The global egg tray packaging market is experiencing steady growth, driven by rising egg consumption, expanding poultry industries, and increasing demand for sustainable packaging solutions. According to a report by Mordor Intelligence, the global egg packaging market is projected to grow at a CAGR of over 5.2% from 2023 to 2028. This expansion is fueled by the need for durable, cost-effective, and eco-friendly packaging, especially in emerging economies where egg production and distribution networks are scaling rapidly. As demand rises, egg tray wholesale manufacturers are playing a critical role in supplying molded fiber packaging that ensures safety and reduces breakage during transit. In this competitive landscape, identifying reliable and high-capacity manufacturers is essential for distributors, agribusinesses, and retailers aiming to meet consumer needs efficiently. Based on production scale, geographic reach, sustainability practices, and market reputation, these top 9 wholesale manufacturers have emerged as key players driving innovation and supply in the global egg tray market.

Top 9 Egg Tray Wholesale Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 egg tray

Domain Est. 2004

Website: eggtray.com

Key Highlights: Free delivery 30-day returnsPlastic egg tray source factory, global shipping, saving you egg packaging costs, with inventory, over 100 styles, customizable molds, labels, ……

#2 Disposable Egg Tray

Domain Est. 2022

Website: lesuipackaging.com

Key Highlights: Lesui is a professional bulk disposable plastic egg trays manufacturer that can provide different types of disposable egg trays. Our disposable egg trays ……

#3 Egg trays

Domain Est. 1996

Website: huhtamaki.com

Key Highlights: Egg tray for 30 eggs. Product type: Egg tray. Raw material: 100% Recycled Fiber Egg sizes: S,M,L ; Egg tray for 30 eggs. Product type: Egg tray ; Raw material: ……

#4 Egg Cartons & Trays

Domain Est. 1998

#5 Bulk Egg Cartons & Flats

Domain Est. 1998

Website: strombergschickens.com

Key Highlights: Free delivery over $150Protect your eggs with bulk egg cartons and flats. Durable and eco-friendly. Ideal for small farms and large operations. Save with wholesale pricing!…

#6 Egg Trays, Crates & Filler Flats

Domain Est. 2000

Website: eggcartons.com

Key Highlights: Free delivery over $25Shop bulk egg trays, egg flats, egg crates & filler flats in paper, cardboard & plastic. Durable trays for eggs or parts. Fast shipping on all bulk orders….

#7 Egg Cartons Online

Domain Est. 2006

Website: eggcartonsonline.com

Key Highlights: Free deliveryWholesale egg carton warehouse We are the number one supplier of Foam Egg Cartons, Plastic Egg Trays, Egg Cases, Plastic Egg Cartons, Egg Filler Flats, ……

#8 Egg Trays

Domain Est. 2018

Website: mauserpackaging.com

Key Highlights: Made from durable HDPE material that meets requirements for food contact, Mauser Packaging Solutions egg trays accommodate a variety of egg sizes. Egg trays fit ……

#9 Disposable Egg Trays

Domain Est. 2019

Website: eggsunlimited.com

Key Highlights: Disposable egg trays are eco-friendly cartons that hold at least 12 eggs. They are available in a variety of sizes and recyclable materials….

Expert Sourcing Insights for Egg Tray Wholesale

2026 Market Trends for Egg Tray Wholesale

The global egg tray wholesale market is poised for significant transformation by 2026, driven by evolving consumer preferences, sustainability mandates, technological innovations, and supply chain dynamics. As demand for eggs continues to rise due to population growth and dietary shifts, the packaging sector—particularly egg trays—must adapt to meet these challenges. Below are the key market trends expected to shape the egg tray wholesale industry in 2026.

Rising Demand for Sustainable Packaging Solutions

Environmental concerns are at the forefront of packaging decisions. By 2026, the egg tray wholesale market will see accelerated demand for biodegradable, compostable, and recyclable materials. Molded fiber (pulp-based) trays made from recycled paper or agricultural waste will dominate, replacing traditional plastic trays in many regions. Governments and retailers are increasingly enforcing eco-friendly packaging regulations, pushing wholesalers to offer sustainable alternatives. This trend will also drive innovation in material sourcing and production efficiency to reduce carbon footprints.

Expansion in Emerging Markets

Asia-Pacific, Latin America, and Africa are expected to be high-growth regions for egg consumption and, consequently, egg tray demand. Urbanization, rising middle-class populations, and increased poultry farming investments will fuel wholesale needs. Countries like India, Nigeria, and Indonesia will see a surge in local production and distribution networks, creating new opportunities for regional and international egg tray suppliers. Wholesalers expanding into these markets will benefit from early-mover advantages and long-term contracts with egg producers.

Consolidation and Vertical Integration in Supply Chains

To improve efficiency and reduce costs, major players in the egg tray wholesale market are expected to pursue vertical integration—controlling both production and distribution. This trend will lead to consolidation among smaller manufacturers, with larger companies acquiring competitors or forming strategic partnerships. Integrated operations will enable better quality control, faster delivery, and customized solutions for large egg producers and supermarket chains. Wholesalers who can offer end-to-end services will gain a competitive edge.

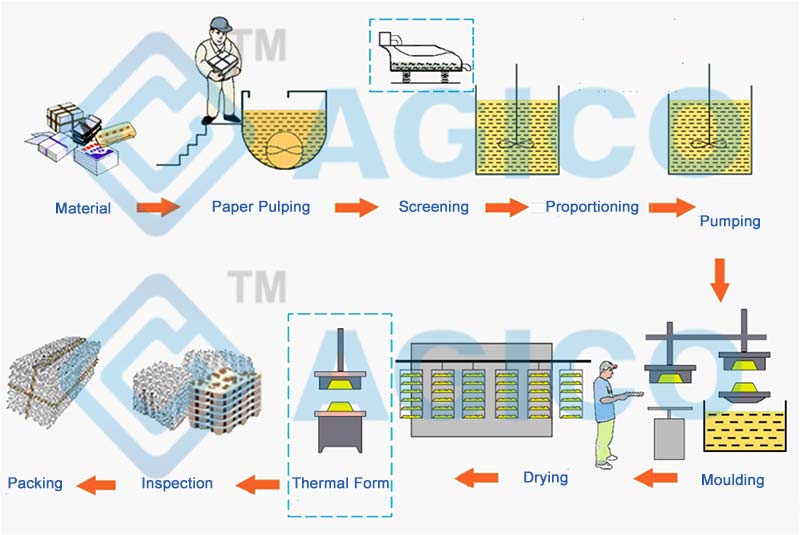

Technological Advancements in Manufacturing

By 2026, automation and smart manufacturing will be standard across leading egg tray production facilities. Advanced molding machines, AI-driven quality inspection systems, and IoT-enabled supply chain tracking will enhance productivity and reduce waste. These technologies will allow wholesalers to scale production rapidly, maintain consistent quality, and respond dynamically to fluctuating demand. Additionally, innovations in lightweight yet durable tray designs will reduce shipping costs and improve stackability—key factors in wholesale logistics.

Customization and Branding Opportunities

Retailers and egg producers are increasingly using packaging as a branding tool. Wholesalers offering customizable egg trays—featuring logos, color printing, and unique structural designs—will see growing demand. This trend is especially prominent in premium and organic egg segments, where packaging reflects product quality and values. Digital printing technologies will make low-volume customization more affordable, enabling even small producers to differentiate their offerings.

Regulatory and Food Safety Pressures

Food safety standards will continue to influence design and material choices in egg trays. By 2026, stricter hygiene regulations—especially in North America and Europe—will require trays that are easy to sanitize, resistant to microbial growth, and free from harmful chemicals. Wholesalers will need to comply with certifications such as FDA, FSC, and ISO standards to remain competitive. Traceability and transparency in the supply chain will also become critical, with blockchain technology potentially being adopted to verify material origins and manufacturing processes.

Conclusion

The 2026 egg tray wholesale market will be shaped by sustainability, technology, and globalization. Wholesalers who invest in eco-friendly materials, embrace automation, expand into high-growth regions, and offer value-added services such as customization and integrated logistics will be best positioned for success. As consumer and regulatory demands evolve, the industry must innovate to remain resilient and profitable in an increasingly competitive landscape.

Common Pitfalls When Sourcing Egg Tray Wholesale (Quality, IP)

Sourcing egg trays in bulk offers cost advantages, but it comes with significant risks—particularly concerning product quality and intellectual property (IP) rights. Avoiding these common pitfalls is crucial for maintaining brand reputation and ensuring compliance.

Poor Material Quality and Durability

One of the most frequent issues is receiving egg trays made from substandard materials. Low-quality recycled paper pulp or inadequate thickness can result in weak trays that crush easily during transport, leading to damaged eggs and customer complaints. Buyers often overlook material specifications, assuming all trays are the same, but variations in pulp density and moisture resistance greatly affect performance.

Inconsistent Manufacturing Standards

Wholesale suppliers—especially those from regions with lax oversight—may lack consistent production processes. This can result in trays with uneven shapes, rough edges, or inconsistent sizing, which can affect packing efficiency and equipment compatibility. Without on-site audits or third-party inspections, these inconsistencies may go unnoticed until after delivery.

Misrepresentation of Eco-Friendliness

Many buyers prioritize sustainable packaging, but some suppliers falsely claim their egg trays are biodegradable or made from 100% recycled materials. Without proper certifications (e.g., FSC, recyclability labels), these claims can be misleading. This not only affects your environmental goals but may also expose your brand to greenwashing allegations.

Intellectual Property Infringement

Copying patented tray designs is a serious risk when sourcing from generic manufacturers. Some suppliers reproduce innovative tray patterns or structural features protected by IP rights. If you import such products, your business could face legal action, product seizures, or customs penalties—even if unintentional. Always verify that designs are either licensed or in the public domain.

Lack of Customization Rights

If you require branded or uniquely designed trays, failing to secure IP ownership in your contract can be a critical error. Some suppliers retain design rights, preventing you from using the tray design with other manufacturers or in future orders. Ensure your agreement explicitly transfers full IP rights for any custom designs.

Inadequate Quality Control Protocols

Wholesale suppliers may lack robust quality assurance systems. Without defined QC checkpoints or batch testing, defective trays can slip through. Always insist on sample testing, production audits, and clear defect tolerances in your contract to catch issues early.

Hidden Costs Due to Rejection

Poor quality often leads to rejected shipments, which incur return fees, delays, and emergency sourcing costs. Factor in the risk of non-compliance when evaluating supplier quotes—cheaper upfront pricing may cost more in the long run.

By addressing these pitfalls proactively—through due diligence, clear contracts, and verification processes—you can secure reliable, high-quality, and legally compliant egg tray supplies.

Logistics & Compliance Guide for Egg Tray Wholesale

Understanding Regulatory Requirements

Egg tray wholesalers must comply with local, national, and international regulations related to food safety, packaging, and transportation. In most regions, egg packaging must meet food-contact material standards (e.g., FDA in the U.S. or EFSA in the EU). Ensure materials used—especially paper pulp or recycled content—are certified as safe for direct contact with food products. Additionally, verify compliance with labeling regulations, including product origin, manufacturer details, and recyclability symbols.

Packaging Standards and Material Certification

Wholesalers should source egg trays made from certified sustainable materials, preferably with FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) accreditation. For export markets, ensure packaging materials meet phytosanitary standards and do not contain contaminants. Provide documentation such as Material Safety Data Sheets (MSDS) and Certificates of Compliance to reassure buyers of quality and safety.

Transportation and Cold Chain Considerations

Although egg trays themselves are not perishable, they are used to transport perishable goods. Coordinate logistics to minimize exposure to moisture, extreme temperatures, and contamination during transit. Use weather-resistant containers and pallet covers when necessary. If shipping internationally, ensure adherence to ISPM 15 regulations for wood packaging materials used in pallets or crates.

Inventory Management and Lead Times

Maintain efficient inventory systems to meet fluctuating demand from egg producers and distributors. Implement just-in-time (JIT) practices or safety stock levels to avoid overstocking or stockouts. Clearly communicate lead times to clients, especially during peak seasons like holidays when egg consumption—and tray demand—increases.

Import/Export Documentation and Tariff Compliance

For international trade, prepare accurate documentation including commercial invoices, packing lists, bill of lading, and certificates of origin. Classify egg trays correctly under the Harmonized System (HS Code)—typically under 4823.00 for paperboard packaging. Research applicable import duties and taxes in destination countries to avoid delays or unexpected costs.

Sustainability and Environmental Compliance

Many markets now require eco-friendly packaging. Ensure egg trays are recyclable and free from harmful inks or coatings. Stay updated on Extended Producer Responsibility (EPR) laws in target markets, which may require registration and reporting of packaging waste. Highlighting compliance with environmental standards can be a competitive advantage.

Quality Control and Batch Traceability

Implement quality checks at production and pre-shipment stages to ensure trays meet structural integrity standards (e.g., stackability, moisture resistance). Maintain batch records for traceability in case of recalls or customer complaints. Use labeling systems that include batch numbers and production dates.

Partnering with Certified Carriers and 3PLs

Work with logistics providers experienced in handling packaging goods and compliant with transportation safety standards. Third-party logistics (3PL) partners should offer tracking, insurance, and reporting capabilities. Confirm that carriers follow good distribution practices (GDP) to maintain product integrity.

Risk Management and Insurance

Secure comprehensive insurance covering cargo damage, loss, and liability related to defective packaging. Include clauses for delays, contamination, or non-compliance penalties. Conduct regular audits of suppliers and logistics partners to mitigate supply chain risks.

Recordkeeping and Audit Preparedness

Maintain organized records of compliance certifications, shipping documents, quality inspections, and customer communications. These records support audits from regulatory bodies or major retail clients. Digital recordkeeping systems improve accessibility and reduce compliance risk.

In conclusion, sourcing egg trays wholesale offers a cost-effective and efficient solution for businesses involved in egg packaging, distribution, or retail. By purchasing in bulk, companies can benefit from reduced per-unit costs, consistent supply, and standardized quality that supports brand reliability and customer satisfaction. It is essential to carefully evaluate suppliers based on material quality—whether recycled paper pulp, plastic, or molded fiber—production capacity, sustainability practices, and compliance with safety standards. Building strong relationships with reputable wholesalers not only ensures timely delivery and scalability but also supports environmental goals through eco-friendly packaging options. Ultimately, strategic wholesale sourcing of egg trays contributes to operational efficiency, cost savings, and long-term business sustainability.