The global tie-down strap market is experiencing steady growth, driven by rising demand across automotive, logistics, construction, and marine industries. According to a report by Mordor Intelligence, the global cargo control and load securement market—of which tie-down straps are a critical component—was valued at USD 6.2 billion in 2023 and is projected to grow at a CAGR of 4.8% through 2029. Similarly, Grand View Research estimates the industrial webbing and strapping market to expand at a CAGR of over 5.1% from 2024 to 2030, fueled by increasing freight transportation volumes and stringent safety regulations for cargo securement. As demand for durable, high-tensile-load restraint solutions rises, endless tie-down straps have gained preference due to their superior strength, reduced wear, and seamless loop design. These market dynamics have spurred innovation and competition among manufacturers, positioning the top players to lead in product quality, scalability, and technological integration. In this evolving landscape, identifying the leading endless tie-down strap manufacturers becomes essential for sourcing performance-driven and reliable load securement solutions.

Top 8 Endless Tie Down Straps Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 The Ratchet Depot, Inc.

Domain Est. 2000

Website: ratchetdepot.com

Key Highlights: – Endless Straps. – Self Contained Ratchet Straps. – Spring-loaded Cambuckle Straps. – Ratchet Straps. – Thumb Ratchet Straps. – Cambuckle Straps. – Powersports ……

#2 Single Part Web Lashing/Endless type Ratchet Strap

Domain Est. 2000

Website: h-lift.com

Key Highlights: Rating 5.0 (1) Our endless ratchet straps come in many different lengths and colors. The ratchet strap can also be made with heavy duty hardware to add extra strength to an ……

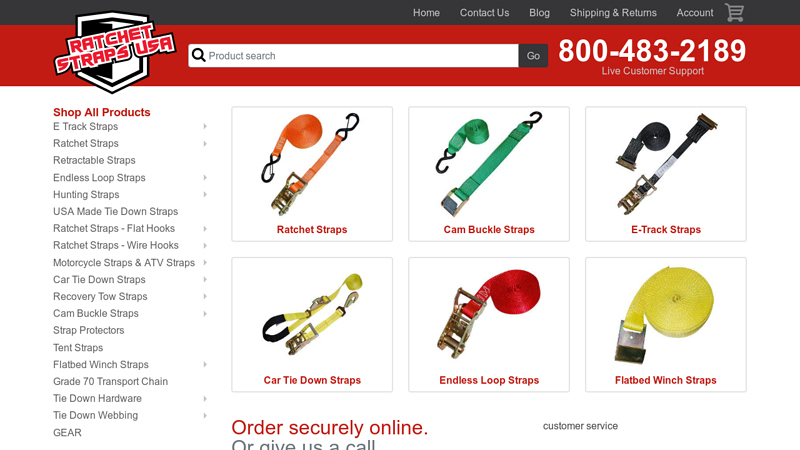

#3 Ratchet Straps

Domain Est. 2001

Website: ratchetstraps.com

Key Highlights: Ratchet Straps that can be custom made for just about any application. We stock Ratchet Straps, Endless Loop Straps, Cam Buckles, and Winch Straps….

#4 Endless Straps

Domain Est. 2003

Website: tarpstiedowns.com

Key Highlights: 6-day deliveryShop Tarps & Tie-Downs for endless straps. Find durable endless loop straps and endless ratchet straps for versatile and secure cargo tie-downs. Order now!…

#5 2″ x 10′ Endless Loop Standard Ratchet Strap

Domain Est. 2004

Website: cargoequipmentcorp.com

Key Highlights: In stock Rating 5.0 (4) The endless loop ratchet strap is designed to go around items that need to be bundled together. Simply wrap the strap around the items needing to be secur…

#6 Custom Made Ratchet Straps

Domain Est. 2004

Website: truckingdepot.com

Key Highlights: 6-day delivery 15-day returnsShop our popular 1-inch to 4-inch Heavy Duty Ratchet Straps with customization options to fit your cargo control needs. Available with different webbin…

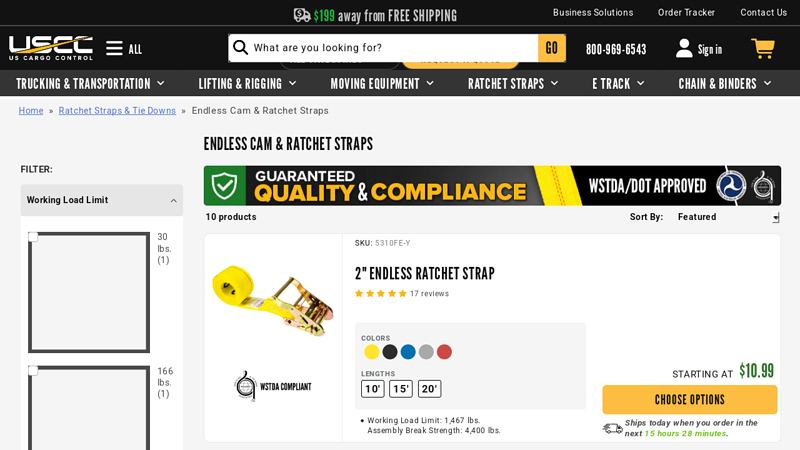

#7 Endless Cam & Ratchet Straps

Domain Est. 2005

Website: uscargocontrol.com

Key Highlights: Free delivery over $199 60-day returns…

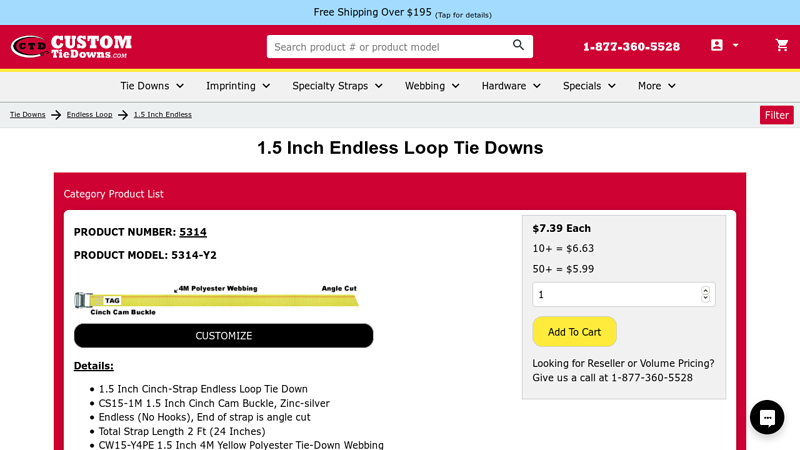

#8 1.5 Inch Endless Loop Tie Downs

Domain Est. 2007

Website: customtiedowns.com

Key Highlights: Free delivery over $195 30-day returns…

Expert Sourcing Insights for Endless Tie Down Straps

H2: 2026 Market Trends for Endless Tie Down Straps

The global market for endless tie-down straps is poised for significant transformation by 2026, driven by evolving industrial demands, technological advancements, and heightened safety regulations. These heavy-duty straps—used primarily in transportation, logistics, construction, and agriculture—are experiencing shifts influenced by material innovation, e-commerce growth, and a growing emphasis on load security and operational efficiency.

-

Rising Demand from E-Commerce and Last-Mile Delivery

The rapid expansion of e-commerce continues to fuel the need for secure, reusable, and versatile cargo restraint solutions. As last-mile delivery networks grow, especially in urban environments, logistics providers are prioritizing modular and damage-resistant tie-down systems. Endless tie-down straps, with their seamless loop design and superior strength-to-weight ratio, are increasingly favored over traditional ratchet straps with open ends that can fray or weaken over time. -

Material Innovation and Lightweighting

By 2026, manufacturers are expected to shift toward high-performance synthetic materials such as ultra-high-molecular-weight polyethylene (UHMWPE) and advanced polyester blends. These materials offer higher tensile strength, UV resistance, and reduced weight compared to conventional nylon or standard polyester. This trend supports sustainability goals by extending product lifespan and reducing material waste. -

Focus on Safety and Regulatory Compliance

Regulatory bodies in North America and Europe are tightening cargo securement standards, especially in commercial transportation. The Federal Motor Carrier Safety Administration (FMCSA) and European Transport Safety Council (ETSC) are expected to enforce stricter guidelines, prompting fleet operators to adopt certified endless straps that meet or exceed Working Load Limit (WLL) and break strength requirements. Demand for straps with traceability tags, load indicators, and certification labels is projected to grow. -

Integration with Smart Logistics Systems

A key emerging trend is the integration of smart technology into load securement. By 2026, early adopters may begin using endless tie-down straps embedded with strain sensors or RFID tags to monitor tension in real time. This data can be fed into fleet management systems, improving safety, reducing inspection times, and enabling predictive maintenance. -

Expansion in Emerging Markets

Growth in infrastructure development across Asia-Pacific, Latin America, and Africa is stimulating demand for durable and cost-effective cargo control solutions. Endless tie-down straps are gaining traction in these regions due to their reusability and lower total cost of ownership. Local manufacturing and distribution partnerships are likely to expand to meet regional standards and reduce lead times. -

Sustainability and Circular Economy Initiatives

Environmental concerns are pushing companies to adopt reusable and recyclable tie-down solutions. Endless straps, with fewer components and reduced wear points, generate less waste. By 2026, leading suppliers may introduce take-back programs or recycled-content straps to align with corporate sustainability targets.

In conclusion, the 2026 market for endless tie-down straps is expected to be shaped by technological innovation, regulatory pressures, and a shift toward smarter, safer, and more sustainable cargo securement. Companies that invest in advanced materials, compliance, and digital integration will be well-positioned to capture growing market share.

Common Pitfalls When Sourcing Endless Tie Down Straps (Quality & Intellectual Property)

Sourcing endless tie-down straps—continuous loop straps used in cargo securement—requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to safety risks, compliance issues, and legal liabilities. Here are key pitfalls to avoid:

Poor Material Quality and Construction

Many low-cost suppliers use substandard polyester webbing that degrades quickly under UV exposure, moisture, or heavy loads. Inferior stitching or weak loop joints compromise the strap’s integrity, increasing the risk of failure during transport. Always verify material specifications (e.g., breaking strength, UV resistance) and request test certifications such as those from WSTDA or EN standards.

Inaccurate Load Rating Claims

Some manufacturers exaggerate working load limits (WLL) or break strength ratings beyond what the materials can safely support. This misrepresentation endangers users and violates transportation safety regulations. Validate claims with third-party lab test reports and ensure compliance with industry standards like FMVSS 108 or ECE R17.

Lack of Traceability and Compliance Documentation

Reputable suppliers provide lot traceability, mill certifications, and compliance documentation (e.g., ISO 9001, OSHA, DOT). Sourcing from vendors without these documents increases the risk of receiving non-compliant or counterfeit products, especially in regulated industries.

Ignoring Intellectual Property Rights

Endless tie-down strap designs—particularly patented closure systems, weave patterns, or proprietary webbing treatments—may be protected by patents or trademarks. Sourcing generic versions that closely mimic branded products (e.g., those resembling established brands like MacGregor or Gunnebo) can expose your company to IP infringement lawsuits. Conduct due diligence to ensure designs do not violate existing patents.

Unverified Manufacturing Origins

Suppliers may claim production in a specific country for compliance or quality perception, but final assembly or material sourcing may occur elsewhere. Hidden supply chain layers can introduce quality inconsistencies or expose your business to customs penalties if origin misrepresentation violates trade regulations (e.g., anti-dumping measures).

Overlooking Customization Risks

When customizing straps with logos or dimensions, confirm that design modifications don’t inadvertently infringe on existing IP. Additionally, ensure that custom tooling or molds remain your property or are properly licensed to avoid future disputes.

Failure to Audit Suppliers

Relying solely on product samples without auditing the manufacturer’s facility increases the risk of inconsistent quality. On-site audits help verify production capabilities, quality control processes, and adherence to ethical labor practices.

By addressing these pitfalls proactively—through rigorous supplier vetting, IP clearance, and quality validation—you can ensure the safe, compliant, and legally secure procurement of endless tie-down straps.

Logistics & Compliance Guide for Endless Tie Down Straps

This guide outlines key logistics considerations and compliance requirements for the transportation, storage, and use of Endless Tie Down Straps. Ensuring proper handling and adherence to regulations helps maintain product integrity, worker safety, and regulatory compliance across supply chains.

Product Overview

Endless Tie Down Straps are continuous loops of high-strength webbing, typically made from polyester or nylon, used to secure cargo during transport. Unlike traditional ratchet straps, they have no metal hardware, making them ideal for sensitive loads and applications requiring even tension distribution. They are commonly used in aviation, military, manufacturing, and heavy equipment transport.

Packaging & Labeling Requirements

Proper packaging ensures product protection and facilitates compliance:

- Standard Packaging: Straps should be coiled and secured with non-abrasive ties, then placed in durable polybags or shrink-wrapped bundles. Bulk shipments may require cartons or pallets.

- Labeling: Each package must include:

- Manufacturer name and part number

- Webbing material (e.g., 100% Polyester)

- Working Load Limit (WLL) and Minimum Break Strength (MBL)

- Compliance markings (e.g., WSTDA, DOT, or military specs if applicable)

- Care and inspection instructions

- Hazard Communication: While non-hazardous, labels should include safe handling instructions and warnings against exposure to UV, chemicals, or high temperatures.

Storage Conditions

To preserve strap integrity and performance:

- Environment: Store in a cool, dry, and well-ventilated area away from direct sunlight and ozone sources (e.g., motors, welding equipment).

- Temperature Range: Maintain between 40°F (4°C) and 100°F (38°C).

- Moisture: Keep dry. Wet straps must be air-dried completely before storage.

- Chemical Exposure: Avoid contact with acids, alkalis, solvents, and oil-based substances.

- Pest Control: Store off the floor on pallets or shelves to prevent rodent damage.

Transportation Guidelines

Ensure safe and compliant shipping:

- Domestic (U.S.): Comply with FMCSA and DOT regulations for cargo securement (49 CFR Part 393, Subpart I). While straps themselves are not regulated, their use in securing loads is.

- International: Follow IATA (air), IMDG (sea), or ADR (road in Europe) as applicable. Endless straps are generally non-regulated goods but must be declared with accurate HS codes (e.g., 6307.90.9989 for other made-up textile articles).

- Palletization: Secure bundles on pallets using stretch wrap or banding. Avoid over-compression to prevent webbing deformation.

- Documentation: Include commercial invoice, packing list, and certificates of compliance (e.g., ISO 9001, WSTDA-1) if required by customer or jurisdiction.

Compliance & Certification Standards

Endless Tie Down Straps must meet industry-specific standards:

- WSTDA (Web Sling & Tie Down Association): WSTDA-TDC-1 outlines testing, marking, and inspection protocols for tie-downs.

- FMCSA / DOT: Requires securement systems to have sufficient WLL to prevent cargo shift. Each strap’s WLL must be clearly marked.

- OSHA: Mandates regular inspection and removal of damaged slings (29 CFR 1910.184).

- Military Specifications: MIL-STD-3010 or MIL-T-44046 may apply for government contracts.

- ISO Certification: Manufacturers should maintain ISO 9001 for quality management.

Inspection & Maintenance Protocols

Regular inspection ensures ongoing safety and compliance:

- Pre-Use Inspection: Check for cuts, abrasions, burns, UV degradation, mold, or chemical damage.

- Frequency: Inspect before each use. Formal documented inspections every 6–12 months, depending on usage.

- Retirement Criteria: Remove from service if:

- Webbing shows visible damage or elongation

- WLL label is illegible

- Exposure to temperatures above 180°F (82°C)

- Cleaning: Wash with mild soap and water only. Air dry away from heat sources.

Training & Handling Procedures

- User Training: Personnel must be trained per OSHA and company safety policies on proper use, inspection, and load securement techniques.

- Load Matching: Ensure strap WLL meets or exceeds the required securement force per DOT guidelines (e.g., 50% of cargo weight forward, 50% rearward, 50% sideways).

- Avoid Twisting: Use straps flat and untwisted to maintain rated strength.

- No Modifications: Never splice, repair, or alter straps in the field.

Disposal & Sustainability

- End-of-Life: Cut into pieces to prevent reuse and dispose of per local regulations. Incineration or landfilling may be required.

- Recycling: Polyester straps may be recyclable through specialized textile recyclers. Confirm with local facilities.

- Sustainability: Choose suppliers with environmental management systems (e.g., ISO 14001) and sustainable sourcing practices.

Summary

Adhering to this logistics and compliance guide ensures Endless Tie Down Straps remain safe, effective, and regulatory-compliant throughout their lifecycle. From proper storage and transport to routine inspection and disposal, each step plays a vital role in maintaining operational safety and meeting industry standards. Always consult manufacturer specifications and applicable regulations for your region and application.

Conclusion for Sourcing Endless Tie-Down Straps

In conclusion, sourcing endless tie-down straps requires a strategic approach that balances quality, durability, cost-efficiency, and supplier reliability. These heavy-duty, seamless straps are essential for secure load containment in transportation and logistics, and their continuous loop design offers superior strength and resistance to wear compared to traditional tie-downs with metal fittings.

When sourcing, it is crucial to prioritize manufacturers or suppliers that use high-quality, UV-resistant polyester webbing and adhere to industry safety standards such as WLL (Working Load Limit) and break strength certifications. Evaluating supplier reputation, production capacity, and compliance with regulations like the FMCSA ensures consistent product reliability and legal compliance.

Additionally, considering factors such as custom sizing, color coding for easy identification, and weather resistance can enhance operational efficiency. Establishing long-term partnerships with reputable suppliers not only ensures supply chain stability but may also lead to cost savings through bulk purchasing and improved lead times.

Ultimately, investing in high-performance endless tie-down straps from trusted sources contributes to safer cargo transport, reduced material replacement costs, and enhanced overall logistics efficiency. A well-considered sourcing strategy will support both operational excellence and compliance in demanding transportation environments.