The global electric car tyre pump market is experiencing robust growth, driven by the rapid expansion of the electric vehicle (EV) sector and increasing consumer demand for advanced, reliable inflation solutions. According to Grand View Research, the global electric vehicle market was valued at USD 628.7 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 14.6% from 2024 to 2030. This surge in EV adoption directly fuels demand for specialized accessories such as electric car tyre pumps, which are essential for maintaining optimal tyre pressure and improving energy efficiency in electric vehicles. Mordor Intelligence further projects that the EV accessories market, including charging and maintenance products, will witness significant investment and innovation through 2028, supported by government regulations and enhanced vehicle connectivity. As OEMs and aftermarket providers respond to this trend, several manufacturers have emerged as leaders in developing high-performance, compact, and smart-enabled electric tyre pumps tailored for the EV ecosystem. The following list highlights the top 8 electric car tyre pump manufacturers shaping this evolving landscape.

Top 8 Electric Car Pump Tyre Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Portable Air Pump for Car

Domain Est. 1999

Website: en.steel-mate.com

Key Highlights: The portable tire inflator is an air pump launched by Steel Mate; the electric air pump can inflate car tires in time. Protect your vehicle security….

#2 Inflation & Pressure Monitoring

Domain Est. 2013

Website: us.michelin-lifestyle.com

Key Highlights: Inflation & Pressure Monitoring. MICHELIN Rapid Lighting 12V Tire Inflator with Pressure Pre-Set….

#3 Electric Tyre Inflator for Bike, Car, Truck Tyres and Beyond

Domain Est. 2015

#4 Top Tire Inflators for Any Car

Domain Est. 2016

Website: astroai.com

Key Highlights: Free deliveryInflate tires anytime, anywhere with the AstroAI portable air compressor for car and tire inflator. Fast, easy, and reliable for any vehicle….

#5 Electric Car Tyre Pumps

Domain Est. 2018

Website: smartnewo.com

Key Highlights: Electric car tyre pump provides an efficient and fast solution for inflating tires. It operates using electricity as its power source….

#6 Tyre Inflator

Domain Est. 2019

Website: agarolifestyle.com

Key Highlights: Galaxy Cordless Tyre Inflator, Portable Air Compressor, Flash Light, Power bank , Multipurpose Use, Rechargeable, Up to 150 PSI Air Pump for Car, Bike, ……

#7 Fanttik X8 APEX EV Tire Inflator

Domain Est. 2020

#8 ETENWOLF

Domain Est. 2021

Website: etenwolf.com

Key Highlights: Free delivery 90-day returnsDiscover ETENWOLF’s smart air pumps and portable tire inflators designed for efficient inflation and safety. Perfect for all your needs—shop now!…

Expert Sourcing Insights for Electric Car Pump Tyre

H2: 2026 Market Trends for Electric Car Pump Tyre

The global market for electric car tire pumps is poised for significant transformation by 2026, driven by the rapid expansion of the electric vehicle (EV) industry, technological innovation, and evolving consumer expectations. As automakers worldwide accelerate their transition to electrification, demand for specialized EV accessories—including high-efficiency, smart tire inflation systems—is rising. Below are key trends shaping the Electric Car Pump Tyre market through 2026.

-

Growing EV Adoption Driving Accessory Demand

With governments enforcing stricter emissions regulations and offering incentives for EV ownership, global EV sales are projected to exceed 40 million units annually by 2030. This surge directly fuels demand for EV-specific accessories. Tire pressure maintenance becomes even more critical in EVs due to their heavier weight and performance efficiency, making reliable electric tire pumps essential. By 2026, the electric car pump market is expected to grow at a CAGR of approximately 12–15%, outpacing the broader automotive accessory sector. -

Smart and Connected Pump Technologies

A defining trend in 2026 is the integration of smart technology into electric tire pumps. Consumers increasingly favor pumps equipped with Bluetooth connectivity, mobile app integration, real-time tire pressure monitoring (TPMS), and automatic shutoff features. These smart pumps not only enhance user convenience but also contribute to EV energy efficiency by maintaining optimal tire pressure—directly impacting range. Leading brands are incorporating AI-driven diagnostics to predict pressure loss and recommend inflation cycles. -

Compact, Portable, and Fast-Charging Designs

As EV owners prioritize convenience and portability, manufacturers are focusing on lightweight, compact, and battery-powered electric pumps. By 2026, a majority of new pumps are expected to support USB-C charging, wireless charging pads, and fast inflation (capable of inflating a flat tire in under 3 minutes). These features align with modern EV lifestyles that value minimalist, high-performance tools. -

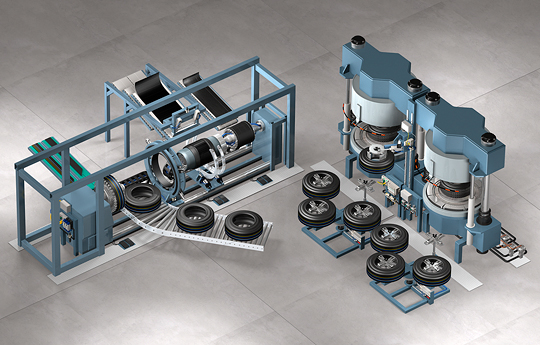

Integration with Vehicle Ecosystems

OEMs (Original Equipment Manufacturers) are increasingly embedding tire inflation systems or partnering with accessory makers to offer branded, compatible pumps. In 2026, we see more electric cars shipped with recommended or pre-paired tire pumps that sync with the vehicle’s infotainment system. This ecosystem integration improves safety and user experience, setting new standards for aftermarket competition. -

Sustainability and Energy Efficiency Focus

As environmental concerns remain central to the EV narrative, manufacturers are developing energy-efficient pumps with low power draw and recyclable materials. Solar-powered tire inflators and models powered by the EV’s own charging port are emerging as niche but growing segments, particularly in eco-conscious markets like Europe and North America. -

Regional Market Dynamics

Asia-Pacific, led by China and India, dominates production and consumption due to strong EV manufacturing and urban mobility needs. Europe follows closely, driven by stringent EU safety regulations requiring TPMS and emergency equipment. North America sees growth through e-commerce and direct-to-consumer brands offering premium smart pumps. -

Competitive Landscape and Innovation

The market is becoming increasingly competitive, with both established automotive brands (e.g., Bosch, Michelin) and tech startups (e.g., Tacklife, AstroAI) launching innovative products. Price competition is balanced by value-added features, pushing R&D investments in durability, speed, and digital integration.

Conclusion

By 2026, the Electric Car Pump Tyre market will be defined by intelligence, integration, and sustainability. As EVs become mainstream, tire pumps will evolve from simple tools to smart, connected components of the vehicle health ecosystem. Companies that prioritize innovation, user experience, and compatibility with EV platforms will lead this high-growth segment.

Common Pitfalls When Sourcing Electric Car Tyre Pumps (Quality & IP)

Sourcing electric car tyre pumps—especially from international suppliers—can be cost-effective, but it comes with significant risks related to product quality and intellectual property (IP). Being aware of these common pitfalls can help prevent costly mistakes, customer dissatisfaction, and legal complications.

Poor Build Quality and Performance

One of the most frequent issues is receiving pumps that fail to meet advertised performance standards. Low-cost suppliers may use substandard motors, plastic housings, or inadequate electronics, resulting in slow inflation, overheating, or premature failure. These units often lack rigorous testing and may not perform reliably in real-world conditions, especially under high pressure or continuous use.

Inaccurate Pressure Readings

Many budget electric pumps come with built-in digital pressure gauges that are poorly calibrated or use low-quality sensors. Inaccurate readings can lead to under- or over-inflation, compromising tyre safety, fuel efficiency, and vehicle handling. Without proper quality control, even minor variances can make the product unreliable.

Lack of Durability and Weather Resistance

Electric tyre pumps are frequently used outdoors and exposed to dust, moisture, and temperature fluctuations. Cheaper models may lack proper ingress protection (IP) ratings—such as IP65 or IP67—meaning they are not adequately sealed against water or dust. This can lead to internal component damage and reduced lifespan, especially in harsh environments.

Misrepresentation of IP Ratings

Suppliers may falsely claim high IP ratings to appear more competitive. However, without independent testing or certification (e.g., from accredited labs), these claims are often unverified. Relying on misrepresented IP ratings can result in product failures, safety hazards, and liability issues if the pump malfunctions in wet conditions.

Non-Compliance with Safety and Regulatory Standards

Many low-cost electric pumps fail to meet essential safety certifications such as CE (Europe), UKCA (UK), or FCC (USA). These standards cover electrical safety, electromagnetic compatibility (EMC), and material safety. Sourcing non-compliant products can lead to customs delays, product recalls, or bans in target markets.

Intellectual Property Infringement

A major risk when sourcing generic or OEM-manufactured pumps is unintentional IP infringement. Many low-cost suppliers produce look-alike versions of branded pumps, copying design elements, circuitry, or software protected by patents, trademarks, or design rights. Importing or selling such products can expose your business to legal action, fines, or seizure of goods by customs authorities.

Limited or No After-Sales Support

Suppliers offering the lowest prices may provide little to no technical support, warranty service, or spare parts. When quality issues arise, resolving them can be difficult and time-consuming, leading to customer dissatisfaction and increased costs for replacements or repairs.

Inconsistent Batch Quality

Even if an initial sample meets expectations, subsequent production batches may vary significantly in quality due to lax manufacturing processes. Without on-site quality inspections or third-party testing, you risk receiving inconsistent products that undermine brand reputation.

Avoiding these pitfalls requires due diligence: vetting suppliers thoroughly, requesting independent test reports, verifying certifications, conducting IP clearance checks, and implementing strict quality control procedures throughout the sourcing process.

Logistics & Compliance Guide for Electric Car Pump Tyre

Overview

This guide outlines key logistics considerations and compliance requirements for the distribution, import, and sale of electric car tyre pumps—portable devices used to inflate vehicle tyres. Ensuring adherence to international regulations, safety standards, and shipping protocols is essential for smooth operations and market access.

Product Classification & HS Code

Electric car tyre pumps are typically classified under the Harmonized System (HS) code 8414.80 – “Other air or vacuum pumps; air or other gas compressors and fans.” However, specific sub-codes may vary by country. Accurate classification is critical for customs clearance, duty determination, and regulatory compliance. Confirm the applicable HS code with local customs authorities or a licensed customs broker.

Safety & Electrical Compliance Standards

Electric tyre pumps must meet electrical safety and electromagnetic compatibility (EMC) standards in target markets:

– Europe (CE Marking): Compliance with the Low Voltage Directive (LVD) 2014/35/EU and EMC Directive 2014/30/EU is required. Testing to standards such as EN 62368-1 (safety of electrical equipment) is often necessary.

– United States (FCC & UL): Devices must comply with FCC Part 15 for radio frequency emissions. While not mandatory, UL certification (e.g., UL 60745) enhances market credibility and safety assurance.

– Canada: Must meet ICES-003 (EMC) and be certified by a recognized body such as CSA or cUL.

– Other Markets: Check local requirements (e.g., KC Mark in South Korea, PSE in Japan, CCC in China).

Packaging & Labeling Requirements

Packaging must ensure product protection during transit and include essential compliance labeling:

– Clearly display required certifications (e.g., CE, FCC, RoHS).

– Include voltage, power rating, model number, and manufacturer/importer details.

– Provide multilingual user instructions and safety warnings if selling in multiple regions.

– Comply with battery labeling standards if the product includes a built-in lithium battery (e.g., UN38.3 for transport).

Battery Regulations (If Applicable)

Many electric tyre pumps include lithium-ion batteries, which are subject to strict transport regulations:

– UN38.3 Testing: Required for all lithium batteries shipped by air or sea. Certification must be provided by the manufacturer.

– IATA & IMDG Compliance: Shipments must follow IATA Dangerous Goods Regulations (air) or IMDG Code (sea). Proper classification, packaging, marking, and documentation (e.g., Shipper’s Declaration for Dangerous Goods) are mandatory.

– Marking: Battery-containing packages must display Class 9 hazardous material labels and orientation arrows.

Import & Customs Documentation

Ensure all shipments include accurate documentation:

– Commercial invoice with detailed product description, value, and HS code.

– Packing list.

– Certificate of Origin (may affect duty rates under trade agreements).

– Test reports and compliance certificates (e.g., CE Declaration of Conformity, FCC ID).

– Dangerous Goods Declaration (if lithium batteries are included).

Shipping & Logistics Considerations

- Mode of Transport: Air freight requires full DG compliance; ocean freight may allow exceptions under certain provisions (e.g., IMDG Special Provision 130).

- Warehousing: Store battery-powered units in dry, temperature-controlled environments. Segregate hazardous inventory if required.

- Insurance: Ensure adequate coverage for high-value or hazardous shipments.

Environmental & Chemical Compliance

- RoHS (EU): Restricts hazardous substances (e.g., lead, mercury, cadmium). Ensure components comply.

- REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals. Declare substances of very high concern (SVHC) if present above thresholds.

- WEEE (EU): Producers may be responsible for end-of-life recycling. Register with national WEEE schemes if selling directly to consumers.

Market-Specific Requirements

- UK: UKCA marking replaces CE for Great Britain (not Northern Ireland). Ensure conformity with UK regulations post-Brexit.

- Australia/New Zealand: Must meet regulatory requirements under the Electrical Equipment Safety System (EESS) and hold RCM marking.

- Middle East: May require G-Mark (Gulf Mark) or SASO certification (Saudi Arabia).

Conclusion

Successfully distributing electric car tyre pumps globally requires careful attention to product classification, safety certifications, battery transport rules, and regional compliance. Partner with certified testing laboratories, experienced freight forwarders, and legal advisors to ensure full adherence to all applicable regulations and avoid customs delays or penalties.

In conclusion, sourcing an electric car tire pump requires careful consideration of several key factors, including reliability, power source (12V socket, battery-operated, or AC/DC), inflation speed, portability, built-in features such as digital pressure gauges and auto-shutoff, and compatibility with your vehicle’s tire valve types. Reputable brands offering durable, user-friendly models with safety certifications should be prioritized to ensure long-term performance and safety. Additionally, evaluating customer reviews, warranty options, and pricing across various suppliers can help identify the best value for your needs. By selecting a high-quality electric tire pump, you enhance convenience, maintain optimal tire pressure for fuel efficiency and safety, and reduce the risk of roadside emergencies—making it a worthwhile investment for every electric and conventional vehicle owner.