The global automotive drivetrain components market is experiencing steady growth, driven by rising vehicle production, increasing demand for fuel-efficient powertrain systems, and the expansion of aftermarket services. According to Mordor Intelligence, the global automotive driveshaft market was valued at USD 14.8 billion in 2023 and is projected to reach USD 19.3 billion by 2029, growing at a CAGR of approximately 4.5% during the forecast period. This growth is further fueled by the longevity of older vehicle platforms—such as the BMW E46—which remain popular in enthusiast and performance circles, sustaining demand for high-quality replacement and performance drive shafts. As a result, manufacturers specializing in precision-engineered driveshafts for legacy models like the E46 are seeing renewed interest. In this landscape, seven manufacturers have distinguished themselves through material innovation, rigorous quality control, and performance validation, making them the top choices for E46 owners seeking reliability and driving precision.

Top 7 E46 Drive Shaft Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

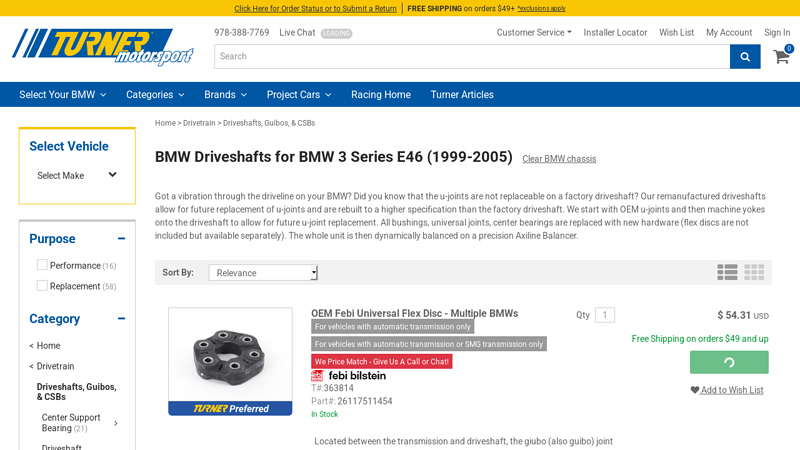

#1 BMW Driveshafts for BMW 3 Series E46 (1999

Domain Est. 1996

Website: turnermotorsport.com

Key Highlights: Free delivery over $49 · 30-day returnsOur remanufactured driveshafts allow for future replacement of u-joints and are rebuilt to a higher specification than the factory driveshaf…

#2 BMW genuine parts and accessories

Domain Est. 2021

Website: bmw-spare-parts.com

Key Highlights: Order your original BMW car spares with our part diagrams ✔️ Search by model or part number ✔️ Honda parts with manufacturer warranty – Secure payment….

#3 Powertrain Industries Driveshaft for E46 323/325 RWD ZF Automatic

Domain Est. 1999

#4 Weighing options for a new (or rebuilt) driveshaft

Domain Est. 1999

Website: e46fanatics.com

Key Highlights: I highly recommend Driveshaft Specialists as the source of supply for a rebuilt BMW driveshaft. Their packaging is top notch making return of the core easy as ……

#5 BMW Driveshafts

Domain Est. 1999

#6 BMW E46 330i M54 3.0L Driveshaft Parts

Domain Est. 2001

Website: ecstuning.com

Key Highlights: Holds the driveshaft where it should be! Isolation dampers minimize vibrations and excess noise. JXB Performance – BMW…

#7 DriveShaftShop Driveshaft, BMW E46

Domain Est. 2023

Website: 5150autosport.com

Key Highlights: Upgrade your BMW E46 with a 1-piece Chromoly or Carbon Fiber driveshaft for improved durability, smoother power transfer, and race-proven performance….

Expert Sourcing Insights for E46 Drive Shaft

H2: 2026 Market Trends for E46 Drive Shaft

As the automotive industry evolves toward electrification and digital integration, niche markets for legacy performance components like the BMW E46 drive shaft remain relevant due to a dedicated enthusiast base and the growing classic car restoration trend. The E46, produced between 1998 and 2006, continues to enjoy enduring popularity among BMW aficionados, particularly the 325i and 330i models that rely on rear-wheel drive and robust mechanical layouts—making the drive shaft a critical drivetrain component.

By 2026, several key trends are expected to shape the E46 drive shaft market:

-

Increased Demand from Restoration and Modified Vehicle Enthusiasts

The E46 generation is increasingly viewed as a modern classic, prompting a surge in full restorations and performance upgrades. As more E46s are pulled from long-term storage or imported (especially high-quality European models), demand for OEM-spec and upgraded drive shafts will rise. Specialty shops and online retailers report consistent year-over-year growth in drivetrain component sales, with drive shafts being a common wear-and-replace item due to age-related wear on guibo joints and center support bearings. -

Growth of Aftermarket Performance Drive Shafts

Lightweight two-piece and carbon fiber drive shafts from brands like Driveshaft Shop, ECS Tuning, and AKG will see increased adoption. These aftermarket options offer reduced rotational mass, improved throttle response, and enhanced durability—appealing to track-day drivers and tuners. By 2026, expect wider availability of modular, application-specific shafts with customizable lengths and flange configurations to support engine swaps (e.g., S54B32 or BMW M3 drivetrain conversions). -

OEM Part Scarcity and Rising Prices

As original BMW E46 drive shafts age, OEM inventory is dwindling. Discontinued part numbers and reliance on salvage yards are driving up prices for factory units. This scarcity is accelerating the shift toward aftermarket and remanufactured alternatives. Some suppliers are responding by reverse-engineering or 3D-scanning original units to reproduce high-fidelity replacements with modern materials. -

Expansion of Online Marketplaces and Global Trade

Platforms like eBay, Pelican Parts, and specialized BMW forums continue to dominate E46 parts distribution. By 2026, cross-border trade in used and refurbished drive shafts will grow, particularly from Europe and Japan where E46s were widely sold and often better preserved. Enhanced logistics and certification of refurbished components will increase buyer confidence in secondhand drivetrain parts. -

Focus on Sustainability and Reconditioning

Environmental considerations are prompting a shift toward remanufactured or refurbished drive shafts. Companies offering balancing, bushing replacement, and spline servicing are gaining traction. This trend supports circular economy principles and appeals to cost-conscious and eco-aware consumers.

In summary, the 2026 E46 drive shaft market will be characterized by sustained demand driven by enthusiast culture, technological improvements in aftermarket offerings, and adaptive business models addressing part scarcity. While electric vehicle trends dominate the broader automotive sector, the E46’s mechanical purity ensures its drivetrain components—especially the drive shaft—will remain in demand for years to come.

Common Pitfalls When Sourcing E46 Drive Shafts: Quality and Intellectual Property Concerns

When replacing drive shafts for the BMW E46 platform, owners and mechanics often encounter challenges related to component quality and intellectual property (IP) issues. Selecting the wrong part can lead to premature failure, safety hazards, and legal complications. Below are the most common pitfalls to avoid.

Poor Quality Aftermarket Components

One of the biggest risks when sourcing an E46 drive shaft is purchasing low-quality aftermarket units. Many third-party manufacturers produce drive shafts using substandard materials and manufacturing processes, resulting in:

- Inferior CV Joints and Boots: Cheap CV joints wear out quickly, leading to clicking noises, vibration, and eventual joint failure. Poor-quality rubber boots crack prematurely, allowing grease to escape and contaminants to enter.

- Imbalanced Shafts: Incorrectly balanced shafts cause noticeable vibrations, especially at higher speeds. This not only degrades driving comfort but can also damage wheel bearings and suspension components over time.

- Weak Flanges and Splines: Lower-grade steel or improper heat treatment can cause flange cracking or spline wear, risking complete drive shaft separation.

Misrepresentation of OEM vs. Genuine Parts

A frequent source of confusion—and potential IP concern—is the mislabeling of parts as “OEM” or “genuine” when they are not. Some suppliers falsely advertise aftermarket shafts as original equipment, misleading buyers.

- Trademark Infringement: Unauthorized use of BMW’s logos, part numbers, or branding on non-genuine parts violates intellectual property laws. Purchasing such items may unknowingly support counterfeit operations.

- Lack of Certification: Genuine BMW or licensed OEM (e.g., GKN, Loebro) drive shafts come with traceable manufacturing data and quality assurance. Counterfeit or misrepresented parts often lack proper documentation or serial traceability.

Use of Recalled or Non-Compliant Designs

Certain aftermarket E46 drive shafts replicate outdated or recalled designs, particularly concerning the inner CV joint (e.g., early Loebro units prone to boot failure and inner joint wear). Sourcing from unreliable vendors increases the risk of installing a known problematic design.

- No Recall Awareness: Reputable suppliers stay informed about service bulletins and design updates. Low-cost vendors may continue selling obsolete versions without warning consumers.

- Lack of Compliance with TÜV or DOT Standards: In some regions, non-compliant parts may fail inspection or void vehicle insurance in the event of an accident.

Inadequate Warranty and Support

Low-cost drive shafts often come with limited or no warranty, and customer support can be nonexistent. If a failure occurs, buyers may face additional labor costs and downtime—especially if the shaft fails soon after installation.

Conclusion

To avoid these pitfalls, always purchase E46 drive shafts from reputable suppliers who clearly specify whether the part is genuine BMW, licensed OEM, or high-quality aftermarket (e.g., Lemförder, Febi Bilstein). Verify part numbers, inspect packaging for branding misuse, and ensure the product comes with proper documentation and warranty. Investing in quality not only protects your vehicle’s performance and safety but also avoids supporting IP violations in the automotive parts market.

Logistics & Compliance Guide for E46 Drive Shaft

This guide outlines the essential logistics and compliance considerations for the handling, transportation, and regulatory adherence related to the E46 Drive Shaft—commonly used in BMW E46 series vehicles (1998–2005). Proper procedures ensure safe delivery, legal compliance, and product integrity.

Product Overview

The E46 Drive Shaft is a precision-engineered component responsible for transmitting torque from the transmission to the rear differential in rear-wheel-drive BMW E46 models. It typically consists of a steel or aluminum shaft, universal or CV joints, and balance weights. Correct identification (e.g., part number, model compatibility) is critical for compliance and fitment.

Packaging Requirements

- Use double-walled corrugated cardboard or heavy-duty polyethylene crates to prevent bending or impact damage.

- Secure the drive shaft with foam inserts or edge protectors at both ends to protect splines and flanges.

- Include desiccant packs if storing or shipping in high-humidity environments to prevent corrosion.

- Clearly label packages with:

- Part number (e.g., 26116772614, 26116769645)

- “Fragile – Precision Automotive Component”

- “This End Up” indicators

Transportation & Handling

- Use padded straps or cradles when lifting or moving to avoid surface damage.

- Do not drag or roll drive shafts; always lift with proper equipment.

- Store horizontally on level surfaces; avoid stacking unless designed for it.

- Maintain temperature-controlled environments (10°C–30°C) and low humidity during transit and storage.

- Use climate-controlled trucks or containers for international shipments to prevent condensation.

Import/Export Compliance

- Verify Harmonized System (HS) Code: Typically 8708.40.90 (Other transmission components). Confirm locally.

- Provide accurate Commercial Invoice, Packing List, and Bill of Lading/Air Waybill.

- Comply with destination country regulations (e.g., REACH in the EU, TSCA in the US) regarding materials used.

- Declare if the component contains restricted substances (e.g., certain lubricants or coatings).

- For shipments to the EU, ensure compliance with End-of-Life Vehicles (ELV) Directive 2000/53/EC.

Safety & Environmental Standards

- Handle with gloves and safety glasses to prevent injury from sharp edges.

- Used drive shafts may contain residual grease or oils—dispose of cleaning waste per local environmental regulations.

- Recycle metal components through certified scrap metal processors.

- Adhere to OSHA (US) or equivalent workplace safety standards when handling or installing.

Documentation & Traceability

- Maintain batch or serial traceability for quality control and warranty claims.

- Retain shipping records, compliance certifications, and material declarations for a minimum of 5 years.

- For OEM suppliers, conform to IATF 16949 quality management standards.

Special Considerations for Reconditioned/Used Units

- Clearly label as “Reconditioned” or “Used” to meet consumer protection laws.

- Perform functional testing and balancing before shipment.

- Disclose wear condition (e.g., joint play, balance status) in product listing or documentation.

Following this guide ensures the E46 Drive Shaft is managed in a way that meets logistical efficiency, legal standards, and end-user safety requirements across global supply chains.

Conclusion for Sourcing E46 Drive Shaft:

Sourcing a drive shaft for an E46 BMW requires careful consideration of vehicle specifications, condition, and budget. After evaluating OEM, aftermarket, and used/remanufactured options, it is clear that OEM shafts offer the highest reliability and longevity, making them ideal for long-term performance and peace of mind. Aftermarket alternatives can provide a cost-effective solution with varying quality—reputable brands often deliver solid performance. Used or refurbished shafts may suit budget-conscious buyers but carry risks related to wear and hidden damage.

Key factors such as model year, transmission type (manual or automatic), and whether the vehicle is rear- or xDrive-equipped must be verified to ensure compatibility. Additionally, inspecting CV joints, center support bearings, and balance during the sourcing process is crucial to avoid vibration and drivability issues.

Ultimately, the best choice depends on individual priorities: long-term reliability favors OEM, value and performance may lean toward quality aftermarket, while immediate budget constraints might justify a carefully sourced used unit. Proper research, supplier credibility, and professional installation are essential to ensure a successful outcome.