The global packaging industry is undergoing rapid transformation, driven by increasing demand for durable, sustainable, and cost-effective solutions—particularly in e-commerce and logistics. A critical factor in evaluating packaging strength and performance is the Edge Crush Test (ECT), which measures the vertical resistance of corrugated board to crushing forces. As reliance on robust packaging grows, so does the need for accurate and reliable ECT equipment. According to Grand View Research, the global corrugated packaging market was valued at USD 68.9 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. This growth directly fuels demand for high-precision testing instruments. With quality control becoming paramount across supply chains, leading manufacturers of Edge Crush Test equipment are innovating to meet evolving industry standards, driving advancements in automation, data accuracy, and compliance. Here’s a look at the top 7 ECT machine manufacturers shaping the future of packaging integrity testing.

Top 7 Edge Crush Test Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 High-Quality EDGE Crush Tester 2025

Domain Est. 1998

Website: prestogroup.com

Key Highlights: Rating 5.0 (600) Presto is a leading Manufacturer and supplier of Edge Crush Tester /RCT/ECT /FCT Digital Model With Best Price. Give a Call Now +91-9210903903….

#2 ECT vs Mullen Test for Box Strength

Domain Est. 1996

Website: nelsoncontainer.com

Key Highlights: The Edge Crush Test (ECT) measures how much weight a box can support vertically before its edges collapse—a critical factor in modern shipping where palletized ……

#3 Edge Crush Test (ECT) – Corrugated Boxes

Domain Est. 1997

Website: westpak.com

Key Highlights: The edge crush test (ECT) is used to assess corrugated fiberboard’s capacity to sustain cross-sectional pressure….

#4 Edge Crush Testing (ECT)

Domain Est. 1997

Website: mecmesin.com

Key Highlights: The edge crush test (ECT) is a standard method used to evaluate the edgewise compressive strength of corrugated fibreboard. It measures how well a sample ……

#5 The edge crush test (ECT)

Domain Est. 2004

Website: complianceonline.com

Key Highlights: The Edge Crush Test (ECT) using a short column specimen is an important test for the boxmaker. This TIP describes the relationship between containerboard edge ……

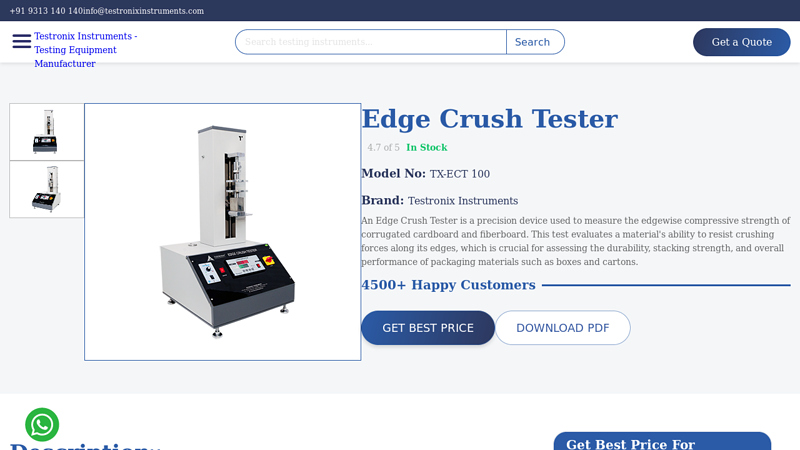

#6 Edge Crush Tester (ECT Digital)

Domain Est. 2015

Website: testronixinstruments.com

Key Highlights: Rating 4.7 (605) An Edge Crush Tester is a precision device used to measure the edgewise compressive strength of corrugated cardboard and fiberboard….

#7 Ensure Your Packaging Quality with the HannYa Edge Crush Tester!

Domain Est. 2023

Website: hannyatesting.com

Key Highlights: The HannYa Edge Crush Tester is your ultimate solution for comprehensive paper and cardboard testing. This versatile machine performs a full range of tests, ……

Expert Sourcing Insights for Edge Crush Test

2026 Market Trends for Edge Crush Test (ECT)

Growing Demand Driven by E-Commerce Expansion

The Edge Crush Test (ECT) market is poised for significant growth by 2026, primarily fueled by the continued rise of global e-commerce. As online shopping becomes the preferred retail method across North America, Europe, and Asia-Pacific, the need for durable and reliable packaging has intensified. ECT, a critical metric for evaluating the compressive strength of corrugated cardboard, is increasingly adopted by packaging manufacturers and logistics companies to ensure product safety during transit. With more shipments involving multiple handling stages and longer supply chains, packaging must withstand stacking and pressure—making ECT a key quality assurance tool.

Advancements in Testing Technology and Automation

By 2026, technological innovation is expected to reshape the ECT landscape. Automated and digital ECT equipment integrated with IoT sensors and data analytics platforms will enable real-time monitoring and predictive maintenance. These smart testing systems will offer higher precision, faster results, and seamless integration into quality control workflows. Additionally, portable ECT devices are gaining traction, allowing on-site testing at manufacturing and distribution centers. This shift toward automation and digitalization not only improves efficiency but also reduces human error, supporting compliance with international packaging standards such as ASTM D642 and ISO 3037.

Sustainability Regulations Influencing Packaging Design

Environmental regulations and corporate sustainability goals are reshaping packaging strategies, directly impacting ECT requirements. By 2026, there will be a growing emphasis on lightweight yet strong corrugated materials that minimize material use without compromising structural integrity. This trend is driving demand for precise ECT data to optimize board grades and flute configurations. Regulatory pressures in regions like the EU and North America—such as extended producer responsibility (EPR) laws and plastic reduction mandates—are pushing companies to adopt recyclable, fiber-based packaging, further increasing the relevance of ECT in material selection and performance validation.

Regional Market Dynamics and Industrial Adoption

Regionally, Asia-Pacific is expected to lead ECT market growth by 2026 due to rapid industrialization, booming e-commerce in countries like China and India, and expanding manufacturing sectors. North America and Europe will maintain strong demand, supported by mature logistics networks and stringent packaging quality standards. Emerging markets in Latin America and Africa are also expected to see increased adoption of ECT as their packaging industries modernize. Key end-use industries—including food and beverage, electronics, pharmaceuticals, and retail—will continue driving ECT adoption to reduce shipping damage and enhance customer satisfaction.

Conclusion: Strategic Importance of ECT in 2026

By 2026, the Edge Crush Test will play a pivotal role in the global packaging ecosystem. Its integration into sustainable design, automated quality control, and supply chain resilience strategies underscores its strategic importance. As companies strive for efficiency, compliance, and environmental responsibility, ECT will evolve from a compliance metric to a core component of packaging innovation and competitive differentiation.

Common Pitfalls in Sourcing Edge Crush Test (ECT) – Quality and Intellectual Property Considerations

When sourcing packaging materials that require Edge Crush Test (ECT) compliance, companies often focus on cost and delivery timelines while overlooking critical quality assurance and intellectual property (IP) risks. These oversights can lead to product damage, customer dissatisfaction, legal exposure, and reputational harm. Below are common pitfalls related to quality and IP when sourcing ECT-rated packaging, particularly from international or third-party suppliers.

Overlooking Certification and Testing Authenticity

One of the most frequent quality pitfalls is assuming that a supplier’s stated ECT value is accurate without independent verification. Suppliers may provide falsified or outdated test reports, or conduct tests under non-standard conditions (e.g., improper humidity, outdated equipment). Relying solely on supplier-provided documentation without third-party validation can result in packaging that underperforms in real-world shipping environments.

Best Practice: Require certified test reports from accredited laboratories (e.g., ISTA-certified or ISO 17025-accredited). Conduct periodic independent ECT testing on batch samples to confirm compliance.

Inconsistent Material Quality Across Batches

Suppliers may use variable raw materials or adjust manufacturing processes between production runs, leading to inconsistent ECT performance. This inconsistency is especially common with recycled linerboard or low-cost corrugated media where fiber quality fluctuates.

Best Practice: Implement strict quality control clauses in sourcing contracts, including minimum ECT tolerances (e.g., ±10%), fiber composition requirements, and right-to-audit provisions.

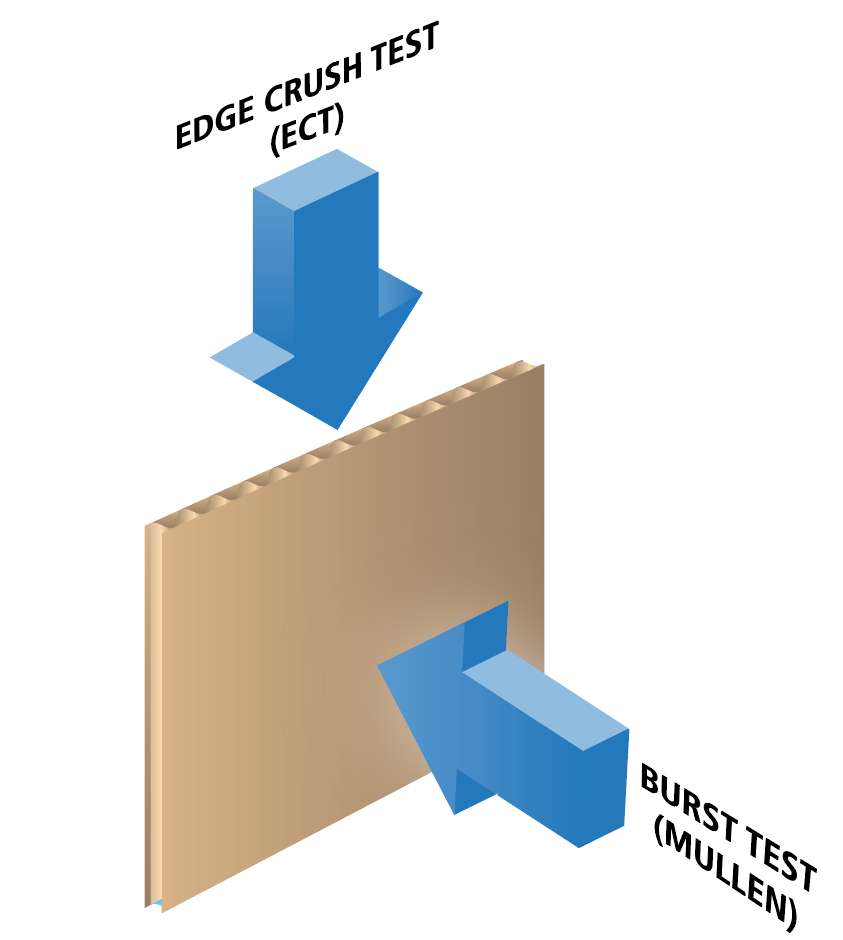

Misunderstanding ECT vs. Burst Strength (Mullen Test)

Some buyers confuse ECT with the older Burst Strength (Mullen) test, leading to incorrect material selection. ECT measures vertical compression resistance (critical for stacked pallets), while burst strength measures resistance to puncture. Using a high-burst, low-ECT board can result in box collapse during storage, even if the supplier met specified burst values.

Best Practice: Clearly specify ECT requirements (e.g., 32 ECT) in procurement documents and educate procurement teams on the functional differences between ECT and burst strength.

Lack of Traceability and IP Infringement Risks

When sourcing custom packaging designs or proprietary corrugated structures, there is a risk of unintentional IP infringement. Some suppliers may replicate patented flute profiles, die-cut designs, or structural innovations without proper licensing. Additionally, lack of documentation and traceability makes it difficult to defend against IP claims or identify the source of design violations.

Best Practice: Conduct IP due diligence on packaging designs and require suppliers to warrant that their products do not infringe on third-party patents. Include indemnification clauses in contracts.

Failure to Protect Proprietary Testing Methods or Formulations

If a company develops a custom ECT-optimized board or testing protocol, failing to protect it through trade secrets, patents, or confidential agreements can lead to IP theft. Suppliers may reverse-engineer formulations or share proprietary data with competitors.

Best Practice: Use non-disclosure agreements (NDAs) and clearly define ownership of innovations in supplier contracts. Consider patenting novel packaging technologies or protecting formulations as trade secrets.

Conclusion

Sourcing packaging with reliable Edge Crush Test performance requires more than checking a specification sheet. Quality pitfalls stem from inadequate testing oversight and material inconsistencies, while IP risks arise from poor documentation, lack of due diligence, and weak contractual protections. A proactive approach—combining independent verification, clear specifications, and robust IP safeguards—ensures both performance reliability and legal compliance in the supply chain.

Logistics & Compliance Guide for Edge Crush Test (ECT)

The Edge Crush Test (ECT) is a critical measurement in the corrugated packaging industry, determining the compressive strength of corrugated board. Understanding its role in logistics and compliance ensures packaging integrity, reduces product damage, and meets carrier and regulatory requirements.

Understanding the Edge Crush Test (ECT)

The Edge Crush Test measures the force required to compress the edge of a corrugated board sample perpendicular to the flute direction. Results are expressed in kN/m (kilonewtons per meter) or lbs/inch. This value correlates directly to a box’s ability to withstand stacking and handling pressures during shipping and storage. Unlike the Mullen burst test, ECT focuses on vertical compression strength—key for modern unitized loads and automated material handling.

Importance in Logistics Performance

In logistics, ECT values guide box selection to match expected distribution environments. Boxes with insufficient ECT ratings risk collapse during stacking, especially in high pallet loads or long-haul transport. This can lead to product damage, increased waste, and higher freight claims. Ensuring proper ECT compliance helps maintain load stability, protects contents, and supports efficient warehouse racking and automated handling systems.

Regulatory and Carrier Compliance Requirements

While there is no universal global regulation mandating specific ECT values, many carriers and retailers enforce ECT standards as part of their packaging specifications. For example:

- Amazon FBA (Fulfillment by Amazon) requires a minimum ECT of 32 ECT (or equivalent Mullen test) for standard-sized boxes.

- FedEx and UPS may require ECT-based box ratings depending on shipment weight and handling class.

- Grocery and pharmaceutical distributors often specify ECT values in vendor compliance manuals to ensure product safety and prevent claims.

Non-compliance can result in rejected shipments, penalties, or disqualification from vendor programs.

Testing Standards and Procedures

ECT testing follows standardized procedures to ensure accuracy and consistency:

- TAPPI T 811: Standard method for Edge Crush Test of corrugated fiberboard (commonly used in North America).

- ISO 3037: International standard for determining edge crush resistance of corrugated fiberboard.

Testing must be conducted under controlled temperature and humidity conditions (typically 23°C and 50% RH per ISO 187). Samples are conditioned for at least 24 hours prior to testing. Results should be documented and available for audits or customer requests.

Selecting Appropriate ECT Ratings

Choosing the right ECT rating depends on several factors:

- Product weight and dimensions

- Pallet configuration and stacking height

- Distribution cycle length and handling intensity

- Storage duration and environmental conditions

General ECT guidelines:

– Light-duty packaging: 23–31 ECT

– Medium-duty: 32–44 ECT

– Heavy-duty: 44+ ECT

Consult with packaging engineers or use Box Compression Test (BCT) predictors (e.g., McKee formula) to correlate ECT to actual box performance.

Documentation and Quality Control

Maintain records of ECT test results for each production batch or supplier lot. Include:

– Date and location of test

– Sample source and conditioning details

– Equipment calibration status

– Test operator and results

Integrate ECT verification into incoming material inspection and quality management systems (e.g., ISO 9001). Regular third-party audits or supplier certifications (e.g., from independent labs) enhance compliance credibility.

Common Pitfalls and Mitigation Strategies

- Using outdated or uncalibrated equipment: Regular calibration and maintenance of ECT testers are essential.

- Ignoring environmental conditioning: Test results can vary significantly with moisture content; always condition samples properly.

- Relying solely on ECT without considering box design: Combine ECT data with overall box construction, closure methods, and dynamic testing.

- Assuming ECT equals overall durability: ECT measures edge strength, not resistance to impacts, punctures, or vibrations.

Conclusion and Best Practices

To ensure logistics efficiency and compliance, integrate ECT specifications into packaging design and procurement processes. Regular testing, adherence to standards, and clear documentation support supply chain reliability. Partner with certified suppliers, conduct periodic audits, and stay updated on carrier and retailer packaging requirements to avoid disruptions and maintain product integrity.

Conclusion for Sourcing Edge Crush Test (ECT):

The Edge Crush Test (ECT) is a critical quality parameter in evaluating the performance and durability of corrugated board used in packaging. When sourcing packaging materials, ensuring that suppliers meet specified ECT ratings is essential for protecting products during handling, storage, and transportation. A higher ECT value indicates greater resistance to crushing forces, which directly impacts the box’s ability to support stacking loads and maintain structural integrity.

In conclusion, incorporating ECT requirements into the sourcing process helps maintain consistent packaging quality, reduces the risk of product damage, and supports supply chain efficiency. It is recommended to establish clear ECT specifications based on product weight, distribution environment, and regulatory or industry standards. Regular testing and supplier audits further ensure compliance and reliability. Ultimately, prioritizing ECT in sourcing decisions contributes to improved customer satisfaction, cost savings from reduced damages, and enhanced sustainability through optimized material use.