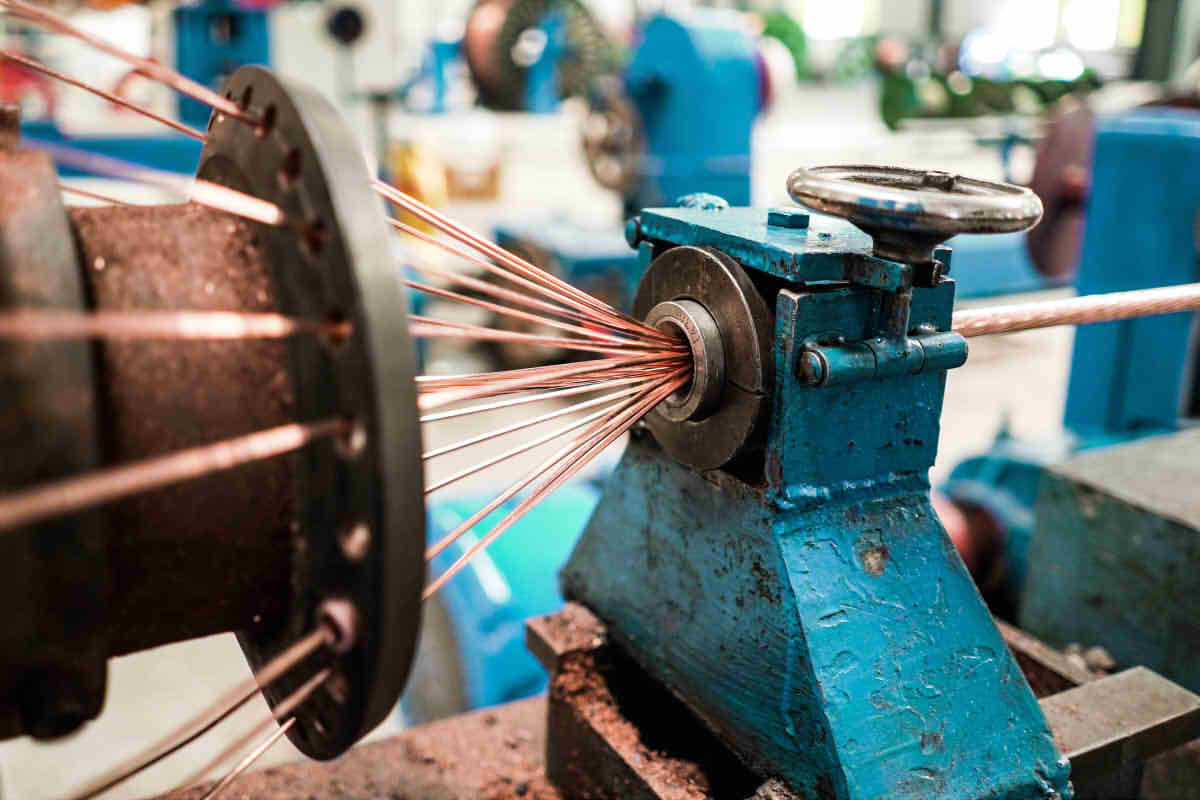

The global electrical cords and cables market is experiencing robust growth, driven by rising infrastructure development, expanding industrial automation, and increasing demand for power transmission and distribution systems. According to Grand View Research, the global electrical cable market was valued at USD 198.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.7% from 2023 to 2030. Similarly, Mordor Intelligence projects a CAGR of over 6% during the forecast period of 2023–2028, fueled by urbanization and the adoption of renewable energy systems requiring reliable connectivity solutions. As demand surges, manufacturers of key electrical cord components—such as conductors, insulation, jackets, connectors, and plugs—play an increasingly critical role in ensuring safety, efficiency, and performance. Behind the scenes of every power cord, extension lead, or appliance cable are specialized component suppliers driving innovation and reliability. Below are nine leading manufacturers of electrical cord parts shaping the backbone of modern electrical connectivity.

Top 9 Electrical Cord Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Electrical Cords and Cables

Domain Est. 1997

Website: centurywire.com

Key Highlights: Century Wire & Cable is the leading manufacturer of electrical wire and cable products….

#2 Arlington

Domain Est. 1998

Website: aifittings.com

Key Highlights: Manufacturer of Quality Electrical Products. Arlington has been a leading manufacturer of quality electrical products and fittings since its founding in 1949….

#3 AC power cord, plugs, sockets and wire harness manufacturer Phino …

Domain Est. 1999

Website: phino.com

Key Highlights: Phino Electric is certified for sales of AC power cords, plugs, sockets, connectors around the world….

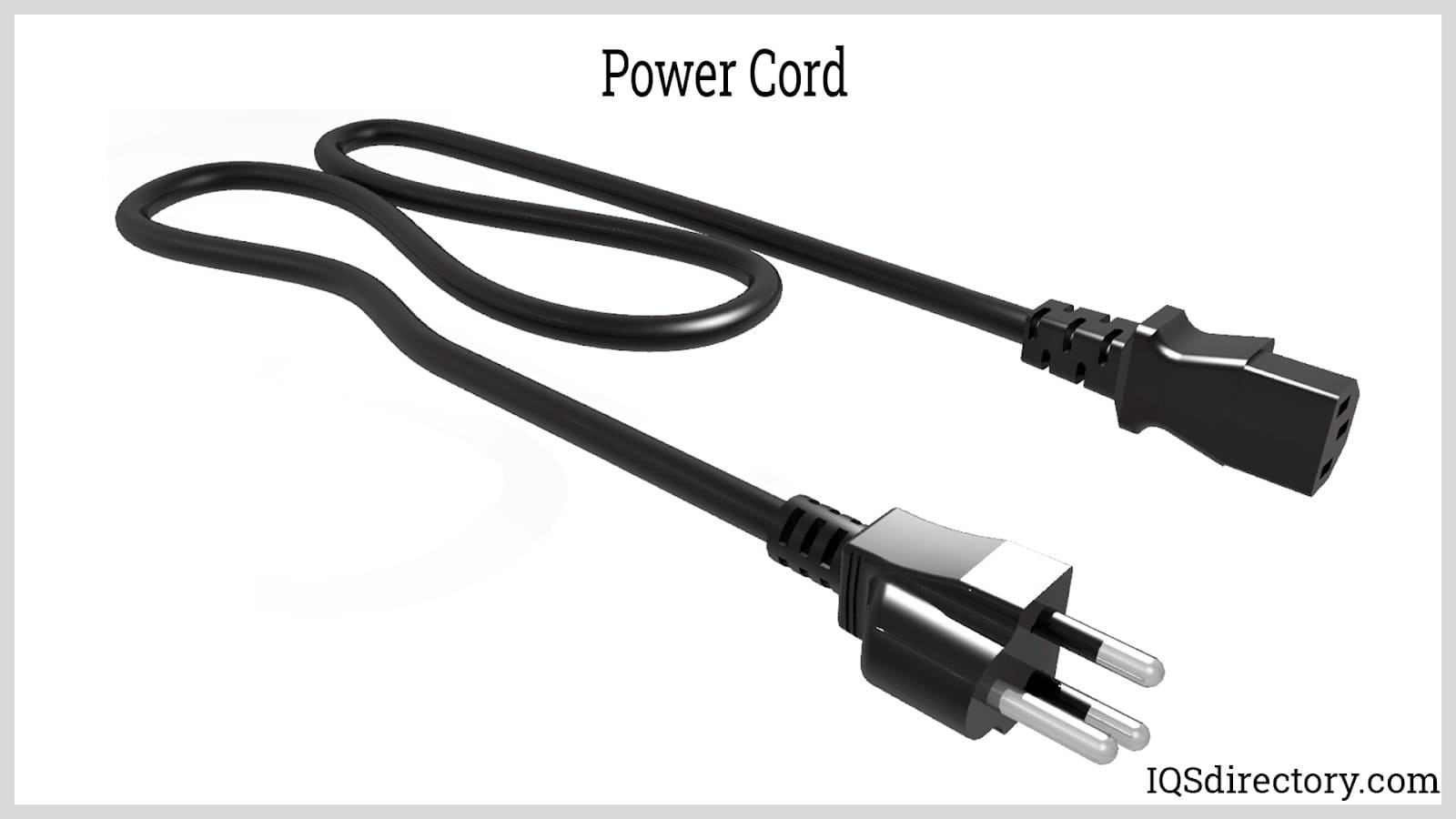

#4 Power Cord Manufacturers

Domain Est. 2001

Website: cordsets.org

Key Highlights: Instantly view the leading power cord manufacturers and suppliers in the United States who offer an assortment of power cords with varying lengths and uses ……

#5 Southwire

Domain Est. 1994

Website: southwire.com

Key Highlights: Choose Southwire for your wire and cable needs – we offer high-performance products that are built to last….

#6 Electrical Products

Domain Est. 1994

Website: molex.com

Key Highlights: Molex offers a complete line of reliable electrical solutions designed to support optimal worker safety and performance for today’s harsh duty environments….

#7 Power Cords and Adapters

Domain Est. 1996

Website: tripplite.eaton.com

Key Highlights: We offer AC power cords, extension cords, splitters and adapters for computers, servers and PDUs. Our cords have innovative features like coiled cords and ……

#8 StayOnline

Domain Est. 1996

#9 US Wire & Cable

Domain Est. 1997 | Founded: 1985

Website: uswireandcable.com

Key Highlights: Since 1985 US Wire & Cable Corporation has produced cable and extension cords right here on American soil….

Expert Sourcing Insights for Electrical Cord Parts

2026 Market Trends for Electrical Cord Parts

As the global demand for reliable and efficient electrical infrastructure continues to grow, the market for electrical cord parts is poised for significant transformation by 2026. Driven by technological advancements, regulatory changes, and evolving consumer needs, several key trends are shaping the future of this sector.

Rising Demand for Smart and Connected Devices

The proliferation of smart homes, electric vehicles (EVs), and Internet of Things (IoT) devices is increasing the need for intelligent electrical cord components. In 2026, manufacturers are expected to focus on integrating data transmission capabilities, overcurrent protection, and plug-and-play connectivity into cord parts such as connectors, plugs, and outlets. These upgrades enhance safety, energy efficiency, and user experience.

Emphasis on Sustainability and Eco-Friendly Materials

Environmental regulations and consumer awareness are pushing companies to adopt sustainable practices. By 2026, biodegradable insulation materials, halogen-free cables, and recyclable metal components are expected to gain prominence. Major markets in Europe and North America are projected to lead in adopting eco-certified electrical cord parts, driven by stringent directives like the EU’s RoHS and REACH standards.

Growth in Electric Vehicle Charging Infrastructure

The global shift toward electric mobility is accelerating the demand for high-performance charging cables and connectors. By 2026, the electrical cord parts market will see increased innovation in high-voltage connectors, weather-resistant sheathing, and fast-charging compatible components. This trend is especially evident in public charging stations, where durability and safety are critical.

Advancements in Material Science

New materials such as thermoplastic elastomers (TPE) and cross-linked polyethylene (XLPE) are enhancing the flexibility, heat resistance, and longevity of electrical cord parts. These materials allow for slimmer, more durable cords suitable for both industrial and consumer applications, supporting the miniaturization trend in electronics.

Regional Market Expansion

Asia-Pacific, particularly China and India, is expected to dominate market growth due to rapid urbanization, industrialization, and government investments in power infrastructure. Meanwhile, North America and Europe will focus on upgrading aging electrical grids and supporting renewable energy integration, increasing demand for compliant and high-efficiency cord components.

Supply Chain Resilience and Localization

Post-pandemic supply chain disruptions have prompted companies to diversify sourcing and localize production. By 2026, nearshoring and vertical integration strategies are anticipated to strengthen supply chain reliability for electrical cord parts, reducing dependency on single-source suppliers and mitigating geopolitical risks.

Regulatory and Safety Standards Evolution

Safety remains a top priority, with updated international standards (e.g., IEC, UL, CSA) expected to mandate stricter performance testing for cord parts. Features such as arc-fault detection, tamper-resistant designs, and improved grounding mechanisms will become standard, influencing product design and compliance requirements.

In conclusion, the 2026 electrical cord parts market will be defined by innovation, sustainability, and adaptability to emerging technologies. Stakeholders who invest in R&D, sustainable materials, and global compliance will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Electrical Cord Parts: Quality and Intellectual Property Issues

Logistics & Compliance Guide for Electrical Cord Parts

This guide outlines the essential logistics and compliance considerations for handling, transporting, and ensuring regulatory adherence of electrical cord parts throughout the supply chain.

Product Classification & Documentation

Electrical cord parts—including plugs, connectors, sockets, cables, strain reliefs, and terminals—must be accurately classified under the appropriate Harmonized System (HS) codes for import/export. Maintain detailed technical specifications, material safety data sheets (MSDS), and bills of materials (BOMs) to support classification and facilitate customs clearance.

Regulatory Compliance Standards

All electrical cord parts must comply with relevant regional and international safety and performance standards. Key regulations include:

- North America: UL/CSA standards (e.g., UL 62, UL 498), FCC Part 15 for electromagnetic interference (if applicable), and compliance with the National Electrical Code (NEC).

- European Union: CE marking per the Low Voltage Directive (LVD 2014/35/EU), RoHS (2011/65/EU) for hazardous substance restrictions, and REACH (EC 1907/2006) for chemical registration.

- Other Regions: IEC standards (e.g., IEC 60884, IEC 60320), UKCA marking (post-Brexit UK), and country-specific certifications such as CCC (China), PSE (Japan), or RCM (Australia/New Zealand).

Ensure all parts are certified by accredited testing laboratories and retain valid compliance documentation.

Packaging & Labeling Requirements

Use packaging that protects against physical damage, moisture, and electrostatic discharge (ESD). Clearly label each package with:

- Part number and description

- Quantity

- Lot/batch number and date of manufacture

- Supplier information

- Compliance marks (e.g., CE, UL, RoHS)

- Handling symbols (e.g., “Fragile,” “Do Not Stack”)

Labeling must be durable and legible throughout transit and storage.

Storage Conditions

Store electrical cord parts in a clean, dry, temperature-controlled environment. Avoid exposure to extreme heat, UV light, or corrosive substances. Maintain separation between compliant and non-compliant stock to prevent mix-ups. Implement a first-in, first-out (FIFO) inventory system to reduce obsolescence risk.

Transportation & Handling

Use carriers experienced in handling electrical components. Secure loads to prevent shifting during transit. For international shipments, ensure proper Incoterms (e.g., FOB, EXW, DDP) are defined in contracts. Monitor shipments with tracking systems and require proof of delivery. Sensitive components may require ESD-safe containers and climate-controlled transport.

Import/Export Controls

Verify export licensing requirements, particularly for dual-use items or shipments to restricted destinations. Screen all parties (suppliers, customers, intermediaries) against denied persons lists (e.g., OFAC, BIS). Complete accurate commercial invoices, packing lists, and certificates of origin. Declare any applicable preferential trade agreements (e.g., USMCA, RCEP) to optimize duty rates.

Quality Assurance & Traceability

Implement a traceability system that links each batch of electrical cord parts to raw materials, manufacturing records, and compliance test results. Conduct incoming inspections and periodic audits to verify conformance to specifications. Maintain a non-conformance process for handling defective or non-compliant items.

Environmental & End-of-Life Compliance

Ensure electrical cord parts are designed and documented to support recycling and responsible disposal. Comply with WEEE (Waste Electrical and Electronic Equipment) directives in applicable markets. Provide take-back or recycling information where required.

Record Retention

Retain all compliance, logistics, and quality records for a minimum of 5–10 years, depending on jurisdiction and industry requirements. Records should include test reports, certificates of compliance, shipping documents, and audit trails.

Adhering to this guide ensures safe, legal, and efficient handling of electrical cord parts across global supply chains.

In conclusion, sourcing electrical cord parts requires a careful and strategic approach to ensure safety, compliance, performance, and cost-effectiveness. Key considerations include selecting reliable suppliers with certifications and quality assurance processes, adhering to industry standards such as UL, CSA, or IEC, and verifying material specifications for durability and electrical conductivity. Additionally, evaluating factors such as lead times, scalability, and total cost of ownership contributes to a sustainable supply chain. By prioritizing quality, regulatory compliance, and strong supplier relationships, businesses can secure electrical cord components that meet technical requirements while minimizing risks and supporting long-term operational success.