The global EDM (Electrical Discharge Machining) machine market is witnessing steady expansion, driven by rising demand for high-precision components in aerospace, automotive, and medical device manufacturing. According to Mordor Intelligence, the EDM machine market was valued at approximately USD 4.2 billion in 2023 and is projected to grow at a CAGR of over 6.8% through 2029. This growth is fueled by advancements in CNC technology, increasing adoption of die-sinking and wire-cut EDM machines, and the need for complex geometries in hard-to-machine materials. As industries push the boundaries of precision engineering, the role of leading EDM machine manufacturers becomes increasingly critical. These top nine manufacturers are not only shaping the competitive landscape but also driving innovation through automation, IoT integration, and energy-efficient designs. Backed by strong R&D investments and a global footprint, they are well-positioned to capitalize on the expanding industrial applications of EDM technology.

Top 9 Edm Machine Meaning Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

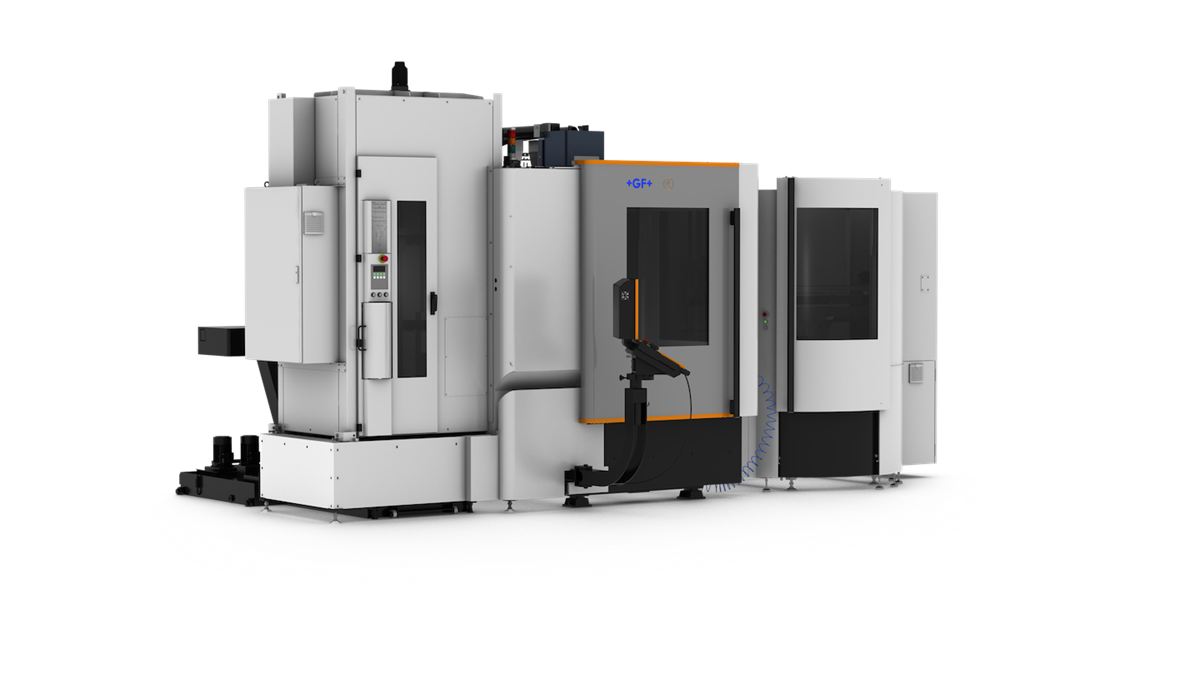

#1 UNITED MACHINING

Domain Est. 1999

Website: gfms.com

Key Highlights: UNITED MACHINING delivers comprehensive, integrated solutions for manufacturers of precision parts, tools, and mold-making — helping them move seamlessly from ……

#2 Electrical Discharge Machining (EDM)

Domain Est. 1997

Website: mmsonline.com

Key Highlights: Electrical discharge machining, or EDM, is a non-contact form of machining that projects sparks from an electrode or wire to vaporize material of any hardness….

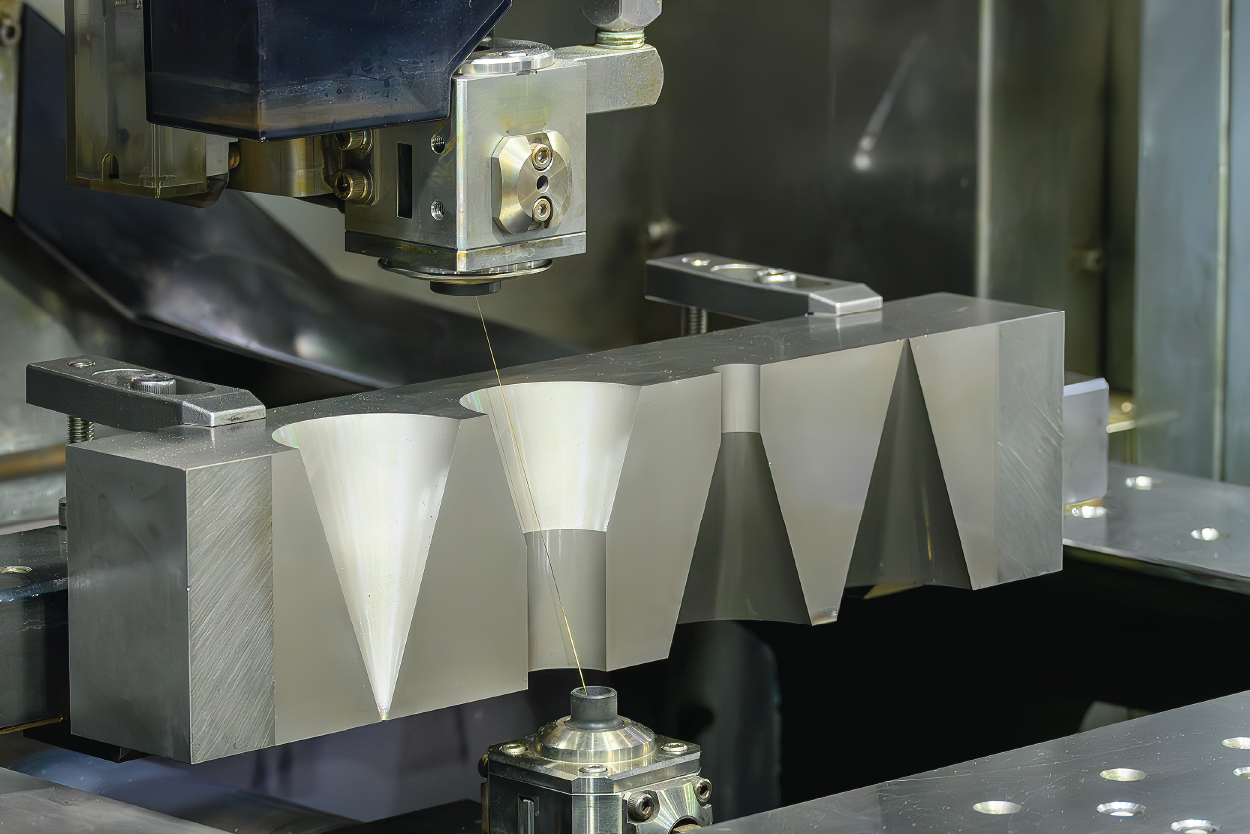

#3 What is Wire EDM?

Domain Est. 1997

Website: xactedm.com

Key Highlights: Wire electrical discharge machining (WEDM) uses a metallic wire to cut or shape a workpiece, often a conductive material, with a thin electrode wire that ……

#4 Applications of Wire EDM in Different Industries

Domain Est. 1997

Website: edmdept.com

Key Highlights: Wire EDM, or Electrical Discharge Machining, is a specialized process that uses a thin wire to cut through conductive materials with a high degree of ……

#5 What Is An EDM Machine Used For?

Domain Est. 1998

Website: sodick.com

Key Highlights: Also known as a spark machining tool, an EDM machine cuts conductive materials using sparks or electricity. By eliminating material, it creates ……

#6 What is Electrical Discharge Machining (EDM)?

Domain Est. 2006

Website: protolabs.com

Key Highlights: EDM is a subtractive manufacturing method that uses electrical discharges to machine features on a mold. There are two distinct varieties of ……

#7 Electrical Discharge Machining

Domain Est. 2015

Website: xometry.com

Key Highlights: Electrical Discharge Machining (EDM) is a nonconventional machining process used primarily for tasks that would be unachievable with conventional methods….

#8 Wire Cutting EDM

Website: fanuc.eu

Key Highlights: Wire EDM (Electrical Discharge Machining) is a precision manufacturing process that uses a thin, electrically charged wire to cut intricate shapes and contours….

#9 What is An EDM Machine? A Beginner’s Guide To …

Domain Est. 1999

Website: cncmasters.com

Key Highlights: EDM in 2024. Manufacturers typically choose electrical discharge machining (EDM) when conventional machining methods cannot provide a solution….

Expert Sourcing Insights for Edm Machine Meaning

H2: Projected 2026 Market Trends for EDM Machines (Electrical Discharge Machining)

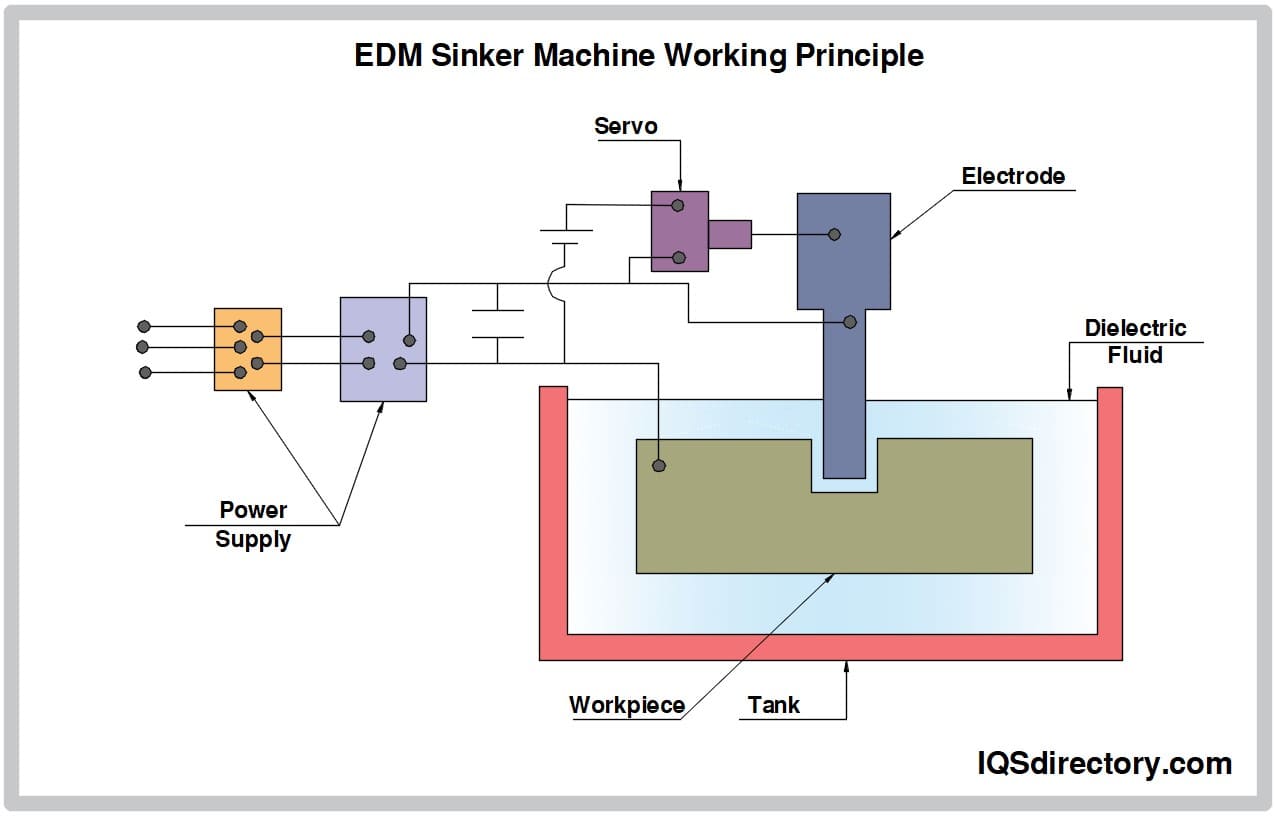

As we approach 2026, the global market for Electrical Discharge Machining (EDM) machines is expected to undergo significant transformation, driven by advancements in manufacturing technologies, increasing demand for precision components, and the adoption of smart manufacturing practices. EDM machines, which utilize controlled electrical sparks to erode conductive materials into complex shapes, are becoming increasingly vital in high-precision industries such as aerospace, automotive, medical devices, and mold & die manufacturing.

Several key trends are expected to define the EDM machine market in 2026:

-

Growth in Demand for Micro-EDM and Precision Applications

The need for miniature and ultra-precise components—especially in medical devices and electronics—is fueling demand for micro-EDM technology. These machines can achieve tolerances in the micrometer range, supporting innovations in wearable devices, surgical tools, and micro-molds. -

Integration with Industry 4.0 and Smart Manufacturing

By 2026, EDM machines are anticipated to feature greater connectivity through IoT sensors, AI-driven process optimization, and cloud-based monitoring. This integration allows for real-time performance tracking, predictive maintenance, and improved process consistency, enhancing overall productivity and reducing downtime. -

Rise of Automation and Robotic Integration

Automated EDM systems, including robotic workpiece handling and palletized electrode changers, are expected to gain traction. This shift supports lights-out manufacturing, where EDM machines operate unattended for extended periods, improving cost-efficiency and scalability. -

Sustainability and Energy Efficiency Focus

With growing regulatory and corporate emphasis on sustainability, EDM machine manufacturers are innovating to reduce energy consumption and dielectric fluid waste. Closed-loop filtration systems and energy-efficient power supplies are becoming standard features. -

Expansion in Emerging Markets

Regions such as Southeast Asia, India, and Latin America are expected to witness increased investment in advanced manufacturing infrastructure. This growth will drive demand for cost-effective and reliable EDM solutions tailored to local industrial needs. -

Hybrid Machining Systems

The convergence of EDM with other machining technologies—such as milling or grinding—in hybrid machines is expected to grow. These systems offer the precision of EDM while maintaining the speed and versatility of traditional machining, appealing to manufacturers seeking multifunctional capabilities. -

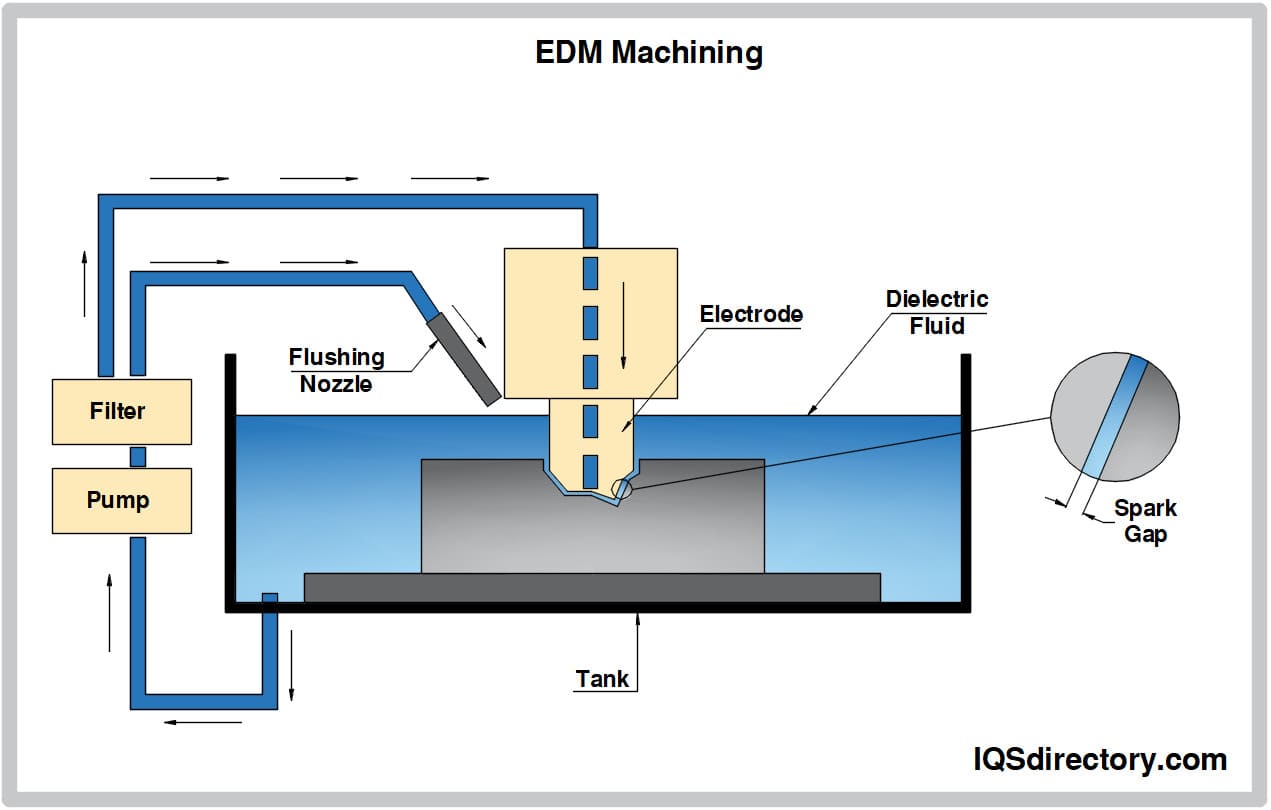

Advancements in Dielectric Fluid Technology

Research into eco-friendly dielectric fluids and improved flushing techniques is expected to enhance machining speed, surface finish, and environmental safety—critical factors for high-performance EDM operations.

In conclusion, the 2026 EDM machine market is poised for robust growth, underpinned by technological innovation, automation, and an increasing demand for precision manufacturing. Companies that invest in smart, sustainable, and integrated EDM solutions are likely to lead the market, meeting the evolving needs of advanced manufacturing sectors worldwide.

Common Pitfalls When Sourcing EDM Machines: Quality and IP Concerns

Logistics & Compliance Guide for EDM Machine Meaning

Understanding the meaning and function of an EDM (Electrical Discharge Machining) machine is essential for proper logistics handling, transportation, and regulatory compliance in industrial and manufacturing environments. This guide outlines key considerations related to the logistics and compliance aspects tied to EDM machines.

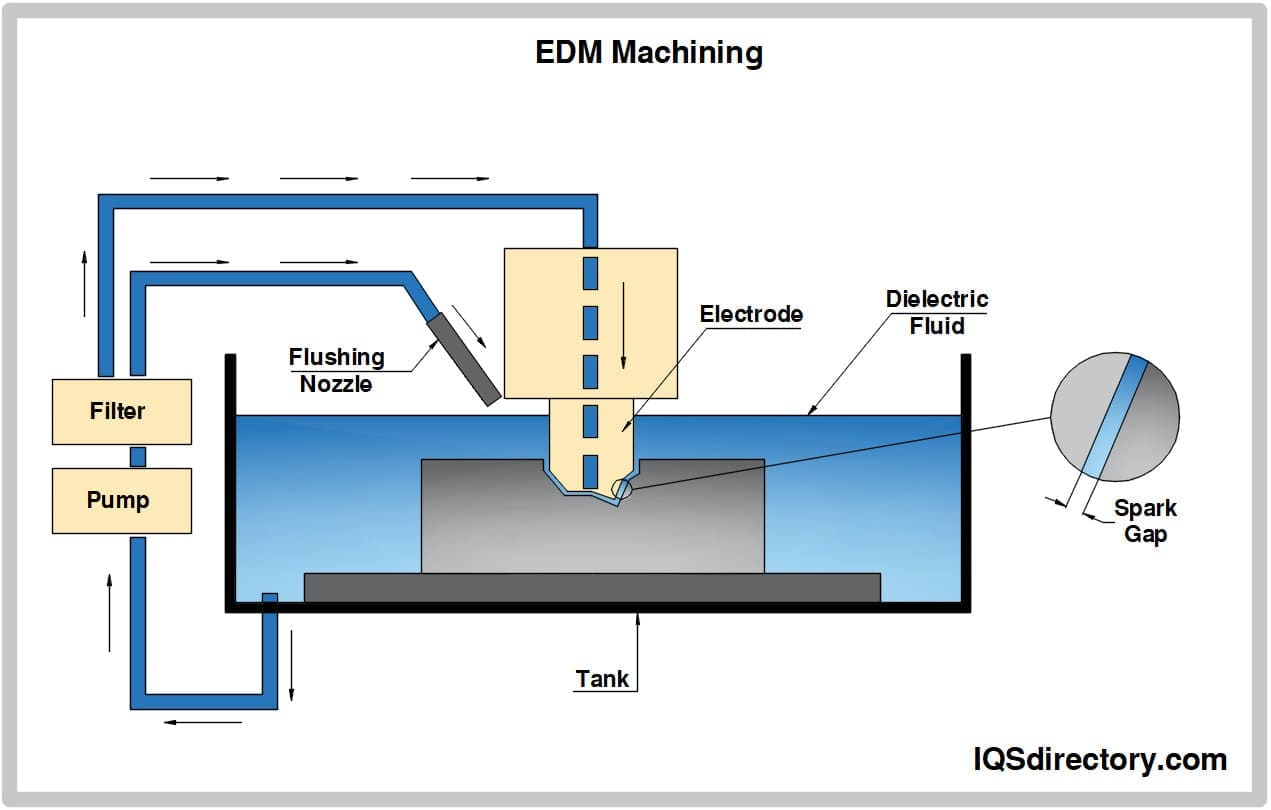

What Is an EDM Machine?

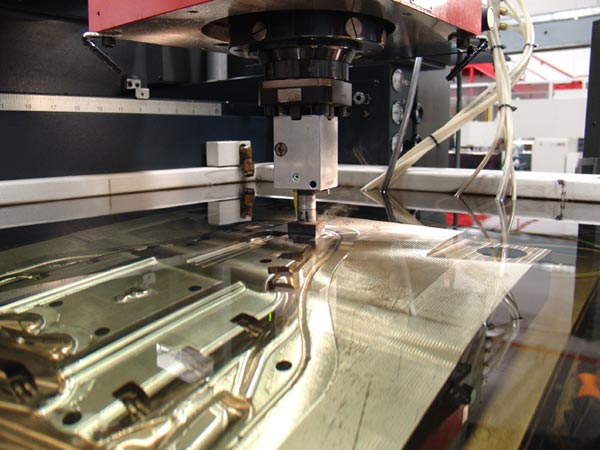

An EDM (Electrical Discharge Machining) machine is a precision manufacturing tool that shapes conductive materials using controlled electrical sparks. Also known as spark machining or wire burning, EDM removes material without direct contact between the tool and workpiece, making it ideal for complex geometries, hard metals, and tight tolerances. Common types include wire EDM, sinker EDM (ram EDM), and hole drilling EDM.

Logistics Considerations for EDM Machines

Transporting and installing EDM machines requires careful planning due to their size, weight, and sensitivity.

Size and Weight Management

EDM machines are often large and heavy, especially industrial-grade models. Proper logistics planning must account for:

– Crane or forklift access at both origin and destination

– Weight limits of elevators, floors, and transport vehicles

– Disassembly requirements for tight spaces

Packaging and Handling

To prevent damage during transit:

– Use original factory packaging or custom crating

– Secure all moving parts and sensitive components

– Include moisture barriers and desiccants for long-distance or maritime shipping

Transportation Mode

Choose the appropriate transport method:

– Road freight for domestic delivery

– Air freight for urgent or international needs (note size/weight limits)

– Sea freight for cost-effective international shipping (requires proper moisture and corrosion protection)

Installation and Site Preparation

- Ensure adequate floor space with vibration-dampening foundations

- Verify power supply compatibility (3-phase power often required)

- Provide clean, climate-controlled environments to protect electronic components

Compliance Requirements

EDM machines must comply with various regulatory standards depending on the region and application.

Electrical Safety Standards

- CE Marking (EU): Complies with Machinery Directive 2006/42/EC and Low Voltage Directive

- UL/CSA (North America): Meets safety standards for electrical equipment

- IEC 60204-1: International standard for safety of machinery – Electrical equipment

Environmental and Waste Compliance

- Coolant and Dielectric Fluid Handling: Used hydrocarbon-based or deionized water fluids must be disposed of according to local environmental regulations (e.g., EPA in the U.S., REACH in the EU).

- Waste Material (Sludge): Metal particles generated during EDM are considered hazardous waste in some jurisdictions and require proper disposal protocols.

Electromagnetic Compatibility (EMC)

EDM machines generate electromagnetic interference. Compliance with:

– EMC Directive 2014/30/EU (EU)

– FCC Part 15 (U.S.)

ensures they do not disrupt nearby equipment.

Import/Export Regulations

For international shipping:

– Classify under correct HS Code (e.g., 8456.30 for EDM machines)

– Comply with customs documentation, including commercial invoices and certificates of origin

– Adhere to trade restrictions or sanctions if applicable

Workplace Safety and Training

- Operators must be trained per OSHA (U.S.) or equivalent national safety standards

- Guarding, emergency stops, and lockout/tagout (LOTO) procedures must be in place

- Risk assessments should address high voltage, moving parts, and fluid exposure

Conclusion

Proper logistics and compliance management for EDM machines ensure safe transport, correct installation, and legal operation. Understanding the technical nature of EDM equipment helps streamline shipping, avoid regulatory penalties, and maintain workplace safety. Always consult local regulations and manufacturer guidelines when planning the movement and deployment of EDM systems.

In conclusion, sourcing an EDM (Electrical Discharge Machining) machine involves a strategic process of identifying, evaluating, and selecting the most suitable machine based on specific manufacturing needs, budget constraints, and technical requirements. Understanding the meaning and function of an EDM machine—its ability to precisely shape conductive materials using controlled electrical sparks—is crucial in determining its value in high-precision industries such as aerospace, automotive, and mold-making. Effective sourcing not only ensures optimal performance and return on investment but also supports long-term production efficiency and competitiveness. Therefore, a thorough understanding of EDM technology, supplier credibility, after-sales support, and future scalability is essential for making informed procurement decisions.