The global dirt bike market has seen steady expansion over the past decade, driven by rising consumer interest in off-road recreation and advancements in engine technology. According to a 2023 report by Mordor Intelligence, the global off-road motorcycle market was valued at USD 8.6 billion and is projected to grow at a CAGR of 5.8% from 2023 to 2028. This growth is fueled by increasing disposable incomes, expanding youth participation in motocross sports, and ongoing innovation in lightweight, high-performance engines. As manufacturers compete to capture market share, engine design has become a critical differentiator—impacting power output, fuel efficiency, and overall rider experience. In this landscape, nine engine platforms stand out for their technical excellence, reliability, and widespread adoption across leading dirt bike brands. These engines, developed by both established OEMs and specialized suppliers, power some of the most popular models in motocross, enduro, and trail segments today.

Top 9 Engine For Dirt Bike Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Boyesen Factory Racing Dirt Bike Parts

Domain Est. 1995

Website: boyesen.com

Key Highlights: Work with Boyesen directly for any special application air-intake, carburetion, or special engine component solution for your Street Bike, Moped, Scooter ……

#2 KTM – READY TO RACE

Domain Est. 1997

Website: ktm.com

Key Highlights: Powered by a distinct READY TO RACE mentality, KTM is Europe’s leading high-performance street and offroad sport motorcycle manufacturer….

#3 BBR Motorsports, Inc

Domain Est. 1998

Website: bbrmotorsports.com

Key Highlights: BBR Motorsports is the industry’s premier adult four-stroke playbike performance technology company. Engineering from the minds of racers, coupled with the ……

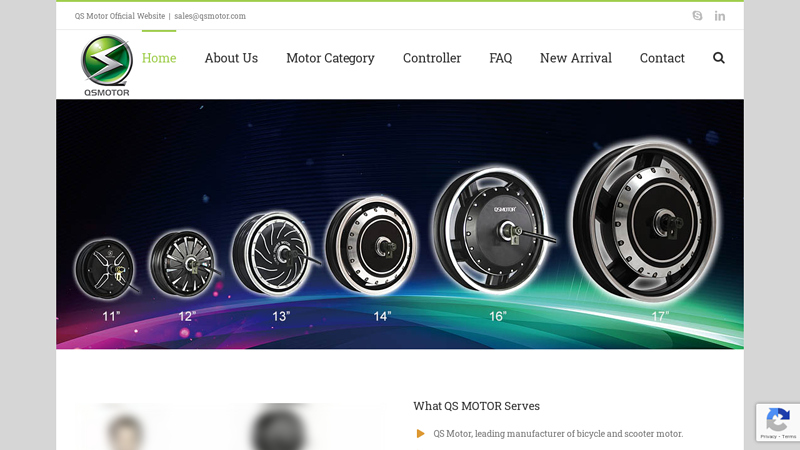

#4 QS Motor Ltd manufacture Bicycle Motor, Scooter Motor, Car Motor

Domain Est. 2014

Website: qsmotor.com

Key Highlights: QS Motor is the leading manufacturer of quality Bicycle Motor, Scooter Motor, Car Motor, Hub Motor in China. 500W to 24kw in power and 10″ to 17″ in size….

#5 Polini Motori

Domain Est. 1998

Website: polini.com

Key Highlights: Visit the official Polini Motori website: we are specialized in the design and production of engines, accessories, special parts and tuning kits for ……

#6 WMR Competition Performance

Domain Est. 2001

Website: wmr1.com

Key Highlights: WMR Competition Performance is your #1 KTM, Husqvarna Motorcycles, Gas Gas, Stark Future and WP Suspension Race Shop in the South East United States….

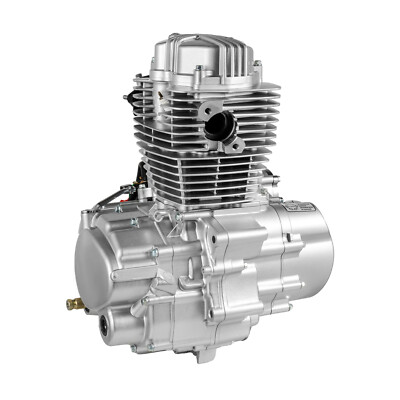

#7 COMPLETE ENGINE “ANIMA”

Domain Est. 2008

Website: daytona-global.com

Key Highlights: COMPLETE ENGINE “ANIMA” ; ANIMA190GP5

5speed Close-Ratio Transmission/without Lighting system. #81281: ANIMA190GP5 5speed Close-Ratio Transmission/without ……

#8 FRP

Domain Est. 2024

Website: frpmoto.com

Key Highlights: Offering various power sports, including mini bikes, mini quad, kids dirt bikes, kids pocket bikes, and etc, for riders to experience the joy of off-road ……

#9 best in

Domain Est. 2005

Website: bmsmotor.com

Key Highlights: BMS Motorsports Inc. is a Leader on the industry of high quality Off-road vehicles and Scooters at competitive pricing….

Expert Sourcing Insights for Engine For Dirt Bike

2026 Market Trends for Engines for Dirt Bikes

The global market for dirt bike engines is poised for significant transformation by 2026, driven by technological innovation, environmental regulations, shifting consumer preferences, and advancements in materials and manufacturing. This analysis explores key trends shaping the future of engines used in off-road motorcycles, focusing on both internal combustion engines (ICE) and the growing influence of electric powertrains.

Growing Demand for High-Performance and Lightweight Engines

Manufacturers are increasingly prioritizing lightweight, high-output engines to meet the demands of competitive riders and recreational enthusiasts. By 2026, the use of advanced materials such as forged aluminum, magnesium alloys, and composite components will become more widespread, reducing engine weight without sacrificing durability. This trend supports improved power-to-weight ratios, enhancing agility and handling—critical factors in motocross and trail riding.

Electrification Gains Momentum

Electric dirt bike engines are expected to capture a larger market share by 2026. With major players like KTM (with their SX-E series), Husqvarna, and Alta Motors (now part of BRP) investing heavily in electric off-road platforms, consumer adoption is rising. Advantages such as instant torque, low maintenance, quiet operation, and zero emissions make electric engines ideal for noise-sensitive areas and eco-conscious consumers. Improvements in battery energy density and fast-charging technologies will further accelerate this trend.

Stricter Emissions Regulations Driving Innovation

Environmental regulations, particularly in Europe and North America, are pushing manufacturers to refine internal combustion engines for lower emissions. By 2026, cleaner-burning two-stroke engines utilizing direct fuel injection (DFI) and advanced catalytic systems will see renewed interest. Additionally, four-stroke engines will continue to dominate the ICE segment, with improvements in fuel efficiency and reduced hydrocarbon emissions through optimized combustion and electronic fuel injection (EFI).

Integration of Smart Technologies

The incorporation of smart engine management systems will be a defining trend. By 2026, dirt bike engines are expected to feature adaptive engine mapping, ride-by-wire throttle systems, and connectivity with smartphone apps or onboard diagnostic tools. These technologies enable riders to customize engine performance based on terrain, skill level, or riding conditions, enhancing both performance and safety.

Expansion in Emerging Markets

Growing popularity of motorsports and off-road recreation in regions like Southeast Asia, Latin America, and parts of Africa will drive demand for affordable and durable dirt bike engines. Localized manufacturing and the production of cost-effective, entry-level models will enable broader market penetration. This expansion will support sustained growth for both ICE and emerging electric platforms tailored to regional needs.

Sustainability and Circular Economy Practices

Sustainability will influence engine design and production processes. OEMs are expected to adopt greener manufacturing techniques, increase recycling of engine components, and explore bio-based lubricants and fuels. The lifecycle management of electric dirt bike batteries—including reuse and recycling—will become a key focus area, aligning with global sustainability goals.

Conclusion

By 2026, the dirt bike engine market will reflect a dynamic balance between traditional combustion technologies and next-generation electric systems. While high-performance ICE engines will remain relevant, especially in professional racing, electrification will continue to disrupt the segment. Innovation in lightweight materials, smart controls, and environmental compliance will define competitive advantage, positioning the market for a more sustainable and technologically advanced future.

Common Pitfalls When Sourcing an Engine for a Dirt Bike (Quality and Intellectual Property Issues)

Sourcing an engine for a dirt bike—especially for replacement, repair, or custom builds—can be challenging. Buyers often face issues related to quality control and intellectual property (IP) infringement. Below are common pitfalls to watch for:

1. Poor Quality Control from Unverified Suppliers

One of the biggest risks when sourcing dirt bike engines is receiving substandard components. Many suppliers, particularly from online marketplaces or third-party vendors in regions with lax manufacturing standards, offer engines that appear identical to OEM (Original Equipment Manufacturer) products but fail prematurely due to inferior materials or poor assembly.

- Inconsistent Tolerances: Non-OEM engines may have improper machining, leading to overheating, oil leaks, or piston seizures.

- Lack of Testing: Reputable brands test engines for performance and durability; knockoff engines often skip these steps.

- Short Lifespan: Low-quality castings, bearings, and gaskets result in early engine failure.

2. Counterfeit or Replica Engines (IP Infringement)

Many aftermarket engines mimic designs from major brands like Honda, Yamaha, KTM, or Kawasaki without licensing. These replicas violate intellectual property rights and often compromise safety and reliability.

- Trademark and Design Infringement: Unauthorized use of logos, part numbers, or engine designs can lead to legal risks for resellers or importers.

- Misrepresentation: Sellers may label engines as “OEM compatible” or “genuine replacement” when they are not officially endorsed.

- No Warranty or Support: IP-infringing products typically come with no manufacturer support or warranty, leaving buyers with limited recourse.

3. Incomplete or Missing Documentation

Legitimate engine suppliers provide technical specs, compliance certifications (e.g., EPA, CARB), and installation manuals. Lack of documentation can signal illicit or low-quality production and may cause issues with registration or emissions compliance.

4. Compatibility Issues Due to Inaccurate Specifications

Some engines are marketed as “universal” or “fits all models,” but slight variations in mounting points, shaft lengths, or ignition systems can render them incompatible. This leads to costly returns or modifications.

5. Supply Chain and After-Sales Support Risks

Many low-cost engine suppliers lack reliable customer service or spare parts networks. If the engine fails, sourcing replacement components or obtaining technical help can be nearly impossible.

6. Import and Customs Complications

Engines that infringe on IP rights may be seized at customs. Additionally, engines not compliant with local emissions regulations (e.g., EPA in the U.S.) can be denied entry or result in fines.

Best Practices to Avoid These Pitfalls

- Purchase from authorized dealers or reputable OEM suppliers.

- Verify certifications and compliance with local regulations.

- Request detailed specifications and compare them with OEM standards.

- Check seller reviews and business credentials, especially on online platforms.

- Consult with a mechanic or engine specialist before purchasing.

By being aware of these quality and IP-related pitfalls, buyers can make informed decisions and avoid costly, unsafe, or illegal engine purchases.

Logistics & Compliance Guide for Engine for Dirt Bike

Product Classification & HS Code

Identify the correct Harmonized System (HS) code for dirt bike engines to ensure accurate customs declarations. Typically, small internal combustion engines for motorcycles fall under HS Code 8407.31 or 8407.32, depending on displacement (e.g., under or over 50cc). Confirm with local customs authorities or a licensed customs broker to avoid misclassification and potential delays or fines.

Import Regulations & Documentation

Ensure all required documentation is prepared prior to shipment:

– Commercial Invoice (detailing product description, value, and parties involved)

– Packing List (with weight, dimensions, and quantity)

– Bill of Lading or Air Waybill

– Certificate of Origin

– Import License (if required by destination country)

Some countries may require additional certifications (e.g., EPA or DOT compliance for the U.S., CE marking for the EU).

Emissions & Environmental Compliance

Verify that the engine meets emissions standards of the destination market:

– United States: Comply with EPA and CARB regulations for off-road engines. Engines must be certified and labeled accordingly.

– European Union: Must meet EU Stage V emission standards for non-road mobile machinery.

– Other Countries: Check local environmental regulations; non-compliant engines may be rejected at customs.

Safety & Technical Standards

Ensure the engine complies with applicable safety and performance standards:

– Confirm adherence to ISO or regional mechanical safety standards.

– Include user manuals in the local language with safety warnings and maintenance instructions.

– For electric dirt bike engines, comply with IEC or UL standards for battery and motor safety.

Packaging & Shipping Requirements

Use robust, secure packaging to prevent damage during transit:

– Crates or heavy-duty boxes with internal bracing.

– Waterproof wrapping to protect against moisture.

– Clearly labeled with handling instructions (e.g., “Fragile,” “Do Not Invert”).

– Include tamper-evident seals for authenticity and security.

Customs Duties & Taxes

Calculate anticipated import duties, VAT, or GST based on the destination country’s tariff schedule. Use the correct valuation method (usually transaction value) and consider utilizing a bonded warehouse or free trade agreement benefits (e.g., USMCA, RCEP) where applicable to reduce costs.

Restricted & Prohibited Items Check

Confirm that used or rebuilt engines are not restricted in the destination country. Some regions ban the import of second-hand engines to promote environmental standards or local industry. New engines typically face fewer restrictions.

After-Sales & Warranty Compliance

Provide clear warranty terms that comply with local consumer protection laws. In regions like the EU, statutory warranty periods may extend beyond manufacturer offers. Include contact details for local service or support centers if available.

Recordkeeping & Audit Readiness

Maintain complete shipping and compliance records for a minimum of 5–7 years, depending on jurisdiction. These records may include customs filings, test reports, certificates, and correspondence with regulatory bodies.

Contact Regulatory Authorities & Experts

Engage with customs brokers, freight forwarders, and legal advisors familiar with automotive parts logistics. Proactive consultation helps avoid compliance pitfalls and ensures smooth cross-border movement of dirt bike engines.

In conclusion, sourcing an engine for a dirt bike requires careful consideration of several key factors including compatibility, performance needs, budget, and long-term reliability. Whether opting for a new OEM engine, a rebuilt unit, or a used engine from a reputable supplier, it is essential to verify specifications such as displacement, mounting points, and ancillary components to ensure a proper fit and function. Additionally, evaluating the seller’s reputation, warranty options, and availability of technical support can greatly influence the success of the project. A well-sourced engine not only restores or enhances the bike’s performance but also contributes to a safer and more reliable riding experience. Taking the time to research and make an informed decision ultimately leads to greater satisfaction and cost-effectiveness in the long run.