The global textile machinery market is undergoing a significant transformation, driven by rising demand for automation and precision in yarn processing. According to a report by Mordor Intelligence, the global textile machinery market was valued at USD 104.5 billion in 2023 and is projected to grow at a CAGR of 5.8% through 2029, with electric yarn winding machines representing a critical segment due to their efficiency and integration into smart manufacturing systems. This growth is fueled by increasing production in the apparel and technical textiles sectors, particularly across Asia-Pacific regions like China, India, and Bangladesh. As manufacturers prioritize consistency, speed, and reduced labor costs, electric yarn winders have become essential equipment in both industrial and artisanal settings. In response to this demand, several companies have emerged as leading innovators in electric yarn winder technology—combining advanced motorization, digital controls, and ergonomic design. Based on market presence, technological capability, customer reviews, and production scale, the following six manufacturers represent the forefront of innovation and reliability in the electric yarn winder space.

Top 6 Electric Yarn Winder Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

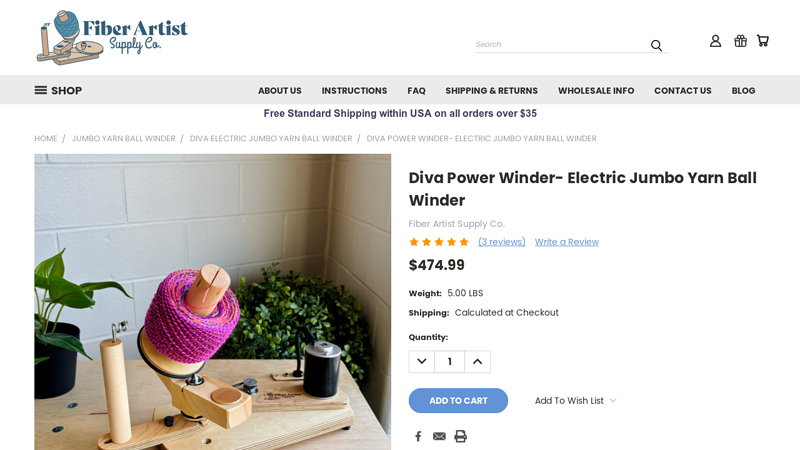

#1 Diva Power Winder

Domain Est. 2008

Website: fiberartistsupply.com

Key Highlights: In stock Rating 5.0 (3) This innovative winder combines the same high-quality components as our popular Maple Jumbo Yarn Ball Winder but adds the convenience of a motor.Missing: …

#2 Lohia Corp

Domain Est. 1998

Website: lohiagroup.com

Key Highlights: Lohia Corp manufactures reliable machinery for woven sacks, monofilament, and strapping, serving industries like packtex, buildtex, agrotex, ……

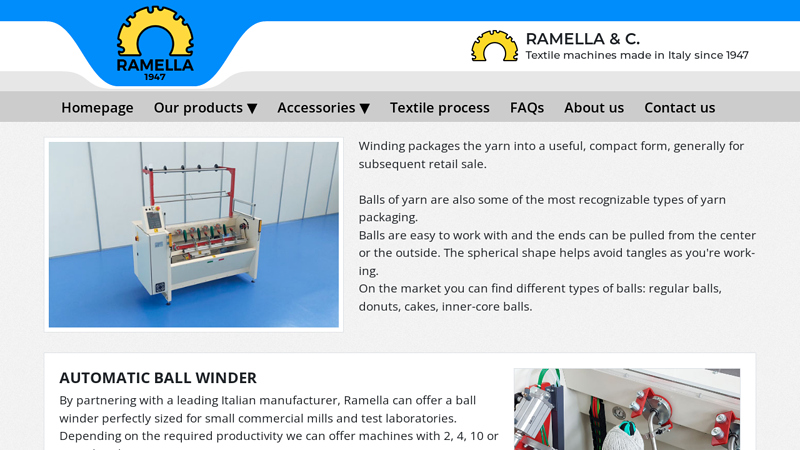

#3 Ball winder for fiber mills and textile laboratories

Domain Est. 2002

Website: ramella.com

Key Highlights: A ball winder perfectly sized for small commercial mills and test laboratories. Depending on the required productivity we can offer machines with 2, 4, 10 or ……

#4 WeaveR The Electric yarn ball winder by Choi Sunny

Domain Est. 2007

Website: indiegogo.com

Key Highlights: WeaveRs electric winder process gets the very best from your yarn.It reduces static and improves your yarn quality to the best it can be, to allow you to knit ……

#5 Electric Yarn Ball Winder M1 Pro

Domain Est. 2019

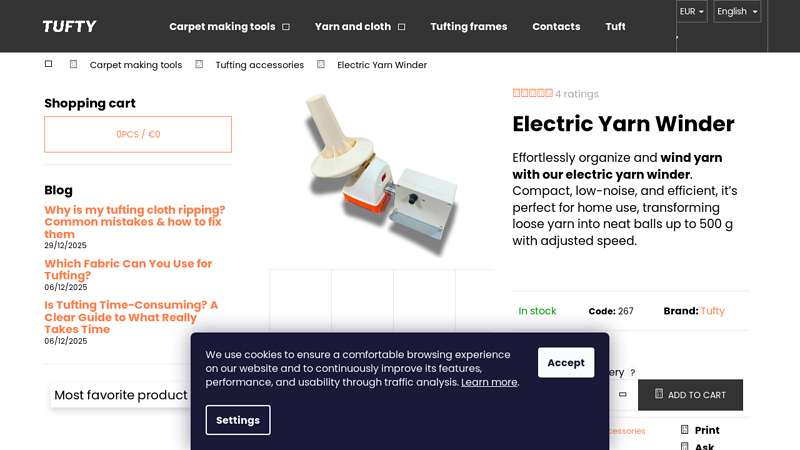

#6 Electric Yarn Winder

Website: tufty.eu

Key Highlights: In stock Rating 4.5 (4) Electric Yarn Winder: Easily wind up to 500 g of yarn into neat balls with this compact, low-noise device. Perfect for efficient home crafting….

Expert Sourcing Insights for Electric Yarn Winder Machine

H2: Market Trends for Electric Yarn Winder Machines in 2026

The global market for electric yarn winder machines is poised for significant transformation by 2026, driven by technological innovation, shifting consumer demands in the textile industry, and increased automation in manufacturing processes. As sustainability and efficiency become central themes across industries, the electric yarn winder machine sector is adapting to meet evolving needs. Below are key market trends expected to shape the landscape in 2026:

-

Increased Automation and Smart Integration

By 2026, electric yarn winder machines are expected to feature advanced automation and IoT (Internet of Things) integration. Manufacturers are incorporating sensors, real-time monitoring systems, and AI-driven diagnostics to optimize winding precision and reduce downtime. These smart machines can self-diagnose performance issues, adjust tension settings automatically, and communicate with other equipment in smart factories, enhancing overall production efficiency. -

Growing Demand from the Handcraft and DIY Textile Sector

The resurgence of handcrafting, knitting, and yarn-based DIY projects has spurred consumer demand for compact, user-friendly electric yarn winders. In 2026, this segment is expected to expand significantly, especially in North America and Europe. Home-based crafters and small-scale producers are increasingly investing in affordable, quiet, and energy-efficient models, prompting manufacturers to develop specialized consumer-grade models. -

Focus on Energy Efficiency and Sustainability

With global emphasis on reducing carbon footprints, manufacturers are designing electric yarn winders that consume less power and utilize recyclable materials. Energy-efficient motors and regenerative braking systems are being integrated to minimize energy waste. Additionally, brands are promoting eco-friendly production practices to appeal to environmentally conscious businesses and consumers. -

Expansion in Emerging Markets

Countries in Southeast Asia, India, and parts of Africa are witnessing rapid growth in textile manufacturing and artisanal production. By 2026, these regions are expected to be key growth markets for electric yarn winder machines. Government initiatives supporting small and medium enterprises (SMEs) in the textile sector are further accelerating adoption. -

Customization and Modular Design

To cater to diverse yarn types (wool, cotton, synthetic blends) and winding requirements, manufacturers are offering modular electric winders with interchangeable components. Customizable speed controls, adjustable tension settings, and compatibility with various cone or spool sizes are becoming standard features, allowing users to tailor machines to specific applications. -

Rise of E-Commerce and Direct-to-Consumer Sales

Online platforms are playing a crucial role in the distribution of electric yarn winder machines. By 2026, an increasing number of manufacturers are leveraging e-commerce channels to reach global customers, offering detailed product comparisons, video tutorials, and customer support. This trend is particularly influential in expanding access for hobbyists and small businesses. -

Competitive Pricing and Market Consolidation

As more players enter the market, competition is intensifying, leading to price optimization and innovation. While established industrial brands dominate the high-end segment, new entrants from China and India are offering cost-effective alternatives. Market consolidation through mergers and acquisitions is expected to increase, especially among mid-tier manufacturers aiming to scale operations and enhance R&D capabilities.

In conclusion, the electric yarn winder machine market in 2026 will be characterized by technological sophistication, sustainability, and broader market accessibility. The convergence of industrial needs and consumer trends will drive innovation, positioning electric winders as essential tools across both large-scale textile operations and niche crafting communities.

Common Pitfalls When Sourcing Electric Yarn Winder Machines (Quality and Intellectual Property)

Sourcing electric yarn winder machines from international suppliers, especially in competitive manufacturing regions, presents several risks related to product quality and intellectual property (IP) protection. Being aware of these pitfalls is crucial for making informed procurement decisions and safeguarding your business.

Poor Build Quality and Substandard Components

One of the most frequent issues is receiving machines constructed with inferior materials and low-grade components. Suppliers may cut costs by using thin metal frames, weak plastic gears, or low-efficiency motors, leading to premature wear, mechanical failure, and inconsistent winding performance. This not only increases maintenance costs but can also disrupt production timelines.

Inaccurate Winding Specifications and Performance

Some suppliers exaggerate machine capabilities, such as winding speed, tension control accuracy, or compatibility with various yarn types. Units delivered may not meet advertised specifications, resulting in uneven winding, yarn breakage, or incompatibility with existing workflows. Without third-party verification or detailed technical documentation, it can be difficult to confirm performance claims before purchase.

Lack of Safety Certifications and Compliance

Many sourced machines lack essential safety certifications (e.g., CE, UL, or ISO standards), especially if fabricated in facilities with lax regulatory oversight. This poses safety risks to operators and can lead to legal liabilities or import restrictions in regulated markets. Always verify compliance documentation before shipment.

Inadequate After-Sales Support and Spare Parts Availability

Suppliers may offer limited technical support, unclear warranty terms, or no local service network. If a machine breaks down, obtaining replacement parts or expert repairs can take weeks or months, causing costly downtime. Some suppliers discontinue models quickly, making long-term maintenance challenging.

Intellectual Property Infringement Risks

A significant but often overlooked risk is sourcing machines that infringe on existing patents or designs. Some manufacturers replicate branded models without authorization, offering “look-alike” machines at lower prices. Purchasing such equipment exposes your business to legal action, customs seizures, or reputational damage, particularly in IP-sensitive markets.

Insufficient Documentation and Language Barriers

Technical manuals, maintenance guides, and control panel interfaces may be poorly translated or incomplete. This complicates installation, troubleshooting, and operator training, increasing the likelihood of misuse and reducing machine lifespan.

Hidden Costs and Unclear Quoting

Initial quotes may exclude shipping, import duties, taxes, or installation services. Some suppliers also charge premium rates for essential accessories or software updates. Without a detailed, itemized quotation, total ownership costs can significantly exceed expectations.

By conducting thorough due diligence—requesting product samples, verifying certifications, performing factory audits, and consulting IP professionals—buyers can mitigate these risks and ensure reliable, lawful sourcing of electric yarn winder machines.

Logistics & Compliance Guide for Electric Yarn Winder Machine

Product Overview

The Electric Yarn Winder Machine is a motorized device designed to efficiently wind yarn from skeins or hanks into neat balls or center-pull cakes. It is commonly used by knitters, crocheters, and textile hobbyists. Key components typically include a motorized drum, tension control system, ball holder, and power supply (AC adapter or direct plug-in).

Classification & Tariff Codes (HS Code)

Proper classification is essential for international shipping and customs clearance. The Electric Yarn Winder Machine generally falls under the following Harmonized System (HS) code:

- HS Code: 8448.39 — Parts and accessories for machines of heading 8444 to 8447, specifically for textile machinery.

- Note: If the machine is classified as a consumer appliance rather than industrial textile equipment, it may fall under 8509.80 (Electromechanical domestic appliances with self-contained electric motors, other than vacuum cleaners).

- Recommendation: Confirm the appropriate HS code with local customs authorities or a licensed customs broker based on the product’s technical specifications and intended use.

Packaging & Shipping Requirements

To ensure safe transit and compliance with international shipping standards:

- Packaging:

- Use sturdy corrugated cardboard boxes with internal cushioning (e.g., foam inserts or molded pulp).

- Secure all moving parts (drum, ball holder) to prevent damage during transport.

-

Include user manuals, safety instructions, and warranty cards inside the package.

-

Labeling:

- Clearly display the product name, model number, voltage rating, manufacturer details, and safety certifications.

-

Include handling labels such as “Fragile,” “This Side Up,” and “Keep Dry.”

-

Shipping Modes:

- Air freight: Suitable for small volumes; requires compliance with IATA regulations for lithium batteries (if applicable).

- Ocean freight: Cost-effective for bulk shipments; ensure proper palletization and moisture protection.

- Express courier (e.g., DHL, FedEx): Ideal for samples or urgent deliveries; complete accurate commercial invoices.

Electrical & Safety Compliance

The Electric Yarn Winder Machine must meet electrical safety standards in the destination market:

- Key Certifications:

- CE Marking (Europe): Required under the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive.

- FCC Certification (USA): Mandatory if the device emits radio frequency energy.

- UL/ETL Listing (USA/Canada): Recommended for consumer electrical safety.

- PSE Mark (Japan): Required for electrical appliances.

-

KC Certification (South Korea): Mandatory for electrical goods.

-

Voltage & Plug Standards:

- Ensure the machine supports local voltage (e.g., 110–120V in North America, 220–240V in Europe).

- Include or specify region-specific power adapters or plugs.

Import Regulations & Documentation

Prepare the following documents for customs clearance:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin

- Product Test Reports (e.g., EMC, safety)

- Import License (if required by destination country)

- Insurance Certificate

Note: Some countries may impose import duties, VAT, or anti-dumping measures on textile machinery. Verify tariff rates and trade agreements (e.g., USMCA, RCEP) applicable to the HS code.

Environmental & RoHS Compliance

The product must comply with environmental regulations restricting hazardous substances:

- RoHS Directive (EU): Limits the use of lead, mercury, cadmium, and other hazardous materials in electrical equipment.

- REACH Regulation (EU): Requires disclosure of Substances of Very High Concern (SVHC).

- WEEE Directive (EU): Applies if the product is classified as electrical waste; requires take-back and recycling provisions.

Ensure suppliers provide RoHS-compliant components and issue a Declaration of Conformity.

Warranty & After-Sales Support

- Provide clear warranty terms (e.g., 1-year limited warranty).

- Include multilingual user manuals and troubleshooting guides.

- Establish a support channel for repairs, spare parts, and customer inquiries.

- Comply with local consumer protection laws (e.g., EU Consumer Rights Directive).

Summary Checklist

- [ ] Confirm correct HS code with customs broker

- [ ] Package securely with protective materials

- [ ] Apply required safety certifications (CE, FCC, UL, etc.)

- [ ] Include multilingual labels and documentation

- [ ] Verify voltage compatibility and plug type

- [ ] Prepare complete customs documentation

- [ ] Ensure RoHS and environmental compliance

- [ ] Establish after-sales service and warranty process

By following this guide, importers and exporters can ensure smooth logistics operations and full compliance when shipping Electric Yarn Winder Machines globally.

Conclusion:

After thorough evaluation of various suppliers, technical specifications, cost considerations, and market demand, sourcing an electric yarn winder machine presents a strategic opportunity to enhance production efficiency, reduce manual labor, and ensure consistent product quality in textile or yarn-handling operations. The availability of reliable machines from reputable manufacturers—both domestically and internationally—offers flexibility in terms of budget, capacity, and automation features.

Key factors such as machine durability, ease of maintenance, energy efficiency, and after-sales support have been prioritized to ensure long-term operational success. Additionally, bulk procurement or partnerships with trusted suppliers can lead to favorable pricing and timely deliveries.

In conclusion, investing in an electric yarn winder machine is a cost-effective and scalable solution that aligns with modern manufacturing standards. By selecting a machine that meets technical requirements and partnering with a dependable supplier, businesses can significantly improve workflow, reduce processing time, and remain competitive in the evolving textile industry.