The global electric fence components market is experiencing steady growth, driven by rising demand for perimeter security across agricultural, residential, and commercial sectors. According to Grand View Research, the global electric fencing market was valued at USD 4.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030. This growth is fueled by increasing security concerns, advancements in smart fencing technologies, and the need for cost-effective livestock management solutions. As urbanization accelerates and rural electrification improves, manufacturers are investing in durable, energy-efficient, and IoT-integrated electric fence components to meet evolving customer needs. In this competitive landscape, a select group of manufacturers has emerged as leaders, setting industry benchmarks for innovation, reliability, and global reach. Here’s a look at the top nine electric fence components manufacturers shaping the future of perimeter security.

Top 9 Electric Fence Components Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Official Gallagher Animal Management Site

Domain Est. 1995

Website: am.gallagher.com

Key Highlights: We lead the market in electric fencing, weighing and electronic identification (EID), data collection, and wireless water monitoring systems. Where to ……

#2 Parmak Electric Fencing

Domain Est. 1996

Website: parmakusa.com

Key Highlights: We offer a complete line electric fence chargers, wire, polywire, polytape, rope, insulators and accessories to help you build an effective and safe electric ……

#3 Dare Products, Inc

Domain Est. 1996

Website: dareproducts.com

Key Highlights: Dare Products has become a cornerstone in the industry–offering a full line of electric fencing equipment and other related agricultural products….

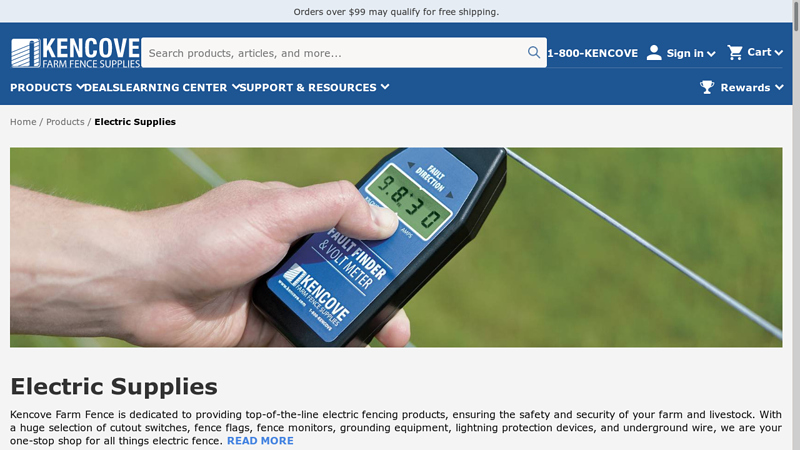

#4 Kencove Electric Fence Solutions

Domain Est. 1996

#5 Zareba® Systems Electric Fencing Supplies

Domain Est. 2000

Website: zarebasystems.com

Key Highlights: Zareba® Systems provides electric fence systems for livestock. Shop all our fence components including chargers or energizers, wire, insulators, posts, ……

#6 Electric Fence – eFENCE1® Pet Containment –

Domain Est. 2000 | Founded: 1990

Website: efence1.com

Key Highlights: Since 1990, we have built our experience by installing and servicing pet containment systems as a full-time, owner-operated business….

#7 Patriot

Domain Est. 2004

Website: patriotglobal.com

Key Highlights: Forming the heart of your electric fence system, energizers provide the source for the electric current that flows through the fence wire….

#8 Powerflex Fence

Domain Est. 2006

Website: powerflexfence.com

Key Highlights: Enhance your fencing with powerflex fence & water supplies solutions from Powerflex Fence — designed for strength, safety, and reliability. Shop trusted….

#9 Gallagher Fence

Domain Est. 2013

Website: gallagherfence.net

Key Highlights: Buy Gallagher Fence products online now at the best prices around. We ship anywhere in the USA and provide free shipping on all fence chargers….

Expert Sourcing Insights for Electric Fence Components

H2: 2026 Market Trends for Electric Fence Components

The global electric fence components market is poised for significant transformation by 2026, driven by technological advancements, growing demand for perimeter security, and expansion in agricultural and livestock management sectors. Key trends shaping the market include:

-

Increased Adoption of Smart and IoT-Enabled Components

By 2026, the integration of Internet of Things (IoT) technology into electric fence systems is expected to accelerate. Smart energizers, remote monitoring through mobile apps, and real-time fault detection are becoming standard features. These innovations enhance system reliability and allow users—especially large-scale farmers and security operators—to manage multiple zones remotely, improving efficiency and response time. -

Growth in Agricultural and Livestock Applications

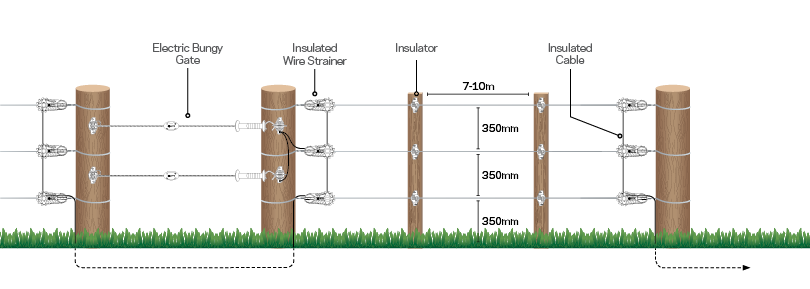

The rising need for efficient pasture management and livestock containment, especially in emerging economies, continues to drive demand. Electric fencing offers a cost-effective and scalable solution for controlling animal movement. With increasing investments in smart farming and precision agriculture, demand for durable and energy-efficient fence components such as polywire, insulators, and solar-powered energizers is projected to grow steadily through 2026. -

Focus on Energy Efficiency and Sustainability

Environmental concerns and off-grid operational needs are pushing manufacturers to develop solar-powered energizers and low-energy-consumption components. By 2026, eco-friendly and energy-efficient designs are expected to dominate product portfolios, especially in rural and remote areas where grid electricity is unreliable or unavailable. -

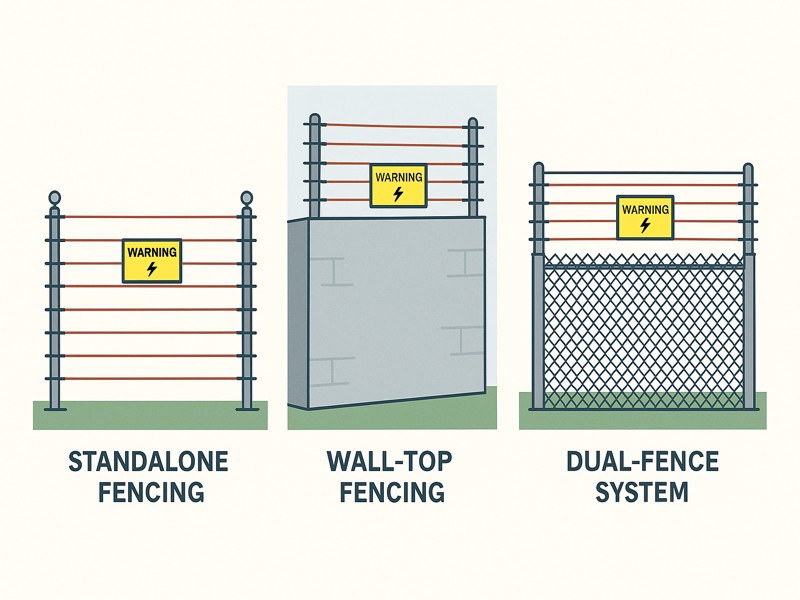

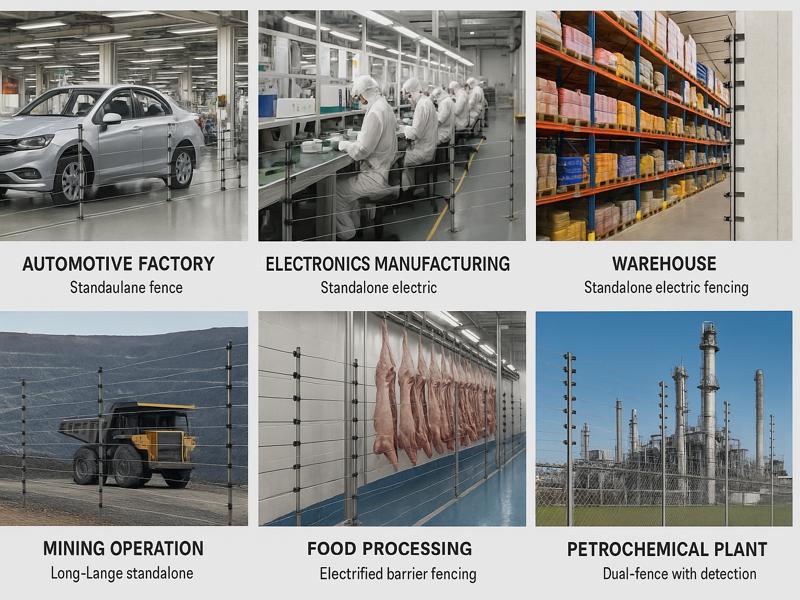

Expansion in Commercial and Perimeter Security Markets

Beyond agriculture, electric fence components are increasingly used in commercial, industrial, and residential security applications. High-risk facilities such as data centers, military installations, and critical infrastructure are adopting enhanced electric fencing systems with tamper alerts and integration capabilities with broader security ecosystems. This trend is expected to boost demand for high-voltage pulsers, alarm units, and reinforced conductors. -

Regional Market Growth in Asia-Pacific and Africa

The Asia-Pacific region, particularly India and Southeast Asia, is witnessing rising adoption due to expanding agricultural activities and government initiatives promoting farm mechanization. Similarly, in Sub-Saharan Africa, electric fencing is gaining traction in wildlife conservation and anti-poaching efforts, further stimulating market growth. These regions are expected to be key growth engines by 2026. -

Product Innovation and Material Advancements

Manufacturers are investing in advanced materials such as UV-resistant polymers for insulators and corrosion-resistant alloys for conductors to improve durability in harsh environments. Additionally, modular and easy-to-install designs are being favored to reduce installation time and labor costs, appealing to both DIY users and professional installers. -

Regulatory and Safety Standards Evolution

As electric fencing becomes more widespread, regulatory bodies are likely to enforce stricter safety standards by 2026. This includes mandatory compliance with low-impedance designs, child-safe warning signs, and fail-safe mechanisms. These regulations will influence product development and drive demand for certified components.

In conclusion, the 2026 electric fence components market will be characterized by smart technology integration, sustainability, and geographic expansion. Stakeholders who prioritize innovation, compliance, and user-centric design will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Electric Fence Components (Quality, IP)

When procuring electric fence components—such as energizers, conductors, insulators, and grounding systems—several critical pitfalls can compromise system performance, safety, and longevity. Paying close attention to quality and Ingress Protection (IP) ratings is essential to avoid these issues.

Poor Quality Materials and Construction

Low-cost electric fence components often use substandard materials that degrade quickly under environmental stress. For example, insulators made from brittle or UV-sensitive plastics may crack or become brittle in sunlight, leading to short circuits. Similarly, thin or corroded wire conductors reduce electrical efficiency and increase the risk of breakage. Always verify material specifications and opt for components made from UV-stabilized polymers, galvanized or high-tensile steel, and corrosion-resistant metals.

Inadequate Ingress Protection (IP) Ratings

Many electric fence energizers and electronic accessories require protection against dust and moisture. Components with insufficient IP ratings (e.g., IP44 or lower) may fail prematurely in outdoor conditions. For reliable outdoor use, select energizers with at least IP65 rating, which ensures complete dust protection and resistance to water jets. Ignoring IP ratings can result in internal component corrosion, electrical shorts, or complete device failure.

Misrepresentation of Power Output and Range

Suppliers may exaggerate energizer output joules or effective fence range. This misleading information can lead to underpowered systems that fail to deter animals. Always cross-check technical specifications with independent reviews or certifications and consider real-world performance factors like vegetation contact and fence line length.

Lack of Compliance with Safety and Regulatory Standards

Non-compliant components may not meet regional electrical safety standards (e.g., CE, RCM, or UL markings), posing risks of electric shock or fire hazards. Ensure all electrical components are certified and include proper warning signage and grounding instructions.

Inconsistent Component Compatibility

Mixing parts from different manufacturers can lead to compatibility issues—such as insulators that don’t fit certain posts or connectors that don’t align with wire gauges. Standardize sourcing from reputable suppliers that offer fully integrated systems to ensure seamless installation and optimal performance.

Insufficient Grounding System Components

An effective electric fence relies heavily on a proper grounding system. Sourcing undersized or inadequate grounding rods and clamps—especially in dry or rocky soils—can severely reduce shock effectiveness. Verify that grounding kits meet length, material, and connection quality standards for reliable performance.

By avoiding these common pitfalls and prioritizing certified quality and appropriate IP ratings, you ensure a durable, safe, and effective electric fencing solution.

Logistics & Compliance Guide for Electric Fence Components

Overview

Electric fence components—including energizers, conductive wires, insulators, grounding systems, and warning signs—are subject to specific logistics handling and regulatory compliance requirements across various jurisdictions. This guide outlines key considerations for the safe, legal, and efficient transportation, storage, and distribution of electric fence equipment.

Regulatory Compliance

Electrical Safety Standards

Electric fence energizers must comply with national and international electrical safety standards such as:

– IEC 60335-2-76 (Safety of household and similar electrical appliances – Particular requirements for electric fence energizers)

– UL 69 (Standard for Electric Fencing System Power Units) in the United States

– AS/NZS 60335.2.76 in Australia and New Zealand

Ensure all units are certified with appropriate marks (e.g., CE, UKCA, UL, RCM) before distribution.

Electromagnetic Compatibility (EMC)

Energizers must meet EMC regulations to avoid interference with other electronic devices. Compliance with directives such as the EU EMC Directive 2014/30/EU or FCC Part 15 in the U.S. is mandatory.

Hazard Communication & Labeling

- Clearly label all energizers with voltage output, safety warnings, and manufacturer information.

- Include multilingual warning signs where applicable, especially in regions with multiple official languages.

- Fulfill OSHA (U.S.) or WHS (Australia) requirements for workplace safety signage if used in agricultural or industrial settings.

Environmental & Chemical Regulations

- Packaging materials must comply with REACH (EU), RoHS, and TSCA (U.S.) regulations regarding restricted substances.

- Batteries (if included) are subject to UN 38.3 testing and IATA/IMDG regulations for transport due to their classification as hazardous goods.

Logistics Considerations

Packaging & Durability

- Use robust, moisture-resistant packaging to protect components during transit.

- Secure conductive wire reels and fragile insulators to prevent damage.

- Include protective caps on metal components to prevent short circuits or corrosion.

Storage Conditions

- Store in dry, temperature-controlled environments (typically 0°C to 40°C).

- Avoid prolonged exposure to direct sunlight, which can degrade plastic insulators and casings.

- Keep away from flammable materials, especially when storing battery-powered units.

Transportation Regulations

- Air Freight: Lithium batteries (if included) must comply with IATA Dangerous Goods Regulations, including proper packaging, labeling (Class 9 hazard label), and documentation.

- Ground & Sea Freight: Follow ADR (Europe), 49 CFR (U.S.), or IMDG Code for hazardous materials. Non-powered components generally are not classified as hazardous.

- Declare energizers accurately on shipping manifests, noting compliance certifications.

Import & Export Requirements

- Verify import duties, customs codes (HS codes), and import permits for destination countries.

- Common HS codes include:

- 8504.40 – Electrical transformers, converters, and rectifiers (may apply to energizers)

- 8544.42 – Insulated wire, not elsewhere specified

- 3926.30 – Plastic insulators

- Provide technical documentation (test reports, conformity certificates) to customs authorities upon request.

Installation & User Compliance

Safety Instructions

- Include multilingual installation and safety manuals with each product.

- Emphasize proper grounding, signage placement, and maintenance procedures.

Regulatory Installation Guidelines

- In the EU, electric fences must comply with national legislation (e.g., Germany’s Bundesnaturschutzgesetz for wildlife protection).

- In the U.S., follow local agricultural codes and avoid use in public-access areas without permits.

- In Australia, adhere to AS 2067 and state-based regulations regarding electrified fencing near public boundaries.

Disposal & End-of-Life

Waste Electrical and Electronic Equipment (WEEE)

- Comply with EU WEEE Directive 2012/19/EU by providing take-back options and labeling products with the crossed-out wheeled bin symbol.

- In other regions, follow local e-waste recycling programs.

Battery Disposal

- Inform end users to dispose of batteries at designated collection points per EU Battery Directive or equivalent.

Conclusion

Successful logistics and compliance for electric fence components require attention to electrical safety, environmental regulations, transportation protocols, and regional legal standards. Proactive documentation, proper labeling, and adherence to international standards ensure smooth cross-border operations and user safety. Always consult local regulators and update compliance procedures as standards evolve.

In conclusion, sourcing electric fence components requires careful consideration of quality, durability, compatibility, and cost-effectiveness to ensure long-term performance and security. It is essential to evaluate suppliers based on reliability, product certifications, and after-sales support. Investing in high-quality components such as energizers, conductive wire, insulators, and grounding systems enhances the efficiency and safety of the electric fence. Additionally, choosing components suited to the specific environment—whether agricultural, residential, or high-security—ensures optimal functionality. By conducting thorough research and establishing relationships with reputable suppliers, businesses and individuals can build reliable, effective fencing systems that meet their security and operational needs.