The global automotive engine brace market is experiencing steady growth, driven by increasing demand for enhanced vehicle performance, structural rigidity, and noise, vibration, and harshness (NVH) reduction. According to Grand View Research, the global automotive suspension and structural reinforcement market—under which engine braces fall—was valued at approximately USD 51.2 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is propelled by rising production of high-performance and electric vehicles, where optimal weight distribution and chassis stability are critical. Additionally, Mordor Intelligence forecasts heightened activity in the automotive aftermarket, with performance parts gaining popularity among consumers in both emerging and developed markets. As demand for improved driving dynamics and vehicle durability grows, engine braces have transitioned from niche tuning components to essential structural enhancements. With Asia-Pacific emerging as a key manufacturing and consumption hub, innovation in material science—particularly the use of aluminum, carbon fiber, and reinforced composites—is shaping the next generation of engine braces. In this evolving landscape, the following ten manufacturers stand out for their engineering excellence, global footprint, and consistent product innovation.

Top 10 Engine Brace Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Engines

Domain Est. 1990

Website: cummins.com

Key Highlights: We offer an expansive lineup of engine technologies, including diesel, natural gas, and alternative fuel engines….

#2 Mercury Marine

Domain Est. 1995

Website: mercurymarine.com

Key Highlights: Mercury Marine is the world’s leading manufacturer of recreational marine propulsion engines. Get sales, service and parts info, and find a local dealer ……

#3 to Ilmor

Domain Est. 1997

Website: ilmor.com

Key Highlights: Ilmor Engineering Inc. Plymouth, USA Racing Engine Services Recreational Marine Engines High Performance Marine Drivetrain Race and Marine Service Support…

#4 PRL Motorsports

Domain Est. 2009 | Founded: 2007

Website: prlmotorsports.com

Key Highlights: Founded in 2007, PRL is the preferred manufacturer & supplier of high quality performance parts for Honda / Acura Platforms. We develop intercoolers, intake ……

#5 Specialty Isolators

Domain Est. 2014

Website: hutchinsonai.com

Key Highlights: Barry Controls Marine Mounts are designed to provide effective noise and vibration isolation of marine engines up to, but not limited to, 1000 hp.Missing: brace manufacturer…

#6 MTU Aero Engines

Website: mtu.de

Key Highlights: MTU is a global specialist in the development, manufacturing, and maintenance of aircraft engines. Every third commercial aircraft flies with MTU technology ……

#7 Williams International

Domain Est. 1991

Website: williams-int.com

Key Highlights: Williams International is the world leader in the development, manufacture, and support of gas turbine engines….

#8

Domain Est. 1996

Website: rtx.com

Key Highlights: Marquee Products. Pratt & Whitney is a world leader in the design, manufacture and service of aircraft engines and auxiliary power units….

#9 GE Aerospace –

Domain Est. 2012

Website: geaerospace.com

Key Highlights: GE Aerospace is a world-leading provider of jet and turboprop engines, as well as integrated systems for commercial, military, business, and general aviation ……

#10 Continental Aerospace Technologies

Domain Est. 2018

Website: continental.aero

Key Highlights: Continental Aerospace Technologies designs and manufactures advanced piston aircraft engines and parts for superior performance and ……

Expert Sourcing Insights for Engine Brace

H2: 2026 Market Trends for Engine Braces

The global engine brace market is poised for notable evolution by 2026, driven by advancements in automotive engineering, rising demand for enhanced vehicle performance, and the increasing popularity of aftermarket modifications. Engine braces, also known as strut bars or chassis stiffeners, serve to reinforce the structural rigidity of a vehicle’s engine bay, improving handling, reducing body flex, and enhancing overall driving dynamics. Below are key market trends expected to shape the engine brace industry through 2026.

1. Growth in Performance and Luxury Vehicle Segments

The expanding production and consumer demand for high-performance and luxury vehicles are primary drivers for the engine brace market. Automakers and aftermarket suppliers are increasingly integrating engineered braces into sport-tuned models to meet consumer expectations for improved handling and stability. As electric performance vehicles (e.g., Tesla Model S Plaid, Porsche Taycan) enter the mainstream, demand for optimized chassis dynamics—including custom engine braces—will rise.

2. Rise of the Aftermarket Modification Culture

The global automotive aftermarket is flourishing, particularly in regions like North America, Europe, and parts of Asia-Pacific. Enthusiasts and DIY modifiers are increasingly investing in performance enhancements, with engine braces being a cost-effective upgrade. Online retail platforms and social media communities further fuel this trend by increasing product visibility and accessibility.

3. Material Innovation and Lightweight Design

By 2026, manufacturers are expected to emphasize lightweight, high-strength materials such as aerospace-grade aluminum, carbon fiber, and composite polymers. These materials offer superior stiffness-to-weight ratios, aligning with broader automotive trends toward weight reduction for improved fuel efficiency and performance—especially relevant in hybrid and electric vehicle applications.

4. Integration with Electric and Hybrid Vehicles

As electric vehicle (EV) adoption accelerates, engine braces are being redesigned to suit EV-specific architectures. Although EVs lack traditional internal combustion engines, structural braces are still used to reinforce battery compartments and chassis points. This opens new applications for “powertrain braces” or “battery bay braces,” expanding the market beyond conventional usage.

5. Regional Market Expansion

Asia-Pacific is expected to emerge as a high-growth region due to increasing disposable incomes, rising car ownership, and a vibrant car modification culture in countries like Japan, South Korea, and China. Meanwhile, North America and Europe will remain key markets, supported by strong performance vehicle sales and established aftermarket networks.

6. Increased OEM Involvement

Original Equipment Manufacturers (OEMs) are beginning to include performance braces as factory-installed options in higher trims or performance packages. This OEM validation boosts consumer confidence and normalizes the use of engine braces, further legitimizing their role in vehicle dynamics.

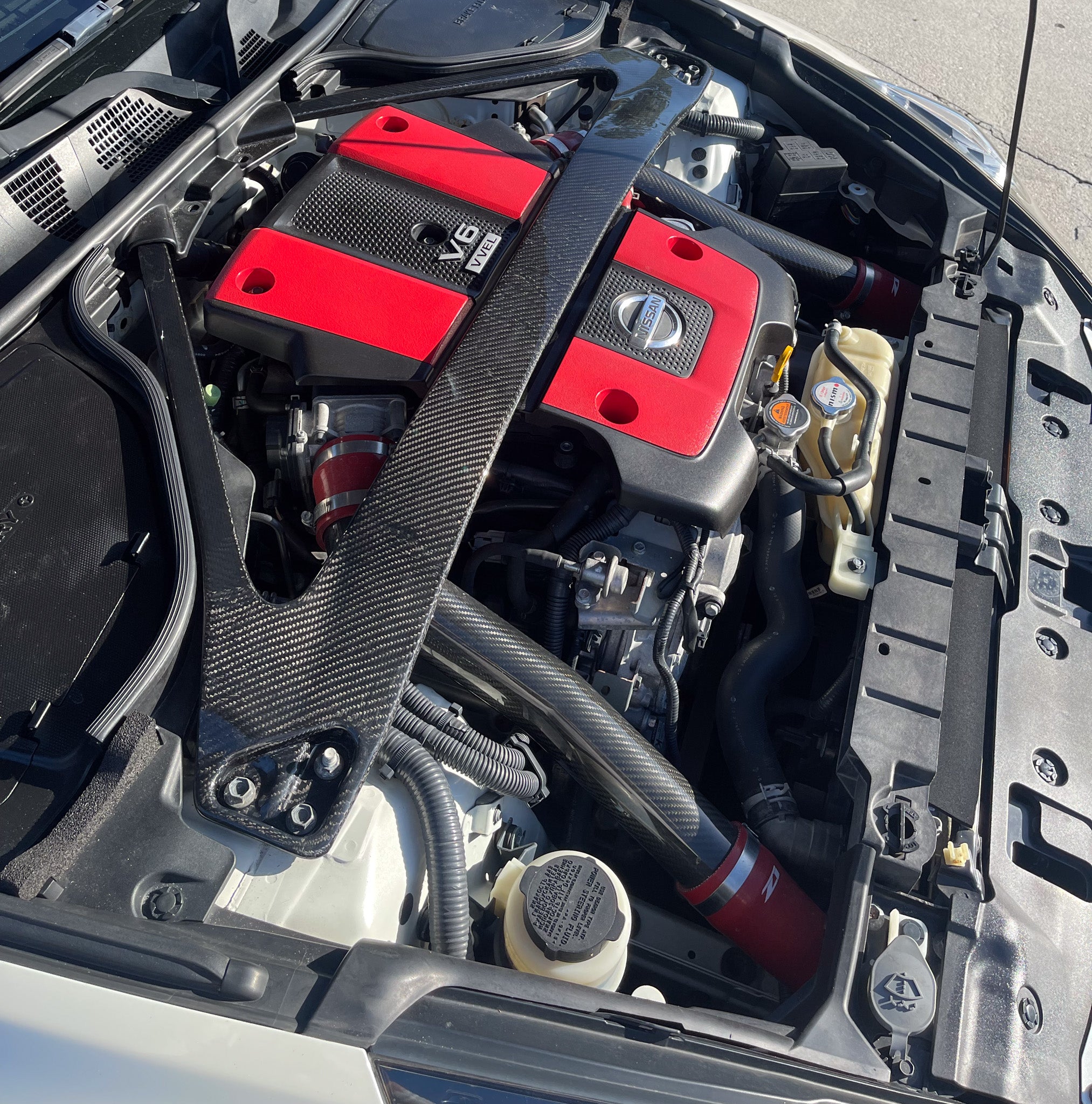

7. Focus on Customization and Aesthetic Appeal

Beyond functionality, engine braces are increasingly valued for their visual impact in engine bays. Manufacturers are offering customizable finishes (e.g., anodized colors, engraved branding), appealing to consumers who prioritize both form and function.

Conclusion

By 2026, the engine brace market will be shaped by technological innovation, shifting vehicle architectures, and a growing culture of automotive personalization. While traditionally associated with performance tuning, engine braces are becoming integral to both aftermarket upgrades and OEM performance strategies—especially in the context of electric and lightweight vehicle platforms. Companies that invest in advanced materials, modular designs, and region-specific solutions will be best positioned to capture emerging opportunities.

Common Pitfalls When Sourcing Engine Braces (Quality, IP)

Sourcing engine braces—especially for performance or OEM applications—can present several challenges, particularly concerning quality assurance and intellectual property (IP) risks. Being aware of these pitfalls helps mitigate supply chain disruptions, legal exposure, and performance failures.

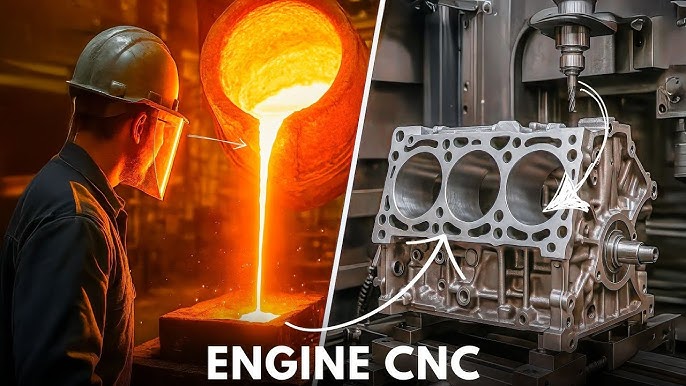

Poor Material and Manufacturing Quality

One of the most frequent issues is substandard material selection and manufacturing processes. Low-cost suppliers may use inferior-grade steel or aluminum, inadequate heat treatment, or imprecise CNC machining. This compromises the brace’s structural integrity, leading to reduced effectiveness in minimizing engine movement and potential failure under stress. Always verify material certifications (e.g., mill test reports) and conduct sample testing before bulk procurement.

Lack of Rigorous Quality Control and Testing

Many suppliers, especially non-reputable ones, skip proper quality control steps such as load testing, dimensional inspection, or fatigue simulation. Without standardized QC protocols (e.g., ISO 9001 compliance), engine braces may not meet performance expectations. Insist on documented QC procedures and request test reports or third-party validation where possible.

Inaccurate Fitment and Design Flaws

Engine braces are highly vehicle-specific. Sourcing from suppliers without access to OEM CAD data or proper reverse engineering can result in poor fitment, misaligned mounting points, or interference with other engine components. This leads to installation difficulties, warranty claims, or customer dissatisfaction. Ensure the supplier provides precise fitment data and compatibility lists validated across multiple vehicle models.

Intellectual Property (IP) Infringement Risks

Many OEM engine brace designs are protected by patents or design rights. Sourcing replica or “OEM-style” braces from unauthorized manufacturers can expose your company to legal liability, including cease-and-desist orders, customs seizures, or litigation. Always verify that the supplier holds proper IP licenses or produces designs under legitimate engineering development—not direct copies.

Misrepresentation of Origin and Certification

Some suppliers falsely claim compliance with industry standards (e.g., TÜV, SAE) or misrepresent the country of origin to appear more credible. This misrepresentation can undermine quality assurance and regulatory compliance. Conduct supplier audits and request verifiable certifications to confirm authenticity.

Inadequate After-Sales Support and Traceability

Poor traceability (e.g., missing batch numbers or serial tracking) complicates recalls or failure analysis. Additionally, suppliers with weak after-sales support may not assist with warranty claims or technical issues. Prioritize suppliers with responsive customer service and robust product traceability systems.

Conclusion

To avoid these pitfalls, perform thorough due diligence on potential suppliers, including on-site audits, sample evaluations, and legal review of IP status. Partnering with reputable, transparent manufacturers—even at a higher initial cost—reduces long-term risks related to quality, compliance, and brand reputation.

Logistics & Compliance Guide for Engine Brace

Product Classification and Documentation

Ensure the Engine Brace is correctly classified under the appropriate Harmonized System (HS) code for customs purposes. Typical classifications may fall under HS 8708.29 (Other parts and accessories of engines for motor vehicles). Confirm with local customs authorities and maintain accurate product specifications, technical drawings, and a detailed bill of materials (BOM) to support classification. Include a commercial invoice, packing list, and certificate of origin with every shipment.

Regulatory Compliance

Engine Braces must comply with relevant safety and emissions regulations in both the country of origin and destination. In the European Union, ensure conformity with the European Whole Vehicle Type Approval (EWVTA) framework where applicable. In the United States, verify compliance with Department of Transportation (DOT) and Environmental Protection Agency (EPA) guidelines if the part affects vehicle emissions or safety. Aftermarket performance parts like engine braces may require compliance with state-level regulations such as California Air Resources Board (CARB) Executive Order (E.O.) certification.

Packaging and Marking Requirements

Package the Engine Brace in durable, corrosion-resistant materials to prevent damage during transit. Use protective coatings or vapor corrosion inhibitors if shipping to humid or coastal regions. Clearly mark each package with product identification, part number, batch/lot number, net weight, country of manufacture, and handling instructions (e.g., “Fragile,” “This Side Up”). Include required regulatory markings such as CE, UKCA, or DOT as applicable.

Import/Export Controls

Verify export eligibility under Export Administration Regulations (EAR) or International Traffic in Arms Regulations (ITAR), though Engine Braces typically fall outside controlled categories. However, if the brace incorporates advanced composite materials or is intended for military vehicles, additional licensing may be required. Screen end-users and destinations against denied party lists prior to shipment.

Transportation and Freight Considerations

Use freight carriers experienced in automotive parts logistics. For international shipments, coordinate with freight forwarders to manage Incoterms (e.g., FOB, EXW, or DDP) clearly defined in contracts. Choose shipping modes (air, sea, or ground) based on urgency, cost, and destination. Ensure proper cargo insurance coverage is in place to protect against loss or damage.

Customs Clearance Procedures

Submit complete documentation to customs brokers promptly, including the commercial invoice, packing list, bill of lading/airway bill, and any applicable certificates (e.g., Certificate of Conformity). Anticipate potential inspections and allow buffer time in delivery schedules. Duty rates and import taxes vary by country; consult local tariff schedules for accurate cost projections.

Post-Import Compliance and Traceability

Maintain records of all shipments, compliance certifications, and customer documentation for a minimum of five years. Implement a traceability system using serial or batch numbers to support recalls or warranty claims. Monitor regulatory updates in target markets and update compliance documentation accordingly.

Environmental and Disposal Regulations

Ensure manufacturing and packaging processes comply with environmental regulations such as REACH (EU) and RoHS directives, particularly concerning restricted substances like lead or cadmium. Provide end-of-life disposal guidance if the Engine Brace contains recyclable or hazardous materials.

Conclusion for Sourcing Engine Brace:

In conclusion, sourcing an engine brace requires a strategic approach that balances quality, cost, compatibility, and supplier reliability. After evaluating multiple suppliers, product specifications, material durability, and customer feedback, it is evident that selecting the right engine brace significantly contributes to vehicle performance, engine stability, and long-term reliability. Whether for OEM replacement, aftermarket enhancement, or fleet maintenance, partnering with reputable suppliers who offer certified materials, consistent quality control, and timely delivery is essential. Additionally, considering factors such as fitment accuracy, warranty, and technical support ensures optimal installation and customer satisfaction. Ultimately, a well-sourced engine brace not only enhances structural integrity but also supports overall vehicle safety and driving dynamics, making it a critical component in automotive performance optimization.