The global electric motor contactor market is experiencing robust growth, driven by rising industrial automation, increased demand for energy-efficient motor control systems, and expanding infrastructure in emerging economies. According to a 2023 report by Mordor Intelligence, the motor contactor market is projected to grow at a CAGR of over 5.8% from 2023 to 2028, reaching an estimated value of USD 11.5 billion by 2028. This growth is further amplified by the adoption of smart manufacturing technologies and stringent energy efficiency regulations worldwide. As critical components in motor control circuits—responsible for safely switching electric motors on and off—contactors play a pivotal role in industries ranging from manufacturing and HVAC to renewable energy and transportation. With increasing electrification and demand for reliable control solutions, leading manufacturers are investing heavily in innovation, durability, and digital integration. In this evolving landscape, identifying the top electric motor contactor manufacturers becomes essential for engineers, procurement teams, and system integrators seeking high-performance, compliant, and future-ready components.

Top 10 Electric Motor Contactor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Contactors

Domain Est. 1986

Website: siemens.com

Key Highlights: Protecting and switching your loads with SIRIUS means high contact reliability, prolonged endurance and usability in extreme conditions….

#2 Contactors and contactor relays

Domain Est. 1990

Website: new.abb.com

Key Highlights: ABB offers a comprehensive selection of contactors for simple and extreme application as well as products with specific purposes….

#3 Contactors: Electrical

Domain Est. 1992

Website: te.com

Key Highlights: We have extensive capabilities in designing and manufacturing contactors for a wide variety of applications, including HVAC, power supply, locomotives, ……

#4 Contactors and starters

Domain Est. 1996

Website: eaton.com

Key Highlights: Contactors and starters. With a broad portfolio that includes everything from phase, voltage and current monitoring relays to motor protection breakers, Eaton ……

#5 Repco Inc

Domain Est. 1996

Website: repcoinc.com

Key Highlights: Repco is the industry-leading source for replacement electrical contacts for DC motor controls manufactured by Clark, Cutler-Hammer, GE, Hubbell, Square D and ……

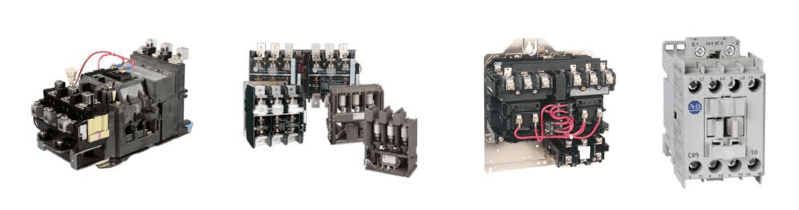

#6 Motor Control

Domain Est. 1997

Website: rockwellautomation.com

Key Highlights: Our motor controllers meet the needs of many applications from low to medium voltage and conform to NEMA or IEC standards….

#7 to the store

Domain Est. 2000

Website: springercontrols.com

Key Highlights: Enclosed Motor Starters · Enclosures · Foot Switches · IEC Contactors & Relays · Contactors & Relays · Overload Relays · Joysticks · Lighting Contactors ……

#8 WEG

Domain Est. 2004

Website: weg.net

Key Highlights: WEG provides global solutions for electric motors, variable frequency drives, soft starters, controls, panels, transformers, and generators….

#9 D.C. Contactors and Disconnect Switches

Domain Est. 2006

Website: albrightinternational.com

Key Highlights: Albright wholly designs and manufactures our own original D.C. Contactors and Disconnect Switches which are available for use in a wide variety of ……

#10 TC Electric Controls

Domain Est. 2016

Website: tcelectriccontrols.com

Key Highlights: IEC CONTACTORS & OVERLOADS. Robusta contactors have been engineered for superior performance. It’s robust construction with heavy duty silver alloy contacts, ……

Expert Sourcing Insights for Electric Motor Contactor

H2: 2026 Market Trends for Electric Motor Contactors

The global electric motor contactor market is poised for significant transformation by 2026, driven by technological advancements, energy efficiency mandates, and the rapid expansion of automation and electrification across industries. As a critical component in motor control systems—used to switch electric motors on and off—contactors are experiencing increased demand due to growing industrialization, rising adoption of electric vehicles (EVs), and the proliferation of smart infrastructure.

One of the key trends shaping the 2026 landscape is the integration of digitalization and IoT-enabled contactors. Smart contactors equipped with sensors and communication modules are gaining traction, allowing for real-time monitoring, predictive maintenance, and remote control. This shift supports the broader Industry 4.0 movement, where manufacturers seek enhanced operational efficiency, reduced downtime, and improved energy management.

Energy efficiency regulations are also influencing product development. Governments worldwide are enforcing stricter energy standards (e.g., IE4 and emerging IE5 motor efficiency classes), prompting OEMs to design contactors compatible with high-efficiency motors. This regulatory push is accelerating the replacement of obsolete, less efficient systems, particularly in Europe and North America.

Additionally, the surge in electric vehicle production is creating new demand channels. EV charging stations, battery manufacturing plants, and automated assembly lines require reliable motor control solutions, driving contactor usage in both light and heavy-duty applications. The renewable energy sector—especially solar and wind installations—also contributes to market growth, as contactors are essential in managing power distribution and motor-driven systems in these environments.

Regionally, Asia-Pacific is expected to dominate the market by 2026, led by industrial expansion in China, India, and Southeast Asia. Meanwhile, North America and Europe are focusing on retrofitting aging infrastructure with smart, energy-efficient components.

In summary, the 2026 electric motor contactor market will be characterized by innovation in smart technologies, regulatory-driven efficiency improvements, and expanding applications in EVs and renewable energy. Companies that invest in digital integration, sustainability, and global supply chain resilience will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Electric Motor Contactors (Quality, IP Rating)

Logistics & Compliance Guide for Electric Motor Contactors

Product Classification and HS Code

Electric motor contactors are typically classified under Harmonized System (HS) codes related to electrical apparatus for switching or protecting electrical circuits. The most common HS code is 8536.41 (Contactors, for a voltage ≤ 1000V). However, exact codes may vary by country and specific product specifications (e.g., voltage rating, current capacity). Always verify with local customs authorities or a licensed customs broker to ensure accurate classification and avoid delays.

Regulatory Compliance Standards

Electric motor contactors must comply with international and regional safety and performance standards. Key certifications include:

– IEC 60947-4-1: International standard for low-voltage electromechanical contactors and motor-starters.

– UL 508: Standard for Industrial Control Equipment (required for U.S. market).

– EN 60947-4-1: European adaptation of IEC standard (CE marking required).

– CCC (China Compulsory Certification): Mandatory for contactors sold in China.

Ensure products bear relevant certification marks and are accompanied by technical documentation (e.g., test reports, declarations of conformity).

Packaging and Handling Requirements

To prevent damage during transit:

– Use anti-static, shock-resistant packaging with internal cushioning (e.g., foam inserts).

– Clearly label packages with product ID, voltage rating, quantity, and handling instructions (e.g., “Fragile,” “Do Not Stack”).

– Avoid exposure to moisture, extreme temperatures, and corrosive environments during storage and transport.

– Follow manufacturer’s stacking limits to prevent crushing of lower units.

Import and Export Documentation

Prepare the following documents for smooth cross-border shipment:

– Commercial Invoice (with detailed product description, HS code, value, and Incoterms)

– Packing List (itemizing contents per package)

– Certificate of Origin

– Safety and Compliance Certificates (e.g., CE, UL, CCC)

– Bill of Lading or Air Waybill

For high-value or regulated shipments, additional documents like a Letter of Credit or Import License may be required.

Transportation Considerations

- Use temperature-controlled and humidity-monitored freight options if shipping through extreme climates.

- Prefer carriers experienced in handling electrical components to minimize risk of electrostatic discharge (ESD) or physical damage.

- For air freight, ensure compliance with IATA regulations regarding battery-powered or magnetized components (if applicable).

- Track shipments in real time and maintain insurance coverage for loss or damage.

Customs Clearance Procedures

- Submit accurate documentation to customs authorities in the destination country.

- Pay applicable duties, taxes, and fees based on declared value and HS code.

- Be prepared for physical inspections, especially if certifications are incomplete or inconsistent.

- Engage a local customs agent if unfamiliar with regional import processes (e.g., EU customs union, US CBP, China Customs).

Environmental and RoHS Compliance

Electric motor contactors must comply with environmental regulations such as:

– RoHS (EU Directive 2011/65/EU): Restricts hazardous substances (e.g., lead, mercury, cadmium).

– REACH (EC 1907/2006): Requires disclosure of Substances of Very High Concern (SVHC).

– WEEE Directive: Mandates proper end-of-life disposal and recycling.

Ensure suppliers provide material declarations and compliance statements.

Storage and Shelf-Life Management

- Store in a dry, clean environment with temperatures between 5°C and 40°C and humidity below 75%.

- Avoid prolonged storage; contactors with mechanical components may degrade over time.

- Rotate stock using FIFO (First In, First Out) to prevent obsolescence.

- Inspect periodically for signs of corrosion, dust accumulation, or packaging damage.

End-of-Life and Disposal Compliance

- Follow local regulations for disposal of electrical equipment.

- Partner with certified e-waste recyclers to handle returned or defective contactors.

- Maintain records of disposal to demonstrate compliance with WEEE or equivalent programs.

Summary and Best Practices

To ensure seamless logistics and compliance:

– Verify certifications and HS codes before shipment.

– Use compliant packaging and reliable carriers.

– Maintain complete, accurate documentation.

– Train staff on handling, storage, and regulatory requirements.

– Audit suppliers regularly for ongoing compliance with international standards.

Conclusion for Sourcing Electric Motor Contactors

In conclusion, sourcing the appropriate electric motor contactor is a critical step in ensuring the safe, efficient, and reliable operation of motor-driven systems. Key factors such as voltage and current ratings, duty cycle, number of poles, coil voltage, environmental conditions, and compliance with industry standards (e.g., IEC or NEMA) must be carefully evaluated to match the contactor to the specific application requirements.

Sourcing from reputable suppliers ensures product quality, authenticity, and access to technical support. Additionally, considering aspects like energy efficiency, ease of installation, maintenance needs, and long-term cost of ownership can lead to improved system performance and reduced operational downtime.

By conducting a thorough assessment of technical specifications, comparing supplier reliability, and balancing cost with performance, organizations can make informed procurement decisions that enhance system reliability and safety while optimizing lifecycle costs. Ultimately, the right contactor not only protects the motor but also contributes to the overall efficiency and longevity of the electrical system.