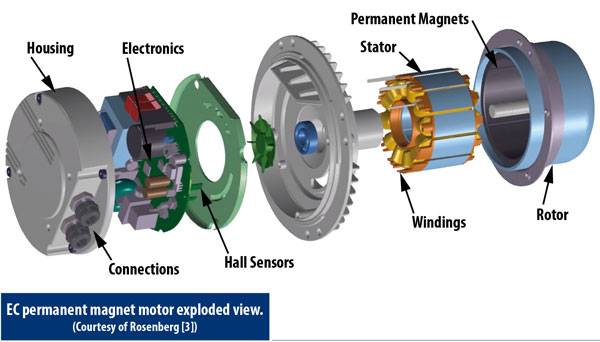

The global ECM (electronically commutated motor) fan motor market is experiencing robust growth, driven by rising demand for energy-efficient HVAC systems across residential, commercial, and industrial sectors. According to Mordor Intelligence, the ECM motor market is projected to grow at a CAGR of over 7.5% from 2024 to 2029, fueled by stringent energy regulations and the global shift toward sustainable building technologies. Additionally, Grand View Research reported that the broader HVAC motor market was valued at USD 14.3 billion in 2023, with ECM motors capturing an increasing share due to their superior efficiency, precise speed control, and reduced operational costs compared to traditional AC motors. As building automation and smart climate control systems become standard, manufacturers specializing in ECM fan motors are well-positioned for long-term expansion. This growing demand has led to intensified competition and innovation, with a select group of manufacturers emerging as leaders in performance, reliability, and technological advancement—setting the standard in the evolving landscape of energy-efficient air movement solutions.

Top 8 Ecm Fan Motor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ECM/EPIC Fan Technology®

Domain Est. 1996

Website: nailor.com

Key Highlights: ECM/EPIC Fan Technology® provides an average 90,000 hours of operation (versus 50,000 hours for a typical PSC motor). This translates into about 10 years for a ……

#2 Evergreen IM ECM High Efficient Furnace Motors

Domain Est. 1999

Website: electricmotorwarehouse.com

Key Highlights: 1–6 day deliveryEVERGREEN IM is a high-efficiency ECM replacement motor that is designed to replace factory PSC blower motors in HVAC systems. That means you can now offer ……

#3 TelcoGreen EC Motors for Various Unique Applications

Domain Est. 1996

Website: telcointercon.com

Key Highlights: TelcoGreen specializes in the design and manufacture of Electronically Commutated Motors (ECM motors) and complete blower assemblies of all kinds….

#4 Loren Cook Company: Air Moving Experts

Domain Est. 1996 | Founded: 1941

Website: lorencook.com

Key Highlights: American-made quality air moving equipment since 1941….

#5 EC Motors

Domain Est. 1997

Website: acim.nidec.com

Key Highlights: US MOTORS® brand EC motors (also called ECM motors and BLDC motors), manufactured by Nidec Motor Corporation, offer high efficiency and energy conservation….

#6 Motors

Domain Est. 2011

Website: marsdelivers.com

Key Highlights: Motors, HVAC/R Components, Service & Installation, JARD, HVAC Equipment, Refrigeration, Resources…

#7 ECM Motors

Domain Est. 2015

Website: universalelectricmotors.com

Key Highlights: ECM Motors | Browse a selection of electronically commutated motors at Universal Electric Motors….

#8 Evergreen® ECM Motors and Control Modules

Domain Est. 2021

Website: regalrexnord.com

Key Highlights: Our Genteq Evergreen line of ECM blower motors are the smartest choice in the aftermarket. Evergreen offers ECM replacement with minimal inventory burden….

Expert Sourcing Insights for Ecm Fan Motor

H2 2026 Market Trends for ECM Fan Motors

As we approach the second half of 2026, the Electronically Commutated Motor (ECM) fan motor market is experiencing accelerated transformation, driven by regulatory mandates, technological innovation, and shifting end-user demands. Here are the key trends shaping the industry:

1. Regulatory Pressure Intensifies Global Adoption

By H2 2026, new and stricter energy efficiency standards—such as the U.S. DOE’s updated HVAC efficiency rules (effective January 2023 and fully adopted in new systems) and similar EU Ecodesign regulations—are in full force. These mandates have made ECM motors the de facto standard in residential and light commercial HVAC systems. OEMs are now almost exclusively integrating ECMs into new units to meet minimum Seasonal Energy Efficiency Ratio (SEER2), Heating Seasonal Performance Factor (HSPF2), and Annual Fuel Utilization Efficiency (AFUE) requirements. Non-compliance is no longer an option, pushing legacy PSC (Permanent Split Capacitor) motors into obsolescence.

2. Smart Integration and IoT Connectivity Dominate New Installations

ECM motors are no longer just energy-efficient components—they have evolved into intelligent nodes within smart building ecosystems. By H2 2026, most new ECMs are equipped with embedded sensors and communication protocols (e.g., BACnet, Modbus, Wi-Fi, Zigbee) enabling real-time monitoring of airflow, temperature, voltage, and motor health. This data is integrated into home automation platforms and building management systems (BMS), supporting predictive maintenance, demand response programs, and optimized indoor air quality (IAQ) control, especially in the wake of heightened post-pandemic health awareness.

3. Demand for Variable-Speed and Ultra-Quiet Operation Reaches Peak

Consumer and commercial preferences have firmly shifted toward variable-speed ECM motors due to their superior comfort control, noise reduction, and energy savings. In H2 2026, over 85% of new residential HVAC units feature variable-speed ECMs capable of modulating speed precisely to match load conditions. This enables near-continuous operation at low speeds, improving humidity control and minimizing temperature swings. Noise levels below 1 sone are now a key selling point, particularly in high-end residential and healthcare applications.

4. Cost Parity and ROI Drive Replacement Market Growth

While ECM motors historically carried a price premium, advancements in manufacturing and scale have significantly narrowed the cost gap with PSC motors. By H2 2026, the total cost of ownership (TCO) strongly favors ECMs due to energy savings of 30–70% and longer lifespans (typically 10–15 years vs. 5–7 for PSC). This compelling ROI is accelerating retrofits in both residential and commercial sectors, especially as utility rebates and government incentives remain available in North America and Europe.

5. Supply Chain Maturity and Regional Manufacturing Expansion

After disruptions in prior years, the ECM motor supply chain has stabilized. By H2 2026, key manufacturers—including Nidec, Regal Rexnord, Johnson Controls, and Chinese OEMs—are expanding regional production in North America and Southeast Asia to reduce logistics costs, mitigate trade risks, and meet localized demand. This has improved lead times and supported faster deployment in growing markets like India, Southeast Asia, and the Middle East.

6. Focus on Sustainability and Circular Design

Sustainability is no longer a secondary concern. Leading ECM manufacturers are introducing motors with higher recyclable content, reduced rare-earth magnet usage, and designs that facilitate disassembly and component recovery. Some are piloting take-back programs and offering refurbished or remanufactured ECM units, appealing to environmentally conscious commercial clients and contributing to ESG (Environmental, Social, Governance) goals.

Conclusion

In H2 2026, the ECM fan motor market is characterized by maturity, intelligence, and sustainability. Regulatory tailwinds, smart technology integration, and proven economic benefits have cemented ECMs as the dominant solution across HVAC applications. The future lies not in whether ECMs will be adopted, but in how they will continue to evolve—driving smarter, quieter, and more sustainable indoor environments globally.

Common Pitfalls When Sourcing ECM Fan Motors (Quality, IP)

Sourcing Electronically Commutated Motor (ECM) fan motors requires careful evaluation to avoid quality issues and intellectual property (IP) risks. Here are key pitfalls to watch for:

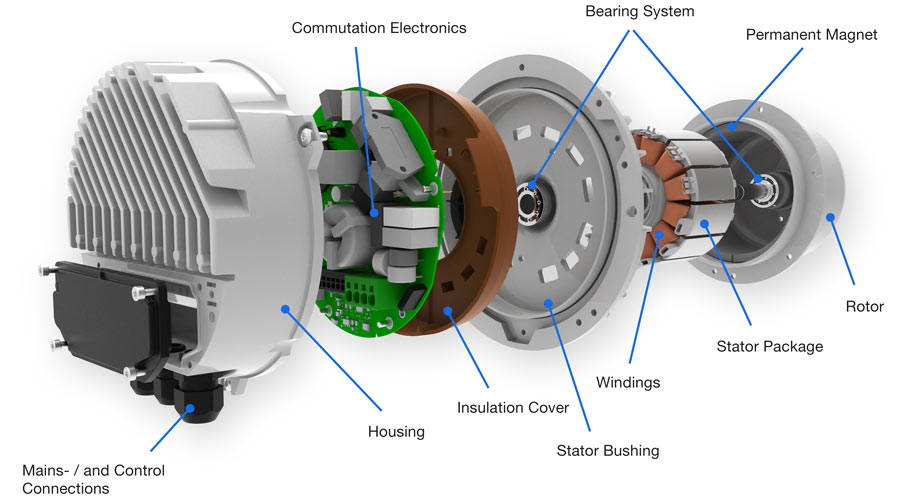

Poor Build Quality and Component Selection

Low-cost ECM motors may use substandard materials such as inferior bearings, low-grade copper windings, or poorly molded housings. These compromises lead to premature failure, reduced efficiency, and increased noise. Always verify component quality through supplier audits or third-party testing.

Inconsistent Performance and Efficiency

ECM motors are prized for energy efficiency and precise speed control. However, poor-quality units often fail to meet published performance specs. Be cautious of exaggerated claims and demand verified test data, such as AMCA certification or independent lab reports.

Inadequate or Misrepresented IP Ratings

Suppliers may falsely claim high IP (Ingress Protection) ratings like IP54 or IP55. Without proper sealing and gasketing, motors can fail in dusty or damp environments. Validate IP ratings through certified test documentation and inspect physical samples for build quality.

Lack of Genuine Intellectual Property or Design Copying

Many low-cost ECM motors are reverse-engineered or infringe on patented technology. This exposes buyers to legal liability and supply chain disruption. Ensure suppliers can demonstrate IP ownership or proper licensing agreements for motor control algorithms and design.

Insufficient Thermal and Overload Protection

Cheap ECM motors often lack robust thermal protection or overload safeguards. This increases the risk of motor burnout under real-world operating conditions. Confirm that units include features like thermal cutoffs and overcurrent protection.

Weak Firmware and Control Integration

ECM performance heavily depends on firmware. Poorly coded firmware can cause erratic behavior, communication errors, or incompatibility with building management systems. Request details on firmware updates, communication protocols (e.g., BACnet, Modbus), and compatibility testing.

Inadequate Documentation and Support

Suppliers may provide incomplete or inaccurate technical documentation, making integration and troubleshooting difficult. Ensure access to detailed datasheets, wiring diagrams, and responsive technical support before finalizing procurement.

Supply Chain and Long-Term Availability Risks

Some ECM motor suppliers lack stable production capacity or go out of business quickly. This jeopardizes long-term service and replacement. Evaluate supplier stability, production capabilities, and product lifecycle plans to mitigate future risks.

Logistics & Compliance Guide for ECM Fan Motor

Overview

This guide outlines the essential logistics and compliance considerations for the transportation, handling, and regulatory adherence of Electronically Commutated Motor (ECM) fan motors. ECM fan motors are energy-efficient brushless DC motors commonly used in HVAC systems. Proper logistics planning and compliance with international and local regulations are critical to ensure safe, timely, and legal delivery.

Product Classification & HS Code

ECM fan motors are typically classified under the Harmonized System (HS) Code:

8501.32 – Motors of an output not exceeding 37.5 W.

Note: Confirm the exact HS code based on motor power output and regional tariff schedules, as classification may vary by country (e.g., 8501.31 for motors over 37.5 W). Accurate classification ensures correct duties, taxes, and import/export documentation.

Packaging & Handling Requirements

- Use anti-static packaging to protect sensitive electronic components.

- Secure motors in rigid, corrugated cardboard boxes with internal cushioning (e.g., foam inserts) to prevent vibration damage.

- Label packages with “Fragile,” “This Side Up,” and “Protect from Moisture” indicators.

- Stack loads evenly on pallets; secure with stretch wrap and avoid overhang.

- Avoid exposure to extreme temperatures, humidity, or direct sunlight during storage and transit.

Transportation Modes

- Air Freight: Suitable for urgent or high-value shipments. Comply with IATA regulations for lithium components (if applicable).

- Ocean Freight: Cost-effective for large volumes. Use sealed containers to prevent moisture ingress.

- Ground Transport: Ideal for regional distribution. Ensure climate-controlled vehicles if shipping through extreme environments.

Regulatory Compliance

- RoHS (EU): Ensure ECM motors comply with Restriction of Hazardous Substances (Directive 2011/65/EU). Documentation must confirm absence of lead, mercury, cadmium, and other restricted materials.

- REACH (EU): Comply with chemical substance registration, evaluation, and authorization.

- UL/CSA (North America): Motors must meet safety standards (e.g., UL 1004, CSA C22.2) for electrical equipment. Certification marks required.

- CE Marking: Mandatory for sale in the European Economic Area (EEA), indicating conformity with health, safety, and environmental standards.

- Energy Efficiency Standards: Adhere to DOE (U.S.) or ERP (EU) regulations for motor efficiency (e.g., DOE 10 CFR Part 431, EU Regulation 547/2012).

Export Controls & Documentation

- Commercial Invoice: Include detailed product description, HS code, value, origin, and terms of sale (e.g., FOB, DDP).

- Packing List: Specify quantity, weight, dimensions, and packaging type per shipment.

- Certificate of Origin: Required by many countries for tariff determination.

- Export Licenses: Verify if motors contain controlled technology (e.g., dual-use items under EAR). Most ECM motors do not require licenses, but confirm based on destination and technical specs.

- Safety Data Sheet (SDS): Not typically required unless hazardous materials are present (e.g., lubricants).

Import Considerations

- Verify destination country’s import restrictions, duties, and VAT requirements.

- Some countries may require product certification (e.g., CCC in China, PSE in Japan).

- Engage a licensed customs broker to facilitate clearance and ensure compliance with local standards.

Environmental & Disposal Compliance

- Design for recyclability; provide end-of-life disposal guidance.

- Comply with WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions.

- Label products with appropriate recycling symbols.

Quality Assurance & Traceability

- Maintain batch/lot tracking for traceability in case of recalls or audits.

- Conduct pre-shipment inspections to verify functionality and packaging integrity.

- Retain compliance documentation (test reports, certifications) for a minimum of 5 years.

Summary

Effective logistics and compliance management for ECM fan motors ensures regulatory adherence, minimizes shipment risks, and supports market access. Always consult with legal, customs, and technical experts to address region-specific requirements and evolving regulations.

Conclusion for Sourcing ECM Fan Motors:

Sourcing ECM (Electronically Commutated Motor) fan motors presents a strategic opportunity to enhance energy efficiency, reduce operational costs, and improve system performance across HVAC and various industrial applications. The advanced technology behind ECM motors—offering variable speed control, higher efficiency, lower power consumption, and quieter operation—makes them a superior alternative to traditional PSC motors.

When sourcing ECM fan motors, it is essential to evaluate key factors such as motor specifications, compatibility with existing systems, energy efficiency ratings, supplier reliability, and long-term maintenance support. Partnering with reputable manufacturers and suppliers ensures access to high-quality, durable components backed by technical support and warranties.

Additionally, considering the total cost of ownership—not just the upfront price—reveals significant lifecycle savings due to reduced energy usage and extended motor lifespan. As energy regulations become stricter and sustainability goals gain importance, adopting ECM technology aligns with both environmental and economic objectives.

In conclusion, sourcing ECM fan motors is a forward-thinking investment that delivers long-term performance benefits, energy savings, and improved system control, making it a critical step toward modernizing and optimizing fan-driven systems in commercial, residential, and industrial environments.