The global stainless steel welding products market is experiencing robust growth, driven by increasing demand from industries such as construction, automotive, energy, and heavy manufacturing. According to a 2023 report by Mordor Intelligence, the global stainless steel market is projected to grow at a CAGR of over 4.5% from 2023 to 2028, with welding materials and consumables forming a significant segment of this expansion. Similarly, Grand View Research estimates that the global welding equipment market size was valued at over USD 25 billion in 2022 and is expected to expand at a CAGR of 5.8% through 2030, fueled by industrialization and infrastructure development across emerging economies. As demand for high-integrity, corrosion-resistant joints rises, manufacturers specializing in Edelstahl (stainless steel) welding solutions are at the forefront of innovation and production capacity. Against this backdrop, the following list highlights the top 10 stainless steel welding manufacturers shaping the industry through technological leadership, global reach, and consistent product performance.

Top 10 Edelstahl Schweißen Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Schweißen

Website: kuhn-edelstahl.de

Key Highlights: Unsere Fertigung arbeitet mit 2 UP-Schweißständen für Verbindungsschweißen: Durchmesser: 150 – 3.200 mm; Länge: 800 – 9.000 mm; Schweißtiefe: 12 – 200 mm ……

#2 Schweißtechniken

Website: edelstahl-mechanik.de

Key Highlights: Edelstahl-Mechanik GmbH ist der Spezialist für Laserschweißen, Laserbearbeitung und Laserschneiden 2D und 3D. Das Unternehmen bietet Dienstleistungen wie ……

#3 Edelstahl

Website: fronius.com

Key Highlights: Das Schweißen von Edelstahl erfordert gute Materialkenntnis – denn die vielen verschiedenen Legierungen und Stahlarten weisen auch unterschiedliche ……

#4 Stainless steel welding

Website: kasag.com

Key Highlights: KASAG undertakes cutting, forming and welding works for manufacturing simple and complex welding constructions of up to a weight of 13 t in stainless steel ……

#5 MIGAL.CO

Website: migal.co

Key Highlights: Entdecken Sie branchenführende Aluminiumschweißzusätze, Kupferschweißmaterialien, hochwertige Edelstahlschweißprodukte und Nickelschweißlösungen bei MIGAL.CO….

#6 Edelstahl schweissen im WIG Verfahren

Website: mirap.ch

Key Highlights: Wir bieten Ihnen innovative Möglichkeiten rund um die dauerhafte Verbindung von Fügeteilen in der Blechverarbeitung. Edelstahl Schweissen dank WIG, hochwertig ……

#7 Edelstahl in der Lebensmittel

Website: safefoodfactory.com

Key Highlights: This brochure offers an overview of the versatility of stainless steel as the material of choice in the European (and, indeed, global) Food and Beverage ……

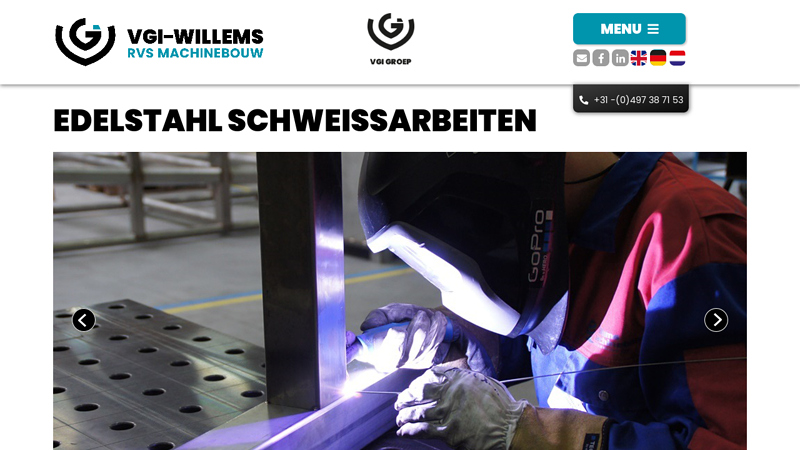

#8 Edelstahl Schweißarbeiten

Website: vgiwillems.nl

Key Highlights: Wir sind umfassend auf das Schweißen von Edelstahl spezialisiert und verfügen über nicht weniger als 30 einzigartige Schweißarbeitsplätze für Edelstahl….

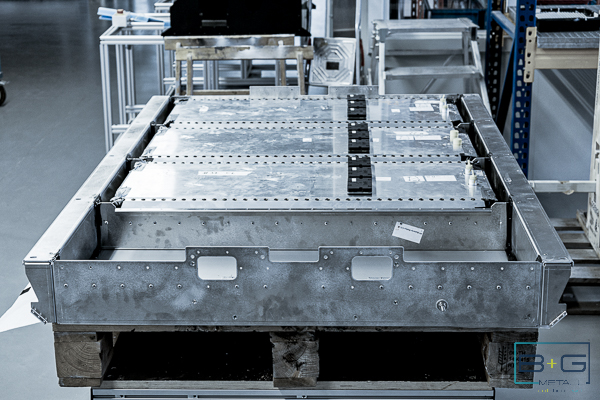

#9 Schweißbaugruppen von B+G Metall

Website: b-g-metall.de

Key Highlights: Egal ob Edelstahl schweißen mit WIG, Aluminium schweißen mit MIG oder Stahl schweißen mit MAG – wir kombinieren modernste Technik mit handwerklicher Präzision….

#10 Edelstahl schweißen (Gestelle, Wannen)

Website: metallbau-pfeuffer.de

Key Highlights: Erfahren Sie bei Metallbau Pfeuffer, wie Edelstahl geschweißt wird. Wir bieten Industrielösungen zum Edelstahl schweißen für Gestelle und Wannen….

Expert Sourcing Insights for Edelstahl Schweißen

2026 Market Trends for Edelstahl Schweißen (Stainless Steel Welding)

The stainless steel welding (Edelstahl Schweißen) market in 2026 is poised for dynamic growth, driven by technological advancements, evolving industrial demands, and a heightened focus on sustainability. Key trends shaping the landscape include:

1. Accelerated Adoption of Automation and Robotics:

The push for higher productivity, consistent weld quality, and reduced labor costs will significantly increase the deployment of automated welding systems and robotics, particularly in high-volume industries like automotive and appliance manufacturing. Collaborative robots (cobots) will become more prevalent, enabling flexible automation even in SMEs.

2. Dominance of Advanced Welding Processes:

Laser Beam Welding (LBW) and Hybrid Laser-Arc Welding (HLAW) are expected to gain substantial market share due to their precision, high speed, and minimal heat input—crucial for maintaining the corrosion resistance of stainless steels. Pulse MIG/MAG welding will remain dominant for its versatility and improved control over heat-affected zones.

3. Focus on Sustainability and Energy Efficiency:

Environmental regulations and corporate ESG goals will drive demand for energy-efficient welding power sources and processes with lower emissions. Increased use of recycled stainless steel will also influence welding parameter optimization to handle varying material compositions.

4. Growth in High-Purity and Specialized Applications:

Sectors such as pharmaceuticals, food & beverage, semiconductor manufacturing, and renewable energy (especially hydrogen infrastructure) will fuel demand for orbital welding and other high-purity techniques that ensure leak-tight, contamination-free joints in stainless steel systems.

5. Digitalization and Smart Welding Solutions:

IoT-enabled welding equipment, real-time process monitoring, and cloud-based data analytics will become standard. These technologies enhance quality control, predictive maintenance, and remote supervision, improving overall operational efficiency.

6. Material Innovation and Welding Challenges:

The growing use of advanced stainless steel grades, including duplex and super-austenitic alloys, will require specialized welding consumables and expertise to manage issues like intermetallic phase formation and maintain mechanical properties.

In summary, the 2026 Edelstahl Schweißen market will be characterized by smarter, faster, and more sustainable welding solutions, with a strong emphasis on automation, digital integration, and high-precision techniques to meet the demands of modern industry.

Common Pitfalls Sourcing Edelstahl Schweißen (Quality, IP)

Sourcing stainless steel welding services—especially in German-speaking markets where “Edelstahl Schweißen” is a common term—can present several challenges, particularly concerning quality assurance and intellectual property (IP) protection. Below are key pitfalls to avoid:

Inadequate Quality Standards and Certification

One of the most frequent issues is engaging suppliers who lack proper certifications such as ISO 3834, EN 1090, or approval according to DIN EN ISO 15614 for welding procedures. Without these, weld integrity and long-term durability cannot be guaranteed, especially in high-stress or corrosive environments.

Inconsistent Material Traceability

Stainless steel quality depends heavily on composition and origin. Poor suppliers may not provide full material test certificates (MTCs) or Mill Test Certificates (EN 10204 3.1 or 3.2), making it difficult to verify that the correct grade (e.g., AISI 304, 316) was used.

Lack of Skilled and Certified Welders

Welding stainless steel requires specific techniques (e.g., TIG welding) and certified personnel (e.g., certified according to DIN EN 287-1). Sourcing from vendors without documented welder qualifications increases the risk of defects such as porosity, cracking, or reduced corrosion resistance.

Poor Process Documentation and Quality Control

Transparent documentation of welding procedures (WPS – Welding Procedure Specifications) and records of inspections (e.g., visual, PT, RT) is often missing. This not only affects quality but complicates compliance in regulated industries like medical, food processing, or aerospace.

Intellectual Property Risks

When outsourcing welding of custom components, especially prototypes or proprietary designs, IP protection becomes critical. Pitfalls include:

- Lack of non-disclosure agreements (NDAs) with suppliers.

- Unsecured design files shared without watermarking or access controls.

- No contractual clauses preventing reverse engineering or unauthorized replication.

Geographic and Communication Challenges

Sourcing from low-cost regions may lead to miscommunication due to language barriers or differing technical standards. Misunderstandings about tolerances, surface finishes, or inspection requirements can result in subpar outcomes.

Insufficient Audit Rights and On-Site Verification

Many procurement agreements fail to include rights for on-site audits or unannounced quality checks. Without these, it’s difficult to verify that stated processes are actually followed during production.

Conclusion

To mitigate these risks, ensure suppliers are certified, require full documentation, enforce IP agreements, and conduct regular quality audits. Investing time upfront in due diligence pays off in product reliability and legal protection.

Logistics & Compliance Guide for Edelstahl Schweißen (Stainless Steel Welding)

This guide outlines key logistical considerations and compliance requirements for stainless steel welding operations, ensuring safety, quality, and regulatory adherence.

Material Handling and Storage

Proper handling and storage of stainless steel materials are essential to prevent contamination and maintain material integrity. Store stainless steel separately from carbon steel to avoid iron contamination, which can lead to corrosion. Use dedicated tools, lifting equipment (e.g., stainless steel slings or plastic-coated clamps), and storage racks. Keep materials in a dry, covered area to prevent moisture exposure, and label all stock clearly to avoid mix-ups.

Welding Environment and Facility Requirements

Ensure the welding area is clean, well-ventilated, and isolated from carbon steel fabrication zones. Use stainless steel-dedicated workbenches with non-ferrous surfaces (e.g., plastic or wood) and implement strict housekeeping protocols. Adequate local exhaust ventilation (LEV) or fume extraction systems must be in place to protect workers from hazardous welding fumes in compliance with occupational health and safety regulations (e.g., OSHA, DGUV).

Equipment and Tooling Compliance

All welding equipment (TIG, MIG, etc.) must be regularly maintained and calibrated. Use welding tools dedicated exclusively to stainless steel (e.g., stainless steel wire brushes, grinders with stainless-specific discs). Equipment should meet relevant safety standards (e.g., EN 60974 series for arc welding equipment) and be inspected periodically to ensure operational safety and weld quality.

Personnel Qualifications and Training

Welders must be certified according to applicable standards such as ISO 9606 (for welder approval) or AWS D1.6 (Structural Welding Code – Stainless Steel). Ensure personnel receive training in proper stainless steel welding techniques, contamination prevention, and safe handling of materials and equipment. Maintain up-to-date certification records and provide ongoing competence assessments.

Quality Control and Documentation

Implement a documented quality management system (e.g., ISO 9001) to control all welding processes. Conduct regular inspections, including visual checks, penetrant testing (PT), and radiographic or ultrasonic testing (RT/UT) as required. Maintain complete welding procedure specifications (WPS), procedure qualification records (PQR), and weld maps for traceability. All non-conformances must be logged and addressed through corrective actions.

Regulatory and Environmental Compliance

Adhere to national and international regulations, including:

– REACH and RoHS (for material substance compliance)

– Pressure Equipment Directive (PED 2014/68/EU) if applicable

– ASME BPVC Section IX for pressure-related applications

Ensure proper disposal of welding waste (e.g., slag, grinding dust) in accordance with local environmental regulations. Monitor and manage emissions to comply with air quality standards.

Traceability and Marking

Maintain full traceability of materials through heat numbers and batch tracking. Clearly mark finished weldments with appropriate identification (e.g., welder ID, job number, date) using non-contaminating methods such as acid-free markers or low-iron paint. Documentation must support full lifecycle traceability for audits and compliance verification.

By following this guide, organizations can ensure safe, compliant, and high-quality stainless steel welding operations across the supply chain.

Zusammenfassende Schlussfolgerung zur Beschaffung von Edelstahl-Schweißdienstleistungen:

Die zuverlässige Beschaffung von Edelstahl-Schweißdienstleistungen erfordert eine sorgfältige Auswahl qualifizierter Partner, die nicht nur über die entsprechende fachliche Expertise, geeignete Zertifizierungen (wie z. B. DIN EN 1090, ISO 3834 oder AWS-Standards) und modernste Schweißtechnologien (z. B. WIG-, MIG- oder Laserschweißen) verfügen, sondern auch Erfahrung mit den spezifischen Anforderungen des jeweiligen Anwendungsgebiets (z. B. Lebensmittelindustrie, Chemie, Medizintechnik oder Bauwesen) nachweisen können.

Entscheidend für eine erfolgreiche Zusammenarbeit sind neben der technischen Kompetenz auch Faktoren wie Zuverlässigkeit, Termintreue, Qualitätsmanagement und transparente Kommunikation. Ein gut durchdachtes Beschaffungsmanagement – inklusive detaillierter Spezifikation der Anforderungen, Vergleich mehrerer Angebote und regelmäßiger Qualitätskontrollen – trägt entscheidend zum langfristigen Projekterfolg bei.

Letztendlich ermöglicht die richtige Quelle für Edelstahl-Schweißarbeiten nicht nur die Einhaltung höchster Qualitäts- und Sicherheitsstandards, sondern auch eine wirtschaftliche und effiziente Realisierung von Bauteilen und Konstruktionen mit langer Lebensdauer und hoher Korrosionsbeständigkeit.