The global elastic shock cord market is experiencing steady expansion, driven by rising demand across industries such as automotive, outdoor recreation, logistics, and apparel. According to a 2023 report by Mordor Intelligence, the global bungee cord and elastic cord market was valued at USD 1.3 billion in 2022 and is projected to grow at a CAGR of 4.6% from 2023 to 2028. This growth is fueled by increasing e-commerce activity, which boosts the need for durable securing solutions in packaging and transportation, as well as rising consumer participation in outdoor and adventure sports requiring reliable elastic fasteners. Additionally, advancements in synthetic rubber and polymer-based materials have enhanced the performance and longevity of shock cords, expanding their applications. As demand grows, manufacturers are focusing on product innovation, sustainability, and supply chain efficiency. In this evolving landscape, the following nine companies have emerged as leading elastic shock cord manufacturers, distinguished by their product quality, global reach, and technological expertise.

Top 9 Elastic Shock Cord Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Products

Domain Est. 1998

Website: americanpowercord.com

Key Highlights: American Power Cord Corporation is a top manufacturer of shock & bungee cords, offering custom assemblies, cutting services, and high-quality cordage ……

#2 Engineered Solutions & Seating Systems for Automotive and Others …

Domain Est. 1999

Website: hopeglobal.com

Key Highlights: Industrial. Global supplier of industrial components: shock cords, bungee cords, netting, webbing, and durable carpet strip for airports ……

#3 Am Power Cord Corporation

Domain Est. 2005

Website: ampowercord.com

Key Highlights: The unit manufactures a wide range of Braided Cords, also known as Round Elastic Cords, Bungee Cords, Stretch Cords or Shock Cords from diameter 1.5mm to 20 mm ……

#4 Shock Cord Products

Domain Est. 1999

Website: johnhowardcompany.com

Key Highlights: John Howard Company offers high quality Shock Cord which is also known as bungee cord or elastic cord, is a type of cord that stretches when pulled….

#5 Braided Bungee Cord

Domain Est. 1999

Website: theecwcorp.com

Key Highlights: We are a trusted supplier of bungee cord, and a wide range of material solutions, including braided cord and elastic cord solutions….

#6 Shock Cord

Domain Est. 2005

Website: gearaid.com

Key Highlights: Replacement Shock Cord by GEAR AID will tighten tarps or hammocks and replace a broken cord in tent poles, backpacks or jackets….

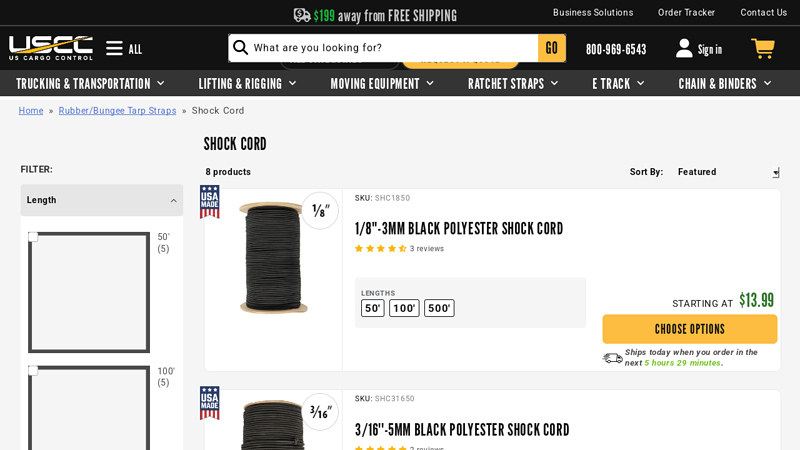

#7 Shock Cord, Elastic Rope, Bungee Cord Rope

Domain Est. 2005

Website: uscargocontrol.com

Key Highlights: Free delivery over $199 60-day returns…

#8 Bungee Cord

Domain Est. 2008

Website: atwoodrope.com

Key Highlights: Free delivery over $99Order the best Bungee Cord from Atwood Rope. Our American-made Bungee Cords offer uniquely strong shock absorption and flexibility. And our bungee rope ……

#9 Elastic Webbing – High Quality Bungee Cord

Website: vardhman.com.au

Key Highlights: 2-day returnsVardhman Threads A&E is a reputable supplier offering a wide range of high-quality elastic webbing and bungee cords suitable for various applications. Their ……

Expert Sourcing Insights for Elastic Shock Cord

2026 Market Trends for Elastic Shock Cord

The global elastic shock cord market is poised for steady evolution by 2026, driven by shifting consumer preferences, technological advancements, and expanding applications across diverse industries. Key trends shaping the market include:

Sustainable Material Innovation

Environmental consciousness is accelerating the development and adoption of eco-friendly elastic shock cords. By 2026, manufacturers are increasingly incorporating bio-based rubbers, recycled latex, and biodegradable sheathing materials. Brands aiming for circular economy compliance are investing in fully recyclable or compostable cord solutions, particularly in outdoor and consumer goods sectors. Regulatory pressures in Europe and North America are further pushing the shift away from petroleum-based synthetics.

Performance Enhancement and Customization

Demand for high-performance cords tailored to specific applications is rising. This includes shock cords with improved UV resistance, temperature stability, and prolonged elasticity retention—critical for aerospace, automotive, and industrial uses. Customization in diameter, tensile strength, color, and coating (e.g., silicone for water resistance) allows manufacturers to serve niche markets such as drone recovery systems, medical devices, and smart wearable technology.

Growth in E-Commerce and DIY Markets

The surge in online retail and home improvement activities is boosting demand for consumer-grade elastic shock cords. By 2026, pre-cut kits, easy-to-use fasteners, and multi-pack bundles are gaining popularity on e-commerce platforms. DIY and outdoor enthusiasts are driving innovation in user-friendly designs, such as cord with integrated clips or retractable mechanisms, enhancing convenience and broadening appeal.

Integration into Smart and Wearable Technology

Elastic shock cords are finding new roles in wearable tech and smart garments. Their flexibility and stretchability make them ideal for integrating sensors, conductive threads, and power transmission in fitness trackers, smart clothing, and rehabilitation devices. As the Internet of Things (IoT) expands, elastic cords with embedded electronics could emerge as a niche but high-growth segment by 2026.

Regional Market Expansion

While North America and Europe remain dominant due to high demand in automotive and outdoor recreation, the Asia-Pacific region is expected to witness the fastest growth. Rising disposable incomes, urbanization, and growth in manufacturing—especially in China, India, and Southeast Asia—are fueling industrial and consumer applications. Localized production and supply chain optimization will be key competitive advantages.

In summary, the 2026 elastic shock cord market will be defined by sustainability, performance, and diversification. Companies that innovate in materials, embrace digital distribution, and tap into emerging tech applications are best positioned to lead in this evolving landscape.

Common Pitfalls Sourcing Elastic Shock Cord (Quality, IP)

Sourcing elastic shock cord may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to product failures, legal issues, and reputational damage. Here are the most common pitfalls to avoid:

Poor Material Quality and Inconsistent Elasticity

Low-cost suppliers often use inferior rubber or synthetic cores that degrade quickly under UV exposure, heat, or moisture. This results in reduced elasticity, premature snapping, and inconsistent performance. Always verify material specifications (e.g., natural rubber vs. synthetic elastomers) and request durability test reports.

Inadequate Tensile Strength and Load Ratings

Many generic shock cords are inaccurately labeled or overrated in terms of load capacity. Using cord that can’t handle the intended stress leads to safety hazards and product recalls. Ensure suppliers provide verifiable tensile strength data and batch testing results.

Lack of UV and Weather Resistance

Outdoor applications demand UV-stabilized jackets (typically nylon or polyester). Sourcing non-UV-resistant cord leads to rapid jacket degradation and core deterioration. Confirm the cord’s weather resistance specifications and suitability for intended environmental conditions.

Inconsistent Diameter and Length Tolerances

Poor manufacturing control leads to variations in cord diameter and stretched/contracted lengths. This inconsistency affects fit and performance, especially in automated assembly or precision applications. Require tight tolerance specifications and inspect sample batches.

Misrepresentation of Stretch Ratio

Suppliers may exaggerate stretch ratios (e.g., claiming 100% stretch when actual performance is 60–70%). This impacts design accuracy and functionality. Test samples under real-world conditions before finalizing sourcing.

Intellectual Property (IP) Infringement Risks

Some branded elastic cords (e.g., patented weave patterns, proprietary coatings) are protected by IP rights. Sourcing counterfeit or imitation products can expose your company to legal liability, especially in regulated markets. Verify supplier authenticity and avoid “copycat” products resembling protected designs.

Non-Compliance with Safety and Industry Standards

Certain applications (e.g., medical devices, aerospace, children’s products) require compliance with safety standards (e.g., REACH, RoHS, FDA). Failing to confirm compliance can result in shipment rejections or regulatory penalties. Request material compliance documentation.

Unreliable Supply Chain and Scalability

Small or unverified suppliers may lack the capacity for consistent large-volume production or fail to maintain quality over time. Assess supplier stability, production capabilities, and scalability before long-term commitments.

Avoiding these pitfalls requires due diligence, clear specifications, and ongoing quality control—ensuring your elastic shock cord performs reliably and legally in your application.

Logistics & Compliance Guide for Elastic Shock Cord

Overview

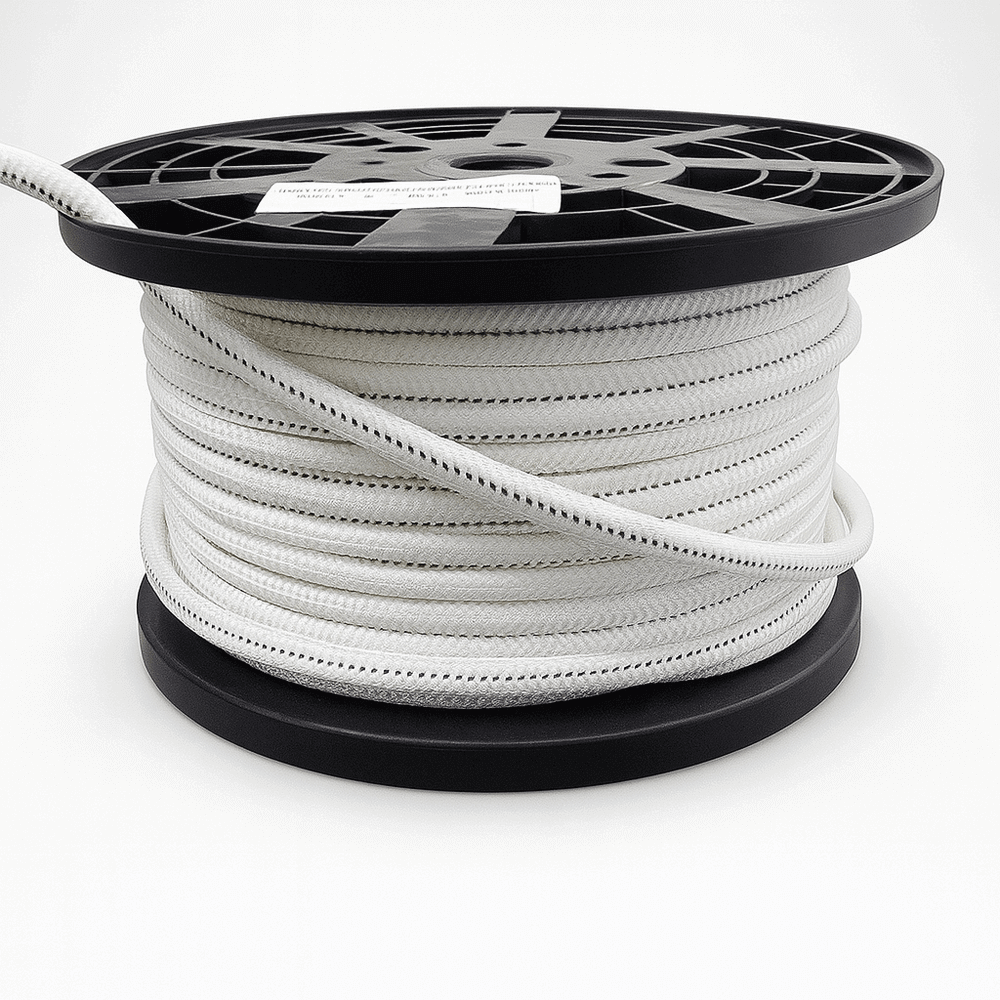

Elastic shock cord, also known as bungee cord, is a stretchable cord consisting of one or more elastic strands enclosed in a woven fabric sleeve. It is commonly used for securing loads, outdoor gear, sports equipment, and various industrial applications. Proper logistics and compliance management ensure safety, regulatory adherence, and efficient distribution.

Classification & Product Specifications

- Material Composition: Typically includes natural or synthetic rubber core (e.g., latex) and a polyester or nylon braided sheath.

- Common Sizes: Diameter (3mm–8mm), lengths (1ft–100ft), and tensile strength ratings (varies by size and construction).

- Standards Compliance: May adhere to ASTM F963 (toy safety), CPSIA (if used in consumer products), or ISO standards for material resilience.

Regulatory Compliance

- REACH (EU): Ensure no restricted substances (e.g., phthalates, heavy metals) in materials.

- RoHS (EU): Apply if shock cords contain electronic components or are part of electrical assemblies.

- CPSIA (USA): Required if marketed for children’s use; mandates lead and phthalate testing.

- Prop 65 (California): Labeling required if components contain listed carcinogens or reproductive toxins (e.g., latex dust).

- Latex Warning: If natural rubber is used, include allergen warnings where required.

Packaging & Labeling Requirements

- Labeling: Include product name, dimensions, stretch capacity, manufacturer details, country of origin, and compliance marks.

- Safety Warnings: “May contain latex,” “Do not overstretch,” “Keep away from children,” as applicable.

- Packaging: Use tamper-evident, durable packaging; bundles should be secured to prevent unraveling.

- Multilingual Labels: Required for international shipments (e.g., EU, Canada).

Shipping & Transportation

- Domestic (USA): Compliant with DOT regulations; no hazardous classification for standard cords.

- International:

- IATA/IMDG: Not classified as dangerous goods unless combined with prohibited components.

- Customs Documentation: Provide commercial invoice, packing list, and bill of lading. Include HTS code (e.g., 5604.90.00 – elastic thread and cord).

- Storage Conditions: Store in cool, dry environments away from UV light, ozone, and sharp objects to prevent degradation.

Import/Export Considerations

- HTS Codes: Confirm correct classification (e.g., 5604.90.0000 for elastic cord in the U.S.).

- Tariffs & Duties: Vary by country; check FTA eligibility (e.g., USMCA, ASEAN).

- Certificates of Origin: Required for preferential tariff treatment.

- Quotas & Restrictions: None typically apply to elastic cord, but verify country-specific rules.

Quality Control & Testing

- Tensile Strength Testing: Verify load capacity and elongation per ASTM D2628 or internal specs.

- Cycle Testing: Assess durability after repeated stretching.

- Aging & UV Resistance: For outdoor-use cords, conduct weathering tests.

- Batch Traceability: Maintain lot numbers and test records for recall readiness.

Environmental & Disposal Compliance

- Recyclability: Polyester/nylon sheaths may be recyclable; rubber cores often require specialized processing.

- Waste Disposal: Follow local regulations for textile and rubber waste. Avoid incineration if toxic fumes are a concern.

- Sustainability Claims: Avoid unsubstantiated “eco-friendly” labels unless certified.

Risk Management & Safety

- Overstretch Hazard: Warn against exceeding 100–150% of original length to prevent snapping.

- Eye/Skin Protection: Recommend handling precautions in industrial settings.

- Child Safety: Design end caps to prevent choking hazards if sold as consumer goods.

Documentation & Recordkeeping

- Maintain:

- Material Safety Data Sheets (MSDS/SDS)

- Test reports and compliance certificates

- Supplier declarations (e.g., REACH SVHC)

- Customs filings and import licenses (if applicable)

Conclusion

Proper logistics and compliance for elastic shock cord involve understanding material regulations, accurate classification, safe handling, and clear documentation. Regular audits and supplier verification help ensure ongoing compliance across global supply chains.

Conclusion for Sourcing Elastic Shock Cord

Sourcing elastic shock cord requires a strategic approach that balances quality, cost, durability, and reliability. After evaluating various suppliers, materials, and specifications, it is evident that selecting the right shock cord depends on the intended application—whether for outdoor gear, industrial use, or consumer products. Key factors such as elasticity, UV and abrasion resistance, dimensional accuracy, and consistent tensile strength must be prioritized to ensure performance and safety.

Establishing relationships with reputable suppliers—whether domestic or international—can enhance supply chain efficiency and reduce lead times. Additionally, conducting sample testing and requesting material certifications help verify product consistency and compliance with industry standards.

In conclusion, a well-informed sourcing strategy that emphasizes quality control, supplier reliability, and application-specific requirements will lead to optimal performance and long-term cost savings. Regularly reviewing supplier performance and staying updated on material advancements will further support continuous improvement in the procurement process.