The global gauges market is experiencing robust growth, driven by rising demand for precision measurement devices across industries such as automotive, manufacturing, HVAC, and oil & gas. According to Mordor Intelligence, the global pressure gauges market size was valued at USD 1.92 billion in 2023 and is projected to expand at a CAGR of 4.8% from 2024 to 2029. This growth is fueled by increasing industrial automation, stringent regulatory standards for equipment safety, and the need for real-time monitoring in critical applications. Within this expanding landscape, Elitech—known for its advanced digital monitoring solutions—has emerged as a key player, partnering with high-precision gauge manufacturers to deliver reliable, technologically integrated instruments. As demand for smart, durable, and accurate gauging systems rises, three elite manufacturers have distinguished themselves through innovation, quality, and global reach, setting the benchmark in the digital gauges sector.

Top 3 Elitech Gauges Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

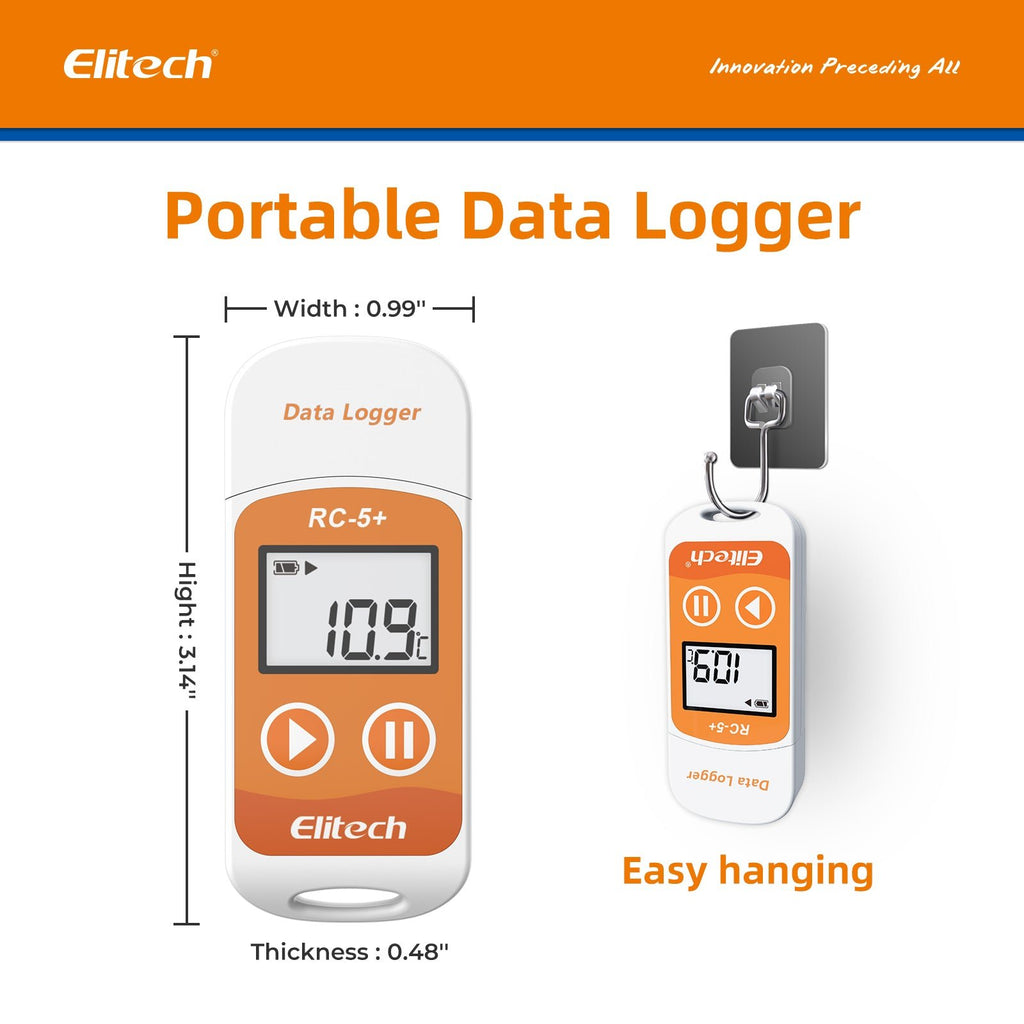

#1 Temperature Data Logger, HVAC Tools, Air Quality Monitor …

Domain Est. 2020 | Founded: 1996

Website: elitecheu.com

Key Highlights: Since 1996, Elitech Technology has been manufacturing measurement instruments in cold chain management and environment monitoring, such as temperature data ……

#2 Elitech HVAC Tools, Make HVAC Technician Work Faster and Easier

Domain Est. 2015

Website: elitechus.com

Key Highlights: Free delivery 30-day returnsElitech HVAC digital Tools are the most convenient and price-friendly you will find in the refrigeration field. 26 years of experience working with many…

#3 Elitech cold chain, HVACR, refrigeration system control, air quality …

Domain Est. 2020

Website: elitechglobal.com

Key Highlights: Elitech is a global company specializing in the R&D and manufacturing of instruments and control systems. We focus on core technologies including temperature ……

Expert Sourcing Insights for Elitech Gauges

H2: Market Trends Shaping Elitech Gauges in 2026

By 2026, the market for Elitech gauges—known for their portable digital thermometers, data loggers, and temperature/humidity monitoring solutions—is poised for significant evolution driven by technological advancements, regulatory shifts, and growing demand for precision monitoring across key industries. Here are the dominant trends expected to shape Elitech’s market position and strategy:

1. Expansion in Cold Chain and Pharmaceutical Logistics

The global demand for temperature-sensitive pharmaceuticals, including biologics, mRNA vaccines, and cell therapies, continues to grow. By 2026, strict regulatory requirements (e.g., FDA, EU GDP, WHO guidelines) will mandate end-to-end visibility in cold chain logistics. Elitech’s data loggers and wireless monitoring systems will be critical for compliance, driving demand in pharma distribution, clinical trials, and vaccine storage. The trend favors compact, high-accuracy devices with long battery life and cloud integration—areas where Elitech has a competitive edge.

2. IoT and Cloud-Based Monitoring Integration

The Internet of Things (IoT) will be deeply embedded in environmental monitoring by 2026. Elitech is likely to expand its ecosystem of Wi-Fi and Bluetooth-enabled gauges that sync with cloud platforms for real-time alerts, remote access, and automated reporting. Users across food safety, healthcare, and laboratories will increasingly expect seamless integration with enterprise systems (e.g., ERP, LIMS), pushing Elitech to enhance API capabilities and cybersecurity features.

3. Sustainability and Energy Efficiency Focus

With rising energy costs and ESG (Environmental, Social, Governance) pressures, businesses will optimize refrigeration and HVAC systems to reduce waste and carbon footprints. Elitech’s temperature and humidity gauges will play a role in monitoring and improving energy efficiency in cold storage, greenhouses, and clean rooms. Devices with low power consumption, recyclable materials, and solar-compatible options may become differentiators.

4. Growth in Food Safety and Precision Agriculture

Global food safety standards (e.g., FSMA, HACCP) will tighten further, increasing the need for continuous monitoring in food processing, storage, and transport. Elitech’s waterproof, durable gauges are well-positioned for this market. Additionally, precision agriculture—using climate data for greenhouse management and livestock monitoring—will drive demand for affordable, multi-sensor devices, especially in emerging markets.

5. Regional Market Diversification and Localization

By 2026, Elitech is expected to deepen its presence in Asia-Pacific, Latin America, and Africa, where infrastructure development and regulatory modernization create opportunities. Success will depend on localized product variants (e.g., multilingual interfaces, region-specific calibration), compliance with local standards (e.g., INMETRO, BIS), and partnerships with regional distributors.

6. Competitive Pressure and Differentiation Challenges

The market will see increased competition from both established players (like Testo, Fluke) and low-cost manufacturers. To maintain its position, Elitech must emphasize product reliability, user-friendly software, responsive technical support, and value-added services such as calibration certifications and data analytics tools.

Conclusion

In 2026, Elitech gauges will benefit from rising demand for traceability, automation, and compliance across healthcare, food, and industrial sectors. Success will hinge on embracing IoT connectivity, enhancing software ecosystems, and adapting to regional and sustainability-driven requirements. By focusing on innovation and customer-centric solutions, Elitech can strengthen its foothold as a trusted provider of environmental monitoring technology.

Common Pitfalls Sourcing Elitech Gauges (Quality, IP)

Sourcing Elitech gauges—particularly temperature and humidity data loggers and controllers—can present several challenges related to quality assurance and intellectual property (IP) protection. Being aware of these pitfalls helps ensure reliable performance and legal compliance.

Quality Inconsistencies Due to Counterfeit or Gray Market Products

One of the most significant risks when sourcing Elitech gauges is encountering counterfeit or unauthorized copies. These products may mimic the appearance of genuine Elitech devices but often use inferior components, leading to inaccurate readings, reduced durability, and potential failure in critical monitoring applications. Purchasing from unauthorized distributors or third-party marketplaces increases the likelihood of receiving substandard units that do not meet Elitech’s original specifications or calibration standards.

Lack of Warranty and Technical Support

Gauges sourced through unofficial channels may not be covered under Elitech’s official warranty. This means users lose access to manufacturer support, firmware updates, and repair services. In regulated environments such as pharmaceuticals or food storage, the absence of verifiable support and calibration documentation can compromise compliance with industry standards like FDA 21 CFR Part 11 or HACCP requirements.

IP Infringement Risks from Cloned Firmware or Design

Elitech holds intellectual property rights over its hardware designs, software interfaces, and firmware. Unauthorized manufacturers often clone Elitech devices, replicating both hardware and software elements without permission. Sourcing from such suppliers not only supports IP infringement but may expose the buyer to legal risks, especially in regions with strict enforcement of IP laws. Additionally, cloned firmware may contain security vulnerabilities or lack critical features found in authentic Elitech software.

Inaccurate IP Ratings and Environmental Protection Claims

Many Elitech gauges are marketed with specific Ingress Protection (IP) ratings (e.g., IP65, IP67), indicating their resistance to dust and water. Counterfeit or low-quality replicas often falsely claim these ratings without undergoing proper testing. This misrepresentation can lead to equipment failure in harsh environments, risking data loss or safety issues in field applications.

Supply Chain Transparency and Traceability Issues

Without sourcing through authorized partners, traceability of the product’s origin becomes difficult. This lack of transparency makes it hard to verify batch numbers, production dates, or compliance with regional safety certifications (such as CE, RoHS, or FCC). In regulated industries, this can hinder audit readiness and compromise product validation processes.

Conclusion

To avoid these pitfalls, always procure Elitech gauges through authorized distributors or directly from Elitech. Verify product authenticity with serial numbers, original packaging, and official documentation. Ensuring legitimate sourcing protects both product quality and your organization’s compliance posture.

Logistics & Compliance Guide for Elitech Gauges

This guide outlines essential logistics and compliance considerations when shipping, handling, and using Elitech temperature monitoring devices (gauges/data loggers) globally. Adherence ensures product integrity, regulatory compliance, and customer satisfaction.

Product Classification & Documentation

- Harmonized System (HS) Code: Identify the correct HS code for Elitech gauges (e.g., 9025.19 or 8543.70, depending on model and functionality) to ensure accurate customs declaration and tariff assessment. Confirm with local customs authorities.

- Commercial Invoice: Provide a detailed commercial invoice including:

- Full product description (e.g., “Elitech RC-4HC Data Logger with LCD Display”)

- Model number and quantity

- Unit and total value (in USD or local currency)

- Country of origin (typically China)

- Reason for export (e.g., sale, sample, return)

- Packing List: Include a comprehensive packing list matching the shipment contents, box quantities, weights, and dimensions.

- Certificate of Conformity (CoC): Supply a CoC confirming compliance with relevant international standards (e.g., CE, RoHS, FCC) as applicable.

Regulatory Compliance

- CE Marking: Required for shipment to European Economic Area (EEA) countries. Elitech gauges must comply with:

- EMC Directive (2014/30/EU): Electromagnetic compatibility

- RoHS Directive (2011/65/EU): Restriction of hazardous substances

- RED (Radio Equipment Directive 2014/53/EU) if the device has wireless functionality (e.g., Bluetooth, Wi-Fi)

- FCC Certification: Mandatory for sale and operation in the United States. Devices with radio emissions (e.g., RC-4 series with Bluetooth) must meet FCC Part 15 rules.

- UKCA Marking: Required for the UK market post-Brexit. Follow UK-specific conformity assessment procedures.

- Other Regional Certifications: Check requirements for target markets (e.g., IC for Canada, KC for South Korea, PSE for Japan).

Shipping & Handling

- Packaging: Use original or equivalent protective packaging to prevent damage during transit. Include cushioning material and secure the device to avoid movement.

- Battery Safety (IATA/IMDG):

- Elitech gauges contain lithium coin or polymer batteries.

- Comply with IATA Dangerous Goods Regulations (DGR) for air freight or IMDG Code for sea freight.

- Typically shipped as “UN3481, Lithium ion batteries contained in equipment” or “UN3091, Lithium metal batteries contained in equipment”.

- Ensure packages are marked, labeled, and documented accordingly (Shipper’s Declaration may be required for larger shipments).

- Temperature Sensitivity: While designed for temperature monitoring, avoid exposing devices to extreme conditions (e.g., freezing or >60°C) during storage and transit to preserve battery life and sensor accuracy.

Import & Customs Clearance

- Import Duties & Taxes: Inform customers of potential import duties, VAT, or GST based on destination country regulations. Use Incoterms (e.g., DDP, DAP, EXW) clearly in contracts.

- Local Regulations: Some countries require additional documentation (e.g., SABER in Saudi Arabia, SONCAP in Nigeria). Verify prior to shipment.

- Restricted End-Use: Ensure gauges are not shipped to embargoed countries or for prohibited uses without proper licensing.

Calibration & Traceability

- NIST Traceable Calibration: Offer NIST-traceable calibration certificates upon request for applications requiring regulatory validation (e.g., pharmaceuticals, food safety).

- Calibration Records: Maintain records of calibration dates and results for audit and compliance purposes.

End-of-Life & Environmental Compliance

- WEEE Directive (EU): Inform EU customers of proper disposal methods. Elitech gauges fall under category 6 (monitoring and control instruments). Encourage use of certified e-waste recyclers.

- Battery Disposal: Advise users to follow local regulations for lithium battery disposal; do not dispose of in household waste.

Quality & Recordkeeping

- Batch/Serial Number Tracking: Maintain logs of serial numbers for traceability in case of recalls or compliance audits.

- Complaint Handling: Establish a process to document and investigate customer-reported compliance or performance issues.

Always consult with logistics partners and legal experts to ensure full compliance with evolving international trade and safety regulations.

Conclusion for Sourcing Elitech Gauges

After a thorough evaluation of suppliers, product specifications, pricing, reliability, and support services, sourcing Elitech gauges presents a strategic advantage for ensuring accurate temperature and humidity monitoring across cold chain, laboratory, pharmaceutical, and food storage applications. Elitech’s reputation for manufacturing high-quality, durable, and precise digital monitoring devices—combined with competitive pricing, wide product availability, and strong technical support—makes them a reliable choice for long-term partnerships.

Key factors supporting the decision to source Elitech gauges include:

- Product Reliability and Accuracy: Elitech gauges are known for consistent performance under varying environmental conditions.

- Range of Options: From basic thermometers to data-logging devices with cloud connectivity, Elitech offers scalable solutions for diverse operational needs.

- Compliance Support: Many models meet regulatory standards (e.g., FDA, HACCP, CE), which is critical for industries requiring traceability and audit readiness.

- Cost-Effectiveness: Competitive pricing without compromising quality improves ROI, especially for large-scale deployments.

- After-Sales Support and Warranty: Availability of technical support, calibration services, and warranty programs reduces downtime and maintenance costs.

In conclusion, sourcing Elitech gauges aligns with operational efficiency, regulatory compliance, and long-term cost savings. Establishing a formal procurement relationship with authorized Elitech distributors or directly with the manufacturer is recommended to ensure authenticity, timely delivery, and access to updates and support. This partnership will enhance monitoring capabilities and contribute to improved quality control across critical processes.