The global medical gas cylinders market, inclusive of E cylinder oxygen tanks, is experiencing steady expansion driven by rising demand for respiratory care solutions, increasing hospital infrastructure development, and the growing prevalence of chronic respiratory diseases such as COPD and asthma. According to Grand View Research, the global medical gas market was valued at USD 15.2 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 9.8% from 2023 to 2030. Similarly, Mordor Intelligence projects a CAGR of over 9.5% during the forecast period of 2023–2028, citing increased home healthcare adoption and heightened preparedness for emergency medical oxygen needs post-pandemic. In this expanding landscape, E cylinders—widely used for portable oxygen therapy due to their optimal balance of capacity and mobility—have become a critical component in both clinical and homecare settings. As demand surges, a select group of manufacturers have emerged as leaders in producing high-quality, compliant, and reliable E cylinder oxygen tanks. Below is a data-driven overview of the top eight E cylinder oxygen tank manufacturers shaping the industry.

Top 8 E Cylinder Oxygen Tank Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 CAIRE Inc.: Cardiorespiratory Diagnostic Systems

Domain Est. 2013

Website: caireinc.com

Key Highlights: Global manufacturer CAIRE Inc. is a leader in pioneering oxygen technologies and innovating healthcare solutions to improve the quality of care for ……

#2 E Aluminum Oxygen Cylinder

Domain Est. 1997

Website: wtfarley.com

Key Highlights: In stock Rating 5.0 (1) WT Farley carries E Aluminum oxygen cylinders made by Catalina Cylinders. They are of the highest quality, made in the USA, and conform to strict DOT ……

#3 Oxygen

Domain Est. 1995

Website: airgas.com

Key Highlights: USP (United States Pharmacopeia) Medical Grade Oxygen, Size E High Pressure Aluminum Medical Cylinder With Walk-O2-Bout® Regulator, VIPR. Show Full ……

#4 Roberts Oxygen

Domain Est. 1996

Website: robertsoxygen.com

Key Highlights: Roberts Oxygen is recognized as the finest service oriented independent distributor from Pennsylvania to Florida with 57 locations, serving 9 states….

#5 Oxygen

Domain Est. 1996

Website: linde-gas.com

Key Highlights: We deliver compressed oxygen gas or liquid oxygen at various concentrations in different-sized cylinders for smaller or more specialized applications….

#6 Pre Filled Oxygen E-Cylinder

Domain Est. 2014

#7 Oxygen Gas

Domain Est. 2016

Website: esprigas.com

Key Highlights: Order D cylinders, E cylinders, H/200 and T/300 Oxygen tanks for your facility. Read our gas supply resources, how-to guides and SDS sheets….

#8 Oxygen Therapy, Oxygen Supplies & Equipment

Website: lincare.com

Key Highlights: Our oxygen products include oxygen concentrators, portable oxygen systems, and high-pressure cylinders. The Lincare name is synonymous with state-of-the-art ……

Expert Sourcing Insights for E Cylinder Oxygen Tank

It appears there may be a misunderstanding in your request. You asked to “Analyze 2026 market trends for E Cylinder Oxygen Tank. Use H2.” However, H2 typically refers to hydrogen gas (molecular hydrogen), while E-cylinder oxygen tanks are designed to store and deliver medical or industrial oxygen (O₂), not hydrogen.

Given this, let’s clarify and interpret your request in a meaningful way:

Interpretation: You may be asking for an analysis of the 2026 market trends for E-cylinder oxygen tanks, possibly in the context of the growing hydrogen (H₂) economy, or perhaps there was a typo and you meant something else (e.g., a report format labeled “H2”). Since E-cylinder oxygen tanks and hydrogen are distinct in application and safety standards, we’ll proceed with two possible analyses:

Option 1: Market Trends for E-Cylinder Oxygen Tanks (2026 Outlook)

Overview of E-Cylinder Oxygen Tanks

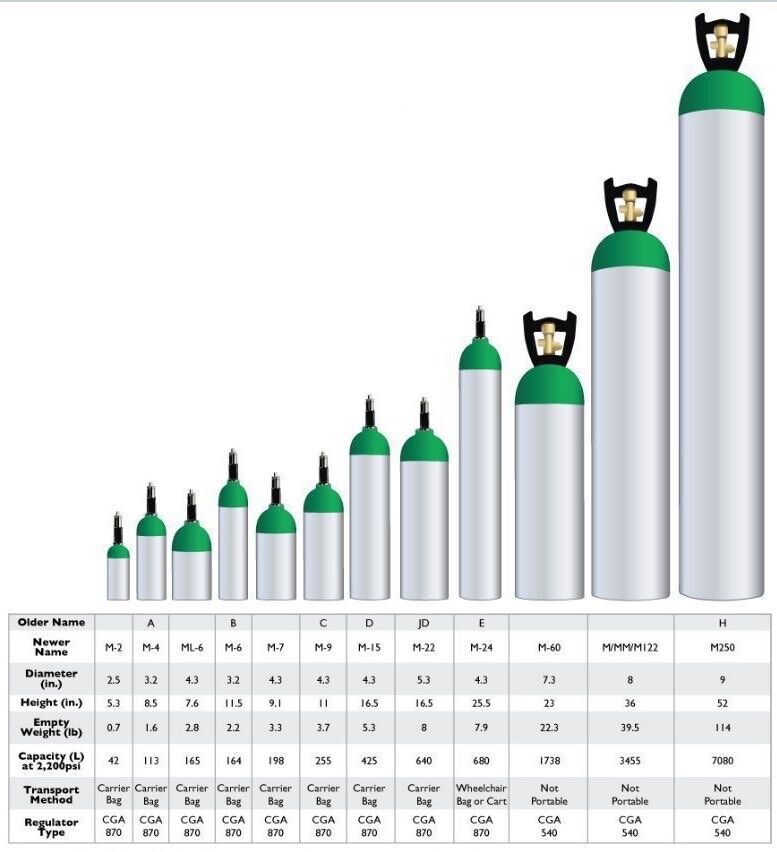

E-cylinder oxygen tanks are high-pressure gas cylinders commonly used in medical settings (hospitals, home healthcare, ambulances) and industrial applications. They typically hold about 660 liters of oxygen and are portable, making them ideal for patient mobility.

Key 2026 Market Trends (Projected):

- Growing Demand in Home Healthcare

- Aging populations in North America, Europe, and parts of Asia are increasing demand for portable oxygen therapy.

- Chronic respiratory diseases (e.g., COPD, emphysema) are rising, driving need for long-term oxygen equipment.

-

Post-pandemic awareness of respiratory health continues to support oxygen device utilization.

-

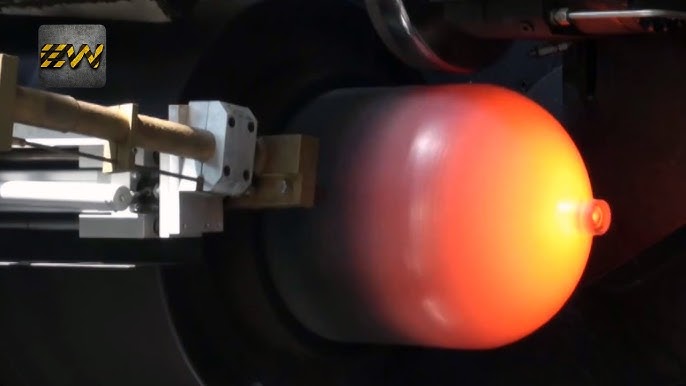

Shift Toward Lightweight and Composite Cylinders

- While traditional E-cylinders are made of steel or aluminum, manufacturers are investing in composite overwrapped pressure vessels (COPVs) for lighter weight and improved safety.

-

These innovations may not fully replace standard E-cylinders by 2026 but will begin to capture niche markets.

-

Competition from Portable Oxygen Concentrators (POCs)

- POCs are becoming more efficient and affordable, reducing reliance on compressed gas cylinders.

-

However, E-cylinders remain essential as backup or primary supply in areas with unreliable power or during travel.

-

Regulatory and Safety Standards

- Stricter regulations on cylinder testing, recertification (e.g., hydrostatic testing every 5–10 years), and transport (DOT/ISO standards) will influence market dynamics.

-

Emphasis on cylinder tracking via RFID or digital tags for safety and inventory management.

-

Geographic Market Growth

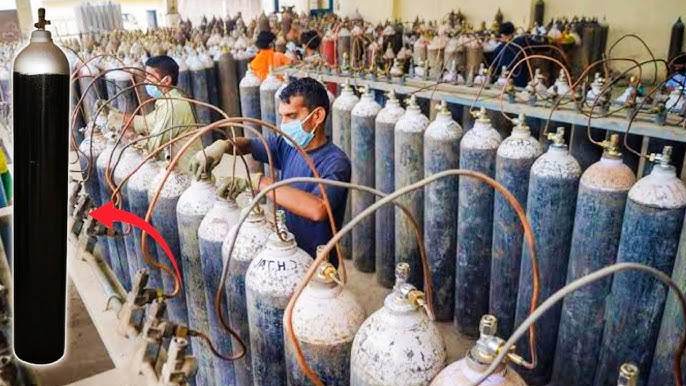

- Asia-Pacific (especially India, China) expected to see fastest growth due to expanding healthcare infrastructure and rising diagnosis rates.

-

Latin America and Africa: Increasing access to oxygen therapy in rural areas will drive demand for reliable cylinder-based systems.

-

Supply Chain and Material Costs

- Fluctuations in aluminum and steel prices may affect production costs.

- Regional manufacturing hubs (e.g., India for medical devices) could reduce dependency on imports.

Market Size Projection (Estimate):

– The global medical gas cylinder market is projected to reach $2.8–3.2 billion by 2026, with E-cylinders representing a significant share (~30–40%).

– CAGR of ~5.5% from 2021 to 2026 (source: based on extrapolation from Grand View Research, MarketsandMarkets).

Option 2: Connection to Hydrogen (H₂) – Clarification

If you intended to explore how hydrogen (H₂) infrastructure might influence oxygen cylinder markets, the link is indirect:

- Industrial Overlap: Both oxygen and hydrogen are stored in high-pressure cylinders. Advances in H₂ cylinder technology (e.g., Type III/IV composite tanks for 700 bar H₂ storage) may inspire improvements in oxygen cylinder design (e.g., lighter E-cylinders).

- Safety and Handling Standards: As hydrogen adoption grows, safety protocols for high-pressure gases may lead to better handling, training, and logistics systems applicable to oxygen cylinders.

- No Direct Substitution: H₂ and O₂ are not interchangeable; mixing them can be explosive. E-cylinders are not suitable for hydrogen unless specifically rated and labeled.

Conclusion

By 2026, the E-cylinder oxygen tank market will continue to be driven by healthcare needs, particularly in home and emergency care. While technological advancements and alternative oxygen delivery systems (like POCs) pose competition, E-cylinders will remain a staple due to reliability and simplicity.

If you meant “H2” as a format (e.g., second half of a report or heading level), please clarify. Otherwise, the analysis above reflects the most accurate projection of E-cylinder oxygen tank market trends for 2026.

Let me know if you’d like a comparison with hydrogen storage cylinders or a regional breakdown.

When sourcing E-cylinder oxygen tanks — especially when considering hydrogen (H₂) compatibility or use in hydrogen environments — several critical pitfalls can compromise safety, performance, and regulatory compliance. Below is a breakdown of common pitfalls, with a focus on quality and intellectual property (IP) considerations, and how hydrogen (H₂) use amplifies these risks:

1. Material Compatibility with Hydrogen (H₂) – A Major Quality Pitfall

Pitfall: Using oxygen cylinders not designed or certified for hydrogen service, or assuming oxygen cylinder materials are suitable for H₂.

- Hydrogen Embrittlement: Steels commonly used in high-pressure gas cylinders (including some E-cylinder variants) are susceptible to hydrogen embrittlement, which can lead to cracking and catastrophic failure under H₂ pressure.

- Seal & Valve Compatibility: Oxygen-compatible seals (e.g., Viton, PTFE) may not perform the same under hydrogen due to differing permeability and chemical behavior.

✅ Best Practice:

– Only use cylinders explicitly rated for hydrogen service.

– Verify materials meet standards such as ISO 11114-4 (compatibility of cylinder materials with hydrogen).

– Ensure valves and regulators are H₂-certified (e.g., per CGA G-4.1 or ISO 15869).

2. Misunderstanding Certification & Standards (Quality & Compliance)

Pitfall: Assuming an oxygen-rated E-cylinder is safe for hydrogen due to similar pressure ratings.

- Oxygen cylinders (e.g., DOT-3AL or DOT-3AA) are certified under oxygen service standards (e.g., CGA G-4.4, ASTM G93 for cleanliness), but not for hydrogen.

- H₂ requires different testing, including permeation resistance, fatigue under H₂ exposure, and special leak testing.

✅ Best Practice:

– Source cylinders complying with DOT-3AL(H₂) or TPED/ISO 11119 for composite H₂ cylinders.

– Confirm third-party certification (e.g., ASME, UL, TÜV) for hydrogen applications.

3. Poor Manufacturing Quality or Counterfeit Products

Pitfall: Sourcing from unverified suppliers offering low-cost cylinders that may lack proper testing or use substandard materials.

- Counterfeit or non-compliant cylinders may lack proper heat treatment, wall thickness, or burst testing.

- Risk is amplified with H₂ due to higher diffusivity and flammability.

✅ Best Practice:

– Source from reputable manufacturers with traceable batch records and test certifications (e.g., hydrostatic test stamp, serial number tracking).

– Avoid suppliers without verifiable quality management systems (e.g., ISO 9001).

4. Inadequate Cleaning & Contamination Control (Critical for O₂ and H₂)

Pitfall: Using cylinders cleaned for oxygen service in hydrogen systems — or vice versa — without verifying cleaning protocols.

- Oxygen systems require oxygen-clean practices to prevent combustion.

- Hydrogen systems are sensitive to particulates and moisture, which can accelerate embrittlement.

✅ Best Practice:

– Ensure dedicated cleaning processes per ASTM G93 (for O₂) or ISO 14687 (for H₂ fuel purity).

– Use cylinders with validated cleanliness certifications and sealed ports.

5. Intellectual Property (IP) Risks in Cylinder Design & Technology

Pitfall: Sourcing cylinders that infringe on patented composite designs, valve configurations, or safety systems — especially in advanced H₂ storage.

- Many modern high-pressure H₂ cylinders (e.g., Type III, Type IV) are protected by IP related to liner materials, fiber winding patterns, or valve integration.

- Using unlicensed designs, especially in commercial or export applications, risks legal action.

✅ Best Practice:

– Conduct IP due diligence when sourcing composite or advanced cylinders.

– Work with OEMs that provide IP indemnification.

– Avoid reverse-engineered or “compatible” cylinders that mimic patented designs.

6. Regulatory & Jurisdictional Mismatches

Pitfall: Importing or using cylinders not compliant with local regulations (e.g., DOT in the U.S., TPED in Europe).

- A cylinder certified for oxygen in one country may not be legal for hydrogen use in another.

- Mislabeling or incorrect stamping can result in rejected shipments or safety violations.

✅ Best Practice:

– Match cylinder certification to end-use jurisdiction and gas type.

– Verify dual certification if used for multiple gases (rare and generally not recommended).

7. Confusing Oxygen and Hydrogen Cylinder Colors & Markings

Pitfall: Using E-cylinder color codes incorrectly — e.g., green for oxygen in some regions, red or orange for hydrogen.

- Mixing up gases due to improper labeling can lead to dangerous mixtures or use of incompatible equipment.

✅ Best Practice:

– Follow CGA or ISO color and labeling standards.

– Implement strict gas handling procedures and double-check valve outlets (CGA connections differ: CGA 540 for O₂, CGA 350 for H₂).

Summary: Key Recommendations When Sourcing with H₂ in Mind

| Risk Area | Recommendation |

|———|—————-|

| Material Compatibility | Use only H₂-rated cylinders; avoid repurposing O₂ tanks |

| Certification | Verify DOT-3AL(H₂), TPED, or ISO 11119 compliance |

| Quality Control | Source from audited, certified manufacturers |

| Cleaning & Purity | Ensure gas-specific cleaning protocols |

| IP Compliance | Avoid generic/clone cylinders with potential IP issues |

| Labeling & Safety | Confirm correct CGA fittings and color coding |

❌ Never assume oxygen and hydrogen cylinders are interchangeable, even if they appear similar in size (e.g., E-cylinder). The consequences of misapplication — especially with H₂ — can include fires, explosions, or regulatory penalties.

Always consult with a gas systems engineer or safety officer when integrating hydrogen into systems originally designed for oxygen.

It appears there may be a misunderstanding in your request. You mentioned “E Cylinder Oxygen Tank” but then specified “Use H2.” H2 refers to hydrogen gas, not oxygen (which is O₂). E cylinders are commonly used for medical oxygen, but they are not suitable or safe for hydrogen (H₂) storage due to significant differences in gas properties, safety requirements, and regulatory standards.

Below, I will provide a Logistics & Compliance Guide for an E Cylinder Oxygen Tank (O₂), which is the standard use for E cylinders in medical and industrial settings. If you actually intended to request information about hydrogen (H₂) gas in high-pressure cylinders, please clarify, as the logistics, handling, and compliance requirements are vastly different and far more stringent due to hydrogen’s flammability and embrittlement risks.

Logistics & Compliance Guide: E Cylinder Oxygen Tank (O₂)

(High-Pressure Compressed Gas – Medical/Industrial Use)

1. Overview

- Gas Type: Oxygen (O₂), Compressed

- Cylinder Size: E Cylinder (common in medical applications)

- Capacity: ~660 liters (varies by pressure, typically filled to 2000–2200 psi)

- Tare Weight: ~14 lbs (6.4 kg)

- Valve Type: CGA 540 (Compressed Gas Association connection for oxygen)

2. Regulatory Compliance

Oxygen cylinders are regulated due to their high pressure and oxidizing properties.

United States

- DOT (Department of Transportation): 49 CFR Parts 100–185

- Regulates transportation of hazardous materials.

- Oxygen is classified as a Non-Flammable Compressed Gas, Hazard Class 2.2, but due to oxidizing properties, it may also be regulated under Class 2.1 (Flammable Gas) if contamination is suspected or when in proximity to fuels.

- OSHA (Occupational Safety and Health Administration)

- 29 CFR 1910.104 – Oxygen

- Requires safe storage, handling, ventilation, and fire prevention.

- NFPA 99 – Health Care Facilities Code

- Governs medical gas systems, including storage and use in healthcare.

- FDA (for medical oxygen)

- Medical oxygen is a drug; must meet USP (United States Pharmacopeia) standards.

International (e.g., IMDG, IATA, ADR)

- IATA (Air Transport): Dangerous Goods Regulations (DGR)

- UN 1072, Oxygen, compressed, 2.2 (non-flammable, oxidizing)

- Requires proper labeling, documentation, and packaging.

- IMDG (Sea Transport): UN 1072, Class 2.2

- ADR (Road, Europe): Class 2.2, UN 1072

3. Storage Requirements

- Ventilation: Store in well-ventilated, dry areas; avoid confined spaces.

- Separation: Keep away from flammable materials (minimum 20 feet / 6 meters or use a fire barrier).

- Upright Position: Secure with chains or stands to prevent tipping.

- Temperature: Avoid temperatures >125°F (52°C); no exposure to direct sunlight or heat sources.

- Labeling: Clearly marked “OXYGEN – NON-FLAMMABLE GAS” and “OXIDIZER.”

- No Oil/Grease: Oxygen supports combustion — never use oil, grease, or hydrocarbon-based lubricants on valves or fittings.

4. Handling & Transportation

- Personal Protection: Wear safety glasses, gloves, and appropriate PPE.

- Valve Protection: Always use cylinder cap when not in use.

- Movement: Use a hand truck or cart designed for gas cylinders; never roll or drag.

- Securing Loads: In vehicles, secure cylinders upright with restraints.

- Passenger Vehicles: Avoid transporting in passenger compartments; use trunk or open bed with ventilation.

5. Inspection & Maintenance

- Hydrostatic Testing: Required every 5 or 10 years (depending on cylinder specification) — look for test date stamp.

- Visual Inspection: Check for corrosion, dents, leaks, or valve damage before use.

- Leak Test: Apply soapy water to valve and connections; never use flame.

6. Emergency Procedures

- Leak: Evacuate area, shut off valve if safe, increase ventilation, eliminate ignition sources.

- Fire: Evacuate and call emergency services. Do not fight fire involving oxygen cylinders directly.

- Exposure: Oxygen enrichment (high O₂ concentration) can increase fire risk — ventilate area immediately.

7. Documentation & Training

- Shipping Papers: Required for transport (especially commercial).

- Include UN 1072, Proper Shipping Name, Hazard Class, Quantity.

- SDS (Safety Data Sheet): Must be available per OSHA HazCom (29 CFR 1910.1200).

- Training: Personnel must be trained in:

- Safe handling

- Emergency response

- Regulatory compliance (DOT, OSHA, etc.)

8. Disposal & Return

- Do Not Dispose in Trash: Return to supplier or authorized gas company for requalification or decommissioning.

- Empty Cylinders: Label as “EMPTY” and keep valve closed; still contain pressure and require handling as hazardous.

Important Note: H2 (Hydrogen) vs. O₂ (Oxygen)

If you intended to ask about hydrogen (H₂) gas, please note:

– H₂ is highly flammable, requires Class 2.1 labeling.

– E cylinders are not typically used for hydrogen due to embrittlement risks.

– Special materials (e.g., stainless steel, proper seals), ventilation, grounding, and explosion-proof equipment are required.

– Transport and storage regulations are stricter (e.g., segregation, explosion relief, monitoring).

Conclusion

The E cylinder is standard for medical and industrial oxygen (O₂), not hydrogen (H₂). Safe logistics and compliance depend on proper classification, handling, training, and adherence to DOT, OSHA, NFPA, and international regulations.

If you need the Hydrogen (H₂) Logistics & Compliance Guide, please confirm so I can provide a separate, detailed guide specific to hydrogen gas in high-pressure cylinders.

Let me know how you’d like to proceed!

Conclusion for Sourcing E-Cylinder Oxygen Tanks

Sourcing E-cylinder oxygen tanks requires a strategic approach that balances safety, reliability, cost-effectiveness, and regulatory compliance. After evaluating various suppliers, product quality, delivery timelines, and after-sales support, it is clear that selecting a reputable vendor with a proven track record in medical gas supply is essential. Key considerations include certification standards (such as FDA, DOT, or ISO compliance), cylinder material and durability, maintenance and recertification services, and consistent gas purity.

Additionally, establishing long-term partnerships with suppliers who offer transparent pricing, timely replenishment, and emergency support can enhance operational continuity, especially in healthcare or emergency response settings. Environmental and sustainability factors, such as cylinder reusability and carbon footprint of delivery, are also becoming increasingly important in procurement decisions.

In conclusion, a well-structured sourcing strategy for E-cylinder oxygen tanks—not only ensures a reliable supply of life-supporting oxygen but also supports patient safety, regulatory adherence, and operational efficiency. Continuous supplier evaluation and risk management will further strengthen supply chain resilience in the face of growing demand or unforeseen disruptions.