The global electric plug sockets market is witnessing robust growth, driven by rising urbanization, increasing construction activities, and the surge in demand for smart and energy-efficient electrical solutions. According to Mordor Intelligence, the market was valued at USD 12.8 billion in 2023 and is projected to grow at a CAGR of over 6.5% from 2024 to 2029. This expansion is further supported by Grand View Research, which highlights the growing adoption of modular wiring devices and the integration of IoT-enabled sockets in residential and commercial infrastructures. With regional markets in Asia-Pacific and North America leading in both production and consumption, manufacturers are increasingly investing in innovation, safety standards, and smart home compatibility. In this competitive landscape, a select group of companies has emerged as industry leaders, shaping the future of electrical connectivity through advanced product design and global supply capabilities. Here are the top 10 electric plug sockets manufacturers driving this transformation.

Top 10 Electric Plug Sockets Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

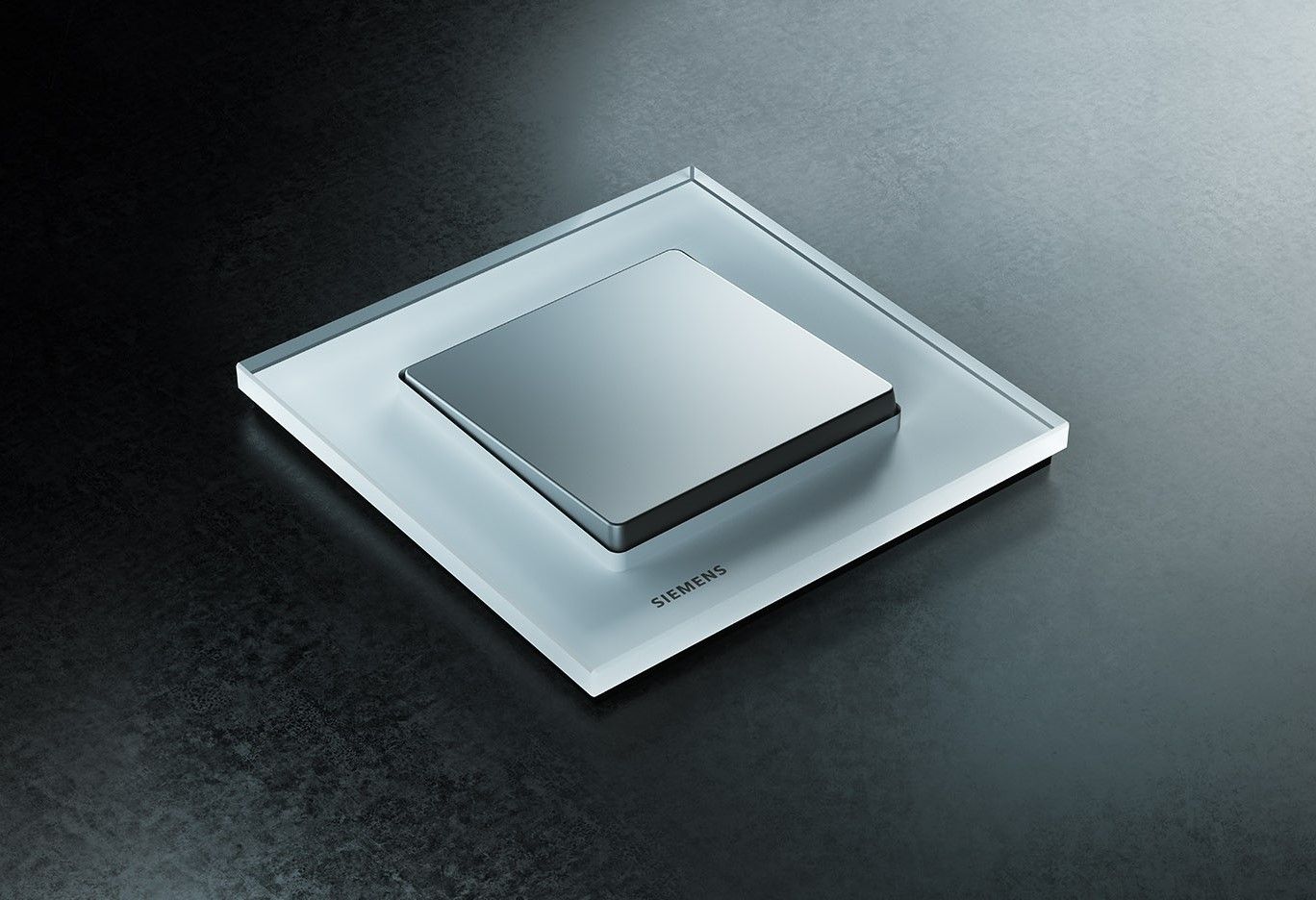

#1 DELTA Switches and Socket Outlets

Domain Est. 1986

Website: siemens.com

Key Highlights: Design in perfection. The DELTA switch and socket ranges combine forward-looking design with innovative and proven technology in high quality….

#2 Leviton

Domain Est. 1995

Website: leviton.com

Key Highlights: Leviton offers a wide range of lighting controls, wiring devices and networking to meet the needs of today’s residential, commercial and industrial ……

#3 Aries Electronics

Domain Est. 1995

Website: arieselec.com

Key Highlights: Aries Electronics is an international electrical socket manufacturer. Order your electronic components online or request a quote!…

#4 Azimuth Electronics, Inc. Custom Made Sockets for Test and Burn

Domain Est. 1997

Website: azimuth-electronics.com

Key Highlights: Azimuth Electronics makes Sockets for Test and Burn-in Packages. From Design to Prototype to Production Wordwide. Socketing Solutions for your packages….

#5 Milbank Manufacturing

Domain Est. 2012

Website: milbankworks.com

Key Highlights: Milbank has been a proud American manufacturer for more than 90 years, making electrical products you can trust….

#6 Electrical Products

Domain Est. 1994

Website: molex.com

Key Highlights: Molex offers a complete line of reliable electrical solutions designed to support optimal worker safety and performance for today’s harsh duty environments….

#7 Plugs, Sockets, & Connectors

Domain Est. 1996

Website: interpower.com

Key Highlights: Our power plugs, sockets, and connectors are designed to meet electrical needs around the world. Choose from our various power plugs, sockets, and connectors….

#8 Plugs and sockets

Domain Est. 1997

Website: catalogue.bals.com

Key Highlights: A large selection of Bals connectors. We manufacture plugs and sockets in different variants and thus cover all your needs for different connection solutions ……

#9 Light Switches and Sockets

Domain Est. 1997

Website: se.com

Key Highlights: What is a Light Switch and How Does it Work? A light switch is a device that controls electrical flow to lights by allowing or stopping current….

#10 World plugs

Website: iec.ch

Key Highlights: The Type C electrical plug (or Europlug) is a two-wire plug that has two round pins. It fits into any socket that accepts 4.0 – 4.8 mm round contacts on 19 mm ……

Expert Sourcing Insights for Electric Plug Sockets

2026 Market Trends for Electric Plug Sockets

Growing Demand for Smart and IoT-Integrated Sockets

By 2026, the electric plug socket market is expected to see significant growth in smart socket adoption, driven by the expansion of the Internet of Things (IoT) and smart home ecosystems. Consumers are increasingly prioritizing energy efficiency, remote control, and automation in household electrical systems. Smart sockets with Wi-Fi, Bluetooth, and Zigbee connectivity will dominate new installations, especially in urban and tech-savvy regions. Integration with voice assistants like Amazon Alexa, Google Assistant, and Apple HomeKit will become standard, enabling seamless home automation experiences.

Expansion of USB and Fast-Charging Capabilities

Electric plug sockets with built-in USB-A and USB-C ports are projected to become the norm by 2026. With the proliferation of mobile devices, tablets, and wearable technology, consumers demand convenient charging solutions without relying on adapters. Manufacturers are responding by incorporating multiple high-wattage USB ports capable of fast charging, including support for Power Delivery (PD) and Quick Charge technologies. This shift is particularly evident in residential, commercial, and hospitality sectors, where user convenience is a key differentiator.

Emphasis on Energy Efficiency and Sustainability

Energy-conscious consumers and tightening global regulations are pushing the market toward energy-efficient socket designs. In 2026, sockets with built-in energy monitoring, automatic shutoff, and low standby power consumption will gain traction. The rise of renewable energy systems and home energy management platforms will further drive demand for sockets that integrate with solar inverters and battery storage systems. Additionally, manufacturers are expected to adopt recyclable materials and eco-friendly production methods to meet sustainability standards.

Regional Standardization and Safety Regulations

As global trade in electrical products increases, there will be growing efforts toward harmonizing plug socket standards, although full standardization remains unlikely due to legacy infrastructure. However, safety regulations are expected to tighten, especially in emerging markets. Features such as child-safe shutters, arc-fault detection, and overload protection will become mandatory in many regions. The European Union, North America, and parts of Asia-Pacific will lead in enforcing advanced safety certifications, influencing global product designs.

Rise of Modular and Customizable Socket Systems

Modular socket systems that allow users to customize configurations—such as combining power outlets, USB ports, switches, and data ports in a single wall plate—are expected to gain popularity by 2026. These systems cater to diverse user needs in homes, offices, and co-working spaces. Design flexibility, aesthetic appeal, and ease of installation will be key selling points. The trend is especially strong in high-end residential and commercial renovations where aesthetics and functionality are equally important.

Conclusion

The electric plug socket market in 2026 will be shaped by technological innovation, sustainability demands, and evolving consumer behaviors. Smart connectivity, integrated charging, energy efficiency, and modular design will define the next generation of sockets. As the world moves toward smarter and greener infrastructure, electric plug sockets will transition from simple power access points to intelligent, user-centric components of the modern electrical ecosystem.

Common Pitfalls Sourcing Electric Plug Sockets (Quality, IP)

Sourcing electric plug sockets—especially with attention to quality and Ingress Protection (IP) ratings—can be challenging. Buyers often encounter several recurring issues that compromise safety, compliance, and long-term performance. Understanding these pitfalls is critical to making informed procurement decisions.

Poor Quality Materials and Construction

One of the most frequent issues is the use of substandard materials such as brittle thermoplastics, thin metal contacts, or recycled components. Low-quality sockets may crack under stress, overheat during use, or fail prematurely. Inferior manufacturing processes—like inconsistent molding or poor contact alignment—further reduce reliability and increase fire or shock risks.

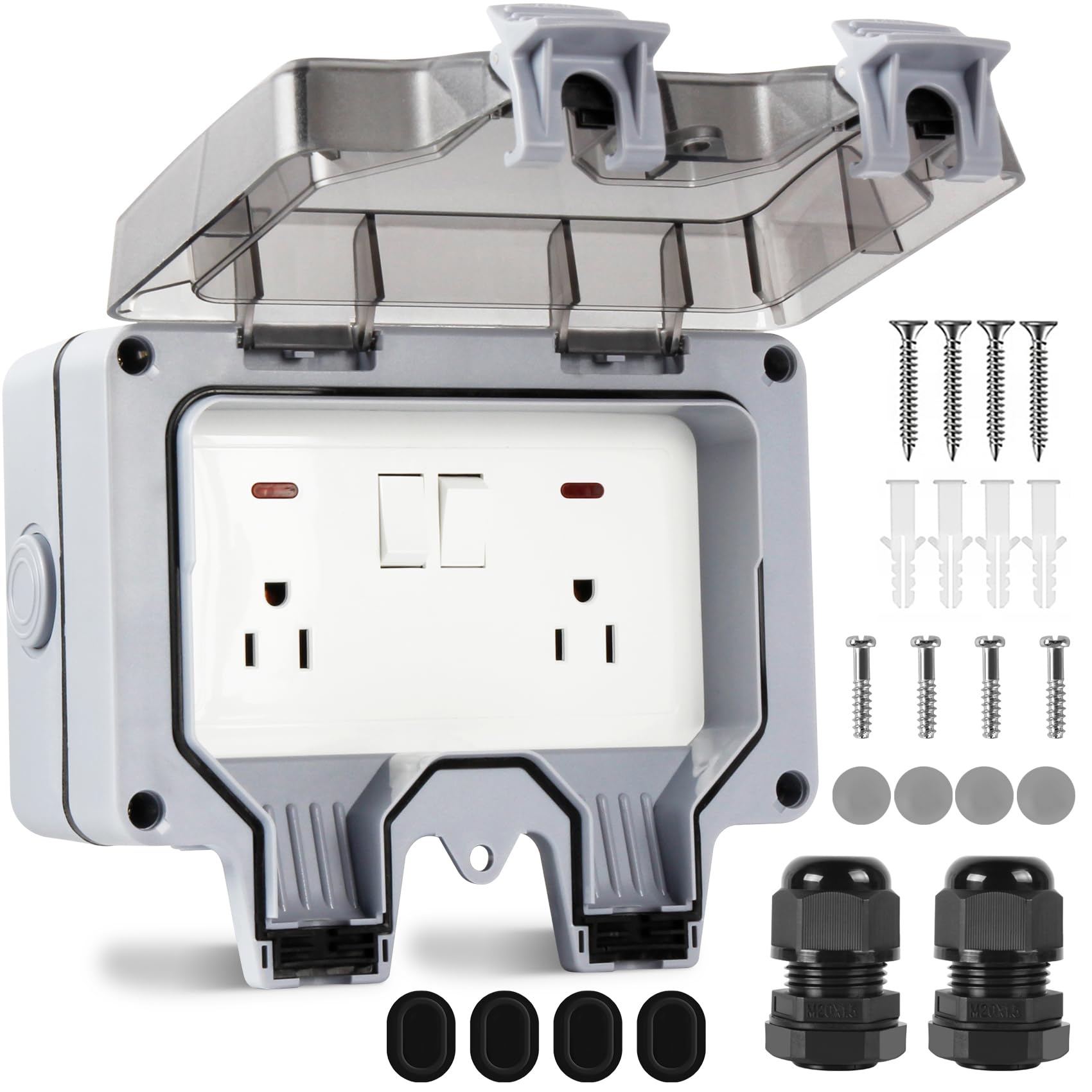

Misleading or Falsified IP Ratings

The Ingress Protection (IP) rating indicates a socket’s resistance to dust and moisture. However, many suppliers misrepresent IP ratings without proper certification. For example, a socket advertised as IP66 may lack adequate sealing, leading to water ingress in outdoor or industrial environments. Always verify IP claims through independent test reports or recognized certifications (e.g., IEC 60529).

Lack of Compliance with Regional Standards

Plug sockets must comply with local electrical standards (e.g., BS 1363 in the UK, AS/NZS 3112 in Australia, or NEC in the US). Sourcing generic or non-compliant models can result in installation rejections, safety hazards, or legal liability. Ensure products carry relevant marks such as CE, UKCA, CCC, or UL, and confirm they meet the target market’s regulatory requirements.

Inadequate Testing and Certification

Many low-cost suppliers provide sockets without third-party testing or valid certification. Relying on self-declared conformity increases the risk of non-compliant or unsafe products entering the supply chain. Always request test reports from accredited laboratories and verify the authenticity of certification bodies.

Counterfeit or Replica Products

Counterfeiting is prevalent in the electrical components market. Fake versions of reputable brands may mimic appearance but fail to deliver the same safety or durability. These products often bypass proper quality control and can pose serious hazards. Purchase only from authorized distributors or verified suppliers with traceable supply chains.

Insufficient Environmental and Load Ratings

Some sockets are not rated for the intended operating conditions—such as high temperature, humidity, or continuous load. Using a socket beyond its rated current (e.g., 10A vs. 16A) or in unsuitable environments can lead to overheating, arcing, or failure. Always match the socket’s specifications to the application’s electrical and environmental demands.

Poor Packaging and Handling

Even high-quality sockets can be compromised during shipping if not properly packaged. Damaged insulation, bent pins, or contaminated contacts reduce performance and safety. Ensure suppliers use robust, protective packaging and implement quality checks prior to dispatch.

Avoiding these pitfalls requires due diligence: vet suppliers thoroughly, demand verifiable certifications, and conduct sample testing when scaling up orders. Prioritizing quality and accurate IP ratings ensures long-term reliability and compliance in any electrical installation.

Logistics & Compliance Guide for Electric Plug Sockets

Overview

Electric plug sockets, as electrical infrastructure components, are subject to stringent logistics requirements and international compliance standards. Ensuring safe transportation, customs clearance, and adherence to technical regulations is critical to avoid delays, safety risks, and legal penalties.

Regulatory Compliance

Electrical Safety Standards

Plug sockets must meet recognized safety standards depending on the target market:

– North America: UL 498 (USA), CSA C22.2 No. 42 (Canada)

– European Union: EN 50075, EN 50085, CE marking under Low Voltage Directive (2014/35/EU) and RoHS 2 (2011/65/EU)

– UK: UKCA marking (post-Brexit), adherence to BS 1363 standards for 13A sockets

– Australia/New Zealand: AS/NZS 3112 compliance, RCM marking

– Other Regions: IEC 60884 series as baseline; local certifications (e.g., CCC in China, PSE in Japan) may apply

Manufacturers must provide test reports and certification documentation from accredited laboratories.

Electromagnetic Compatibility (EMC)

In regions like the EU and UK, plug sockets with integrated surge protection or smart features may require EMC compliance (e.g., EN 55032, EN 55035) to prevent interference with other devices.

Environmental Regulations

- RoHS (EU/UK/China): Restricts hazardous substances (lead, mercury, cadmium, etc.)

- REACH (EU): Requires disclosure of Substances of Very High Concern (SVHC)

- WEEE (EU): Obligates producers to manage end-of-life product recycling

Packaging & Labeling

Safety Packaging

- Use robust, non-conductive packaging to prevent physical damage and electrical hazards

- Include protective caps on terminals to avoid short circuits

- Clearly label as “Electrical Equipment – Handle with Care”

Mandatory Labeling

Each unit or package must display:

– Manufacturer/importer name and address

– Voltage and current rating (e.g., 250V~, 16A)

– Model number and serial (if applicable)

– Compliance marks (e.g., CE, UKCA, UL, CSA)

– Warning symbols (e.g., lightning bolt for electrical risk)

Logistics & Transportation

Classification

- UN Number: Electric sockets without batteries are typically not classified as dangerous goods (UN3481 may apply if shipped with batteries)

- Harmonized System (HS) Code: Common codes include 8536.69 (other electrical apparatus for switching or protecting circuits)

Storage Conditions

- Store in dry, temperature-controlled environments (typically 10°C–30°C)

- Avoid exposure to moisture, dust, and corrosive atmospheres

- Keep packaging sealed until point of installation

International Shipping

- Prepare commercial invoice, packing list, and certificate of conformity

- Verify import duties and taxes per destination country

- Use freight forwarders experienced in electrical goods for customs clearance

Market-Specific Requirements

North America

- Sockets must be certified by Nationally Recognized Testing Laboratories (NRTLs) such as UL or CSA

- Field evaluation may be required for non-certified modifications

European Union

- CE marking must be affixed visibly, legibly, and indelibly

- Technical documentation (including risk assessment and test reports) must be retained for 10 years

United Kingdom

- UKCA marking required for Great Britain (England, Scotland, Wales); CE still accepted until 2025

- Northern Ireland follows UKCA or CE under the Northern Ireland Protocol

Middle East & Asia

- Many countries require SASO (Saudi Arabia), GOST (Russia), or BIS (India) certification

- Third-party inspection (e.g., SABER for Saudi) often required pre-shipment

Quality Assurance & Documentation

Required Documentation

- Certificate of Conformity (CoC)

- Test reports from accredited labs

- Declaration of Conformity (DoC) for CE/UKCA

- Bill of Materials (BOM) for traceability

Post-Market Surveillance

- Monitor for product recalls or non-compliance notices

- Maintain records of customer complaints and corrective actions

- Update certifications as standards evolve

Conclusion

Compliance and logistics for electric plug sockets involve a multi-faceted approach combining electrical safety, environmental regulations, and precise documentation. Proactive adherence to regional standards and proper handling throughout the supply chain ensures market access, consumer safety, and operational efficiency.

In conclusion, sourcing electric plug sockets requires careful consideration of several key factors including safety standards, regional electrical specifications, quality certifications, and supplier reliability. Adhering to local and international regulations such as IEC, UL, or CE ensures that the products are safe, compliant, and suitable for intended use. Evaluating suppliers based on reputation, production capabilities, and ability to provide consistent quality helps mitigate risks related to performance and liability. Additionally, balancing cost-efficiency with long-term durability and sustainability contributes to a successful sourcing strategy. By conducting thorough due diligence and maintaining clear communication with suppliers, businesses can ensure reliable access to high-quality electric plug sockets that meet technical requirements and support safe, efficient electrical systems.