The global electrical components market is experiencing robust growth, driven by rising demand across industrial automation, energy, automotive, and consumer electronics sectors. According to a report by Mordor Intelligence, the electrical components market was valued at USD 660.5 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of over 5.8% from 2024 to 2029. Similarly, Grand View Research estimates that the electrical components market size could surpass USD 930 billion by 2030, fueled by advancements in smart infrastructure, renewable energy integration, and increasing electrification in emerging economies. As innovation accelerates and global supply chains evolve, identifying leading manufacturers becomes critical for procurement, sourcing, and strategic partnerships. Here’s a data-informed look at the top 10 electrical parts manufacturers shaping the industry’s future.

Top 10 Electrical Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 NorthEast Electrical

Domain Est. 1999

Website: needco.com

Key Highlights: 4-day delivery 30-day returnsNorthEast serves electrical contractors, industrial, OEM, utility, & institutional customers with electrical supplies and solutions….

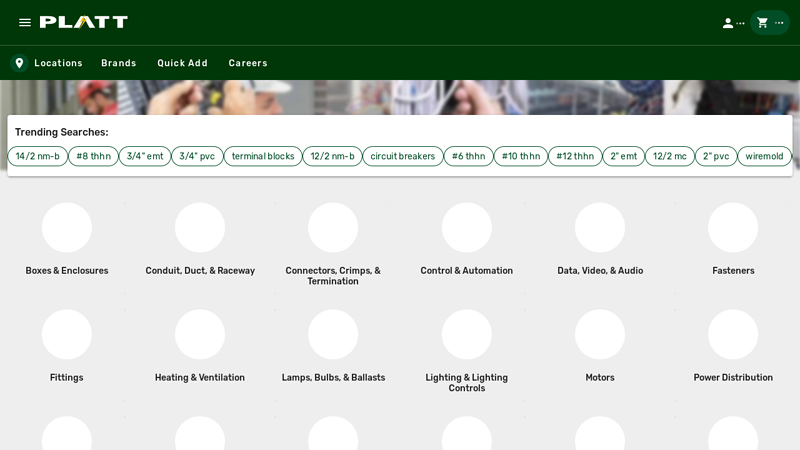

#2 Platt Electric Supply

Domain Est. 1995

Website: platt.com

Key Highlights: Buy Electrical Supplies Online at Platt Electric Supply. Wholesale electrical, industrial, lighting, tools, control and automation products….

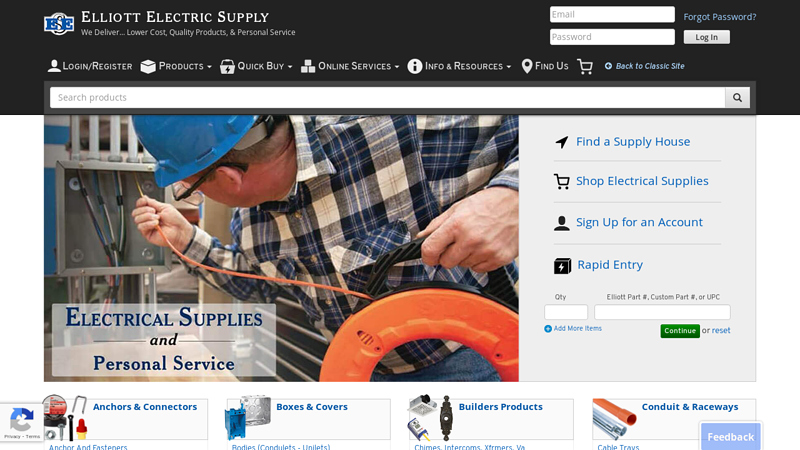

#3 Elliott Electric Supply Company

Domain Est. 1997

Website: elliottelectric.com

Key Highlights: We offer you the lowest cost and real-time stock numbers on the industry’s best quality electrical supplies for residential, commercial, and industrial ……

#4 Cooper Electric

Domain Est. 1997

Website: cooper-electric.com

Key Highlights: 2–10 day delivery 90-day returnsCooper Electric provides quality electrical supplies & services with 60yrs of experience for contractors, industrials, utilities, commercial, reside…

#5 Crawford Electric Supply

Domain Est. 2013

Website: crawfordelectricsupply.com

Key Highlights: 2–10 day deliveryHeadquartered in Houston, Crawford serves the commercial, industrial, and residential markets in Texas and Louisiana with electrical supplies and experts….

#6 Mayer Electric

Domain Est. 1997

Website: mayerelectric.com

Key Highlights: Mayer is one of the nation’s largest wholesale distributors of electrical products and equipment, connected solutions, lighting, digital tools, datacom ……

#7 Kendall Electric

Domain Est. 1997

Website: kendallelectric.com

Key Highlights: Partner with Kendall Electric for electrical, automation, and networking solutions that power progress with local expertise, reliable service, and results….

#8 Viking Electric

Domain Est. 1997

Website: vikingelectric.com

Key Highlights: Visit Viking Electric for quality electrical supplies, services & solutions. Shop online for your materials, tools & equipment – plus free delivery or ……

#9 Electric Supply Center

Domain Est. 2005

Website: escctr.net

Key Highlights: FEATURED CATEGORIES · Electric Vehicle Charging · Conduit, Raceway & Cable Support · Lighting · Electrical Fittings · Wire, Cords & Cables · Wiring Devices ……

#10 Standard Electric Supply Co.

Domain Est. 2011

Website: standardelectricsupply.com

Key Highlights: $8.50 delivery Free 30-day returnsShop Electrical Supplies Online With Unmatched 24/7 Technical Support & Customer Service at Standard Electric Supply Co. Electrical Distributor Wi…

Expert Sourcing Insights for Electrical Parts

H2: 2026 Market Trends for Electrical Parts

The global electrical parts market is poised for significant transformation by 2026, driven by technological innovation, sustainability mandates, and evolving energy demands. Key trends shaping this landscape include:

1. Accelerated Electrification & Renewable Integration:

The global push towards decarbonization will drive massive investments in renewable energy (solar, wind) and grid modernization. This necessitates a surge in demand for electrical components like inverters, switchgear, transformers, and advanced circuit protection devices designed for variable renewable inputs and bidirectional power flow.

2. Dominance of Automation & Industry 4.0:

Smart factories and automated processes will fuel demand for intelligent electrical parts. Sensors, programmable logic controllers (PLCs), industrial IoT (IIoT) connectivity modules, and robust power distribution units (PDUs) will see increased adoption, emphasizing reliability, data integration, and predictive maintenance capabilities.

3. Rise of E-Mobility Infrastructure:

The exponential growth of electric vehicles (EVs) will create a parallel boom in charging infrastructure. This will significantly increase demand for high-power connectors, charging stations (AC/DC), power conversion modules, and robust cabling systems, requiring components rated for higher voltages and currents.

4. Focus on Energy Efficiency & Miniaturization:

Stringent energy efficiency regulations (e.g., IE4/IE5 motors, high-efficiency transformers) and the need for compact designs in consumer electronics and EVs will drive innovation. Expect advancements in materials (e.g., wide-bandgap semiconductors like SiC and GaN) enabling smaller, lighter, and more efficient components with lower power losses.

5. Supply Chain Resilience & Regionalization:

Ongoing geopolitical tensions and past disruptions will push companies towards diversifying suppliers and nearshoring/reshoring production. This trend will impact sourcing strategies for critical components (e.g., semiconductors, rare earth magnets), potentially increasing regional manufacturing hubs and investment in local supply chains.

6. Digitalization & Smart Components:

Electrical parts will increasingly incorporate embedded intelligence and connectivity. Smart breakers, sensors with data logging, and components with digital twins will enable real-time monitoring, remote management, and enhanced system diagnostics, moving towards predictive rather than reactive maintenance.

7. Sustainability & Circular Economy:

Environmental regulations (e.g., RoHS, REACH) and corporate ESG goals will intensify focus on recyclability, use of sustainable materials, reduced hazardous substances, and extended product lifecycles. Design for disassembly and remanufacturing will gain traction.

8. Advancements in Power Electronics:

The demand for efficient power conversion across various sectors (renewables, EVs, data centers) will accelerate the adoption of Wide-Bandgap (WBG) semiconductors (Silicon Carbide – SiC, Gallium Nitride – GaN). These materials enable higher efficiency, faster switching, and operation at higher temperatures, revolutionizing power supplies, motor drives, and inverters.

In summary, the 2026 electrical parts market will be defined by intelligence, efficiency, connectivity, and sustainability, underpinned by the global transitions to clean energy, electrified transport, and advanced automation.

Common Pitfalls When Sourcing Electrical Parts: Quality and Intellectual Property Risks

Sourcing electrical components is critical for product performance, safety, and compliance. However, companies often encounter significant challenges related to quality assurance and intellectual property (IP) protection. Overlooking these areas can lead to product failures, legal disputes, and reputational damage.

Quality-Related Pitfalls

1. Inadequate Supplier Vetting

Failing to conduct thorough due diligence on suppliers increases the risk of receiving substandard or counterfeit parts. Many suppliers, particularly in global markets, may lack proper certifications or quality control systems. Relying solely on price as a selection criterion often results in compromised reliability and long-term cost increases due to field failures.

2. Counterfeit Components

The electrical components market is plagued by counterfeit parts, including recycled, remarked, or cloned devices. These components often fail prematurely, pose safety risks, and are difficult to detect without rigorous testing. Sourcing from unauthorized distributors or gray market channels significantly increases exposure to this threat.

3. Inconsistent Quality Standards

Suppliers may not adhere consistently to international quality standards such as ISO 9001, IPC, or IEC. Variability in manufacturing processes across batches or production sites can lead to intermittent failures, especially in mission-critical applications like medical or aerospace systems.

4. Lack of Traceability

Without full component traceability—from raw materials to final assembly—it becomes nearly impossible to conduct root cause analysis in case of failure. Poor documentation also hinders compliance with regulatory requirements and recalls.

Intellectual Property-Related Pitfalls

1. Use of Cloned or Reverse-Engineered Components

Some suppliers offer functionally similar parts at lower prices by reverse-engineering proprietary designs. These clones may infringe on patents, trademarks, or circuit layout rights, exposing the buyer to legal liability, even if unintentional.

2. Unauthorized Manufacturing and Distribution

Sourcing from suppliers not authorized by the original component manufacturer (OCM) risks purchasing parts produced without proper licensing. These parts may violate the OCM’s IP rights and lack performance guarantees.

3. Ambiguous Licensing Agreements

Failure to verify software or firmware licenses associated with programmable components (e.g., microcontrollers, FPGAs) can result in IP violations. Some components include embedded IP that requires specific usage rights, which may not be transferred through third-party sales.

4. Weak Contractual Protections

Supply agreements that lack clear IP indemnification clauses leave buyers vulnerable. If a sourced component leads to an IP infringement claim, the buyer may bear legal costs unless the supplier is contractually obligated to defend and compensate.

Mitigation Strategies

To avoid these pitfalls, organizations should implement a structured sourcing strategy that includes:

– Partnering with authorized distributors and certified suppliers

– Conducting regular supplier audits and component testing (e.g., X-ray, decapsulation)

– Requiring full traceability documentation (e.g., lot numbers, CoC)

– Including strong IP indemnification and warranty clauses in contracts

– Maintaining an approved vendor list (AVL) and monitoring component lifecycle status

Proactive management of quality and IP risks ensures reliable supply chains and protects both product integrity and legal standing.

Logistics & Compliance Guide for Electrical Parts

Overview

Electrical parts—including components such as circuit breakers, connectors, transformers, PCBs, and power supplies—are subject to stringent logistics and compliance requirements due to safety, performance, and environmental concerns. This guide outlines key considerations for the safe, legal, and efficient handling, transportation, and regulatory compliance of electrical parts throughout the supply chain.

Regulatory Compliance Requirements

International Standards & Certifications

Electrical parts must comply with internationally recognized standards to ensure safety, reliability, and interoperability. Key certifications include:

- IEC (International Electrotechnical Commission): Global standards for electrical and electronic technologies (e.g., IEC 60950 for IT equipment safety).

- UL (Underwriters Laboratories): Widely accepted in North America; parts may require UL listing or recognition.

- CE Marking (Europe): Mandatory for electrical equipment placed on the European market, indicating conformity with health, safety, and environmental protection standards.

- RoHS (Restriction of Hazardous Substances): Prohibits the use of specific hazardous materials (e.g., lead, mercury) in electrical and electronic equipment within the EU and other regions.

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals): Regulates the use of chemical substances in products sold in the EU.

- FCC (Federal Communications Commission): Required in the U.S. for parts that may emit radio frequency interference (e.g., power supplies, motor drives).

Country-Specific Regulations

- USA: Compliance with NEC (National Electrical Code), OSHA regulations, and state-level electrical codes.

- China: CCC (China Compulsory Certification) for specified electrical products.

- India: BIS (Bureau of Indian Standards) certification for select electrical components.

- Japan: PSE (Product Safety Electrical Appliance & Material) certification required.

Packaging & Handling Guidelines

Protective Packaging

Electrical parts are often sensitive to electrostatic discharge (ESD), moisture, and physical shock. Use:

- ESD-safe packaging (e.g., static-shielding bags, conductive foam) for semiconductors and PCBs.

- Desiccants and moisture barrier bags for humidity-sensitive components.

- Rigid outer packaging with cushioning to prevent mechanical damage.

Labeling Requirements

Labels must include:

– Part number, manufacturer, and date code.

– Compliance markings (e.g., CE, UL, RoHS).

– Handling symbols (e.g., “Fragile,” “ESD Sensitive,” “Do Not Stack”).

– Hazard warnings if applicable (e.g., high voltage components).

Transportation & Logistics

Mode of Transport Considerations

- Air Freight: Preferred for high-value or time-sensitive parts. Must comply with IATA regulations, especially for lithium batteries or components containing hazardous materials.

- Sea Freight: Cost-effective for bulk shipments; ensure proper moisture protection and secure palletization.

- Ground Transport: Ideal for regional distribution. Monitor temperature and vibration exposure.

Temperature & Environmental Control

Some electrical components (e.g., capacitors, sensors) are sensitive to extreme temperatures, humidity, and contaminants. Maintain:

– Temperature-controlled environments when necessary.

– Clean, dry storage conditions during transit and warehousing.

Customs & Documentation

Ensure accurate documentation for international shipments:

– Commercial invoice with detailed product descriptions and HS codes.

– Certificates of conformity (e.g., CE, UL, RoHS).

– Bill of lading, packing list, and ESD compliance statements if applicable.

– Import licenses or permits where required (e.g., for high-voltage equipment).

Storage & Inventory Management

Warehouse Conditions

- Store in a climate-controlled environment (typically 15–25°C, 30–60% RH).

- Keep away from dust, corrosive gases, and direct sunlight.

- Use anti-static flooring and shelving in ESD-protected areas.

Shelf Life & Rotation

- Observe manufacturer-recommended shelf life, especially for electrolytic capacitors and adhesives.

- Implement FIFO (First In, First Out) inventory practices.

- Monitor for obsolescence; track lifecycle status of components.

Risk Mitigation & Best Practices

Counterfeit Prevention

- Source parts only from authorized distributors or OEMs.

- Verify authenticity through traceability codes, datasheets, and independent testing when necessary.

- Train procurement and receiving staff on counterfeit detection.

Sustainability & End-of-Life Compliance

- Follow WEEE (Waste Electrical and Electronic Equipment) directives for disposal and recycling in applicable regions.

- Partner with certified e-waste recyclers.

- Design for recyclability and minimize hazardous materials in product development.

Conclusion

Effective logistics and compliance management for electrical parts ensures product safety, regulatory adherence, and supply chain reliability. By following international standards, using proper handling techniques, and maintaining accurate documentation, businesses can reduce risks, avoid delays, and support sustainable operations. Regular audits and staff training are recommended to stay current with evolving regulations and technologies.

In conclusion, sourcing electrical parts suppliers requires a strategic approach that balances quality, cost, reliability, and compliance. Identifying suppliers with strong certifications (such as ISO, UL, or RoHS), proven track records, and the capability to meet volume and technical specifications is essential for ensuring the integrity and performance of electrical systems. Building long-term relationships with dependable suppliers enhances supply chain resilience, reduces lead times, and facilitates better support for technical challenges. Additionally, leveraging global sourcing opportunities can offer cost advantages, but must be weighed against logistics, communication, and regulatory considerations. Ultimately, a well-vetted supplier base supports operational efficiency, product quality, and overall business success in industries reliant on electrical components.