The global electronic soldering flux market is experiencing robust growth, driven by rising demand for compact and high-performance electronics, expansion in the automotive and telecommunications sectors, and the increasing adoption of surface mount technology (SMT) in manufacturing. According to a report by Mordor Intelligence, the global electronic chemicals and materials market—of which soldering flux is a critical component—is projected to grow at a CAGR of over 6.5% from 2023 to 2028. Similarly, Grand View Research estimates that the global soldering materials market size was valued at USD 2.9 billion in 2022 and is expected to expand at a CAGR of 6.8% from 2023 to 2030, fueled by advancements in miniaturized electronics and the proliferation of 5G infrastructure. As reliability and precision in electronic assembly become increasingly vital, the role of high-performance fluxes in ensuring durable solder joints has never been more critical. In this evolving landscape, a select group of manufacturers are leading innovation in flux formulation, environmental compliance, and application-specific solutions. Below is a data-driven ranking of the top 10 electronic soldering flux manufacturers shaping the industry today.

Top 10 Electronic Soldering Flux Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 SMIC Senju Metal Industry Co., Ltd.

Domain Est. 1997

Website: senju.com

Key Highlights: This is the official web page of Senju Metal Industry Co., Ltd. With soldering materials, factory automation equipment, and slide bearings as our mainstay ……

#2 Interflux Electronics

Domain Est. 1996

Website: interflux.com

Key Highlights: Interflux Electronics specialises in researching, developing and producing soldering materials for electronics manufacturers. Best known for soldering ……

#3 KOKI COMPANY LIMITED

Domain Est. 2021

Website: koki-global.com

Key Highlights: Koki Company Limited is a global manufacturer and supplier of soldering materials for elecctronic and electrical industries.Solder Paste,unleaded,Liquid ……

#4 FluxPlus™ Paste Flux

Domain Est. 1993

Website: nordson.com

Key Highlights: Nordson EFD’s FluxPlus™ paste remains in place without contaminating nearby areas. It is perfect for BGA rework, mobile device repair, and solder paste ……

#5 Indium Corporation Global Solder & PCB Assembly Materials Supplier

Domain Est. 1995

Website: indium.com

Key Highlights: Explore our wide range of offerings, including solder pastes and powders, metals and compounds, flux and epoxies, thermal interface materials, and more….

#6 Kester

Domain Est. 1995

Website: kester.com

Key Highlights: Solder Wire · Liquid Solder Flux · Solder Paste · Tacky Solder Flux · Preforms · Bar Solder · Other · ALPHA HiTech · SMD Adhesives · Underfills · Edgebond….

#7 Electronic Solder Flux

Domain Est. 1996

Website: canfieldmetals.com

Key Highlights: Canfield Technologies offers electronic solder flux for the electronic assembly industry. Contact us today to learn more about our product offerings….

#8 Superior Flux Page

Domain Est. 1997

Website: superiorflux.com

Key Highlights: Superior Flux manufactures a wide range of fluxes for soldering, brazing and welding. Our soldering line includes fluxes that can stand up to the rigors of ……

#9 SRA Soldering Products

Domain Est. 1998

Website: sra-solder.com

Key Highlights: 1–6 day delivery 30-day returnsWelcome to the SRA web site. We offer a wide selection of soldering and brazing alloys in paste and wire form. We carry Aoyue soldering, desoldering….

#10 Solder Flux & Liquid Flux Products

Domain Est. 2018

Website: macdermidalpha.com

Key Highlights: Explore our range of solder flux and liquid flux products designed for superior performance in electronic assembly processes….

Expert Sourcing Insights for Electronic Soldering Flux

H2: Projected 2026 Market Trends for Electronic Soldering Flux

The global electronic soldering flux market is poised for significant transformation by 2026, driven by evolving technological demands, environmental regulations, and shifts in manufacturing practices. Key trends shaping the market include the rising adoption of lead-free and no-clean flux formulations, increased miniaturization in electronics, growth in automotive and consumer electronics sectors, and regional shifts in electronics production.

One of the most prominent trends is the continued shift toward environmentally sustainable flux solutions. Regulatory frameworks such as the EU’s RoHS (Restriction of Hazardous Substances) and REACH are pushing manufacturers to adopt halogen-free, low-VOC (volatile organic compound), and biodegradable fluxes. By 2026, these eco-friendly formulations are expected to dominate new product development and account for a growing share of market volume, particularly in Europe and North America.

The demand for high-performance fluxes is also being fueled by the miniaturization of electronic components, especially in advanced applications like 5G devices, wearables, and IoT sensors. These applications require precision soldering with minimal residue and high thermal stability, boosting the adoption of no-clean and water-soluble fluxes. Additionally, advancements in rework and repair processes are increasing the need for fluxes compatible with automated and high-reliability assembly lines.

The automotive electronics sector is emerging as a key growth driver. With the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), there is a growing need for fluxes that ensure long-term reliability under harsh operating conditions. High-temperature and high-reliability flux formulations are expected to see accelerated demand in this segment by 2026.

Regionally, Asia-Pacific will remain the largest market due to concentrated electronics manufacturing in China, Japan, South Korea, and increasingly Vietnam and India. However, geopolitical factors and supply chain diversification efforts may lead to a more balanced regional production footprint, boosting local flux production and customization.

In summary, by 2026, the electronic soldering flux market will be characterized by innovation in formulation chemistry, stricter environmental compliance, and growing demand from high-tech and automotive electronics. Companies that invest in R&D for sustainable, high-performance flux solutions and adapt to regional manufacturing shifts will be best positioned for growth.

Common Pitfalls in Sourcing Electronic Soldering Flux: Quality and Intellectual Property Concerns

Sourcing electronic soldering flux is a critical step in ensuring reliable solder joints and long-term product performance. However, several common pitfalls related to quality and intellectual property (IP) can compromise manufacturing outcomes and expose companies to legal and operational risks. Being aware of these issues helps in selecting trustworthy suppliers and maintaining product integrity.

Poor Quality Control and Inconsistent Performance

A major pitfall is procuring flux from suppliers with inadequate quality control measures. Low-cost or uncertified fluxes may exhibit batch-to-batch inconsistencies in viscosity, activation temperature, or residue characteristics. This variability can lead to defects such as solder bridging, poor wetting, or incomplete reflow, directly impacting yield rates and field reliability. Always verify that the flux meets industry standards such as IPC-J-STD-004 and request Material Safety Data Sheets (MSDS) and test reports.

Misrepresentation of Flux Type and Classification

Some suppliers may mislabel or inaccurately classify flux types (e.g., claiming a no-clean flux is halide-free when it is not). This misrepresentation can result in improper flux selection for sensitive electronics, leading to corrosion or electrical leakage due to ionic residues. Ensure that flux classification (R, RMA, RA, OA, or No-Clean) aligns with your assembly process and end-product requirements by validating specifications through independent testing.

Use of Counterfeit or Unbranded Products

Counterfeit or unbranded fluxes are prevalent in the market, especially through non-authorized distributors. These products often mimic reputable brands but lack the formulation consistency and reliability of genuine materials. Using counterfeit flux not only jeopardizes solder joint integrity but may also void warranties on other components. Source flux exclusively from authorized distributors or directly from manufacturers to avoid this risk.

Intellectual Property Infringement

Manufacturers sometimes reverse-engineer proprietary flux formulations and sell them under different names, infringing on patents or trade secrets. Using such flux, even unknowingly, can expose your company to IP litigation, especially in regulated industries or export markets with strict IP enforcement. Conduct due diligence on suppliers’ innovation claims and verify whether formulations are licensed or developed in-house.

Lack of Traceability and Documentation

Inadequate documentation—such as missing lot numbers, RoHS/REACH compliance certificates, or full ingredient disclosure—hampers traceability and regulatory compliance. This becomes particularly problematic during audits, failure analysis, or recalls. Insist on full supply chain transparency and comprehensive documentation to support quality assurance and compliance efforts.

Overlooking Compatibility with Other Materials

Flux must be compatible with solder alloys, surface finishes (e.g., ENIG, immersion silver), and cleaning processes. Sourcing without considering system-wide compatibility can result in unexpected interactions, such as residue entrapment or delamination. Always test new flux candidates in your specific production environment before full-scale adoption.

By addressing these pitfalls proactively—through rigorous supplier vetting, specification validation, and adherence to industry standards—companies can ensure they source electronic soldering flux that delivers consistent performance and complies with both quality and IP requirements.

Logistics & Compliance Guide for Electronic Soldering Flux

Overview of Electronic Soldering Flux

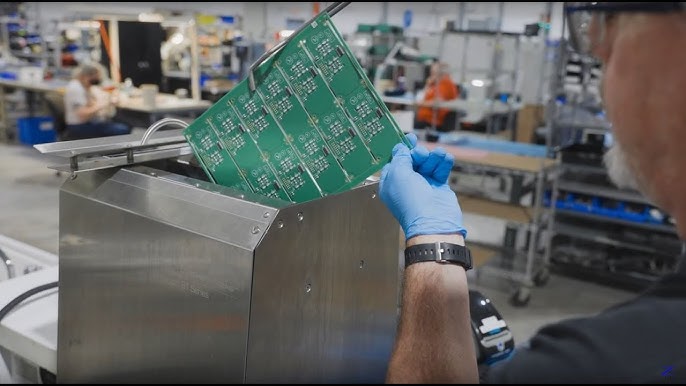

Electronic soldering flux is a chemical cleaning agent used in electronics manufacturing to remove oxides from metal surfaces, improve solder wetting, and ensure reliable electrical connections. Due to its chemical composition—often containing rosin, organic acids, solvents, or activators—flux is subject to specific logistics handling, storage, transportation, and regulatory compliance requirements.

Classification and Hazard Identification

Electronic soldering flux formulations vary widely, and their hazard classification depends on ingredients. Most fall into one or more of the following categories under the Globally Harmonized System (GHS):

– Flammable liquids (if solvent-based)

– Skin/eye irritants

– Respiratory sensitizers (e.g., rosin fumes)

– Hazardous to the aquatic environment

Always consult the Safety Data Sheet (SDS) provided by the manufacturer to determine exact classifications. Flux products must be labeled with appropriate GHS pictograms, signal words, hazard statements, and precautionary statements.

Regulatory Compliance Requirements

International Regulations

- REACH (EU): Ensure flux components are registered under Regulation (EC) No 1907/2006. Substances of Very High Concern (SVHC) must be declared if present above thresholds.

- RoHS (EU): Confirm flux is free of restricted substances (e.g., lead, cadmium, hexavalent chromium) per Directive 2011/65/EU.

- TSCA (USA): Verify all chemical substances are listed on the TSCA Inventory.

- CLP Regulation (EU): Proper classification, labeling, and packaging per Regulation (EC) No 1272/2008.

- OSHA HazCom (USA): Comply with Hazard Communication Standard (29 CFR 1910.1200) using SDS and proper labeling.

Transportation Regulations

Soldering flux may be classified as hazardous for transport depending on flash point and composition:

– UN Number: Common classifications include UN1133 (Flammable liquid, n.o.s.) or UN3082 (Environmentally hazardous substance, liquid).

– IMDG Code (Maritime): Required for sea freight; packaging must meet performance standards.

– IATA DGR (Air): Strict rules on quantity, packaging, and documentation for air transport.

– 49 CFR (USA Ground): Regulates domestic shipping via road or rail; includes requirements for placarding and shipping papers.

Always use certified packaging and declare flux accurately on shipping documents.

Storage Guidelines

Environmental Conditions

- Store in a cool, dry, well-ventilated area away from direct sunlight and heat sources.

- Temperature range: Typically 5°C to 30°C (41°F to 86°F); verify with manufacturer specifications.

- Avoid freezing unless specified as freeze-thaw stable.

Compatibility and Segregation

- Store away from strong oxidizers, acids, and alkalis.

- Use non-reactive shelving (e.g., polyethylene or coated metal).

- Keep containers tightly closed to prevent evaporation and contamination.

Safety Measures

- Implement spill containment (e.g., spill trays or berms).

- Provide appropriate fire extinguishing equipment (e.g., CO₂ or dry chemical for flammable types).

- Ensure eyewash stations and safety showers are accessible in storage and use areas.

Handling and Use Procedures

Personal Protective Equipment (PPE)

- Gloves: Chemically resistant (e.g., nitrile or neoprene).

- Eye Protection: Safety goggles or face shield.

- Respiratory Protection: Use NIOSH-approved respirators if ventilation is inadequate, especially when heating flux (rosin fumes can cause asthma).

- Protective Clothing: Lab coat or apron to prevent skin contact.

Engineering Controls

- Use local exhaust ventilation (fume extractors) at soldering stations.

- Ensure general ventilation in work areas to prevent vapor accumulation.

Spill and Leak Response

- Contain spill with absorbent materials (e.g., spill pads or vermiculite).

- Collect waste in approved hazardous waste containers.

- Clean affected area with appropriate solvent or cleaner; dispose of residues per local regulations.

- Report significant spills to relevant authorities if environmentally hazardous.

Disposal and Waste Management

- Flux-contaminated materials (e.g., wipes, solder tips, filters) are often classified as hazardous waste.

- Dispose of according to local, state, and federal regulations (e.g., RCRA in the USA).

- Use licensed waste disposal contractors for hazardous waste streams.

- Never pour flux or rinse water down the drain.

Documentation and Recordkeeping

Required Documents

- Safety Data Sheet (SDS): Maintain up-to-date SDS for each flux product (minimum 3 years).

- Transport Documents: Include proper shipping name, UN number, hazard class, and quantity.

- Waste manifests: Required for hazardous waste disposal.

- Training records: Document employee training on handling, hazards, and emergency procedures.

Compliance Audits

Regular internal audits should verify:

– Accurate labeling and SDS availability.

– Proper storage conditions and segregation.

– Employee adherence to safety protocols.

– Up-to-date regulatory registrations (e.g., REACH, TSCA).

Supplier and Supply Chain Management

- Source flux from reputable suppliers providing full compliance documentation.

- Verify that suppliers follow ISO 9001 and ISO 14001 standards where applicable.

- Conduct periodic supplier audits for quality and regulatory compliance.

Emergency Response

- Post emergency contact numbers (e.g., poison control, fire department, manufacturer).

- Train personnel in first aid:

- Skin contact: Wash with soap and water.

- Eye contact: Rinse thoroughly for 15 minutes; seek medical attention.

- Inhalation: Move to fresh air; seek medical help if breathing is difficult.

- Maintain spill kits and fire extinguishers in accessible locations.

Summary

Safe and compliant logistics of electronic soldering flux require strict adherence to chemical safety, transportation, and environmental regulations. By understanding hazard classifications, implementing proper storage and handling procedures, maintaining documentation, and training personnel, organizations can mitigate risks and ensure regulatory compliance throughout the supply chain. Always refer to the manufacturer’s SDS and consult local regulatory authorities for jurisdiction-specific requirements.

Conclusion:

Sourcing electronic soldering flux requires a careful balance of quality, compatibility, cost, and reliability. Selecting the right type of flux—whether rosin-based (RA, RMA), water-soluble, or no-clean—is critical to ensuring strong, reliable solder joints and long-term performance of electronic assemblies. It is essential to partner with reputable suppliers who adhere to industry standards (such as IPC-J-STD-004) and provide consistent product specifications, safety data sheets (SDS), and traceability.

Factors such as application method (manual, wave, or reflow soldering), environmental and safety considerations, and post-soldering cleaning requirements should guide the selection and sourcing process. Additionally, evaluating suppliers based on technical support, lead times, and scalability helps ensure a smooth integration into the manufacturing workflow.

In conclusion, a well-informed sourcing strategy for electronic soldering flux enhances product reliability, reduces defects, and supports efficient production—making it a vital component of successful electronics manufacturing.