The global electric vehicle (EV) conversion market is gaining momentum as consumers and businesses seek sustainable alternatives to internal combustion engine (ICE) vehicles. According to a report by Mordor Intelligence, the Electric Vehicle Conversion Kit Market is projected to grow at a CAGR of over 12.8% from 2024 to 2029. This growth is fueled by rising environmental awareness, supportive government policies, and advancements in battery and motor technologies. With more vehicle owners looking to retrofit existing cars into EVs, manufacturers of electric motor conversion kits are stepping up innovation to meet demand. As the market expands, a select group of companies are leading the charge in reliability, performance, and ease of integration. Here’s a data-driven look at the top 10 electric motor conversion kit manufacturers for cars shaping this transformative industry.

Top 10 Electric Motor Conversion Kits For Cars Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

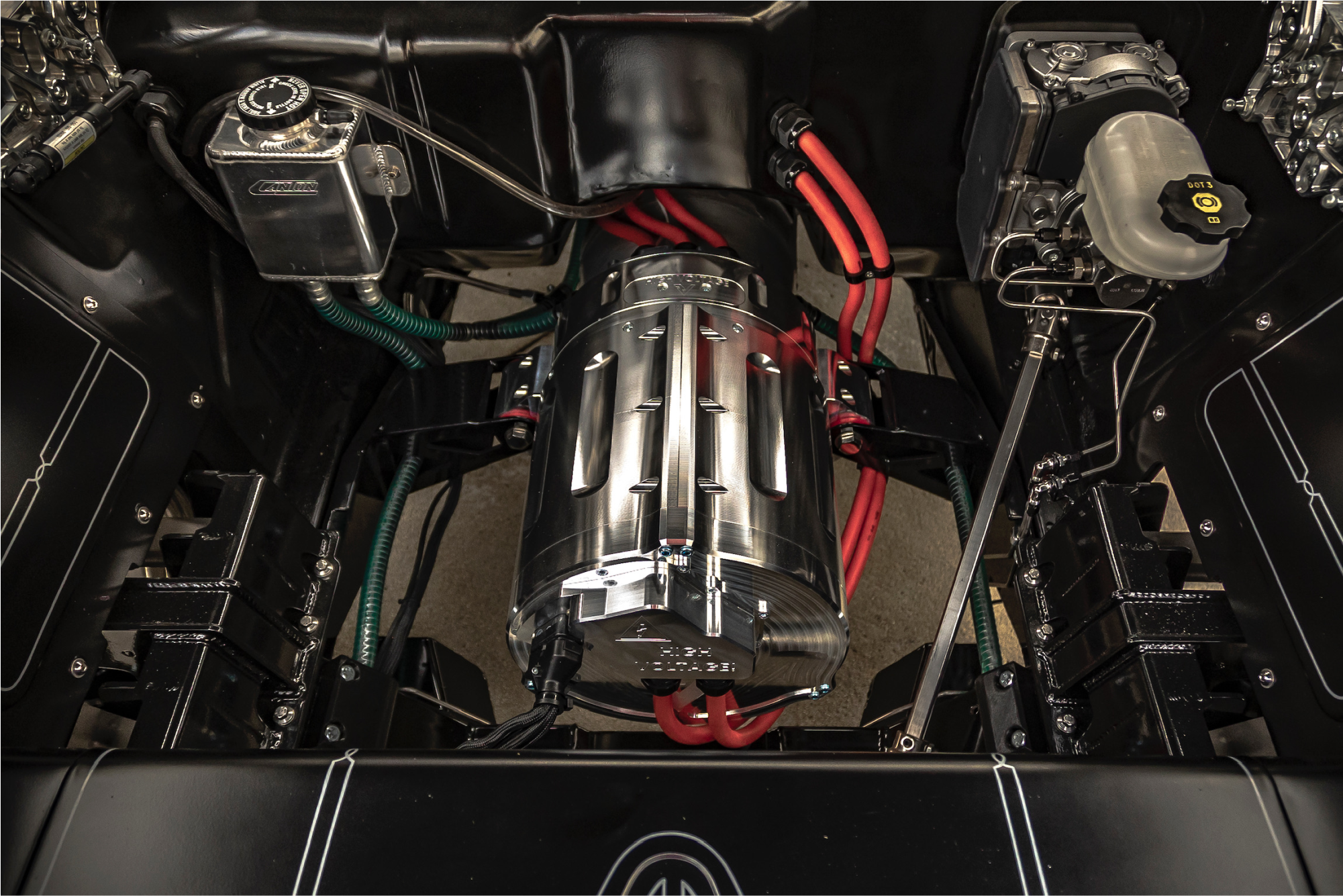

#1 Electrogenic

Domain Est. 2018

Website: electrogenic.co.uk

Key Highlights: Electrogenic is a world-leading EV powertrain OEM. We develop, design and manufacture EV powertrains and powertrain technology for car manufacturers….

#2

Domain Est. 2002

Website: electricmotorsport.com

Key Highlights: Electric Motorsport designs and builds high-performance EV drive systems for electric vehicle conversions, marine propulsion, and industrial electrification….

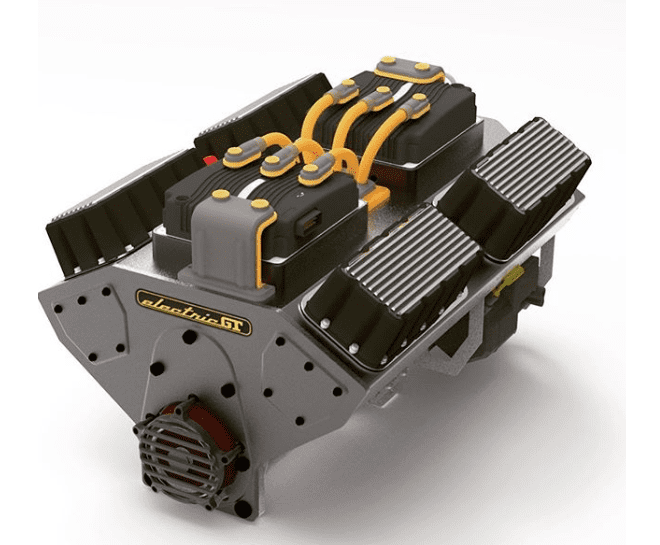

#3 Electric GT

Domain Est. 2014

Website: electricgt.com

Key Highlights: Providing OEM EV turnkey powertrains for low volume manufacturing, specialty builders vehicle integration and the aftermarket vehicle conversion industry….

#4 Thunderstruck Motors

Domain Est. 2000

Website: thunderstruck-ev.com

Key Highlights: 30-day returnsBrowse through the category links on the left for tested and verified EV Components and Kits that will get your electric vehicle up-and-running!…

#5 Electric Car Motors & EV Conversion Kits

Domain Est. 2001

Website: ddmotorsystems.com

Key Highlights: Discover high-quality electric car motors for your DIY EV conversion. We offer top-rated EV motors, including NetGain Motors and other leading brands, ……

#6 EV Conversions

Domain Est. 2008

Website: aemelectronics.com

Key Highlights: I want to convert my vehicle to electric, what should I be considering? · High Voltage or Low Voltage? · Transmission or Direct Drive? · Drive ……

#7 Legacy EV

Domain Est. 2013

Website: legacyev.com

Key Highlights: Legacy EV delivers EV education, certification, and curriculum to prepare future technicians—plus conversion kits and parts for hands-on learning….

#8 SiAECOSYS

Domain Est. 2018

Website: siaecosys.com

Key Highlights: SiAECOSYS work on electric motor conversion kits as electric powertrain for electric bike,electric scooter,electric motorcycle,include QS Motor,Votol ……

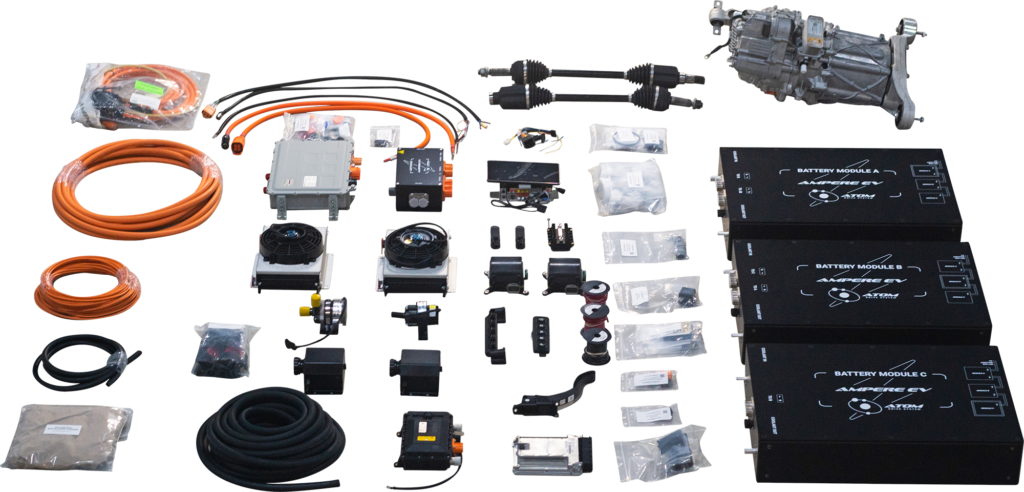

#9 Ampere EV

Domain Est. 2020

Website: ampereev.com

Key Highlights: Atom Drive is the most comprehensive aftermarket EV system available. It delivers reliability, power, range and modern conveniences….

#10 Orbis Electric

Domain Est. 2023

Website: orbiselectric.com

Key Highlights: Orbis Electric has engineered turnkey axial-flux motor, generator, and pump systems that deliver unmatched electrical efficiency across industries….

Expert Sourcing Insights for Electric Motor Conversion Kits For Cars

2026 Market Trends for Electric Motor Conversion Kits for Cars

Growing Demand for Sustainable Transportation

The global shift toward decarbonization and sustainable mobility is a primary driver behind the rising interest in electric vehicle (EV) conversion kits. By 2026, increasing environmental regulations, consumer awareness, and government incentives are expected to boost demand for electric motor conversion kits. These kits allow internal combustion engine (ICE) vehicle owners to retrofit their existing cars into electric vehicles, offering a cost-effective and eco-friendly alternative to purchasing new EVs.

Regulatory Support and Incentives

Governments worldwide are implementing policies to phase out fossil fuel vehicles. By 2026, countries such as the UK, France, and members of the European Union will have stricter emissions standards and deadlines for banning new ICE vehicle sales. In parallel, financial incentives—such as tax rebates, grants, and reduced registration fees—for EV conversions are anticipated to expand. For instance, California and select European nations are already piloting programs supporting vehicle electrification through conversions, setting a precedent for broader adoption by 2026.

Technological Advancements and Kit Accessibility

Electric motor conversion kits are becoming more sophisticated, affordable, and user-friendly. By 2026, improvements in battery technology—particularly in lithium iron phosphate (LiFePO4) and solid-state batteries—will lead to higher energy density, longer range, and faster charging times in converted vehicles. Additionally, plug-and-play conversion systems with integrated motor controllers, regenerative braking, and smart battery management systems will lower technical barriers for both professionals and DIY enthusiasts.

Expansion of the Classic and Niche Vehicle Conversion Market

A significant segment driving the conversion kit market is the restoration and modernization of classic and vintage cars. Enthusiasts seek to preserve automotive heritage while reducing emissions. By 2026, specialized conversion kits tailored for iconic models (e.g., Volkswagen Beetle, Ford Mustang, Porsche 911) will dominate niche markets. Companies like Zero Labs Automotive and EV West are already leading this trend, and increased competition is expected to lower prices and improve performance options.

Challenges and Barriers

Despite positive momentum, several challenges remain. Regulatory hurdles regarding vehicle safety certification, insurance, and homologation for converted vehicles vary significantly by region, potentially limiting mainstream adoption. Additionally, the upfront cost of high-quality conversion kits—ranging from $10,000 to $30,000—remains a barrier for average consumers. However, as production scales and battery costs decline, prices are projected to drop by 20–30% by 2026, improving market accessibility.

Market Growth and Competitive Landscape

The global electric motor conversion kit market is expected to grow at a compound annual growth rate (CAGR) of approximately 14–18% between 2023 and 2026. Key players include EMotorWerks, AC Propulsion, and Zelectric Motors, alongside emerging startups in Europe and Asia. Increased investment from traditional auto parts suppliers and tier-1 manufacturers may lead to OEM-backed conversion solutions, further legitimizing the market.

Conclusion

By 2026, electric motor conversion kits for cars will occupy a strategic niche in the broader EV ecosystem. Fueled by environmental imperatives, policy support, and technological innovation, the market will expand beyond hobbyists to include fleet operators, restoration specialists, and eco-conscious consumers. While challenges in regulation and affordability persist, the convergence of sustainability goals and modular electrification technology positions conversion kits as a viable pathway toward a greener automotive future.

Common Pitfalls Sourcing Electric Motor Conversion Kits for Cars (Quality, IP)

Sourcing electric motor conversion kits for cars—especially for DIY or small-scale conversions—can be fraught with challenges, particularly concerning quality and intellectual property (IP). Being aware of these pitfalls is essential to avoid costly mistakes, safety hazards, and legal complications.

Poor Quality Components and Inconsistent Performance

One of the most significant risks when sourcing conversion kits—especially from lesser-known or overseas suppliers—is receiving components that do not meet safety, durability, or performance standards. Many kits on the market use repurposed or low-grade industrial motors, controllers, and battery systems not specifically designed for automotive applications. This can lead to:

- Overheating and premature failure due to inadequate thermal management.

- Mismatched component specifications, such as controllers not properly rated for continuous load, resulting in system shutdowns or damage.

- Substandard wiring, connectors, and shielding, increasing fire risk and electromagnetic interference (EMI).

- Lack of certification (e.g., CE, UL, ISO) or falsified compliance documentation.

Without rigorous testing and quality control, these kits may function initially but fail under real driving conditions, compromising safety and reliability.

Lack of Technical Support and Documentation

Low-cost kits often come with minimal or poorly translated manuals, incomplete wiring diagrams, and no accessible technical support. This becomes a critical issue when troubleshooting or integrating components with a specific vehicle platform. Users may find themselves unable to:

- Calibrate the motor controller.

- Diagnose error codes.

- Safely integrate the kit with existing vehicle systems (e.g., braking, HVAC, instrumentation).

The absence of reliable support increases project time, frustration, and the likelihood of incorrect installation.

Intellectual Property (IP) Infringement Risks

Many affordable conversion kits—particularly those originating from certain manufacturing regions—may incorporate designs, firmware, or components that infringe on existing patents or copyrighted software. This poses several risks:

- Use of cloned or reverse-engineered controllers: Some motor controllers replicate the functionality of established brands (e.g., Curtis, ZF, Siemens) without licensing, potentially violating patents.

- Proprietary firmware tampering: Unauthorized modification or distribution of firmware can breach software licenses.

- Trademark misuse: Kits may feature branding or model numbers that imitate recognized manufacturers, misleading buyers about origin and quality.

Purchasers or integrators using such kits in commercial conversions could face legal liability, especially if the conversion is offered as a service or product.

Inadequate IP Protection for Custom Solutions

On the flip side, developers creating their own conversion kits or modifying existing designs must also be cautious about IP. Without proper protection:

- Unique designs or control algorithms may be copied by competitors.

- Open-sourcing code or schematics without clear licensing can lead to unintended commercial use.

- Collaborating with suppliers without IP assignment agreements risks losing ownership of innovations.

Conclusion

When sourcing electric motor conversion kits, due diligence is crucial. Prioritize suppliers with verifiable quality certifications, transparent technical documentation, and clear IP provenance. Avoid kits that seem too inexpensive, as they may cut corners on quality or infringe on intellectual property. For commercial or professional use, consider partnering with reputable engineering firms or licensed technology providers to mitigate both performance and legal risks.

Logistics & Compliance Guide for Electric Motor Conversion Kits For Cars

This guide outlines key logistics considerations and compliance requirements for businesses involved in the distribution, import, export, or installation of electric motor conversion kits for cars. These kits enable the retrofitting of internal combustion engine (ICE) vehicles into electric vehicles (EVs) and are subject to various regulations across jurisdictions.

Regulatory Classification and Tariff Codes

Electric motor conversion kits may be classified differently depending on their components and intended use. Accurate classification under the Harmonized System (HS) is essential for international trade. Common classifications may include:

- 8501.31 or 8501.32: Electric motors of an output not exceeding 75 kW or over 75 kW.

- 8708.29: Parts and accessories of motor vehicles, including electric traction motors.

- 8504.40: Power converters (e.g., inverters) used in EV systems.

- 8542.31: Electronic control units, if included.

Consult local customs authorities or a licensed customs broker to determine the correct HS codes for your specific kit configuration to ensure proper duty assessment and avoid delays.

Vehicle Homologation and Road Legality

Converting a vehicle using a motor kit may impact its roadworthiness and legal status. Key compliance areas include:

- National Type Approval: In regions like the EU, converted vehicles may require Individual Vehicle Approval (IVA) or Small Series Type Approval, depending on volume and modifications.

- FMVSS (USA): In the United States, modified vehicles must comply with Federal Motor Vehicle Safety Standards. Conversions may trigger requirements for crashworthiness, electrical safety, and lighting.

- ADR Compliance (Australia): Conversions must meet Australian Design Rules. Certification through an accredited person is typically required.

- Emissions and Noise Regulations: Even though EVs produce zero tailpipe emissions, national noise regulations may still apply.

Always verify local vehicle modification laws and ensure kits are designed to support compliant installations.

Electrical Safety and Certification

Electric motor kits involve high-voltage components and must meet electrical safety standards:

- IEC 60529: Ingress Protection (IP) ratings for enclosures.

- UL 2202 / UL 2580: Safety standards for electric vehicle power conversion systems and batteries (primarily North America).

- UN ECE R100: Electric powertrain safety for EVs, widely adopted in Europe and other regions.

- ISO 6469: Electric vehicle safety standards (parts 1–3 cover on-board electrical energy, propulsion systems, and protection against electric shock).

Manufacturers should provide certification documentation proving compliance with applicable electrical safety standards.

Battery Regulations and Transportation

If the kit includes lithium-ion batteries, additional regulations apply:

- UN 38.3 Testing: Required for all lithium batteries transported by air, sea, or land. Certification confirms safety under various stress conditions.

- IMDG Code (Sea): Governs maritime transport of dangerous goods, including lithium batteries.

- IATA Dangerous Goods Regulations (Air): Applies to air shipment; proper packaging, labeling, and documentation are mandatory.

- 49 CFR (USA): Regulates ground transportation of hazardous materials, including lithium batteries.

Batteries must be shipped at ≤30% state of charge and in compliant packaging to reduce fire risks.

Environmental and End-of-Life Compliance

Conversion kits contribute to sustainable mobility, but environmental regulations still apply:

- RoHS (EU): Restriction of Hazardous Substances in electrical equipment.

- REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals.

- WEEE (EU): Waste Electrical and Electronic Equipment—producers may have take-back obligations.

- Battery Directive 2006/66/EC (EU): Requires labeling and recycling of batteries.

Ensure suppliers provide RoHS and REACH compliance documentation, and plan for responsible end-of-life management.

Documentation and Labeling Requirements

Proper documentation is essential for logistics and compliance:

- Technical Dossiers: Detailed specifications, safety data, and installation instructions.

- Certificate of Conformity (CoC): Required in many markets to prove compliance with safety and emissions standards.

- Safety Labels: Clear high-voltage warnings, component ratings, and manufacturer information on all parts.

- User Manuals: Must include installation procedures, maintenance guidelines, and safety precautions.

Import/Export Controls and Trade Compliance

- Export Licenses: Some high-power electric components may be subject to dual-use export controls (e.g., under EU Dual-Use Regulation or U.S. EAR).

- Sanctions Screening: Ensure no parties involved are on restricted entity lists (e.g., OFAC, EU sanctions lists).

- Incoterms: Clearly define responsibilities for shipping, insurance, and customs clearance (e.g., FOB, DDP).

Use licensed freight forwarders experienced in handling automotive and high-voltage goods.

Installation and Aftermarket Liability

- Qualified Installers: Recommend or require installation by certified electricians or automotive technicians familiar with high-voltage systems.

- Warranty and Liability: Clearly define responsibility for system performance and safety—manufacturer vs. installer vs. end-user.

- Software and Firmware: Ensure any control units comply with cybersecurity and over-the-air (OTA) update regulations where applicable.

Conclusion

Successfully navigating the logistics and compliance landscape for electric motor conversion kits requires attention to classification, safety, transportation, and regulatory standards. Proactive engagement with legal, technical, and customs experts is recommended to ensure market access and customer safety. As regulations evolve with the growth of the EV aftermarket, ongoing compliance monitoring is essential.

In conclusion, sourcing electric motor conversion kits for cars presents a promising opportunity for individuals and businesses seeking to transition from internal combustion engines to electric propulsion. These kits offer a sustainable, cost-effective solution for reducing carbon emissions and dependence on fossil fuels, while extending the life of existing vehicles. However, successful implementation requires careful consideration of kit compatibility, quality, performance specifications, and local regulations.

When sourcing conversion kits, it is essential to evaluate suppliers based on reputation, technical support, warranty offerings, and component reliability—including motors, controllers, battery integration, and mounting hardware. Additionally, professional installation and adherence to safety standards are critical to ensure performance, longevity, and compliance with road safety regulations.

As the electric vehicle market continues to grow, the availability and sophistication of conversion kits are expected to improve, supported by advancements in battery technology and growing demand for sustainable transportation. Ultimately, electric motor conversion kits not only contribute to environmental sustainability but also empower vehicle owners to embrace electrification at a flexible pace and scale. With the right research and planning, converting a conventional car into an electric one can be a viable and rewarding endeavor.