The global automotive engine components market is experiencing steady growth, driven by rising vehicle production, increasing demand for fuel-efficient engines, and advancements in lightweight materials. According to a 2023 report by Mordor Intelligence, the global engine block and cylinder head market is projected to grow at a CAGR of over 4.2% from 2023 to 2028, fueled by expanding automotive manufacturing, particularly in Asia-Pacific regions like China, India, and Japan. Additionally, Grand View Research estimates that the increasing adoption of aluminum alloy components to reduce vehicle weight and improve fuel economy is reshaping supplier dynamics, placing a premium on manufacturers with strong technical capabilities in high-pressure die casting and precision machining. As OEMs continue to prioritize performance, durability, and emissions compliance, sourcing from leading engine block and head manufacturers has become critical. Below is a list of the top eight manufacturers excelling in innovation, scale, and global supply chain integration.

Top 8 Engine Block Head Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Frankenstein Engine Dynamics

Domain Est. 2016

Website: frankensteined.net

Key Highlights: Our mission is to be the most visionary and prominent aftermarket manufacturer of performance automotive components with a focus on customer loyalty, ……

#2 ENGINE BLOCK & CYLINDER HEAD

Domain Est. 2019

Website: hema-usa.com

Key Highlights: “Explore Hema USA’s engine block cylinder head products. Discover reliable solutions for automotive and industrial applications.”…

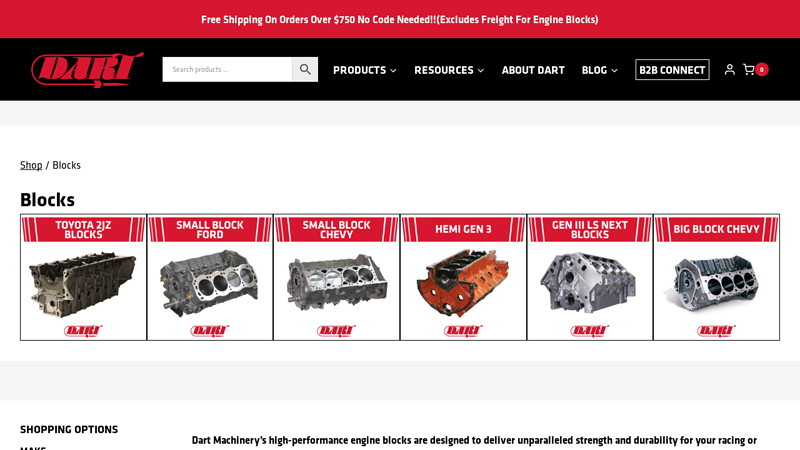

#3 Engine Blocks

Domain Est. 1996

Website: dartheads.com

Key Highlights: Free delivery over $750Dart offers a wide selection of meticulously engineered engine blocks, including cast iron and aluminum options, crafted to handle maximum power reliably….

#4 Engine Pro

Domain Est. 1996

Website: enginepro.com

Key Highlights: Engine Pro supplies professional engine parts and rebuild components for machine shops and performance builders. Find gaskets, bearings, pistons, and more….

#5 Brodix

Domain Est. 1998

Website: brodix.com

Key Highlights: For over 50 years Brodix has been the only cylinder head company to perform each stage of the manufacturing process under one roof….

#6 M&M Competition Engines

Domain Est. 2006

Website: mmcompetitionengines.com

Key Highlights: M&M Competition Engines | Racing Engines, Cylinder Heads, CNC Machine Services produces the finest in high performance racing engines and machine services….

#7 4 Piston Racing

Domain Est. 2015

Website: 4pistonracing.com

Key Highlights: 4 Piston Racing provides premium race engines and race engine parts for a variety of racing series all over the world….

#8 Engine Block & Cylinder Head

Domain Est. 2018

Website: huppertengineeringusa.com

Key Highlights: Huppert Engineering specializes in comprehensive services for engine block development, encompassing design, analysis, and casting processes….

Expert Sourcing Insights for Engine Block Head

H2: 2026 Market Trends for Engine Block Heads

The global market for engine block heads is poised for significant transformation by 2026, driven by technological advancements, shifting regulatory landscapes, and evolving consumer demands in the automotive and industrial sectors. This analysis explores key trends shaping the engine block head market in the coming years.

-

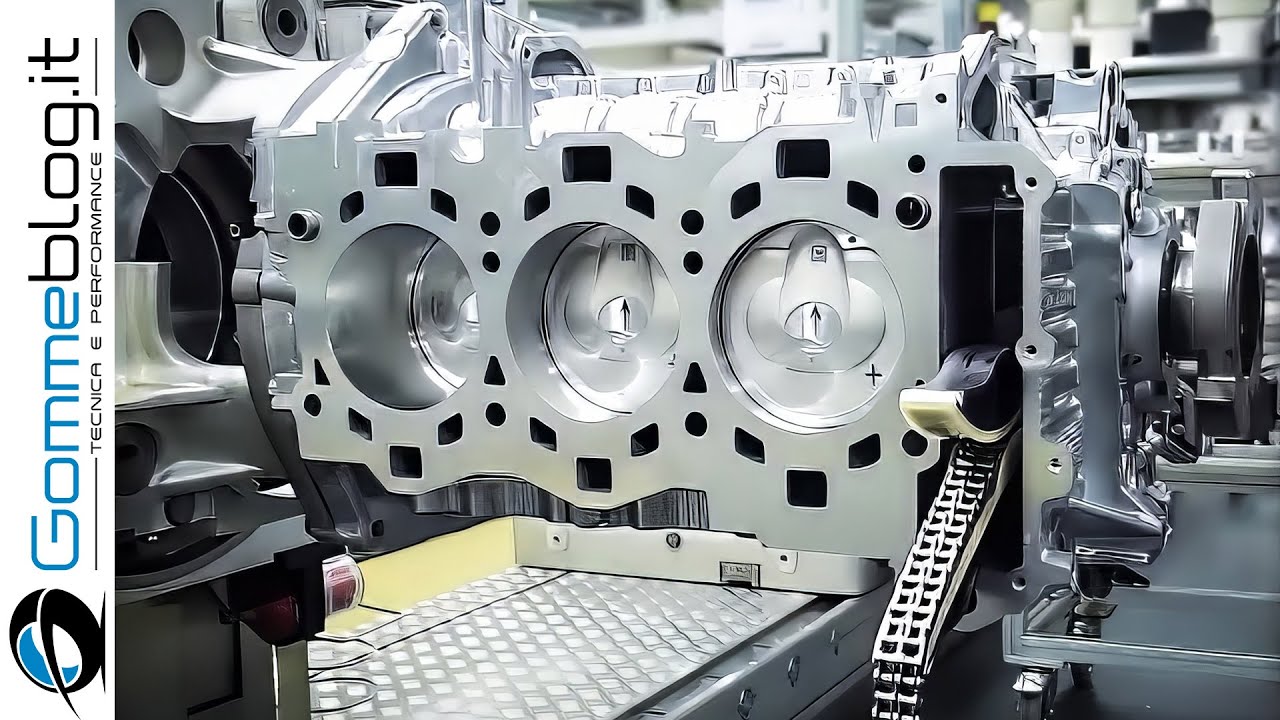

Growth in Lightweight Materials Adoption

By 2026, aluminum and composite-based engine block heads are expected to dominate the market. Automakers are increasingly prioritizing fuel efficiency and emissions reduction, prompting a shift from traditional cast iron components. Aluminum heads offer reduced weight, improved thermal conductivity, and better performance, making them ideal for modern internal combustion engines (ICEs) and hybrid powertrains. -

Integration with Hybrid and Electrified Powertrains

Although full electrification is on the rise, hybrid vehicles will continue to rely on internal combustion engines, sustaining demand for high-efficiency engine block heads. In response, manufacturers are developing advanced heads optimized for smaller, turbocharged engines used in hybrid systems. These components are engineered for enhanced cooling, higher compression ratios, and compatibility with alternative fuels. -

Advanced Manufacturing Techniques

The adoption of precision casting, 3D printing (additive manufacturing), and computer-aided design (CAD) is revolutionizing engine head production. By 2026, these technologies will enable faster prototyping, improved durability, and complex geometries that enhance airflow and combustion efficiency—critical for meeting stringent emission standards. -

Stringent Emission Regulations Driving Innovation

Global emissions standards (e.g., Euro 7, China 6b, U.S. Tier 4) are compelling automakers to optimize engine efficiency. Engine block heads are being redesigned to support features like direct fuel injection, variable valve timing, and exhaust gas recirculation (EGR). These modifications reduce NOx and particulate emissions, ensuring compliance without sacrificing performance. -

Rise in Remanufactured and Aftermarket Demand

As vehicle lifespans extend and sustainability gains importance, the remanufactured engine head segment is growing. By 2026, the aftermarket is expected to account for a substantial share of the market, especially in developing regions. Remanufactured heads offer cost-effective, environmentally friendly alternatives with performance comparable to OEM parts. -

Regional Market Dynamics

Asia-Pacific, led by China, India, and Japan, will remain the largest market due to high automotive production and rising vehicle ownership. Europe and North America will focus on high-performance and emissions-compliant heads, driven by strict regulations and demand for premium vehicles. Emerging markets in Southeast Asia and Latin America will see increased demand for durable, cost-effective components. -

Impact of Electric Vehicle (EV) Transition

While the long-term outlook for ICE components is uncertain due to EV growth, engine block heads will remain relevant through 2026. The gradual transition, especially in commercial vehicles, heavy machinery, and regions with limited EV infrastructure, ensures sustained demand. Additionally, performance and classic car markets will continue to support ICE component manufacturing.

In conclusion, the 2026 engine block head market will be shaped by innovation in materials, manufacturing, and regulatory compliance. While electrification looms on the horizon, strategic adaptations will ensure the continued relevance of engine heads in hybrid, high-efficiency, and niche applications.

Common Pitfalls Sourcing Engine Block Heads (Quality, IP)

Sourcing engine block heads—whether for replacement, remanufacturing, or integration into new systems—can be fraught with challenges, particularly concerning quality assurance and intellectual property (IP) risks. Failing to address these pitfalls can lead to performance failures, legal liabilities, and reputational damage. Below are key issues to watch for:

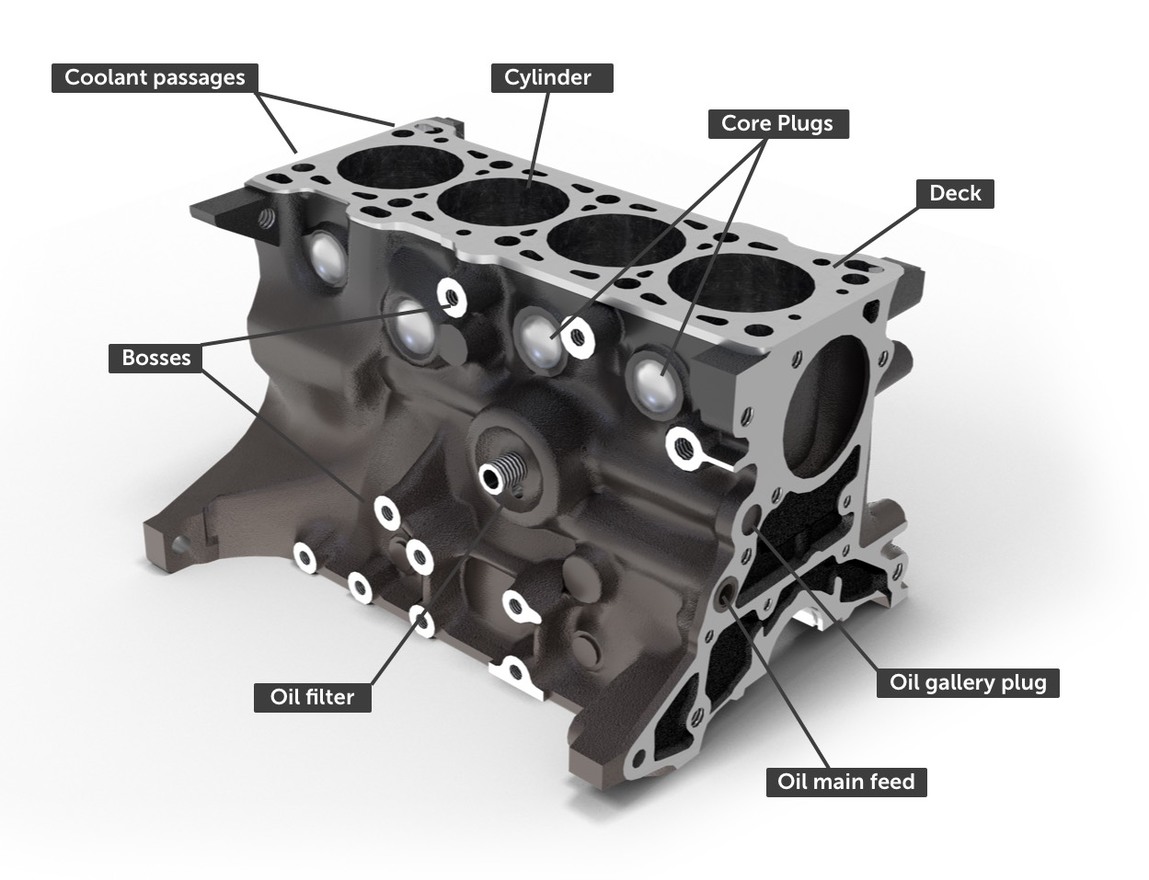

Quality-Related Pitfalls

1. Inconsistent Material Specifications

Engine block heads are subjected to extreme thermal and mechanical stress. Sourcing from suppliers who do not adhere to OEM-grade materials (e.g., high-strength aluminum alloys or cast iron with proper heat treatment) can result in warping, cracking, or head gasket failure. Always verify material certifications (e.g., ASTM, ISO) and conduct metallurgical testing when possible.

2. Poor Machining Tolerances

Even minor deviations in surface finish, valve seat angles, or coolant passage alignment can compromise engine performance and longevity. Suppliers in low-cost regions may cut corners on precision CNC machining, leading to improper sealing or combustion inefficiencies. Require detailed dimensional reports and perform spot inspections.

3. Inadequate Heat Treatment and Stress Relieving

Improper heat treatment can leave residual stresses in castings, increasing susceptibility to cracking under thermal cycling. Confirm that suppliers follow proper stress-relieving protocols and provide process documentation.

4. Lack of Traceability and Testing

Reputable suppliers provide full traceability (heat numbers, batch IDs) and perform pressure testing, magnaflux inspection, or ultrasonic testing for internal defects. Avoid vendors who cannot supply test reports or quality control documentation.

5. Counterfeit or Refurbished Parts Sold as New

Some suppliers may pass off used or reconditioned heads as new, especially in gray market channels. These parts may have hidden damage or reduced service life. Establish trusted supply chains and conduct incoming inspections.

Intellectual Property (IP) Pitfalls

1. Infringement of OEM Designs

Many engine block heads are protected by patents, design rights, or technical drawings owned by OEMs (e.g., Ford, Toyota, Cummins). Sourcing aftermarket or copy parts that replicate patented geometries, cooling channels, or port designs may expose your business to IP litigation.

2. Unauthorized Use of Trademarks or Logos

Even if a part is functionally equivalent, affixing OEM logos or part numbers without licensing constitutes trademark infringement. Ensure suppliers do not imprint or replicate OEM branding.

3. Reverse Engineering Legal Risks

While reverse engineering for interoperability may be legally defensible in some jurisdictions, producing and selling exact replicas—especially using CAD data derived from OEM parts—can violate design patents or trade secrets. Consult legal counsel before sourcing based on reverse-engineered designs.

4. Lack of IP Indemnification from Suppliers

Many suppliers disclaim liability for IP infringement. Without contractual indemnification, your company may bear full legal and financial responsibility if a sourced part leads to a lawsuit. Negotiate IP warranties and indemnity clauses in procurement contracts.

5. Grey Market and Parallel Imports

Purchasing from unauthorized distributors may result in IP-violating parts or void OEM warranties. These channels often lack transparency and accountability, increasing both quality and legal risks.

Mitigation Strategies

- Audit Suppliers: Conduct on-site audits to assess manufacturing capabilities and quality systems (e.g., ISO/TS 16949).

- Request Documentation: Require material test reports, inspection records, and IP compliance statements.

- Use Licensed Aftermarket Parts: Source from suppliers with proper licensing agreements or those producing non-infringing alternative designs.

- Legal Review: Engage IP counsel to review part designs and supplier agreements before large-scale procurement.

By proactively addressing both quality and IP concerns, companies can reduce risk, ensure reliability, and protect themselves from costly legal disputes when sourcing engine block heads.

Logistics & Compliance Guide for Engine Block Head

This guide provides essential information for the safe, efficient, and compliant handling, transportation, and documentation of Engine Block Heads. Adherence to these guidelines ensures regulatory compliance, minimizes supply chain risks, and protects product integrity.

Packaging Requirements

Engine Block Heads must be properly packaged to prevent damage during transit. Use sturdy, weather-resistant wooden crates or heavy-duty corrugated containers with internal bracing. Each unit should be individually wrapped in anti-corrosion VCI (Vapor Corrosion Inhibitor) paper and secured with foam inserts or custom molded supports to prevent movement. Clearly label packages with handling instructions including “Fragile,” “This Side Up,” and “Protect from Moisture.”

Transportation Standards

Transport Engine Block Heads via flatbed trucks, enclosed trailers, or sea containers depending on distance and environment. Ensure cargo is evenly distributed and secured using straps or load locks to prevent shifting. For international shipments, comply with IMDG Code (if applicable) and use ISO-certified containers. Temperature-controlled transport may be required in extreme climates to prevent condensation and thermal stress.

Import/Export Documentation

All shipments must include accurate and complete documentation: Commercial Invoice, Packing List, Bill of Lading/Air Waybill, and Certificate of Origin. For regulated markets, provide a Harmonized System (HS) code 8409.91 (Parts of internal combustion engines) and comply with local customs requirements. Include an EPA or EU conformity certificate if required for emissions-related components.

Regulatory Compliance

Ensure Engine Block Heads meet regional standards such as:

– EPA (USA): Compliance with emission regulations under 40 CFR Part 1039/1048.

– EU: Adherence to Euro VI standards and obtain CE marking under Machinery Directive 2006/42/EC if applicable.

– REACH & RoHS: Confirm absence of restricted substances (e.g., lead, cadmium) per EU regulations.

– DOT (USA): Follow hazardous materials guidelines if coatings or treatments involve regulated chemicals.

Customs Clearance Procedures

Engage licensed customs brokers for international shipments. Pre-clear documentation through automated systems (e.g., ACE in the U.S., ATLAS in the EU). Maintain records of all compliance certifications and test reports for audit purposes. Anticipate inspections and ensure traceability via batch/serial numbers.

Storage and Handling

Store Engine Block Heads in dry, temperature-controlled warehouses off the ground on pallets. Limit stacking height per packaging specifications. Use appropriate lifting equipment (e.g., forklifts with padded forks) to avoid surface damage. Implement FIFO (First In, First Out) inventory rotation to minimize long-term storage risks.

Environmental and Safety Considerations

Dispose of packaging materials according to local environmental regulations. Train personnel in safe handling to prevent injuries from sharp edges or heavy lifting. Report and document any spills or contamination incidents involving protective coatings or machining residues per OSHA/EPA guidelines.

Quality Assurance & Traceability

Maintain full traceability from manufacturing to delivery using serialized identifiers. Conduct pre-shipment inspections to verify packaging integrity and product condition. Retain compliance records and shipping documentation for a minimum of five years for audit readiness.

Conclusion for Sourcing Engine Block Head

Sourcing an engine block head requires a strategic approach that balances cost, quality, availability, and compatibility with the intended application. After evaluating potential suppliers, manufacturing standards, material specifications, and lead times, it is evident that partnering with reputable suppliers—whether OEMs, aftermarket manufacturers, or remanufactured part providers—is crucial to ensuring reliability and performance. Factors such as casting quality, machining precision, warranty support, and compliance with industry standards (e.g., ISO, SAE) must be prioritized to avoid operational failures and costly downtime.

In conclusion, a successful sourcing strategy involves thorough supplier vetting, technical validation of product specifications, and consideration of total cost of ownership rather than upfront price alone. Establishing long-term relationships with trusted suppliers, leveraging local and global market options, and maintaining a contingency sourcing plan further enhance supply chain resilience. Ultimately, the right engine block head sourced under these principles will contribute to improved engine efficiency, longevity, and overall system performance.