The global electrical connectors market, which includes critical components like electrical jumpers, was valued at USD 86.6 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030, according to Grand View Research. This expansion is driven by rising demand in automotive, industrial machinery, and consumer electronics sectors, where reliable electrical connectivity is paramount. With increasing investments in electric vehicles, renewable energy infrastructure, and smart manufacturing, the need for high-performance electrical jumpers has intensified. As supply chains grow more complex and quality standards more stringent, a select group of manufacturers have emerged as leaders through innovation, scalability, and strict adherence to international certifications. These top-tier suppliers not only dominate in production capacity but also set benchmarks in material science, automation, and global logistics—making them pivotal players in today’s electrified industrial landscape.

Top 8 Electrical Jumper Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wire and Cable Manufacturers

Domain Est. 1996

Website: encorewire.com

Key Highlights: Encore Wire is the leading manufacturer of copper and aluminum for residential, commercial and industrial wire needs. We’re unlike any other wire company….

#2 Pomona Electronics

Domain Est. 1998

Website: pomonaelectronics.com

Key Highlights: Leading manufacturer of test and measurement accessories for professionals worldwide … Catalog · Jumper Test Leads. Test jumpers for nuclear power ……

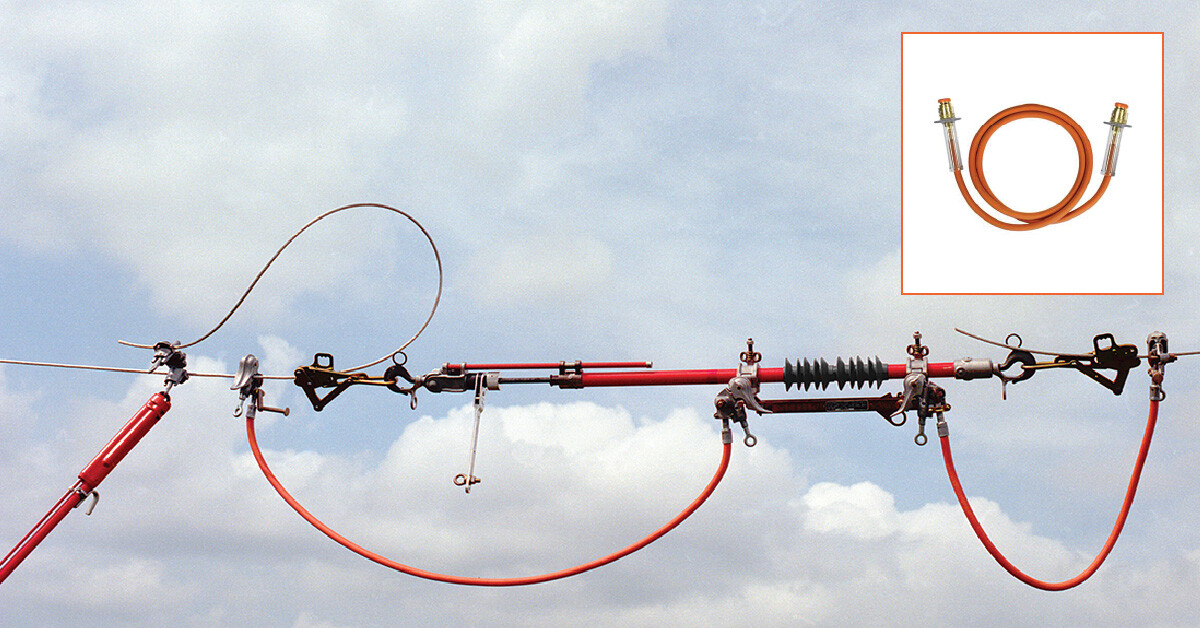

#3 MacLean Power Systems

Domain Est. 1999

Website: macleanpower.com

Key Highlights: We supply world class products and programs worldwide to fulfill the needs of customers maintaining the electric utility power infrastructure….

#4 Jumper Components & Assemblies – Automation

Domain Est. 1988

Website: automation.honeywell.com

Key Highlights: Explore Honeywell’s range of electrical safety jumper components and assemblies, including insulated bypass jumper sets, single grounding assemblies, ……

#5 3M Electrical

Domain Est. 1988

Website: 3m.com

Key Highlights: 3M Electrical Construction Services can help save you time by creating custom engineered kits directly to your job location. 337 products. Filter….

#6 Electrical Products

Domain Est. 1994

Website: molex.com

Key Highlights: Molex offers a complete line of reliable electrical solutions designed to support optimal worker safety and performance for today’s harsh duty environments….

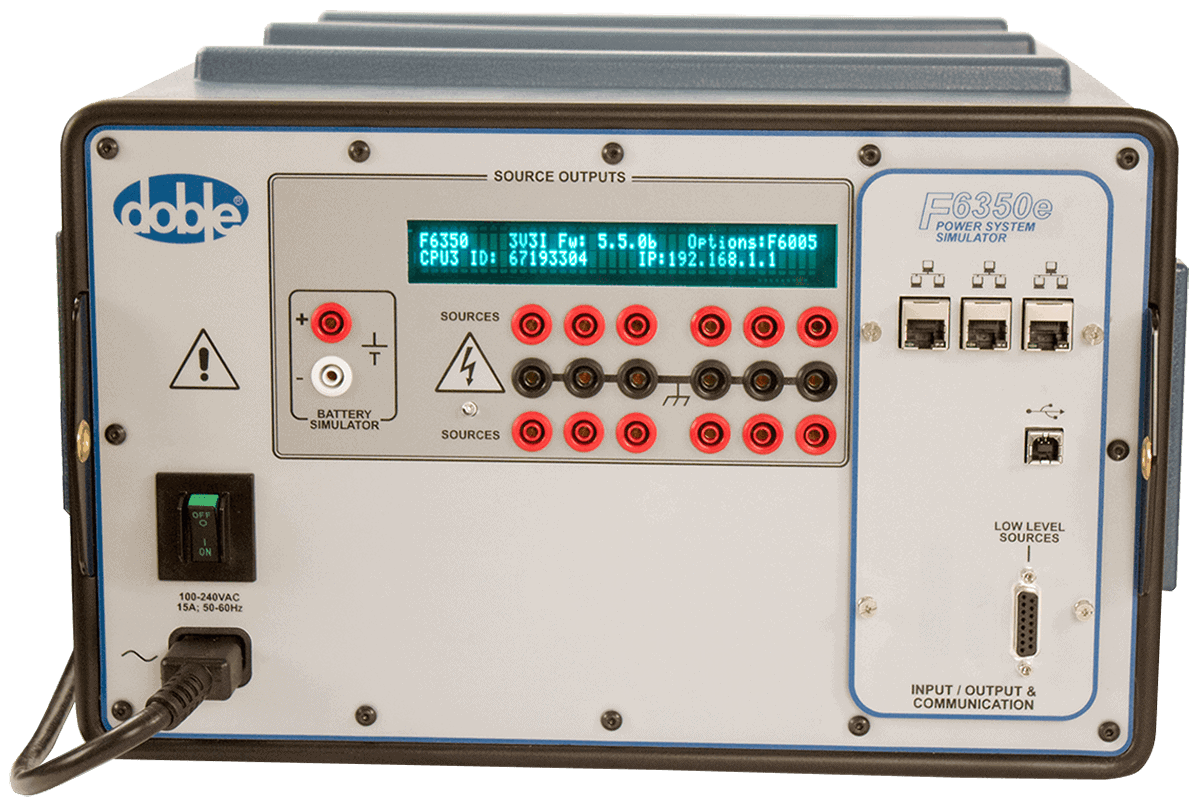

#7 Doble Engineering

Domain Est. 1995

Website: doble.com

Key Highlights: Understand asset health through Doble diagnostic test equipment, software & services for the electric power industry….

#8 Jumper

Domain Est. 1997

Website: muellerelectric.com

Key Highlights: Mueller Electric manufactures a full line of test leads and interconnection leads for almost any application….

Expert Sourcing Insights for Electrical Jumper

H2: 2026 Market Trends for Electrical Jumpers

The electrical jumper market is poised for significant evolution by 2026, driven by technological advancements, shifting industry demands, and global sustainability initiatives. Key trends shaping the market include:

1. Surge in Demand from Renewable Energy & EV Infrastructure: The rapid global expansion of solar and wind power installations, coupled with the accelerating deployment of electric vehicle (EV) charging networks, is creating substantial demand for high-reliability, high-current electrical jumpers. These applications require jumpers capable of handling fluctuating loads, harsh environments, and ensuring minimal energy loss, pushing innovation in materials and design.

2. Advancements in Material Science & Miniaturization: Expect increased adoption of advanced conductive materials like high-purity copper alloys, aluminum composites, and even emerging graphene-enhanced conductors. These materials offer superior conductivity, lighter weight, and better thermal management. Simultaneously, miniaturization trends in consumer electronics, data centers, and industrial automation are driving demand for smaller, more flexible, and densely packed jumper solutions, including micro-jumpers and flexible printed circuits (FPCs).

3. Focus on Sustainability and Circular Economy: Environmental regulations (e.g., RoHS, REACH) and corporate ESG goals are pushing manufacturers towards sustainable practices. This includes using recycled copper, developing more energy-efficient manufacturing processes, and designing jumpers for easier disassembly and recyclability at end-of-life. Biodegradable or recyclable insulation materials may gain traction.

4. Growth of Automation and Smart Manufacturing: The rise of Industry 4.0 is increasing demand for automated testing and assembly. Pre-fabricated, standardized jumper harnesses with consistent quality and reliable connectors are becoming essential. Integration of smart sensors into jumper systems (e.g., for temperature or current monitoring) is an emerging niche, enabling predictive maintenance in critical infrastructure.

5. Supply Chain Resilience and Regionalization: Geopolitical uncertainties and past disruptions have highlighted supply chain vulnerabilities. By 2026, there will be a stronger emphasis on building resilient, geographically diversified supply chains. This may lead to increased regional manufacturing hubs for jumpers, particularly near major end-user markets (e.g., North America, Europe, Southeast Asia), potentially impacting global sourcing strategies.

6. Rising Importance of High-Frequency and High-Speed Applications: The proliferation of 5G infrastructure, high-performance computing (HPC), and advanced data centers demands jumpers capable of handling high-frequency signals with minimal signal loss (low insertion loss) and crosstalk. This drives innovation in coaxial jumpers, shielded designs, and impedance-controlled solutions.

7. Consolidation and Value-Added Services: The market may see continued consolidation among manufacturers, with larger players acquiring niche specialists. Competition will increasingly focus on value-added services like custom design engineering, rapid prototyping, kitting, and comprehensive testing/certification support, moving beyond simple component supply.

In summary, the 2026 electrical jumper market will be characterized by innovation driven by energy transition and digitalization, a strong push for sustainability, and the need for smarter, more reliable, and efficiently supplied components. Manufacturers who adapt to these H2 trends – particularly in renewable energy, EVs, advanced materials, and sustainability – will be best positioned for growth.

Common Pitfalls When Sourcing Electrical Jumpers (Quality, IP)

Sourcing electrical jumpers—especially those requiring specific quality standards and Ingress Protection (IP) ratings—can present several challenges. Procurement teams and engineers often encounter pitfalls that compromise performance, safety, and compliance if not carefully managed.

1. Overlooking IP Rating Requirements

One of the most frequent mistakes is failing to verify that the jumper’s IP rating matches the environmental conditions of the application. For instance, using an IP65-rated jumper in a submersible or high-moisture environment requiring IP68 can lead to premature failure, short circuits, or safety hazards. Always confirm the required IP rating based on exposure to dust, water, and other contaminants.

2. Inadequate Quality Control from Suppliers

Sourcing from low-cost suppliers without rigorous quality assurance processes increases the risk of receiving substandard jumpers. Poor materials, inconsistent manufacturing, or counterfeit components can result in unreliable connections, overheating, or failure during critical operations. Always audit suppliers and request certifications (e.g., ISO 9001, UL, CE) to ensure quality compliance.

3. Misrepresentation of IP Ratings by Suppliers

Some suppliers may claim high IP ratings without proper testing or certification. Relying solely on marketing claims without requesting third-party test reports or certification documentation can lead to non-compliant installations. Always ask for test evidence, such as IP certification from accredited laboratories.

4. Using Incompatible Materials for the Environment

Electrical jumpers exposed to harsh environments (e.g., UV radiation, chemicals, extreme temperatures) require specific jacketing materials (e.g., PUR, silicone, or halogen-free compounds). Selecting a jumper with unsuitable materials can result in degradation, insulation failure, or reduced service life. Match material specifications to the operating environment.

5. Neglecting Mechanical Durability and Flex Life

In dynamic applications (e.g., robotics, moving machinery), jumpers must endure repeated flexing. Standard jumpers not designed for flexing may break or short internally. Ensure the jumper is rated for the expected mechanical stress and number of flex cycles.

6. Improper Connector Quality and Sealing

Even if the cable has the correct IP rating, poor connector design or assembly can compromise the entire system. Inadequate sealing, low-quality contacts, or improper strain relief can create entry points for moisture and contaminants. Verify connector IP ratings independently and ensure proper assembly methods.

7. Lack of Traceability and Documentation

Without proper traceability—such as batch numbers, material certifications, or test reports—it becomes difficult to address quality issues or conduct recalls. Ensure suppliers provide full documentation to support compliance and quality control.

8. Cost-Cutting Leading to Compromised Performance

Opting for the lowest-cost jumper often leads to long-term costs due to downtime, maintenance, or safety incidents. Balance cost considerations with performance requirements, especially in mission-critical or safety-sensitive applications.

By addressing these common pitfalls during the sourcing process, organizations can ensure reliable, safe, and compliant electrical jumper installations. Prioritize supplier credibility, verify technical specifications, and demand proper certification and documentation.

Logistics & Compliance Guide for Electrical Jumpers

Electrical jumpers are critical components used in electrical systems to establish temporary or permanent connections between conductors or terminals. Proper logistics and compliance management ensures safety, reliability, and adherence to regulatory standards throughout the product lifecycle—from manufacturing to installation. This guide outlines key considerations for handling, transporting, storing, and complying with regulations applicable to electrical jumpers.

Product Classification & Regulatory Standards

Electrical jumpers fall under various regulatory scopes depending on their application, voltage rating, and materials. Common standards include:

- IEC 61439 – For low-voltage switchgear and controlgear assemblies where jumpers are used.

- UL 891 – Standard for switchboards (North America).

- NEC (NFPA 70) – National Electrical Code, governing installation requirements in the U.S.

- RoHS & REACH – Applicable to material content, restricting hazardous substances in the EU.

- CE Marking – Required for sale within the European Economic Area.

- UKCA Marking – Required for the UK market post-Brexit.

Ensure all electrical jumpers are certified by recognized bodies (e.g., UL, CSA, TÜV) and accompanied by technical documentation, test reports, and Declarations of Conformity.

Packaging & Handling Requirements

Proper packaging prevents mechanical damage, contamination, and degradation during shipping and storage:

- Use anti-static or ESD-safe packaging if components are sensitive.

- Secure jumpers with protective end caps or insulation sleeves to prevent terminal damage.

- Clearly label packages with product ID, voltage rating, length, and handling instructions (e.g., “Fragile,” “Do Not Bend”).

- Avoid coiling jumpers too tightly; use gentle loops or lay flat to prevent internal conductor strain.

Storage Conditions

Store electrical jumpers in a controlled environment to maintain performance:

- Temperature: 10°C to 30°C (50°F to 86°F)

- Humidity: Below 60% relative humidity

- Ventilation: Well-ventilated, dry area free from corrosive gases or moisture

- Shelving: Store horizontally on racks; avoid stacking heavy items on top

Avoid exposure to direct sunlight, extreme temperatures, or chemicals that may degrade insulation materials (e.g., PVC, silicone, or EPDM).

Transportation Guidelines

During transit, ensure compliance with national and international shipping regulations:

- Use secure transport methods to prevent vibration, impact, or crushing.

- For international shipments, classify goods under the correct HS Code (e.g., 8544.42 or 8536.90 for insulated wire assemblies).

- Comply with IATA/IMDG regulations if shipping hazardous materials (e.g., jumpers with halogenated insulation).

- Maintain chain-of-custody documentation, especially for regulated markets.

Import & Export Compliance

When shipping across borders:

- Prepare accurate commercial invoices, packing lists, and certificates of origin.

- Verify destination country’s electrical safety certification requirements (e.g., INMETRO for Brazil, CCC for China).

- Screen consignees against denied party lists (e.g., U.S. OFAC, EU Consolidated List).

- Apply for export licenses if required (e.g., for high-voltage or military-spec jumpers under ITAR/EAR).

Installation & Field Use Compliance

End-users must follow compliance best practices:

- Install jumpers in accordance with manufacturer specifications and local electrical codes.

- Use proper torque on terminations to prevent overheating or loosening.

- Inspect jumpers regularly for signs of wear, corrosion, or damage.

- Replace jumpers that show insulation cracking, conductor deformation, or overheating marks.

Documentation & Traceability

Maintain full traceability for quality and compliance audits:

- Assign unique batch or serial numbers to jumper assemblies.

- Retain material test reports (MTRs), production records, and certification documents for at least 10 years.

- Provide end-customers with installation manuals, safety data sheets (SDS), and compliance certificates.

Disposal & Environmental Compliance

Dispose of defective or obsolete electrical jumpers responsibly:

- Follow WEEE (Waste Electrical and Electronic Equipment) directives in the EU.

- Recycle metals and insulation materials where feasible.

- Use certified e-waste handlers to prevent environmental contamination.

Adherence to this logistics and compliance guide ensures electrical jumpers are safely handled, legally transported, and compliant with global standards, minimizing risk and supporting operational reliability.

Conclusion for Sourcing Electrical Jumpers

In conclusion, sourcing electrical jumpers requires a careful evaluation of technical specifications, material quality, application requirements, and supplier reliability. Selecting the right jumper involves ensuring compatibility with existing electrical systems, adherence to industry standards (such as UL, CE, or RoHS), and consideration of environmental factors like temperature, current load, and exposure to moisture or vibration. Cost-effectiveness should not compromise safety or performance, making it essential to partner with reputable suppliers who provide consistent quality, timely delivery, and responsive technical support. By conducting thorough due diligence in the sourcing process, organizations can ensure the long-term reliability, efficiency, and safety of their electrical systems while minimizing maintenance costs and downtime.