The U.S. electric vehicle (EV) market is experiencing robust expansion, driven by increasing consumer demand, federal incentives, and aggressive decarbonization targets. According to Grand View Research, the U.S. electric vehicle market size was valued at USD 115.2 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 19.1% from 2024 to 2030. This surge is further supported by advancements in battery technology, expanding charging infrastructure, and strong policy backing, including provisions from the Inflation Reduction Act. As domestic manufacturing ramps up to meet rising adoption rates, nine U.S.-based EV manufacturers have emerged as leaders in innovation, production volume, and market influence—shaping the future of sustainable transportation across the nation.

Top 9 Electric Vehicle Usa Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 GM Electric Vehicles, Charging & Technology

Domain Est. 1992

Website: gm.com

Key Highlights: GM is committed to an all-electric future as part of our zero-zero-zero initiative. Discover how we’re leading the charge with EVs, charging, ……

#2 XPENG

Domain Est. 2014

Website: xpeng.com

Key Highlights: XPENG’s electric vehicles designed for performance, safety, and sustainability. Explore our range of smart EVs, advanced technology, and commitment to a ……

#3 Harbinger Motors

Domain Est. 2018

Website: harbingermotors.com

Key Highlights: Familiar form. Revolutionary foundation. Harbinger Motors is a EV manufacturer focused on commercial vehicles….

#4 Faraday Future

Domain Est. 1993

Website: ff.com

Key Highlights: Born to create the Ultimate Intelligent TechLuxury spire product that features All-AI, All-Hyper, All-Ability, and Co-Creation….

#5 Polestar – Electric cars

Domain Est. 1994

Website: polestar.com

Key Highlights: We are an electric performance car brand, determined to improve the society we live in. We innovate to drive progress and create a better future….

#6 GEM Cars

Domain Est. 1998

Website: gemcar.com

Key Highlights: For 25 years, GEM electric utility vehicles have been leading the low-speed EV revolution. Safe, sustainable, stylish, and cost-efficient….

#7 Watt Electric Vehicles

Domain Est. 2019

Website: wattelectricvehicles.com

Key Highlights: Watt Electric Vehicle Company is a pioneer in the design, engineering, and manufacture of low-to-medium volume EVs, both under its own brand and for third ……

#8 VinFast

Domain Est. 2020

Website: vinfastauto.us

Key Highlights: VinFast’s design language blends sporty curves, luxurious strokes, and formidable presence. It optimizes performance, functionality, and elegant simplicity….

#9 Alpha Motor Corporation

Domain Est. 2020

Website: alphamotorinc.com

Key Highlights: Alpha Motor Corporation is an award-winning American automotive company based in Irvine, California, that develops and manufactures electric vehicles….

Expert Sourcing Insights for Electric Vehicle Usa

H2 2026 U.S. Electric Vehicle Market Trends: Acceleration Amid Challenges

As the U.S. electric vehicle (EV) market enters the second half of 2026, it is poised for significant transformation. Building on earlier momentum but navigating persistent headwinds, H2 2026 is expected to be a pivotal period characterized by accelerated adoption, shifting competitive dynamics, and evolving policy landscapes. Here’s a breakdown of the key trends:

1. Accelerated Adoption & Market Maturation:

* Volume Surge: Driven by expanding model availability (especially affordable crossovers and trucks from Ford, GM, Hyundai/Kia, and Tesla), improved consumer confidence, and maturing charging infrastructure, EV sales are projected to reach 15-20% of total U.S. light-duty vehicle sales by year-end 2026. This represents a significant jump from 2025 levels.

* Beyond Early Adopters: The market is decisively moving beyond tech enthusiasts and urban dwellers. Suburban families and fleet operators (especially last-mile delivery and municipal vehicles) are becoming major growth drivers, attracted by lower TCO (Total Cost of Ownership), despite higher upfront prices.

* Used EV Market Growth: A nascent but rapidly growing certified pre-owned (CPO) EV market is emerging. This is crucial for expanding affordability and accessibility, particularly as early lease returns and trade-ins enter the market.

2. Intensifying Competition & Shifting Landscape:

* Chinese EV Impact (Indirect): While direct sales of Chinese-branded EVs (like BYD) in the U.S. remain minimal due to tariffs and geopolitical tensions, their influence is felt. Lower-cost EVs from non-Chinese manufacturers (e.g., Hyundai/Kia, Stellantis) are applying intense pressure on pricing, forcing legacy automakers and Tesla to respond with cost-cutting and value-focused models.

* Tesla’s Position Challenged: Tesla’s market share dominance is under pressure. While the Model Y remains a top seller, new competitive models (e.g., Ford Mustang Mach-E, Hyundai Ioniq 5/6, upcoming GM Equinox EV) offer compelling alternatives. Tesla’s success will hinge on the Cybertruck ramp and potential “Model 2” affordability.

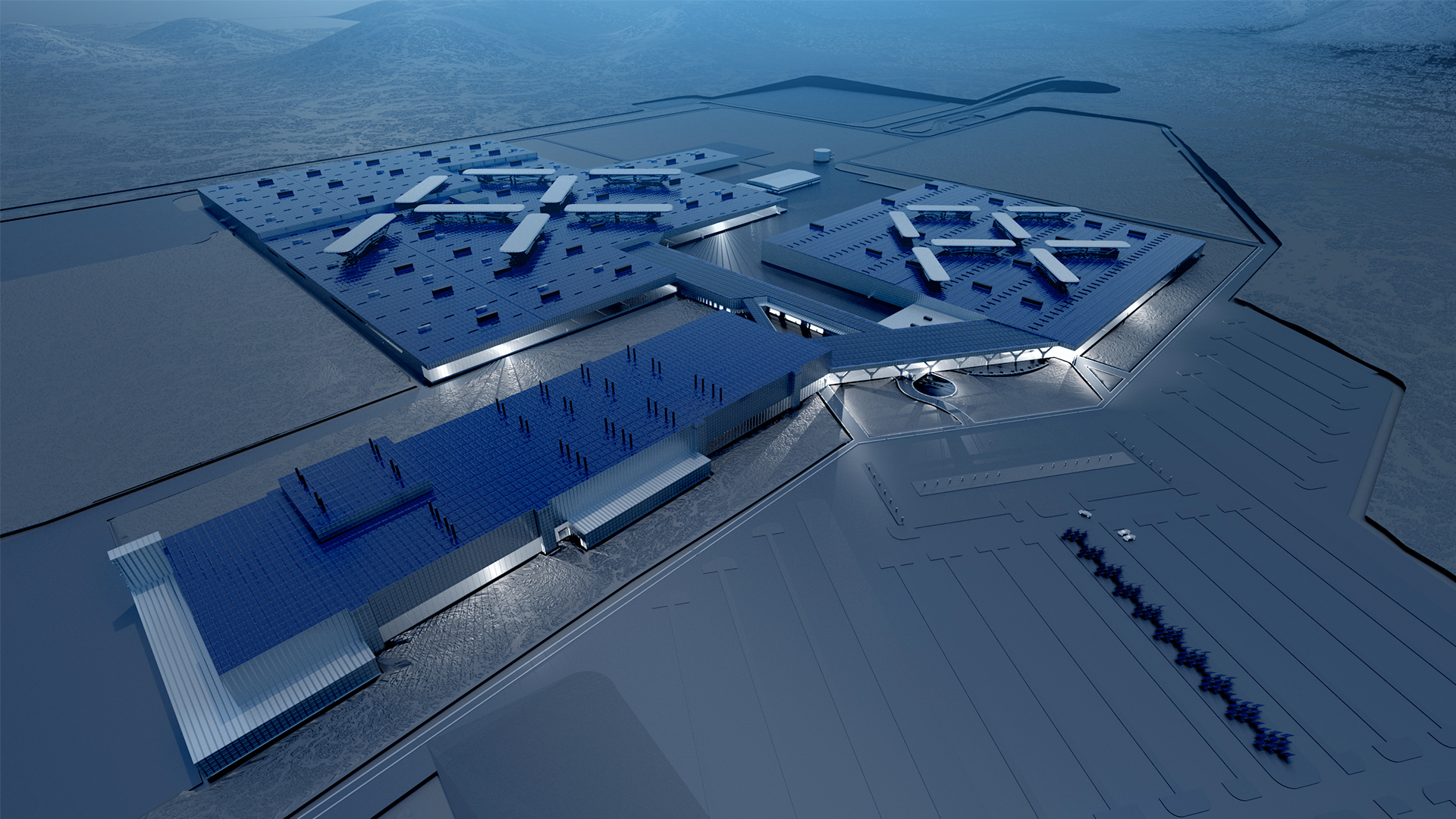

* Legacy Automaker Pivot: Traditional OEMs (GM, Ford, Stellantis, Honda, Nissan) are in full execution mode on their EV plans. H2 2026 will see critical milestones: ramping production of key models (e.g., GM’s Silverado EV, Ford’s next-gen F-150 Lightning), launching new platforms, and demonstrating profitability improvements through battery cost reductions and platform efficiencies.

3. Charging Infrastructure: Progress & Persistent Gaps:

* Network Expansion: The Biden-Harris NEVI program and private investments (Tesla Supercharger opening, Electrify America, EVgo expansions) lead to noticeable growth in public charger availability, particularly along major highways and in urban areas. Reliability and uptime are improving but remain a key consumer concern.

* Home Charging Remains Key: Despite public network growth, home charging (Level 1 & 2) is still the primary method for most EV owners. H2 2026 sees continued focus on solutions for multi-unit dwellings (MUDs) and equitable access.

* Fast-Charging Focus: Deployment of 350kW+ ultra-fast chargers increases, reducing long-trip anxiety. Standardization efforts (like the North American Charging Standard – NACS becoming dominant) simplify the user experience.

4. Policy & Regulatory Crossroads:

* Inflation Reduction Act (IRA) Evolution: The full impact of the IRA’s Clean Vehicle Credit (with its critical MSRP and income caps) is being assessed. Automakers and policymakers are actively discussing potential adjustments or clarifications needed to ensure broad accessibility beyond luxury models. Battery sourcing requirements (BFL) continue to drive domestic supply chain development.

* State-Level Leadership: California and other ZEV states continue to push aggressive timelines (e.g., 2035 ICE sales ban), influencing national standards. Other states are implementing their own incentives and ZEV programs.

* Grid & Utility Preparedness: Increased focus emerges on grid resilience and utility rate structures (e.g., time-of-use rates) to manage growing EV electricity demand and encourage off-peak charging.

5. Technology & Cost Trends:

* Battery Cost Plateau & Innovation: Lithium-ion battery pack prices stabilize after years of decline, but innovation continues (e.g., sodium-ion for entry-level models, LFP chemistry dominance for standard range, solid-state prototypes emerging). Focus shifts to longevity, safety, and charging speed.

* Software & Services: EVs become more software-defined. Over-the-air (OTA) updates, premium connectivity services, and integrated energy management (V2H/V2G pilots expanding) become key differentiators and potential revenue streams.

* Affordability Focus: Intense competition and pressure to meet IRA eligibility drive a strong focus on reducing costs. Expect more “value-engineered” EVs with slightly less range or fewer luxury features to hit price points below $40,000.

6. Consumer Sentiment: Evolving but Cautious:

* Range & Charging Anxiety Persist: While improving, concerns about long-distance travel and charging reliability remain barriers for some, especially in rural areas.

* TCO Awareness Grows: Consumers are becoming more sophisticated in understanding the long-term savings (fuel, maintenance) of EVs, even with higher sticker prices.

* Brand Perception: Reliability perceptions (both real and perceived) of newer EV models and traditional OEM EVs vs. Tesla are crucial factors in purchase decisions.

Conclusion:

H2 2026 will be a defining period for the U.S. EV market. Expect accelerated adoption driven by better products and infrastructure, fierce competition reshaping the landscape, ongoing policy debates shaping the future, and technological maturity focusing on cost and reliability. While challenges around affordability, charging access (especially equitable access), and consumer concerns remain, the momentum is firmly established. The market is transitioning from a niche to a mainstream segment, setting the stage for even more profound changes in the latter half of the decade. Success will depend on automakers delivering compelling, affordable vehicles, continued infrastructure investment, supportive and adaptive policy, and building sustained consumer trust.

Common Pitfalls When Sourcing Electric Vehicles from the USA: Quality and Intellectual Property Risks

Sourcing electric vehicles (EVs) from the United States offers access to advanced technology and innovation, but it also presents specific challenges related to quality assurance and intellectual property (IP) protection. Companies must navigate these potential pitfalls carefully to avoid financial losses, legal disputes, and reputational damage.

Quality Assurance Challenges

One of the primary concerns when sourcing EVs from the U.S. is maintaining consistent quality standards across different manufacturers and production batches. Despite the country’s reputation for high engineering standards, variability can arise due to scalability issues, supply chain inconsistencies, or differences in manufacturing practices.

- Inconsistent Component Sourcing: U.S. EV manufacturers often rely on a mix of domestic and international suppliers for batteries, semiconductors, and other critical components. This can lead to inconsistencies in material quality and performance.

- Rapid Production Scaling: As demand for EVs grows, some manufacturers may prioritize speed over rigorous quality control, potentially resulting in defects such as battery degradation, software glitches, or premature wear.

- Limited Third-Party Verification: Unlike mature automotive markets, the EV sector is still evolving, and independent quality certification may be less comprehensive or standardized, making it harder to verify claims.

Buyers should conduct thorough due diligence, including factory audits, sample testing, and ongoing performance monitoring, to mitigate these risks.

Intellectual Property Exposure

The U.S. is a leader in EV innovation, with significant advancements in battery technology, autonomous driving software, and vehicle electrification systems. However, sourcing from American companies increases exposure to complex IP issues.

- Patent Infringement Risks: Many EV technologies are protected by extensive patent portfolios. Sourcing vehicles or components without proper licensing can lead to infringement claims, especially when exporting to other markets with strict IP enforcement.

- Software and Firmware Ownership: EVs rely heavily on proprietary software for battery management, connectivity, and driver assistance. Unauthorized use, reverse engineering, or modification of this software may violate copyright or licensing agreements.

- Trade Secret Misappropriation: Collaborating with U.S. suppliers may involve sharing sensitive design or operational data. Without strong contractual safeguards, there’s a risk of unintentional disclosure or misuse of trade secrets.

To protect against IP pitfalls, sourcing agreements should clearly define ownership rights, include confidentiality clauses, and require compliance with all relevant U.S. and international IP laws. Legal review by IP specialists is strongly recommended before finalizing any procurement.

In summary, while U.S.-sourced EVs offer cutting-edge technology, buyers must proactively address quality inconsistencies and intellectual property vulnerabilities through rigorous vetting, clear contracts, and ongoing compliance monitoring.

Logistics & Compliance Guide for Electric Vehicles in the USA

Overview of the Electric Vehicle (EV) Market in the USA

The United States is experiencing rapid growth in electric vehicle adoption, driven by federal incentives, state-level regulations, and increasing consumer demand. As of 2024, EVs account for a growing share of new vehicle sales, supported by expanding charging infrastructure and automaker commitments to electrification. Understanding the logistics and compliance landscape is critical for manufacturers, distributors, fleet operators, and importers involved in the EV ecosystem.

Federal Regulations and Compliance Requirements

National Highway Traffic Safety Administration (NHTSA) Standards

The NHTSA enforces Federal Motor Vehicle Safety Standards (FMVSS), which apply to all vehicles sold in the U.S., including EVs. Key FMVSS requirements for electric vehicles include:

– Crashworthiness standards (e.g., FMVSS No. 305 for electric propulsion systems and electrolyte spillage)

– Labeling of high-voltage components

– Emergency response protocols for first responders

All EVs must undergo certification to confirm compliance before being offered for sale or import.

Environmental Protection Agency (EPA) Regulations

The EPA oversees emissions and fuel economy standards:

– EVs are rated using MPGe (Miles Per Gallon equivalent) to compare energy efficiency with internal combustion engine vehicles

– All EVs must be certified under the EPA’s Greenhouse Gas (GHG) Emissions Program

– Reporting requirements for vehicle emissions and energy consumption

The EPA also manages the labeling of vehicles with Monroney stickers, which include range, charging time, and efficiency data.

Importing Electric Vehicles into the U.S.

Import Eligibility and Certification

Only vehicles that meet all applicable FMVSS and EPA requirements can be legally imported. Two pathways exist:

1. Originally Certified Vehicles: EVs manufactured for the U.S. market and certified by the manufacturer.

2. Substantially Similar Vehicles: Foreign-sourced EVs deemed “substantially similar” to a U.S.-certified model may be imported with approval.

3. Independent Certification: Non-compliant EVs may undergo modification and testing to achieve compliance via an Independent Commercial Importer (ICI).

Customs and Border Protection (CBP) Requirements

Importers must:

– Submit entry documentation to CBP, including bill of lading, commercial invoice, and EPA/NHTSA compliance statements

– Pay applicable duties (note: many EVs enter duty-free under HTSUS 8703.80)

– Provide an HS-7 Declaration (EPA Form) and DOT HS-7 form (NHTSA)

Failure to comply may result in vehicle seizure or denial of entry.

State-Level Regulations and Incentives

Zero Emission Vehicle (ZEV) Programs

California leads with its ZEV mandate, requiring automakers to sell a certain percentage of zero-emission vehicles. Other states (e.g., New York, Massachusetts, Oregon) have adopted California’s standards under Section 177 of the Clean Air Act.

Registration and Titling

EVs are registered similarly to conventional vehicles but may incur additional fees in some states to offset reduced fuel tax revenue. Examples:

– Virginia: $64 annual EV fee

– Texas: $200 annual surcharge

– Washington: $150 annual fee

States also offer incentives such as:

– HOV lane access for EVs

– Reduced registration fees

– State tax credits or rebates (e.g., Colorado’s $5,000 tax credit)

Charging Infrastructure Logistics

Network Deployment and Standards

Key considerations for deploying EV charging infrastructure:

– Use of standardized connectors: CCS1 (SAE J1772) for DC fast charging; CHAdeMO and Tesla’s NACS (joining national networks in 2024)

– Compliance with the National Electrical Code (NEC) and local permitting

– Accessibility under the Americans with Disabilities Act (ADA)

Federal funding through the National Electric Vehicle Infrastructure (NEVI) Formula Program supports charging station deployment along major highways.

Utility Interconnection and Grid Integration

Charging stations must comply with utility interconnection standards (e.g., IEEE 1547). Large fleets or depot charging require coordination with local utilities for demand management and potential infrastructure upgrades.

Battery Handling, Recycling, and Environmental Compliance

Transportation of Lithium-Ion Batteries

EV batteries are regulated under:

– Department of Transportation (DOT) Hazardous Materials Regulations (49 CFR)

– International Air Transport Association (IATA) for air shipments

– International Maritime Dangerous Goods (IMDG) Code for ocean freight

Requirements include:

– Proper packaging, labeling, and documentation

– UN 38.3 testing certification for lithium cells and batteries

– State of charge restrictions (typically ≤30%)

End-of-Life and Recycling

While no federal mandate exists for EV battery recycling, the EPA encourages responsible end-of-life management. States like California are developing battery stewardship programs. Best practices include:

– Partnering with certified recyclers (e.g., those adhering to UL 1185 or R2 standards)

– Data tracking for battery provenance and chain of custody

– Compliance with RCRA for hazardous waste handling, if applicable

Incentives and Tax Credits

Federal Tax Credits

The Inflation Reduction Act (IRA) of 2022 provides:

– Clean Vehicle Credit: Up to $7,500 for new EVs meeting assembly and critical mineral requirements

– Commercial Clean Vehicle Credit: Up to $7,500–$40,000 for EVs used in business (based on GVWR)

– Alternative Fuel Vehicle Refueling Property Credit: 30% of installation costs for commercial charging stations (up to $100,000 per site)

State and Local Incentives

Many states offer additional rebates, grants, and tax exemptions. Examples:

– California: Clean Vehicle Rebate Project (CVRP) offers up to $2,000

– New York: Drive Clean Rebate up to $2,000

– Colorado: $5,000 state income tax credit

Fleet and Commercial EV Operations

Compliance for Commercial Fleets

Fleets adopting EVs must consider:

– OSHA standards for workplace charging safety

– Hours of Service (HOS) adjustments for charging time (under FMCSA guidelines)

– ADA compliance for public or employee-accessible charging stations

Maintenance and Training

EV-specific maintenance includes:

– High-voltage system servicing by certified technicians (e.g., ASE certification with electric vehicle endorsement)

– Regular battery health diagnostics

– Software updates for vehicle and charging systems

Employee training on EV handling, charging protocols, and emergency response is essential.

Conclusion and Key Recommendations

To ensure smooth logistics and compliance for electric vehicles in the U.S.:

– Verify all vehicles meet NHTSA and EPA standards prior to sale or import

– Stay informed on evolving federal and state regulations, especially tax credit eligibility

– Partner with certified recyclers and follow DOT guidelines for battery transport

– Leverage federal and state incentives to reduce total cost of ownership

– Invest in workforce training and safe charging infrastructure deployment

By adhering to this guide, stakeholders can navigate the complex regulatory environment and contribute to the sustainable growth of the U.S. EV market.

In conclusion, sourcing electric vehicle (EV) manufacturers in the USA presents a compelling opportunity for businesses, investors, and stakeholders committed to sustainable transportation and innovation. The U.S. EV market is rapidly expanding, supported by strong government incentives, increasing consumer demand, and significant advancements in battery technology and charging infrastructure. Key players such as Tesla, Rivian, Lucid Motors, and legacy automakers like Ford and General Motors are driving the industry forward with diverse product offerings and domestic manufacturing capabilities.

When sourcing from U.S.-based EV manufacturers, factors such as production capacity, technological innovation, supply chain resilience, and compliance with environmental and labor standards should be carefully evaluated. Additionally, geographic proximity, trade policies, and access to federal and state incentives can enhance the value proposition for sourcing locally.

Ultimately, partnering with American EV manufacturers not only supports national economic growth and energy independence but also aligns with global sustainability goals. As the transition to electrified transportation accelerates, establishing strategic sourcing relationships within the U.S. EV ecosystem positions organizations at the forefront of the clean mobility revolution.