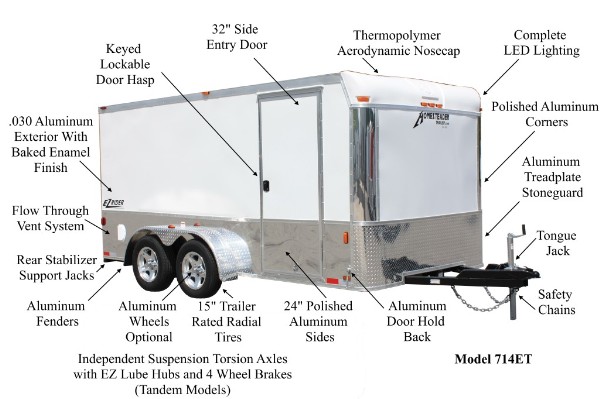

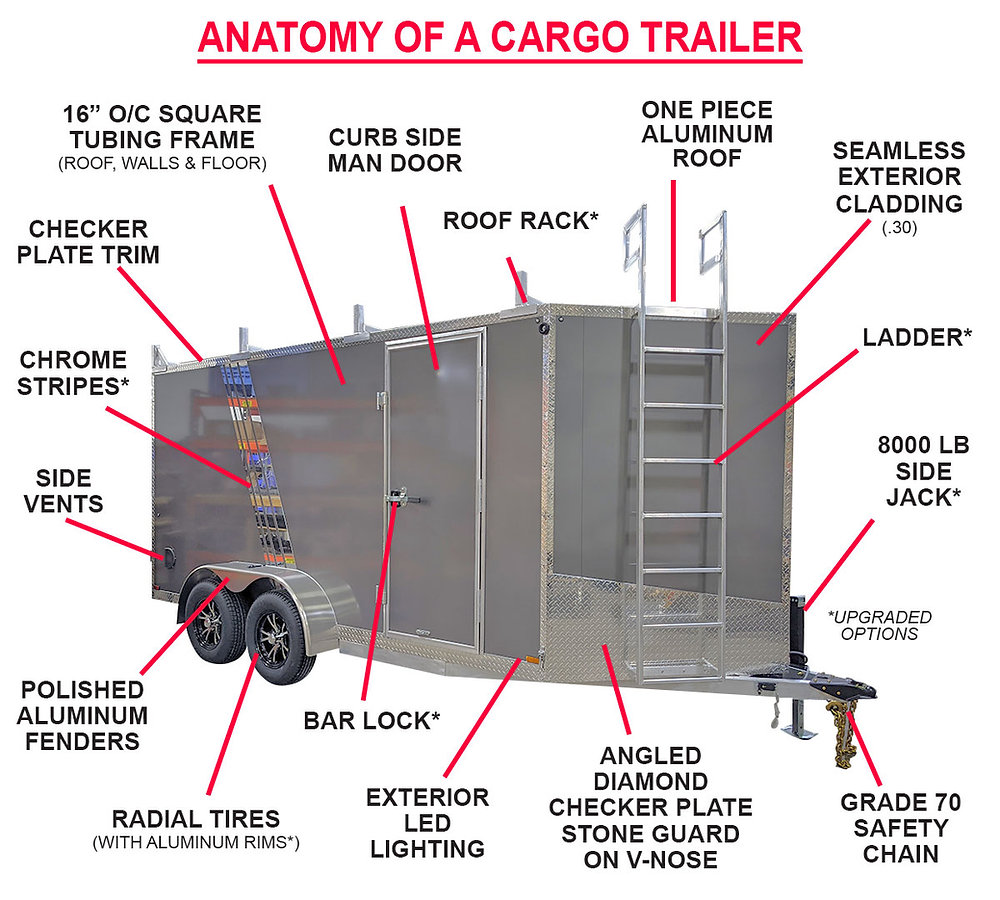

The global enclosed trailers market is experiencing steady expansion, driven by rising demand across construction, manufacturing, and recreational sectors. According to a report by Mordor Intelligence, the trailer market—encompassing enclosed, utility, and specialty units—is projected to grow at a CAGR of approximately 4.8% from 2023 to 2028. This growth is fueled by increasing e-commerce logistics needs, infrastructure development, and the expansion of mobile service businesses requiring durable, weather-protected hauling solutions. As the demand for high-performance trailers rises, so does the need for reliable, high-quality components—from axles and brakes to lighting systems and aluminum siding. The success of any enclosed trailer hinges on the performance and durability of its parts, making manufacturers who specialize in precision-engineered components critical to the sector’s supply chain. The following list highlights nine leading enclosed trailer parts manufacturers positioned at the forefront of innovation, quality, and market reach.

Top 9 Enclosed Trailers Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Parts

Domain Est. 1998

Website: interstatetrailers.com

Key Highlights: Interstate Trailers stocks a full line of premium trailer parts and accessories. Wheels & tires, oak decking, OE wiring, DOT approved lighting, brakes, hitches,…

#2

Domain Est. 2005

Website: alcomusa.com

Key Highlights: ALCOM Trailers, the leading aluminum trailer manufacturer in the USA, proudly builds lightweight, long lasting open and enclosed trailers for every hauling need…

#3 Leading Manufacturer of Highly Engineered Components and …

Domain Est. 2018

Website: dexterindex.com

Key Highlights: Trailer Parts Pro, exclusive to Dexter Distribution, is the leading brand of aftermarket packaged trailer products. Spruce up any showroom or parts store with ……

#4 Haulmark

Domain Est. 1995

Website: haulmark.com

Key Highlights: Your 1-Stop Shop for Genuine Haulmark Parts! Whether you’re looking to customize your trailer with a flash, add some cargo control systems or just need a ……

#5 US Cargo Trailers

Domain Est. 1996

Website: uscargo.com

Key Highlights: US Cargo builds a wide range of high-quality cargo trailers, landscaping trailers, car haulers, snowmobile trailers, as well as specialty and commercial ……

#6 Cargo Express

Domain Est. 1997

Website: cargoexpress.com

Key Highlights: Shop enclosed cargo trailers built for durability, function, and day-to-day hauling. Find your trailer and request a quote today….

#7 Interstate Trailers

Domain Est. 2001

Website: interstatecargo.com

Key Highlights: We manufacture a variety of enclosed cargo trailers. From 4 feet to 8.5 feet wide. Quality, durability and functionality to perform beyond your expections….

#8 LOOK® Trailers

Domain Est. 2010

Website: looktrailers.com

Key Highlights: Built for durability and versatility, our enclosed cargo trailers are designed to keep your gear safe on every journey, from daily tasks to weekend getaways….

#9 Anvil Trailer. Your for the World’s Finest Cargo Trailer

Domain Est. 2023

Website: therealanviltrailer.com

Key Highlights: Anvil Trailer builds the World’s Finest Cargo Trailers. We build Standard, Goosenecks, and Stackers. Over 150 Dealers Nationwide. Find a Dealer Near You….

Expert Sourcing Insights for Enclosed Trailers Parts

2026 Market Trends for Enclosed Trailer Parts

The enclosed trailer parts market is poised for notable evolution by 2026, shaped by technological advancements, shifting consumer demands, and broader economic and regulatory influences. Understanding these trends is critical for manufacturers, distributors, and service providers aiming to maintain competitiveness and capitalize on emerging opportunities.

Rising Demand Driven by E-Commerce and Last-Mile Delivery

The continued expansion of e-commerce and the intensification of last-mile delivery services will significantly boost demand for enclosed trailers, particularly cargo and specialty transport variants. As logistics companies seek secure, weather-protected solutions for high-value goods and perishables, the need for durable, reliable trailer components—including axles, suspension systems, lighting, and secure door hardware—will grow. This trend will drive innovation in lightweight yet robust materials to improve fuel efficiency and payload capacity.

Technological Integration and Smart Components

By 2026, smart technology integration will increasingly influence enclosed trailer parts. Expect wider adoption of IoT-enabled sensors for real-time monitoring of tire pressure, brake health, and cargo security. Components such as smart axles, telematics-ready lighting systems, and digitally enhanced suspension setups will become more commonplace, especially in commercial fleets seeking to reduce downtime and improve operational efficiency through predictive maintenance.

Focus on Lightweight and Sustainable Materials

Environmental regulations and fuel economy concerns will accelerate the shift toward lightweight, high-strength materials such as aluminum alloys, advanced composites, and high-tensile steel. These materials reduce overall trailer weight, allowing for greater payload without exceeding legal limits, while also lowering emissions. The demand for recyclable and eco-friendly components will influence manufacturing processes and supply chain decisions.

Customization and Modular Design

End-users—ranging from contractors and event organizers to mobile businesses—will increasingly demand customization in enclosed trailers. This trend will drive growth in modular and interchangeable parts, such as configurable interior wall systems, retractable ramps, and adaptable flooring solutions. Manufacturers offering customizable kits and upgradeable components will gain a competitive edge in a fragmented and niche-driven market.

Supply Chain Resilience and Local Sourcing

Ongoing global supply chain volatility will push OEMs and aftermarket suppliers to strengthen domestic sourcing and inventory resilience. By 2026, companies investing in localized production of critical parts—such as frames, doors, and electrical systems—will be better positioned to meet demand and reduce lead times. This shift could lead to regional manufacturing hubs and stronger partnerships with local suppliers.

Growth in the Aftermarket and DIY Sector

The aging fleet of existing enclosed trailers will support robust growth in the aftermarket parts segment. Consumers and small businesses performing their own maintenance will drive demand for affordable, high-quality replacement parts, including LED lighting, roof vents, hinges, and flooring materials. Online sales platforms and enhanced technical support (e.g., video guides, compatibility tools) will be essential for capturing this segment.

Regulatory and Safety Standards Evolution

Safety standards, particularly regarding braking systems, lighting visibility, and structural integrity, will continue to tighten in North America and Europe. Compliance with FMVSS (Federal Motor Vehicle Safety Standards) and similar regulations will necessitate upgrades in parts such as electric-over-hydraulic (EOH) brakes and compliant reflectors. Proactive adaptation to these standards will differentiate compliant and trustworthy brands.

Conclusion

The 2026 outlook for the enclosed trailer parts market is characterized by innovation, sustainability, and responsiveness to logistical and technological shifts. Success will depend on embracing smart technologies, prioritizing material efficiency, and offering flexible, customer-centric solutions across both OEM and aftermarket channels. Companies that anticipate these trends and align their product development and supply strategies accordingly will be best positioned for sustained growth.

Common Pitfalls Sourcing Enclosed Trailer Parts (Quality, IP)

Sourcing parts for enclosed trailers—whether for manufacturing, repair, or resale—comes with several risks, particularly concerning quality and intellectual property (IP). Overlooking these pitfalls can lead to performance issues, safety hazards, legal disputes, and reputational damage. Below are key challenges to watch for:

Quality Consistency and Material Integrity

One of the most frequent issues when sourcing trailer parts is inconsistent quality across suppliers. Components like axles, brakes, lighting systems, and structural framing must meet strict safety and durability standards. Low-cost suppliers may cut corners by using substandard materials (e.g., thinner gauge steel, inferior welds), leading to premature failure, safety risks, or non-compliance with DOT or other regulatory requirements.

Lack of Certifications and Compliance Documentation

Many suppliers, especially overseas or non-specialized vendors, fail to provide proof of compliance with industry standards such as ISO, DOT, or SAE. Without proper documentation, it’s difficult to verify that parts meet required safety and performance benchmarks. This can result in rejected shipments, regulatory fines, or liability in case of accidents caused by faulty components.

Counterfeit or Non-OEM Parts Misrepresented as Genuine

A significant risk in the trailer parts market is the sale of counterfeit or imitation parts labeled as original equipment manufacturer (OEM) products. These parts often mimic branding and packaging but lack the engineering, materials, or testing of authentic components. Using such parts can void warranties, compromise trailer integrity, and expose buyers to legal and safety liabilities.

Intellectual Property Infringement

Sourcing parts that replicate patented designs, trademarks, or proprietary technology—especially common with specialized components like suspension systems or custom door mechanisms—can lead to IP violations. Even unintentional use of infringing parts may result in cease-and-desist letters, litigation, or customs seizures, particularly when importing from regions with weak IP enforcement.

Poor Fit and Interchangeability Issues

Not all “compatible” parts are truly interchangeable. Dimensions, mounting configurations, or electrical specifications may vary slightly between manufacturers, leading to installation difficulties or operational flaws. Relying on generic or untested replacements without proper fitment verification can increase labor costs and downtime.

Inadequate Supplier Vetting and Traceability

Failing to conduct due diligence on suppliers—such as site audits, sample testing, or background checks—increases exposure to unreliable vendors. Without traceability (e.g., batch numbers, material certifications), it becomes nearly impossible to address quality issues or recalls effectively.

Hidden Costs from Rework and Downtime

Low initial part prices can be misleading. Poor-quality components often require rework, replacement, or lead to trailer downtime, inflating long-term costs. Additionally, handling warranty claims with disreputable suppliers can be time-consuming and unrewarding.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Require material certifications and compliance documentation.

– Source from reputable, vetted suppliers with industry experience.

– Conduct sample testing and on-site audits when possible.

– Verify authenticity of OEM parts through authorized distributors.

– Consult legal counsel when using parts with potential IP concerns.

– Maintain traceability and detailed procurement records.

Proactive risk management in sourcing ensures not only reliable trailer performance but also legal and operational safety.

Logistics & Compliance Guide for Enclosed Trailer Parts

Transporting and handling enclosed trailer parts involves navigating a complex network of logistical considerations and regulatory requirements. This guide outlines key aspects to ensure smooth, compliant operations across the supply chain.

Supply Chain Coordination

Effective logistics begins with seamless coordination between suppliers, manufacturers, distributors, and end customers. Establish clear communication channels and use integrated inventory management systems to track part availability, order fulfillment, and delivery timelines. Standardize part numbering and packaging specifications to minimize errors and improve handling efficiency across all touchpoints.

Packaging & Handling Standards

Enclosed trailer parts—ranging from structural components to electrical systems—require protective packaging to prevent damage during transit. Use moisture-resistant materials, secure crating for fragile items (e.g., windows, lighting), and cushioning for metal components to prevent scratching or warping. Clearly label packages with part numbers, handling instructions (e.g., “Fragile,” “Do Not Stack”), and shipment identifiers to ensure proper treatment throughout the distribution process.

Domestic & International Shipping Regulations

When shipping domestically, comply with Department of Transportation (DOT) regulations regarding weight limits, load securement, and hazardous materials (if applicable, e.g., batteries or adhesives). For international shipments, adhere to International Maritime Organization (IMO) standards and International Air Transport Association (IATA) rules where relevant. Ensure accurate Harmonized System (HS) codes are used for customs declarations, and provide complete commercial invoices, packing lists, and certificates of origin to prevent delays.

Import/Export Compliance

Importing or exporting enclosed trailer parts requires adherence to customs regulations in both origin and destination countries. Verify that parts meet regional safety and environmental standards (e.g., CE marking in the EU, DOT or FMVSS compliance in the U.S.). Maintain records of compliance documentation, including product specifications, test reports, and conformity certificates. Utilize licensed customs brokers to facilitate clearance and ensure adherence to trade agreements and tariffs.

Inventory Management & Warehousing

Maintain organized warehouse operations with designated storage zones based on part type, size, and turnover rate. Implement a first-in, first-out (FIFO) system for components with shelf-life considerations (e.g., seals, adhesives). Use barcode or RFID tracking systems for real-time inventory visibility and to reduce picking errors. Ensure storage areas are climate-controlled if necessary to protect sensitive materials from humidity or temperature extremes.

Regulatory Compliance for Specific Components

Certain trailer parts are subject to additional regulations:

– Lighting & Electrical Systems: Must comply with FMVSS 108 (U.S.) or equivalent international standards. Certification documentation should accompany shipments.

– Braking Systems: Subject to FMVSS 121 requirements; documentation proving compliance is essential for commercial trailer parts.

– Tires & Wheels: Must meet DOT or ECE safety standards, with proper markings and certification.

– Tie-Downs & Load Securement Equipment: Should comply with WSTDA or DOT performance standards.

Environmental & Safety Considerations

Handle and dispose of packaging materials in accordance with local environmental regulations. Recycle cardboard, plastic, and metal packaging where feasible. Train staff in safe handling practices to prevent workplace injuries, especially when moving heavy or sharp components. Maintain Material Safety Data Sheets (MSDS/SDS) for any hazardous substances used in part manufacturing or packaging.

Documentation & Recordkeeping

Maintain comprehensive records for all shipments, including:

– Bills of Lading

– Customs documentation

– Certificates of Compliance

– Quality inspection reports

– Proof of delivery

Retention periods should align with industry standards and regulatory requirements (typically 5–7 years) to support audits, warranty claims, and compliance verification.

Continuous Improvement & Audits

Regularly audit logistics processes and compliance procedures to identify inefficiencies or gaps. Stay updated on changes in transportation laws, trade policies, and safety standards. Invest in staff training and technology upgrades to enhance accuracy, reduce lead times, and maintain a compliant, resilient supply chain for enclosed trailer parts.

Conclusion for Sourcing Enclosed Trailer Parts

Sourcing enclosed trailer parts requires a strategic approach that balances quality, cost, availability, and compatibility. After evaluating various suppliers, materials, and component specifications, it is clear that reliable sourcing hinges on establishing relationships with reputable manufacturers and distributors who offer durable, industry-standard components. Whether replacing structural elements, electrical systems, doors, ramps, or interior accessories, prioritizing OEM or high-quality aftermarket parts ensures longevity, safety, and optimal trailer performance.

Additionally, considering factors such as shipping times, warranty options, and technical support can significantly impact overall efficiency and reduce downtime. Utilizing online marketplaces, specialty trailer supply stores, and direct manufacturer channels offers flexibility and competitive pricing. Ultimately, a well-informed sourcing strategy not only maintains trailer integrity but also supports operational reliability and cost-effectiveness in the long term. Regular assessment of market trends and part innovations will further enhance sourcing decisions, ensuring trailers remain in peak condition for their intended applications.