

Website: magnaloy.com

Key Highlights: Magnaloy Coupling Company has been manufacturing precision machined products since 1956, including the original light weight, heavy-duty flexible drive ……

#5 Couplings

Domain Est. 1997

Website: flender.com

Key Highlights: Our compact steel couplings provide highly precise transmission of high torques especially under harsh operating conditions and at extreme temperatures….

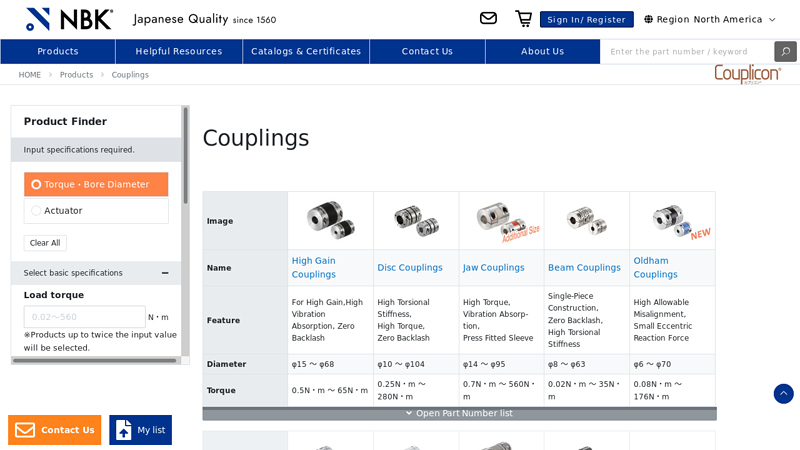

#6 Couplings

Domain Est. 2000

Website: nbk1560.com

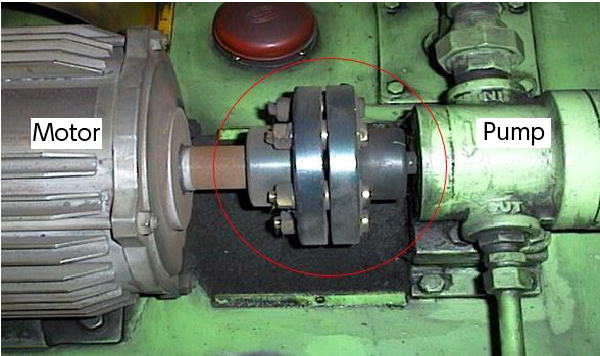

Key Highlights: Coupling is a component used to connect a drive shaft and a driven part, for example, a motor shaft and a ball screw for the purpose of transmitting the torque….

#7 start page

Domain Est. 2000

Website: rw-couplings.com

Key Highlights: Couplings from R+W work dynamically, precisely and backlash-free. They reduce friction to a minimum, are low-wear and maintenance-free….

#8 reich

Domain Est. 2007 | Founded: 1946

Website: reich-kupplungen.com

Key Highlights: REICH produces torsionally flexible couplings and power transmission and operates a global sales network. Competence in power transmission since 1946….

#9 CENTA Flexible Couplings and Drive Shafts

Domain Est. 2013

Website: centa24.pl

Key Highlights: We are a leading distributor and representative of CENTA flexible couplings and drive shafts which are applyied to industry, marine, rail and energy ……

#10 Kop

Domain Est. 2021

Website: regalrexnord.com

Key Highlights: Kop-Flex offers the broadest range of coupling products available on the market today – from high performance, high-speed disc, diaphragm and gear couplings….

Expert Sourcing Insights for Engine Shaft Coupling

H2: 2026 Market Trends for Engine Shaft Coupling

The global engine shaft coupling market is projected to experience significant transformation by 2026, driven by technological innovation, increasing industrial automation, and the growing demand for energy-efficient machinery across key sectors such as automotive, aerospace, marine, and power generation. Several macro and microeconomic factors are shaping the trajectory of this market, positioning it for steady growth and strategic evolution.

-

Rise in Industrial Automation and Smart Manufacturing

As industries adopt Industry 4.0 principles, the demand for precision-engineered, high-performance couplings is increasing. Engine shaft couplings are being integrated with sensors and condition-monitoring systems to enable predictive maintenance and real-time performance tracking. This shift toward smart couplings is expected to accelerate through 2026, particularly in automated production lines and robotics. -

Growth in Renewable Energy and Electric Mobility

The expansion of wind energy and the surge in electric vehicle (EV) production are creating new applications for advanced shaft couplings. In wind turbines, flexible and torsionally resilient couplings are critical for managing variable loads and minimizing drivetrain stress. Similarly, EV manufacturers are demanding lightweight, high-torque couplings capable of handling rapid acceleration and regenerative braking systems. These applications are expected to be major growth drivers by 2026. -

Material Innovation and Lightweighting

Manufacturers are increasingly adopting composite materials, high-grade alloys, and engineered polymers to reduce coupling weight while enhancing durability and misalignment compensation. This trend supports efficiency improvements in aerospace and automotive applications, where weight reduction directly impacts fuel economy and emissions—key regulatory concerns through 2026. -

Expansion in Emerging Markets

Rapid industrialization in Asia-Pacific (particularly China, India, and Southeast Asia), coupled with infrastructure development in Latin America and Africa, is fueling demand for industrial machinery and transportation systems. Local manufacturing hubs are creating opportunities for domestic coupling producers, supported by government initiatives to boost manufacturing capabilities. -

Focus on Energy Efficiency and Sustainability

Regulatory standards such as ISO 50001 and growing corporate sustainability mandates are pushing industries to adopt energy-efficient components. High-efficiency shaft couplings that minimize power loss and vibration contribute to improved system performance and reduced lifecycle costs—an attractive value proposition expected to gain momentum by 2026. -

Consolidation and Strategic Partnerships

The market is witnessing increased consolidation, with key players acquiring niche technology providers or forming joint ventures to expand product portfolios and geographic reach. Companies are also partnering with OEMs to co-develop application-specific coupling solutions, enhancing customization and integration capabilities. -

Impact of Supply Chain Resilience and Digitalization

Post-pandemic supply chain challenges have prompted manufacturers to localize production and adopt digital supply chain tools. By 2026, coupling producers are expected to leverage AI-driven forecasting, blockchain for traceability, and additive manufacturing for rapid prototyping and on-demand production.

In conclusion, the 2026 engine shaft coupling market will be defined by innovation, sustainability, and digital integration. With growing demand from high-growth sectors and regions, manufacturers that prioritize R&D, agility, and customer-specific solutions will be best positioned to capitalize on emerging opportunities.

Common Pitfalls Sourcing Engine Shaft Couplings (Quality, IP)

Sourcing Engine Shaft Couplings involves critical considerations around quality and intellectual property (IP). Overlooking these aspects can lead to operational failures, legal risks, and financial losses. Below are common pitfalls to avoid:

Poor Quality Materials and Manufacturing

One of the most frequent issues is selecting couplings made from substandard materials or with inadequate manufacturing processes. Low-quality couplings may use inferior alloys, improper heat treatment, or inconsistent machining tolerances, leading to premature wear, misalignment, vibration, or catastrophic failure under load. Always verify material certifications (e.g., ASTM, ISO) and insist on documented quality control processes such as ISO 9001 compliance.

Inadequate Performance Specifications

Sourcing couplings without matching exact torque, speed, misalignment tolerance, and environmental requirements can result in poor performance. Many suppliers provide generic data sheets that don’t reflect real-world conditions. Ensure the coupling is rated for the specific engine’s operational parameters, including temperature extremes, vibration levels, and duty cycles.

Lack of Reverse Engineering or IP Infringement

A significant IP risk arises when sourcing replacement couplings, especially for proprietary or OEM-designed systems. Some suppliers may offer “compatible” couplings that closely mimic patented designs, potentially violating intellectual property rights. Purchasing such products—even unknowingly—can expose the buyer to legal liability, product seizures, or reputational damage.

Insufficient Documentation and Traceability

High-quality sourcing requires full traceability, including material test reports (MTRs), production lot numbers, and inspection records. Without these, verifying quality or conducting root cause analysis during failure becomes nearly impossible. Avoid suppliers who cannot provide comprehensive documentation.

Overreliance on Price Over Value

Opting for the lowest-cost option often compromises durability and reliability. Cheap couplings may save money upfront but lead to increased downtime, maintenance costs, and safety hazards. Evaluate total cost of ownership, including lifespan and failure risk, rather than initial purchase price.

Unverified Supplier Credentials

Working with uncertified or unqualified suppliers increases the risk of receiving counterfeit or non-compliant products. Always vet suppliers for relevant industry certifications, audit history, and customer references—especially when sourcing safety-critical components.

Ignoring Compliance and Standards

Ensure couplings meet applicable industry standards (e.g., API,AGMA, DIN) and any regional regulatory requirements. Non-compliant products may fail inspections or void equipment warranties, leading to costly rework or project delays.

By addressing these pitfalls proactively, organizations can ensure the reliable, legal, and efficient sourcing of Engine Shaft Couplings.

Logistics & Compliance Guide for Engine Shaft Coupling

Overview

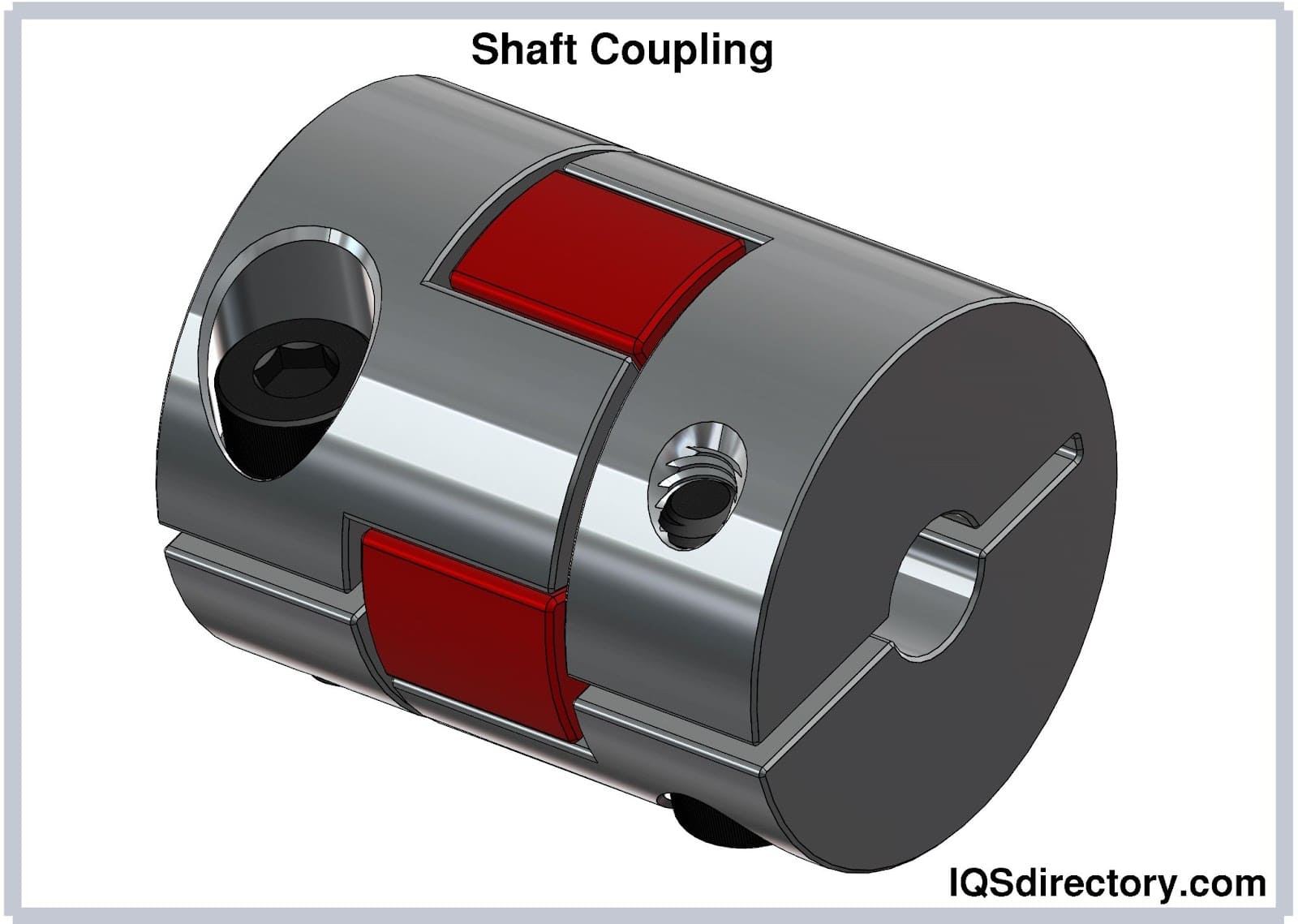

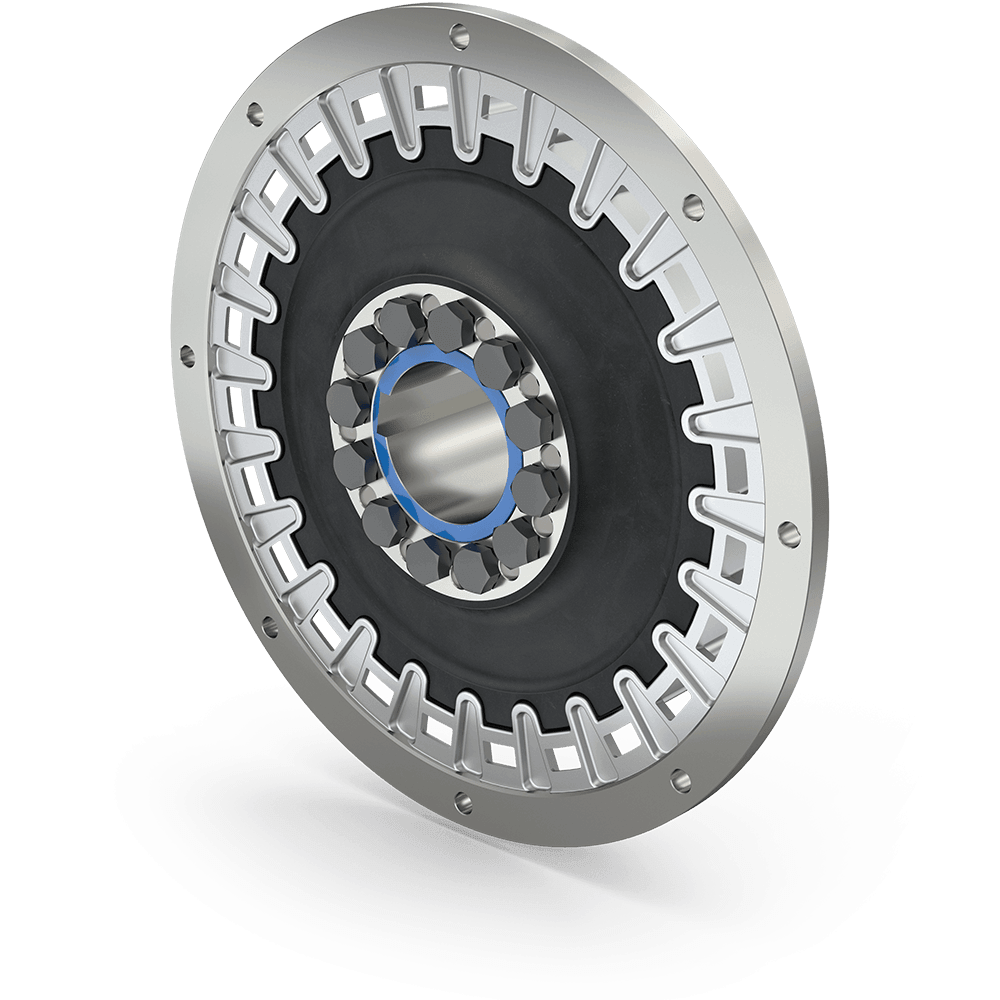

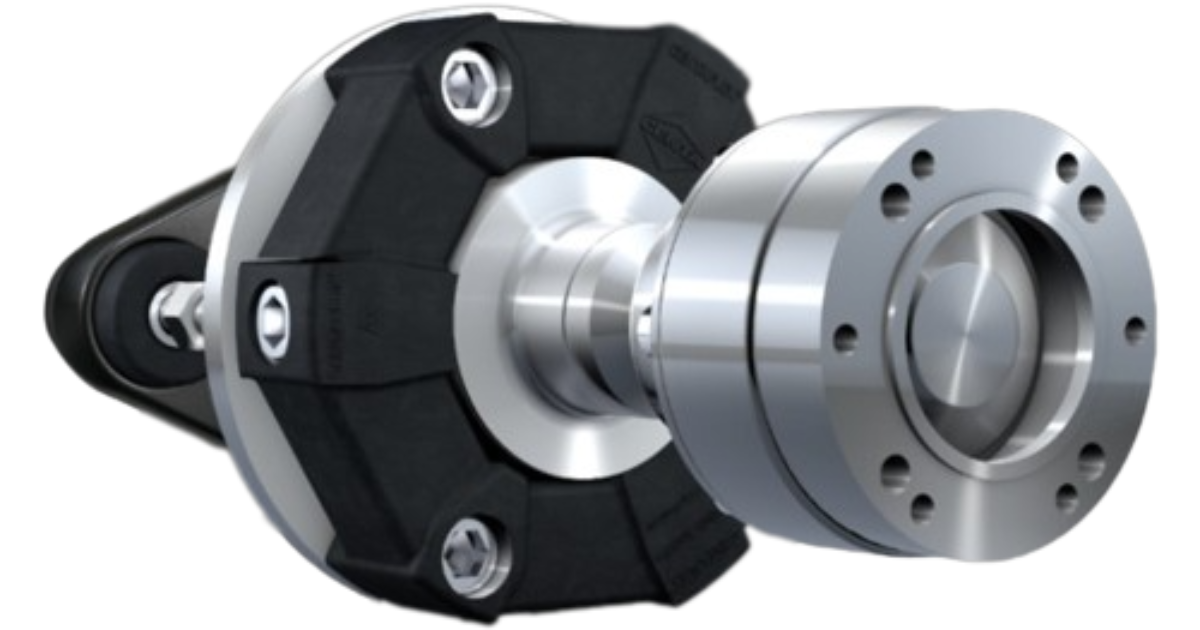

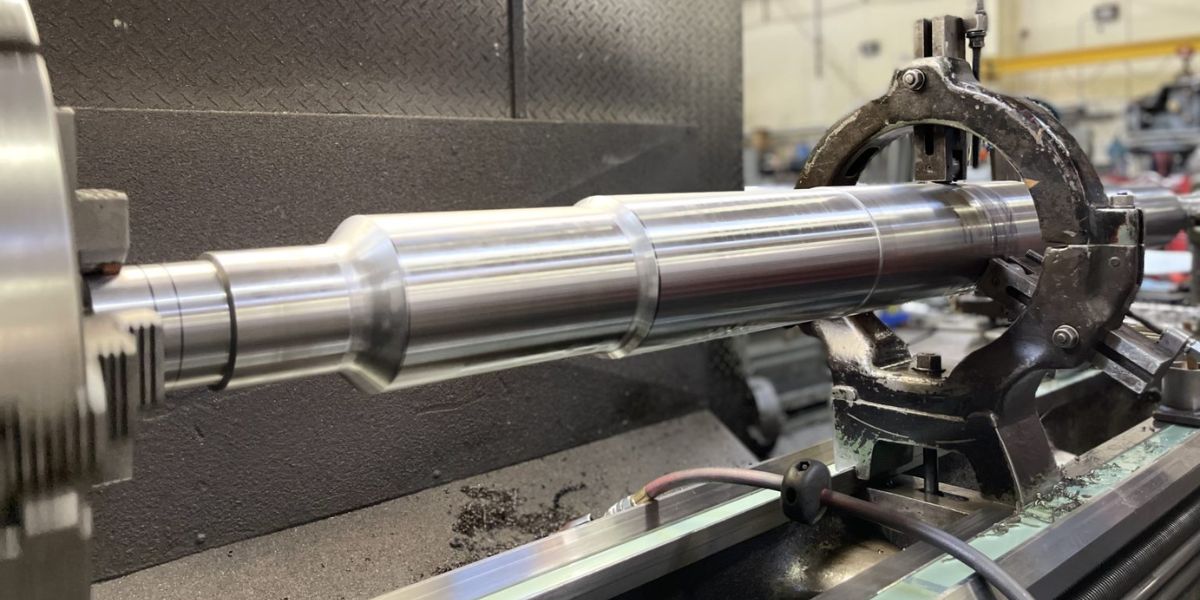

Engine shaft couplings are critical mechanical components used to connect two shafts together at their ends to transmit power. Due to their industrial nature and international usage, proper logistics planning and compliance with regulatory standards are essential for safe, efficient, and legal transportation and operation.

Packaging & Handling

- Use robust, moisture-resistant packaging (e.g., wooden crates or heavy-duty corrugated boxes) to protect against impact, vibration, and environmental exposure.

- Apply anti-corrosion coatings or VCI (Vapor Corrosion Inhibitor) paper to prevent rust during transit.

- Clearly label packages with handling instructions: “Fragile,” “Do Not Stack,” “Keep Dry,” and orientation arrows.

- Secure couplings with foam inserts or custom molds to avoid internal movement during shipping.

Storage Conditions

- Store in a dry, temperature-controlled environment (ideally 10°C to 30°C).

- Avoid exposure to direct sunlight, humidity, and corrosive chemicals.

- Keep couplings on pallets off the floor and cover with dust-proof tarpaulins if stored long-term.

- Follow FIFO (First In, First Out) inventory practices to minimize aging-related degradation.

Transportation Requirements

- Use ISO-standard containers for sea freight or palletized loads for air/road transport.

- Ensure secure lashing and bracing to prevent shifting during transit.

- For oversized or heavy couplings, coordinate with freight forwarders for special handling and permits.

- Maintain documentation such as packing lists, shipping manifests, and delivery notes.

International Shipping & Documentation

- Prepare commercial invoice, bill of lading/airway bill, and packing list with accurate Harmonized System (HS) code (typically 8483.60 for mechanical couplings).

- Include product specifications: material (e.g., steel, aluminum), weight, dimensions, and declared value.

- Comply with import/export regulations of origin and destination countries.

- Obtain necessary export licenses if shipping to embargoed or restricted regions.

Regulatory Compliance

- Adhere to REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) if applicable (e.g., lubricants or coatings used).

- Comply with RoHS (Restriction of Hazardous Substances) directives for electrical or electronic components in smart couplings.

- Meet ISO 14691 or ANSI B11.0 standards for mechanical safety and performance where required.

- Provide CE marking (for EU) or equivalent certification (e.g., UKCA, CCC) based on destination market.

Customs Clearance

- Provide a Certificate of Conformity (CoC) if required by the importing country.

- Declare accurate country of origin to qualify for trade agreements (e.g., USMCA, ASEAN).

- Be prepared for customs inspections, especially for high-value or industrial machinery parts.

- Use bonded warehouses or temporary admission procedures for consignment or repair shipments.

Environmental & Safety Compliance

- Classify shipments correctly under ADR (road), IMDG (sea), or IATA (air) if hazardous materials (e.g., lubricants) are included.

- Dispose of packaging materials in accordance with local environmental regulations.

- Ensure workplace safety during handling using proper lifting equipment and PPE.

Recordkeeping & Traceability

- Maintain batch/lot numbers and serial numbers (if applicable) for traceability.

- Keep copies of all shipping, compliance, and inspection documents for a minimum of 5 years.

- Implement a quality management system (e.g., ISO 9001) for consistent compliance tracking.

Summary

Proper logistics and compliance for engine shaft couplings ensure product integrity, regulatory adherence, and smooth cross-border operations. Partner with certified freight providers and stay updated on international trade regulations to minimize delays and avoid non-compliance penalties.

Conclusion for Sourcing Engine Shaft Coupling:

In conclusion, the successful sourcing of an engine shaft coupling requires a comprehensive evaluation of technical specifications, operational requirements, material compatibility, and supplier reliability. Selecting the appropriate coupling type—whether rigid, flexible, elastomeric, or metallic—is critical to ensuring efficient power transmission, misalignment accommodation, vibration damping, and overall system longevity. Factors such as torque capacity, shaft sizes, operating environment, maintenance needs, and cost-effectiveness must be carefully balanced to achieve optimal performance and reliability.

Sourcing from qualified, experienced suppliers with a proven track record in delivering high-quality, standardized (e.g., ISO, ANSI, DIN compliant) couplings ensures both safety and durability in demanding applications. Additionally, considering lifecycle costs rather than initial purchase price can lead to significant long-term savings through reduced downtime and maintenance.

Ultimately, a well-sourced engine shaft coupling not only enhances mechanical efficiency but also contributes to the overall reliability and operational success of the power transmission system. Effective collaboration between engineering, procurement, and maintenance teams is essential to make informed sourcing decisions that align with technical and strategic objectives.