The EDM (Electrical Discharge Machining) manufacturing sector in Michigan is experiencing renewed momentum, driven by the state’s deep-rooted industrial infrastructure and growing demand for precision components across aerospace, automotive, and medical device industries. According to Grand View Research, the global EDM market size was valued at USD 4.8 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 7.1% from 2024 to 2030. With Michigan remaining a cornerstone of U.S. advanced manufacturing—boasting over 13,000 manufacturing facilities and a skilled technical workforce—the state hosts a concentrated cluster of high-caliber EDM service providers meeting stringent industry tolerances. Supported by automation integration and increasing adoption of die-sinking and wire-cut EDM technologies, Michigan-based manufacturers are well-positioned to capitalize on this upward market trajectory. The following list highlights the top seven EDM manufacturers in Michigan, selected based on technical capabilities, industry certifications, capacity, and customer verticals served.

Top 7 Edm Michigan Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 CNC Dealer

Domain Est. 2010

Website: wsmtechnology.com

Key Highlights: WSM Technology is your CNC dealer and Mitsubishi EDM reseller, providing high accuracy manufacturing solutions for CNC milling machines, EDM machines and more ……

#2 Manufacturing Services Detroit, MI

Domain Est. 1997

Website: edmdept.com

Key Highlights: EDMIS is the source for all EDM Manufacturing Services serving Detroit, Michigan including Wire EDM, Sinker EDM, EDM Hole Drilling and Laser Ablation….

#3 Belmont Equipment & Technologies

Domain Est. 1997 | Founded: 1960

Website: belmont4edm.com

Key Highlights: Experts in EDM since 1960. Our committed team has over 300 combined years of unmatched experience with electrical dischard machines and EDM supplies….

#4 Metal Fabrication Machinery

Domain Est. 1998

Website: mcmachinery.com

Key Highlights: MC Machinery Systems, a supplier of metal fabrication machines, provides EDM, milling, laser, press brake, finishing, and automation solutions….

#5 Apollo EDM

Domain Est. 1999 | Founded: 1969

Website: apolloedm.com

Key Highlights: Apollo EDM is a family owned and operated business since 1969. Apollo has earned a reputation for doing difficult, precision EDM machining jobs….

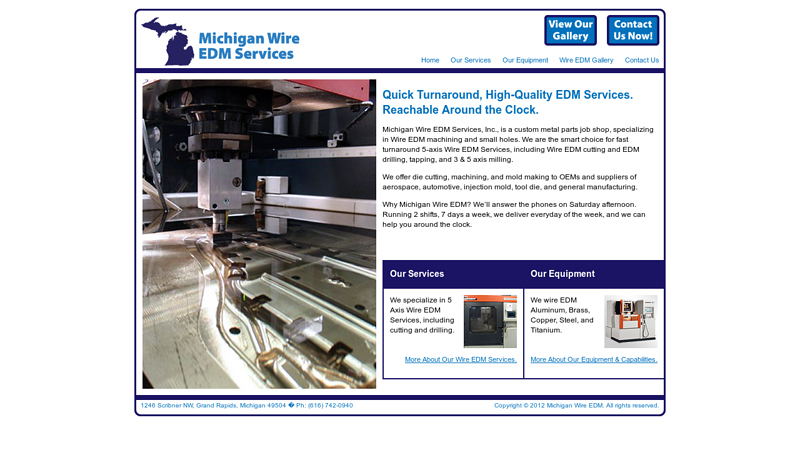

#6 Michigan Wire EDM Services

Domain Est. 2009

Website: michiganwireedm.com

Key Highlights: We are the smart choice for fast turnaround 5-axis Wire EDM Services, including Wire EDM cutting and EDM drilling, tapping, and 3 & 5 axis milling….

#7 SST Consumables

Domain Est. 2020

Website: sstconsumables.com

Key Highlights: SST is the largest EDM consumables supplier in North America. SST carries the most popular and trusted brands of EDM wire, filtration products, and more….

Expert Sourcing Insights for Edm Michigan

H2: 2026 Market Trends for EDM in Michigan

As the electronic dance music (EDM) scene continues to evolve globally, Michigan is poised to experience significant shifts in its local EDM market by 2026. Historically rooted in techno—originating in Detroit during the 1980s—the state is leveraging its legacy while adapting to new technological, cultural, and economic trends. Here are the key market trends anticipated for the EDM landscape in Michigan through 2026:

-

Revival and Expansion of Detroit’s Techno Heritage

By 2026, Detroit’s status as the birthplace of techno is expected to drive a renewed emphasis on cultural preservation and innovation. City-led initiatives and private investments aim to elevate local talent through artist grants, studio residencies, and public art installations that celebrate the genre’s history. International attention, amplified by the UNESCO City of Music designation (awarded in 2024), will likely increase tourism and festival attendance, particularly around the annual Movement Electronic Music Festival. -

Growth of Immersive and Hybrid Events

Michigan’s EDM events are transitioning toward hybrid (in-person and virtual) formats, integrating augmented reality (AR), 360-degree livestreams, and blockchain-powered ticketing. Major venues in Detroit, Ann Arbor, and Grand Rapids are investing in tech infrastructure to support immersive experiences, appealing to younger, digitally native audiences. By 2026, over 40% of mid-to-large EDM events in Michigan are projected to offer some form of virtual access. -

Rise of Independent and DIY Collectives

A surge in grassroots collectives and underground promoters is transforming Michigan’s EDM ecosystem. These groups prioritize inclusivity, queer-friendly spaces, and experimental sound, often operating outside traditional club circuits. Supported by decentralized funding platforms and social media marketing, these collectives are expected to host over half of all local EDM events by 2026, fostering a more diverse and resilient scene. -

Increased Focus on Sustainability

Environmental consciousness is shaping event planning across the state. By 2026, Michigan-based festivals are anticipated to adopt zero-waste policies, carbon offset programs, and renewable energy sources for stages and operations. Collaborations with green tech startups and universities will further position Michigan as a leader in sustainable event production within the EDM industry. -

Expansion of Music Technology and Education Programs

Michigan’s higher education institutions, including Wayne State University and the University of Michigan, are expanding curricula in music production, audio engineering, and electronic music entrepreneurship. Partnerships with local studios and labels are creating internship pipelines, ensuring a skilled workforce to support the growing EDM economy. These programs are expected to produce over 500 graduates annually by 2026, fueling innovation and local job creation. -

Commercialization and Brand Partnerships

As EDM gains mainstream traction, Michigan artists and events are attracting increased sponsorship from lifestyle, tech, and beverage brands. Expect to see more branded experiences, artist endorsements, and product integrations at festivals. However, this commercial growth may spark tension between authenticity and monetization within the underground community. -

Regional Talent Going Global

Michigan-based DJs and producers are gaining international recognition, supported by digital distribution and social media. By 2026, several artists from Detroit and surrounding areas are projected to appear on major festival lineups (e.g., Tomorrowland, Ultra) and sign with global labels, boosting the state’s profile as a continued hub for cutting-edge electronic music.

In conclusion, the 2026 EDM market in Michigan reflects a dynamic blend of historical reverence and forward-thinking innovation. With strong cultural roots, technological adoption, and community-driven growth, the state is well-positioned to remain a pivotal force in the national and global electronic music landscape.

Common Pitfalls When Sourcing EDM Services in Michigan: Quality and Intellectual Property Concerns

When sourcing Electrical Discharge Machining (EDM) services in Michigan, manufacturers must navigate several critical challenges, particularly around quality assurance and intellectual property (IP) protection. Overlooking these areas can lead to production delays, compromised product integrity, and legal risks. Below are key pitfalls to avoid:

Inconsistent Quality Standards

One of the most frequent issues when sourcing EDM services is variability in part quality. Not all Michigan-based EDM shops adhere to the same precision standards. Some may lack proper calibration procedures, experienced operators, or robust quality control systems such as ISO certification. This can result in out-of-tolerance components, surface finish defects, or inconsistent electrode wear—especially problematic in high-precision industries like aerospace or medical device manufacturing.

Mitigation Strategy: Vet potential suppliers for certifications (e.g., ISO 9001), request first-article inspections (FAI), and conduct regular audits. Review their process documentation and ask for sample workpieces to assess consistency.

Inadequate Material and Process Documentation

Many EDM providers fail to maintain detailed records of machining parameters, electrode materials, or post-processing steps. This lack of traceability makes it difficult to replicate results or troubleshoot defects. Without proper documentation, reproducing a successful process becomes guesswork, increasing the risk of quality deviations across production runs.

Mitigation Strategy: Require comprehensive process documentation as part of your service agreement. Ensure the supplier logs key variables such as pulse settings, dielectric fluid type, and electrode wear compensation.

Intellectual Property Exposure

Sharing detailed CAD models, toolpaths, and proprietary design features with an EDM vendor exposes sensitive IP. In Michigan, while non-disclosure agreements (NDAs) are common, enforcement can be challenging. Some suppliers may inadvertently—or intentionally—use design data for competitive advantage, especially if they serve similar industries.

Mitigation Strategy: Execute strong, jurisdiction-specific NDAs before sharing any design files. Limit data access to only necessary components and consider watermarking or obfuscating non-critical design elements. Choose vendors with a proven track record of IP confidentiality.

Weak Contractual Safeguards

Verbal agreements or vague contracts often fail to address ownership of tooling, electrode designs, or process know-how developed during the EDM project. This gray area can lead to disputes over IP rights, especially if the supplier claims co-ownership of custom fixturing or optimized machining strategies.

Mitigation Strategy: Clearly define IP ownership in contracts. Specify that all designs, tooling, and process innovations developed for your project are your exclusive property. Include clauses on data retention and destruction post-project.

Overreliance on Supplier Expertise Without Verification

Some companies assume that local EDM shops inherently possess advanced capabilities. However, not all providers in Michigan invest in the latest CNC EDM technology or staff training. Outdated equipment or inexperienced operators can lead to longer lead times, higher scrap rates, and subpar surface finishes.

Mitigation Strategy: Conduct technical evaluations of the supplier’s equipment, software, and staff qualifications. Ask for case studies or client references in your industry to validate expertise.

By proactively addressing these quality and IP-related pitfalls, companies sourcing EDM services in Michigan can ensure reliable production outcomes and protect their competitive advantages.

Logistics & Compliance Guide for EDM Michigan

When engaging in Electrical Discharge Machining (EDM) operations in Michigan, businesses must navigate a combination of logistical considerations and regulatory compliance requirements. This guide outlines key aspects to ensure efficient operations while adhering to state and federal standards.

Facility Location and Layout

Choose a facility location with access to major transportation routes such as I-75, I-94, and proximity to freight rail and airports (e.g., DTW). Ensure adequate floor space, ceiling height, and reinforced flooring to support heavy EDM machinery. Proper zoning compliance for industrial use is required under local municipal codes.

Equipment Transportation and Installation

Coordinate equipment shipping through certified industrial rigging companies familiar with precision machinery. Plan for crane access, load-bearing assessments, and controlled environmental conditions (temperature, humidity) during installation. Verify that electrical service (typically 480V 3-phase) meets machine specifications.

Regulatory Compliance

Adhere to Michigan-specific environmental and safety regulations. The Michigan Department of Environment, Great Lakes, and Energy (EGLE) mandates proper handling and disposal of dielectric fluids and filter waste. Facilities must comply with Part 111 of the Michigan Safe Drinking Water Act and Part 31 of the Natural Resources and Environmental Protection Act (NREPA) for hazardous waste classification and reporting.

Worker Safety and Training

All operators must be trained in accordance with OSHA 29 CFR 1910 standards, including machine guarding, lockout/tagout (LOTO), and fire prevention. Michigan OSHA (MIOSHA) requires documented safety programs and regular equipment inspections. Provide ongoing training on EDM-specific hazards such as electrical safety and fume exposure.

Waste Management and Recycling

Used oil, sludge, and filters generated from sinker and wire EDM processes are often classified as hazardous waste. Partner with EGLE-licensed waste disposal vendors for manifesting and tracking. Explore recycling options for metals (e.g., brass wire, electrode remnants) through certified recyclers to reduce environmental impact and disposal costs.

Permitting and Reporting

Obtain necessary air emissions permits if using EDM machines that generate significant particulate matter. Facilities may need to file Part 550 Air Quality Permits with EGLE depending on operation scale. Maintain logs for waste disposal, material safety data sheets (MSDS/SDS), and employee training records for compliance audits.

Supply Chain and Material Sourcing

Establish reliable suppliers for EDM consumables such as electrodes, brass wire, and dielectric fluid. Ensure suppliers provide Michigan Right-to-Know Act compliant SDS documentation. Maintain inventory controls to minimize downtime and support just-in-time manufacturing workflows.

Cybersecurity and Data Compliance

For CNC-integrated EDM systems, implement cybersecurity best practices to protect design files and operational data. Comply with data privacy standards if handling client intellectual property, particularly in defense or medical sectors subject to ITAR or HIPAA regulations.

Emergency Preparedness

Develop and post emergency response plans addressing fire, chemical spills, and power failures. Equip facilities with Class C fire extinguishers, spill kits, and emergency shutoffs. Conduct drills semi-annually and maintain coordination with local fire and hazardous materials response teams.

Continuous Improvement and Audits

Perform internal compliance audits at least annually. Stay updated on changes to MIOSHA, EGLE, and federal EPA regulations. Invest in energy-efficient EDM machines to reduce operational costs and support Michigan’s Clean Energy Future initiatives.

Conclusion for Sourcing EDM in Michigan:

Sourcing Electrical Discharge Machining (EDM) services in Michigan offers numerous advantages due to the state’s strong manufacturing heritage, skilled workforce, and proximity to key industries such as automotive, aerospace, and medical device manufacturing. Michigan is home to a network of advanced machine shops and contract manufacturers with expertise in precision EDM techniques—including wire, sinker, and small-hole drilling—ensuring high accuracy and tight tolerances for complex components.

Additionally, the state’s robust industrial ecosystem, supportive infrastructure, and commitment to technological innovation make it an ideal location for reliable and efficient EDM sourcing. By partnering with experienced EDM providers in Michigan, businesses can benefit from shorter lead times, improved supply chain resilience, and high-quality machining capabilities tailored to meet rigorous industry standards.

In conclusion, sourcing EDM services in Michigan combines technical excellence with logistical advantages, making it a strategic choice for companies seeking precision manufacturing solutions in the U.S. Midwest.