The global elastomeric connector market is experiencing steady growth, driven by rising demand in electronics, automotive, medical devices, and industrial applications. According to Mordor Intelligence, the market was valued at approximately USD 1.7 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. This expansion is attributed to the increasing miniaturization of electronic devices, the proliferation of flexible printed circuits, and the need for reliable, high-performance interconnect solutions in harsh environments. Elastomeric connectors—known for their durability, resistance to vibration and temperature extremes, and ability to provide consistent electrical contact—are becoming critical components in advanced manufacturing and next-generation technology systems. As innovation accelerates across key end-use industries, a select group of manufacturers are leading the charge in product development, precision engineering, and global supply capability. Below is a data-driven look at the top nine elastomeric connector manufacturers shaping the future of interconnect technology.

Top 9 Elastomeric Connector Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Custom Elastomeric Connector Product, Manufacturers

Domain Est. 2024

Website: cmaisz.com

Key Highlights: Find high-quality elastomeric connectors at competitive prices from Shenzhen Changmai Technology Co., Ltd. Browse our products and request a quote today….

#2 Elastomeric components

Domain Est. 1996

Website: axon-cable.com

Key Highlights: Addix, a company of the Axon’ group, has a long-standing expertise in manufacturing elastomeric parts for connectors such as micro-D, nano-D, circular ……

#3 Greene Tweed

Domain Est. 1996

Website: gtweed.com

Key Highlights: Greene Tweed develops o-rings, rubber seals, PEEK & PEK thermoplastics, FKM & FFKM elastomers, and electrical connectors for demanding applications….

#4 The what, why and how of elastomeric connectors

Domain Est. 1999

Website: compelma.com

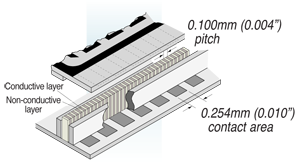

Key Highlights: Elastomeric connectors ensure high density connection (0.05 mm pitch between two contact points) and assemble mechanically (without soldering) through ……

#5 Custom Connectors

Domain Est. 2003

Website: zaxisconnector.com

Key Highlights: The Z-Axis Connector Company manufactures custom electronic connectors, commonly known as Elastomeric Connectors….

#6 Custom Elastomeric Connectors (Zebra Connectors)

Domain Est. 2018

Website: custominjectedplastics.com

Key Highlights: We produce conductive rubber elastomeric connectors (zebra connectors) and non-conductive (IR) rubber spacers to help guard against dust intrusion….

#7 Elastomeric Connectors – cost-effective connectors

Domain Est. 2020

Website: zaxeu.com

Key Highlights: Z-Axis Europe offers revolutionary elastomeric connectors made of tightly spaced parallel rows of conductive filaments embedded in a silicone core….

#8 Elastomeric Connectors: What You Should Know

Domain Est. 2022

Website: nelsonmillergroup.com

Key Highlights: An elastomeric connector is a type of electrical connector that’s characterized by a unique design with multiple alternating layers of conductive and ……

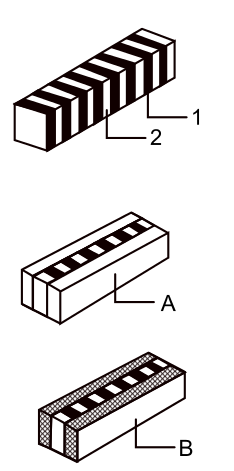

#9 Elastomeric Connectors

Website: osco.uk.com

Key Highlights: ZEBRA Elastomeric Connectors are a comprehensive group of high performance interconnect devices with applications throughout the entire field of electronics….

Expert Sourcing Insights for Elastomeric Connector

H2: 2026 Market Trends for Elastomeric Connectors

The elastomeric connector market is poised for significant evolution by 2026, driven by technological advancements, shifting industry demands, and global economic factors. Key trends shaping the market include:

1. Accelerated Demand in Consumer Electronics & Wearables: The proliferation of advanced smartphones, foldable devices, AR/VR headsets, and next-generation wearables (e.g., health monitors, smart clothing) will drive demand for ultra-miniaturized, highly flexible, and reliable elastomeric connectors. These components are essential for enabling compact designs, repeated folding/unfolding, and robust interconnections in space-constrained environments.

2. Growth in Automotive Electronics & Electrification: The transition to electric vehicles (EVs) and the rise of advanced driver-assistance systems (ADAS) and in-vehicle infotainment (IVI) will increase the need for connectors that withstand harsh environments (temperature, vibration, moisture). Elastomeric connectors offer advantages in thermal management, EMI shielding, and reliable signal integrity in automotive control units, sensors, and battery management systems.

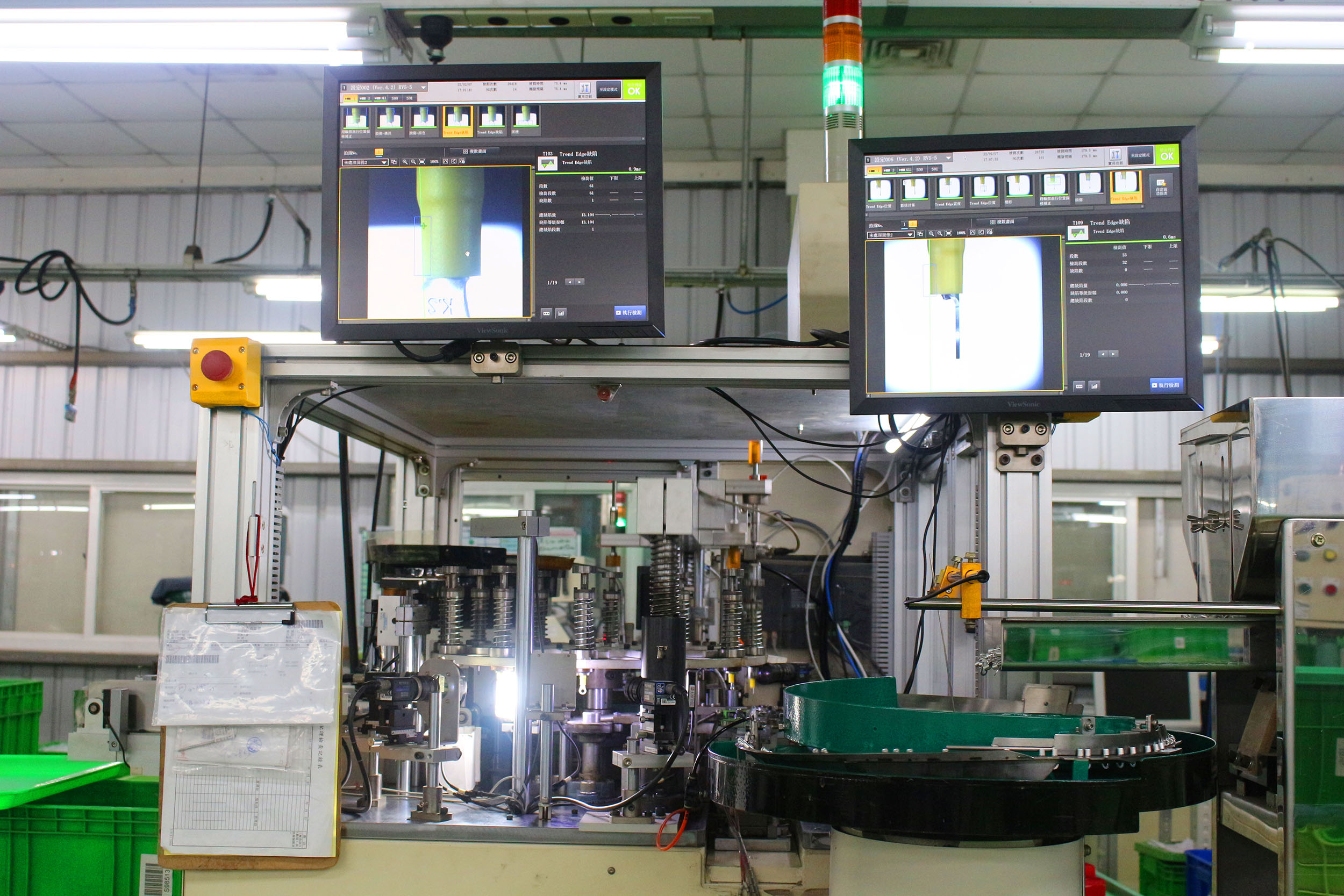

3. Advancements in Materials and Manufacturing: By 2026, expect innovations in conductive elastomer formulations (e.g., improved anisotropy, higher conductivity, enhanced durability) and precision manufacturing techniques like automated Z-axis bonding. These advancements will enable higher pin counts, finer pitch capabilities, and better performance in high-frequency applications, expanding use into data centers and high-speed communication devices.

4. Sustainability and Supply Chain Resilience: Growing regulatory and consumer pressure will push manufacturers toward sustainable materials (e.g., recyclable elastomers) and eco-friendly production processes. Simultaneously, geopolitical factors will drive efforts to diversify supply chains and nearshore production, particularly for critical electronics components used in defense and medical applications.

5. Expansion in Medical and Industrial IoT Applications: The increasing adoption of portable medical devices, implantable electronics, and industrial sensors will favor elastomeric connectors due to their biocompatibility options, sealing capabilities, and reliability in sterile or rugged environments. Their ability to provide both electrical connection and environmental sealing makes them ideal for IoT edge devices.

In summary, the 2026 elastomeric connector market will be characterized by innovation in materials and miniaturization, strong growth in automotive and consumer electronics, and a strategic focus on sustainability and supply chain stability. Companies investing in R&D and diversified applications will be best positioned to capitalize on these trends.

Common Pitfalls Sourcing Elastomeric Connectors (Quality, IP)

Sourcing elastomeric connectors (also known as zebra connectors or anisotropic conductive films) involves navigating several critical quality and intellectual property (IP) challenges. Failure to address these pitfalls can lead to product failures, supply chain disruptions, and legal exposure.

Quality-Related Pitfalls

Inconsistent Conductive Strip Uniformity

Variations in the thickness, alignment, or composition of conductive stripes within the elastomeric material can result in unreliable electrical contact. Poor manufacturing control may cause intermittent connections, increased contact resistance, or complete circuit failure—especially under thermal cycling or mechanical stress.

Insufficient Compression Force Specifications

Many suppliers fail to provide detailed, validated compression force requirements. Under-compression leads to poor contact, while over-compression can permanently damage the connector or mating components. Without clear force-deflection curves, integration into the final product becomes risky.

Poor Environmental Durability

Elastomeric connectors are susceptible to degradation from temperature extremes, humidity, and UV exposure. Low-quality materials may harden, crack, or lose conductivity over time. Sourcing without proper testing data (e.g., thermal cycling, humidity resistance) increases long-term reliability risks.

Material Compatibility Issues

Incompatible elastomer compounds can outgas, react with adjacent materials, or attract particulates. For instance, silicone-based connectors may interfere with optical components or contaminate sensitive environments like medical or aerospace applications.

Lack of Traceability and Batch Consistency

Without lot traceability and strict process controls, performance can vary significantly between production batches. This inconsistency complicates quality assurance and complicates root cause analysis during field failures.

Intellectual Property-Related Pitfalls

Unlicensed Use of Proprietary Designs

Many high-performance elastomeric connector designs are protected by patents—particularly in anisotropic conductive materials and manufacturing processes. Sourcing from unauthorized or gray-market suppliers risks infringing IP, potentially leading to legal action, product recalls, or import bans.

Copycat or Reverse-Engineered Products

Some suppliers offer lower-cost alternatives that closely mimic patented connectors. These may appear functionally similar but often fail under stress or lack durability. Purchasing such products may expose the buyer to contributory infringement claims.

Ambiguous IP Ownership in Custom Designs

When working with contract manufacturers on custom elastomeric connectors, failure to clearly define IP ownership in contracts can lead to disputes. Suppliers may claim rights to tooling, materials formulation, or design modifications, limiting future sourcing flexibility.

Inadequate Documentation of Freedom to Operate (FTO)

Buyers often overlook the need for suppliers to provide FTO assurances. Without evidence that a connector design doesn’t violate existing patents, companies risk costly litigation, especially in highly competitive sectors like consumer electronics or automotive.

Hidden Licensing Fees or Royalties

Some patented connector technologies require ongoing royalties. These may not be transparently disclosed during sourcing, leading to unexpected costs or contractual obligations post-production.

To mitigate these risks, conduct thorough supplier audits, demand full compliance documentation, perform independent reliability testing, and consult IP counsel when sourcing elastomeric connectors—especially for high-volume or safety-critical applications.

Logistics & Compliance Guide for Elastomeric Connectors

Overview

Elastomeric connectors are flexible, conductive components used in electronic devices to establish reliable electrical connections between PCBs, displays, and other circuit elements. Due to their sensitive nature and application in regulated industries (e.g., medical, automotive, aerospace), proper logistics handling and compliance with international standards are critical. This guide outlines best practices for transportation, storage, and regulatory compliance.

Packaging Requirements

Elastomeric connectors must be protected from mechanical stress, moisture, and electrostatic discharge (ESD). Use anti-static, sealed packaging with desiccants to control humidity. Individual components should be housed in compartmentalized trays or tubes to prevent deformation. Outer packaging must be clearly labeled with ESD-sensitive and fragile indicators.

Storage Conditions

Store elastomeric connectors in a climate-controlled environment with temperatures between 15°C and 30°C and relative humidity of 30–60%. Avoid exposure to direct sunlight, ozone, and solvents. Shelf life varies by manufacturer; refer to product datasheets. Typically, storage should not exceed 12 months unless retested and approved for extended use.

Transportation Guidelines

Use certified ESD-safe containers during transit. Minimize vibration and shock by employing cushioned packaging and avoiding stacking heavy items on top. For international shipments, ensure compliance with IATA, IMDG, or ADR regulations if applicable. Temperature-controlled logistics (e.g., cold chain) may be required for sensitive variants.

Regulatory Compliance

Elastomeric connectors used in regulated applications must comply with relevant standards:

– RoHS (EU Directive 2011/65/EU): Restriction of hazardous substances.

– REACH (EC 1907/2006): Registration, Evaluation, Authorization, and Restriction of Chemicals.

– IPC-6012 / IPC-J-STD-001: Quality and performance standards for electronic interconnections.

– ISO 13485: Required if used in medical devices.

– UL / CSA Certification: For connectors used in safety-critical or consumer electronics.

Documentation & Traceability

Maintain full traceability through batch/lot numbers and Certificates of Compliance (CoC). Documentation must include material composition, RoHS/REACH declarations, and any applicable test reports. For export, include commercial invoices, packing lists, and Harmonized System (HS) codes—typically under 8536.90 for electrical contact elements.

Handling & ESD Precautions

All personnel handling elastomeric connectors must wear ESD-safe attire (wrist straps, heel straps, smocks) and work in ESD-protected areas (EPA). Avoid direct finger contact with conductive surfaces. Use grounded workstations and ionizers to neutralize static charges.

Import & Customs Considerations

Verify country-specific import regulations. Some regions require additional certifications (e.g., CCC in China, KC in South Korea). Duty rates and import taxes vary; consult local customs authorities. Ensure all connectors are properly classified to avoid delays or penalties.

Disposal & Environmental Responsibility

Non-conforming or expired elastomeric connectors must be disposed of in accordance with local e-waste regulations. Partner with certified recyclers for proper material recovery. Do not incinerate or landfill due to potential halogen content in some elastomers.

Supplier & Quality Assurance

Source elastomeric connectors only from qualified suppliers with documented quality management systems (ISO 9001). Conduct regular audits and require ongoing compliance reporting. Implement incoming inspection protocols to verify dimensions, conductivity, and packaging integrity.

Conclusion for Sourcing Elastomeric Connectors:

After a thorough evaluation of the technical requirements, market suppliers, quality standards, and cost considerations, elastomeric connectors have been identified as a reliable and efficient interconnection solution for applications requiring flexibility, vibration resistance, and high-density routing—particularly in compact electronic devices such as displays, medical equipment, and automotive systems.

Key findings from the sourcing analysis include the importance of selecting suppliers with proven expertise in silicone-based anisotropic conductive materials, consistent manufacturing precision, and compliance with industry standards (e.g., RoHS, ISO 9001). Leading suppliers offer customization options in pitch, z-axis conductivity, and mechanical durability, enabling optimal performance for specific design needs.

While initial costs may be higher compared to traditional connectors, the long-term benefits—including reduced assembly complexity, enhanced reliability in dynamic environments, and resistance to thermal and mechanical stress—justify the investment. Additionally, establishing relationships with qualified vendors ensures supply chain resilience and access to technical support throughout product lifecycle stages.

In conclusion, sourcing elastomeric connectors from reputable manufacturers, aligned with application-specific performance criteria and quality assurance protocols, will support the development of robust, high-performance electronic systems. Continuous supplier evaluation and ongoing collaboration are recommended to adapt to evolving design and market demands.