The global electrical conduit market is experiencing steady growth, driven by rising infrastructure development, increased adoption in commercial and industrial construction, and stringent safety regulations mandating the use of protective cabling systems. According to Grand View Research, the global electrical conduit market size was valued at USD 14.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This expansion underscores the growing demand for reliable conduit components, including reducers—essential fittings that connect conduits of differing diameters while maintaining electrical continuity and mechanical protection. As construction activities accelerate globally and smart building technologies become more prevalent, the need for high-performance, code-compliant conduit accessories continues to rise. In this evolving landscape, a select group of manufacturers has emerged as leaders in producing durable, precision-engineered electrical conduit reducers, combining innovation, quality assurance, and global supply capabilities to meet the demands of modern electrical installations.

Top 8 Electrical Conduit Reducer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cantex PVC Conduit

Domain Est. 1996

Website: cantexinc.com

Key Highlights: LEADING MANUFACTURER OF PVC ELECTRICAL PRODUCTS CANTEX is the largest manufacturer of PVC electrical conduit, fittings, and boxes in the United States….

#2 Kraloy Fittings

Domain Est. 1999

Website: kraloyfittings.com

Key Highlights: Kraloy has been a pioneer leader in PVC conduit fittings for over 40 years. As the first UL approved manufacturer of PVC fittings, we are steadfast in our ……

#3 IPEX Inc.

Domain Est. 2009

Website: ipexna.com

Key Highlights: IPEX Inc. manufactures advanced PVC & CPVC piping systems for several applications for the Canadian market. Learn more….

#4 PVC Reducer Bushings

Domain Est. 2010

Website: atkore.com

Key Highlights: Non-corrosive PVC reducer bushings in 3/4″–4″ sizes. Reliable, non-conductive fitting for conduit applications.Missing: electrical manufacturer…

#5 Conduit Reducer Bushings

Domain Est. 1995

#6 Conduit Reducers

Domain Est. 1996

Website: stateelectric.com

Key Highlights: 6–10 day deliveryIt provide the versatility to convert fittings and boxes to many different sizes and configurations….

#7 Conduit Reducers

Domain Est. 1999

Website: reynoldsonline.com

Key Highlights: T&B® 1250-TB Female Threaded Conduit Reducer, 3/4 to 1/2 in, For Use With Rigid/IMC Conduits, Malleable Iron. MFG Part #:1250-TB….

#8 Bridgeport

Domain Est. 2004

Website: nsiindustries.com

Key Highlights: Bridgeport can simplify every installation with our superior cable and conduit fittings, cord grips, wire mesh, molded cord and cordsets. We keep your business ……

Expert Sourcing Insights for Electrical Conduit Reducer

H2: 2026 Market Trends for Electrical Conduit Reducer

The global market for electrical conduit reducers is poised for steady growth through 2026, driven by expanding construction activities, rising demand for energy-efficient infrastructure, and technological advancements in electrical installation systems. As critical components in electrical conduit systems, reducers ensure seamless transitions between conduits of different diameters, enhancing safety and system performance in residential, commercial, and industrial applications.

One of the key trends shaping the 2026 outlook is the surge in smart building and green construction projects. With increased emphasis on sustainable development and compliance with energy codes, electrical installations are becoming more standardized and reliable. This shift is boosting demand for high-quality conduit accessories, including reducers made from durable, corrosion-resistant materials such as PVC, galvanized steel, and stainless steel.

Additionally, rapid urbanization—particularly in Asia-Pacific and Latin America—is fueling construction booms, directly increasing the need for electrical infrastructure components. Countries like India, China, and Brazil are witnessing significant investments in industrial parks, data centers, and commercial complexes, all of which require extensive conduit systems. Electrical conduit reducers are essential in these installations to accommodate varying conduit sizes and ensure safe cable routing.

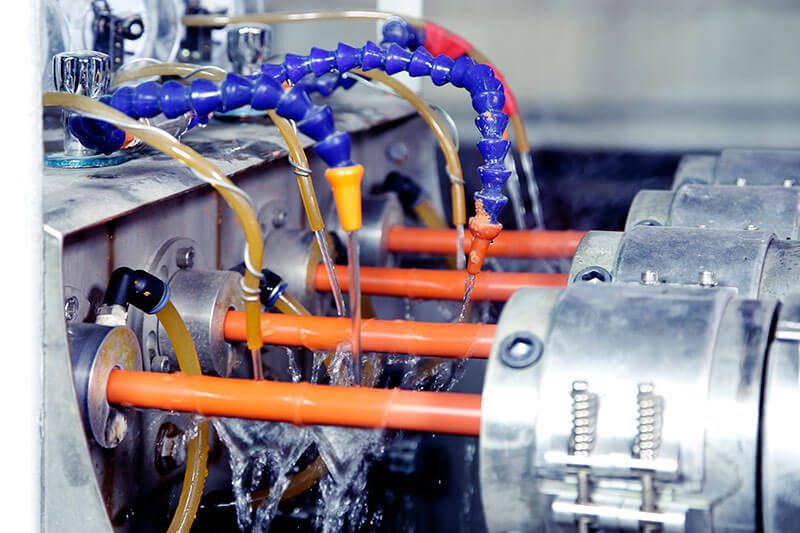

Technological integration is another emerging trend. Manufacturers are focusing on developing lightweight, easy-to-install reducers with improved thread precision and compatibility with modular electrical systems. The adoption of Building Information Modeling (BIM) in construction is also influencing product design, with conduit components now being optimized for digital planning and seamless integration.

Moreover, regulatory standards and safety requirements are becoming more stringent worldwide. This is pushing demand for certified conduit reducers that meet IEC, NEC, and UL standards. As a result, leading players are investing in R&D and quality assurance to maintain compliance and gain a competitive edge.

In conclusion, the 2026 market for electrical conduit reducers is set to benefit from infrastructural development, sustainability initiatives, and technological innovation. Stakeholders who prioritize product quality, regulatory compliance, and adaptability to smart construction ecosystems will be well-positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Electrical Conduit Reducers (Quality, IP)

Sourcing electrical conduit reducers may seem straightforward, but overlooking critical quality and Ingress Protection (IP) factors can lead to safety hazards, compliance issues, and costly failures. Below are key pitfalls to avoid:

Poor Material Quality and Durability

Choosing conduit reducers made from substandard materials—such as brittle plastics or low-grade metals—compromises mechanical strength and longevity. Inferior materials may crack under stress, corrode prematurely, or fail to maintain a secure connection, especially in harsh environments. Always verify material specifications (e.g., UV-resistant PVC, galvanized steel, or stainless steel) and ensure they meet relevant standards like UL, IEC, or EN.

Inadequate Ingress Protection (IP) Rating

Using reducers with insufficient IP ratings for the installation environment is a major oversight. For example, selecting an IP54-rated reducer for outdoor or wet locations may allow dust and moisture ingress, leading to electrical faults or corrosion. Always match the IP rating (e.g., IP66, IP68) to the environmental conditions—considering dust, water exposure, and washdown requirements—and confirm the entire conduit system maintains continuity of protection.

Non-Compliance with Electrical Codes and Standards

Sourcing reducers that don’t comply with regional or international electrical codes (e.g., NEC, CEC, IEC 61481) can result in failed inspections or unsafe installations. Ensure products are certified by recognized bodies (UL, CSA, TÜV, etc.) and explicitly rated for electrical conduit use. Generic or unbranded fittings often lack proper certification.

Improper Dimensional Fit and Compatibility

Reducers that don’t precisely match conduit outer diameters (ODs) can create loose connections, reducing mechanical integrity and IP performance. Variations in sizing standards (metric vs. imperial) or manufacturing tolerances may lead to gaps or difficulty in assembly. Always confirm exact size compatibility with both the larger and smaller conduits being joined.

Lack of Corrosion Resistance in Harsh Environments

In industrial, coastal, or high-humidity settings, standard metallic reducers may corrode over time, weakening the connection and jeopardizing safety. Avoid using non-corrosion-resistant materials without protective coatings. Opt for stainless steel, nylon, or adequately coated fittings where exposure to chemicals, salt, or moisture is expected.

Ignoring Temperature and UV Resistance

Plastic reducers exposed to extreme temperatures or direct sunlight may degrade, warp, or become brittle if not designed for such conditions. Ensure the material has appropriate thermal ratings and UV stabilization, especially for outdoor installations, to maintain structural and sealing integrity over time.

Compromised Sealing and Gasket Quality

Many reducers rely on integrated or separate gaskets to maintain IP ratings. Poorly designed or low-quality seals can deteriorate quickly, leading to compromised environmental protection. Verify that sealing components are durable, compatible with the housing material, and designed to retain compression over the product’s lifespan.

By avoiding these common pitfalls, you can ensure reliable, safe, and code-compliant electrical installations when sourcing conduit reducers.

Logistics & Compliance Guide for Electrical Conduit Reducer

Product Overview

Electrical conduit reducers are fittings used to connect conduits of differing diameters in electrical installations. They ensure secure, continuous pathways for electrical wiring while maintaining grounding continuity and protecting against environmental hazards. Proper logistics and compliance are essential for safe and legal distribution and use.

Classification & HS Code

The Harmonized System (HS) code for electrical conduit reducers typically falls under:

8544.42 – Insulating fittings for electrical conduits, tubes, or ducts, of plastics.

Alternatively, if made of metal: 7307.29 – Tube or pipe fittings (e.g., elbows, unions, flanges) of iron or steel.

Note: Final classification should be verified based on material composition and country-specific tariff schedules.

Regulatory Compliance Requirements

International Electrotechnical Commission (IEC) Standards

- IEC 61386 – Conduit systems for cable management: Specifies requirements for mechanical and electrical performance of conduit fittings, including reducers.

- Compliance ensures interoperability, mechanical strength, and suitability for intended environments.

National Electrical Code (NEC) – United States

- NEC Article 342 & 344 – Covers requirements for rigid metal and nonmetallic conduit, including approved fittings such as reducers.

- Reducers must be listed and labeled by a Nationally Recognized Testing Laboratory (NRTL) such as UL or ETL.

UL Certification

- UL 514B – Standard for Conduit, Tubing, and Cable Fittings.

- Products must be evaluated and certified to this standard for legal sale in the U.S. market. Look for UL listing marks on packaging or product.

European Conformity (CE Marking)

- Must comply with Low Voltage Directive (2014/35/EU) and EMC Directive (2014/30/EU) as applicable.

- Assessment under EN 61386 series standards is required.

- Technical documentation and EU Declaration of Conformity must be maintained.

RoHS & REACH Compliance (EU)

- RoHS (2011/65/EU): Restricts use of hazardous substances (e.g., lead, cadmium) in electrical equipment.

- REACH (EC 1907/2006): Requires disclosure of Substances of Very High Concern (SVHC).

- Suppliers must provide compliance documentation for materials used.

Packaging & Labeling Requirements

- Clearly label product with:

- Product name and size (e.g., “1/2” to 3/4” Conduit Reducer”)

- Material type (e.g., PVC, galvanized steel)

- Compliance marks (UL, CE, etc.)

- Manufacturer name and part number

- Batch/lot number and date of production

- Use anti-corrosive and moisture-resistant packaging for metal products.

- Include multilingual safety and installation instructions where required.

Shipping & Transportation Considerations

- Mode of Transport: Suitable for air, sea, or ground freight.

- Packaging: Use sturdy cartons with internal dividers to prevent damage. Palletize for bulk shipments.

- Hazard Classification: Non-hazardous under IATA, IMDG, and ADR regulations.

- Storage Conditions: Store in dry, temperature-controlled environments to prevent degradation (especially for PVC reducers).

Import/Export Documentation

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Conformity (CoC)

- Test Reports (e.g., UL, IEC)

- Certificate of Origin (required for preferential tariffs)

- Import Declaration (varies by country)

Country-Specific Requirements

- USA: NRTL certification (UL/ETL), NEC compliance, customs bond required for importers.

- Canada: Must meet CSA C22.2 No. 45 standards; cULus listing preferred.

- UK: UKCA marking required post-Brexit; adherence to UK Wiring Regulations (BS 7671).

- Australia: Must comply with AS/NZS 3000 and carry RCM (Regulatory Compliance Mark).

- Middle East (GSO, SASO): G-Mark or SASO Conformity required; often need local certification body approval.

Quality Assurance & Traceability

- Maintain lot traceability through batch records and QC testing logs.

- Conduct periodic audits of manufacturing processes and supplier compliance.

- Implement corrective action procedures for non-conforming products.

Disposal & Environmental Responsibility

- Metal reducers are recyclable; PVC reducers should be disposed of in accordance with local plastic waste regulations.

- Follow WEEE (Waste Electrical and Electronic Equipment) guidelines if applicable in region of sale.

Summary

Electrical conduit reducers must meet stringent safety, performance, and environmental regulations across global markets. Adhering to standards such as UL, IEC, CE, and NEC, along with accurate documentation and proper logistics planning, ensures smooth import/export operations and end-user safety. Always verify specific country requirements before shipment.

Conclusion:

Sourcing the appropriate electrical conduit reducer is a critical step in ensuring the safety, compliance, and functionality of electrical installations. By carefully evaluating factors such as material compatibility, size specifications, environmental conditions, and adherence to relevant electrical codes (e.g., NEC, IEC), procurement decisions can significantly impact the long-term reliability of the system. It is essential to source reducers from reputable suppliers who provide certified, high-quality products to avoid risks associated with poor connections, mechanical stress, or code violations. Additionally, considering cost-effectiveness without compromising on quality ensures both efficiency and durability in electrical projects. Ultimately, a well-informed sourcing strategy for electrical conduit reducers supports seamless installation, reduces maintenance needs, and enhances overall system integrity.