The global dye sublimation fabric market is experiencing robust growth, driven by rising demand in the apparel, home textiles, and promotional graphics industries. According to Grand View Research, the digital textile printing market—of which dye sublimation holds a significant share—was valued at USD 3.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 9.2% from 2023 to 2030. This surge is fueled by the increasing adoption of sustainable, on-demand production methods and the superior color vibrancy and durability offered by sublimation printing. Mordor Intelligence further projects that the Asia Pacific region will dominate market growth, supported by expanding manufacturing capabilities and rising consumer demand for fast fashion and customized products. In this evolving landscape, identifying leading dye sublimation fabric manufacturers has become crucial for brands seeking high-quality, scalable, and innovative textile solutions. Here, we present the top 10 manufacturers shaping the future of sublimation textiles based on production capacity, technological advancement, global reach, and customer reviews.

Top 10 Dye Sublimation Fabric Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

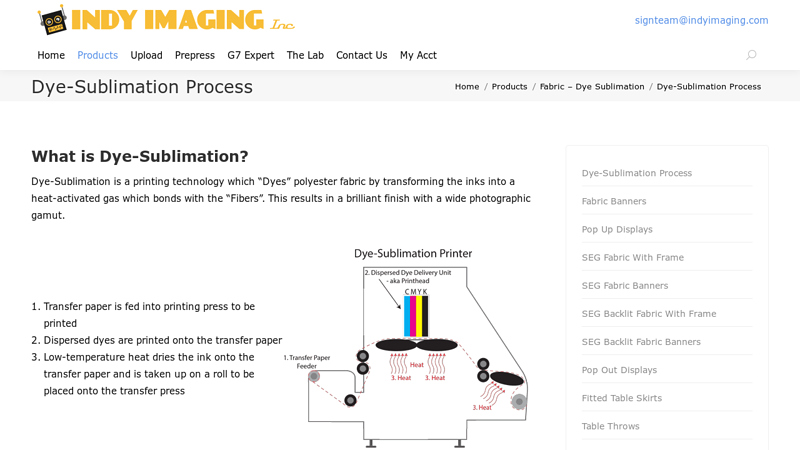

#1 Dye

Domain Est. 2003

Website: indyimaging.com

Key Highlights: Dye-Sublimation is a printing technology which “Dyes” polyester fabric by transforming the inks into a heat-activated gas which bonds with the “Fibers”….

#2 Dye Sublimation Printing

Domain Est. 2001

Website: tvfinc.com

Key Highlights: All Resources · Cotton and Linen · Dye Sublimation Troubleshooting · Fabric Dyeing · Finishes and Coatings · Fleece · Nylon and Polyester · Sign and Graphics · Testing….

#3 Dye Sublimation Fabric Printing Company

Domain Est. 2007

Website: mammothimaging.com

Key Highlights: We are a leading company in dye sublimation fabric & digital textile printing offering high-quality products at competitive prices. Learn more here!…

#4 Dye Sublimation Fabric Solutions

Domain Est. 1995

Website: speedpro.com

Key Highlights: SpeedPro provides dye sublimation fabric solutions for vibrant, long-lasting prints. Contact us for your next project….

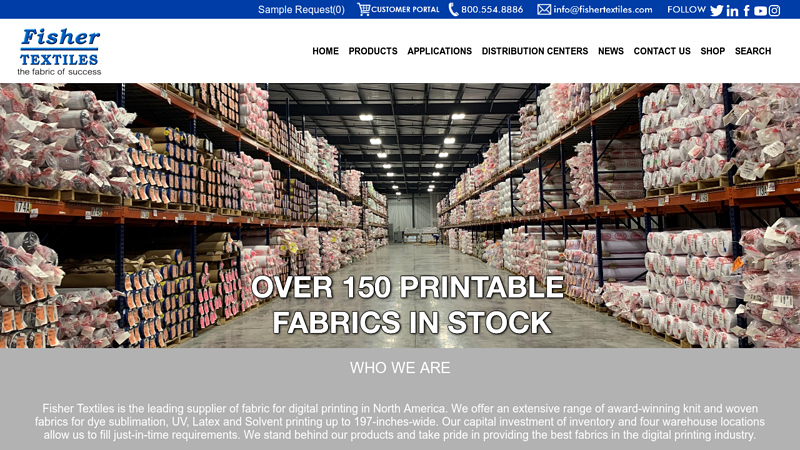

#5 Fisher Textiles

Domain Est. 1996

Website: fishertextiles.com

Key Highlights: We offer an extensive range of award-winning knit and woven fabrics for dye sublimation, UV, Latex and Solvent printing up to 197-inches-wide….

#6 Dye Sublimation

Domain Est. 1996

Website: testrite.com

Key Highlights: When viewed side-by-side, dye sublimation blows UV fabric printing and Ecosolvent fabric printing out of the water. We can UV print fabrics too, so we know!…

#7 Dye Sublimation Printed Fabric

Domain Est. 1997

Website: eacgs.com

Key Highlights: Enhance a Colour (EaC) is one of the few companies that print seamless, custom dye-sub printed fabrics, up to 16 ft. wide, with two framing options….

#8 Fabric printing

Domain Est. 2001

Website: duodisplay.com

Key Highlights: Dye-sublimation printing offers exceptional contrast, intensity and depth. Colors are vibrant and available in a wide range, including at high density….

#9 Dye Sublimation Printing

Domain Est. 2008

Website: fush.rs

Key Highlights: Dye sublimation printing only works effectively on synthetic fibres like recycled polyester. As polyester is the fabric of choice for most of our clients….

#10 S-RACE® Sublimation Papers

Domain Est. 2016

Website: s-race.com

Key Highlights: Dye sublimation paper by S-RACE® is impressively fast, efficient and precise. Our Portfolio is covering dye sublimation papers for any kind of application….

Expert Sourcing Insights for Dye Sublimation Fabric

H2: Projected 2026 Market Trends for Dye Sublimation Fabric

The dye sublimation fabric market is poised for significant growth and transformation by 2026, driven by technological advancements, rising demand for sustainable textiles, and expanding applications across industries. Key trends shaping the market include:

-

Sustainability and Eco-Friendly Production

By 2026, environmental concerns will continue to influence manufacturing practices, with a growing shift toward waterless dyeing processes and recyclable polyester substrates. Dye sublimation, which uses less water and produces minimal wastewater compared to traditional dyeing methods, will gain favor among eco-conscious brands and consumers. Increased adoption of bio-based and recycled polyester fabrics will further support the green credentials of sublimation printing. -

Growth in Customization and On-Demand Manufacturing

The demand for personalized and on-demand textile products will fuel the expansion of digital dye sublimation. Businesses in apparel, home décor, and promotional products will increasingly leverage sublimation for short-run, high-variability production. Advances in digital printing speed and quality will make small-batch customization more cost-effective, supporting direct-to-consumer (DTC) and e-commerce models. -

Expansion in Sportswear and Performance Apparel

Dye sublimation is ideal for printing vibrant, durable designs on moisture-wicking polyester fabrics used in sportswear. By 2026, the athletic and activewear sectors will remain major growth drivers, with brands seeking lightweight, breathable, and aesthetically versatile fabrics. Sublimation allows intricate patterns and team branding without compromising fabric performance, making it the preferred method for team uniforms and performance gear. -

Integration with Smart Textiles and Wearable Technology

As wearable tech gains traction, dye sublimation will play a role in embedding visual design elements into smart fabrics. The compatibility of sublimation dyes with technical textiles enables seamless integration of conductive fibers and sensors while maintaining aesthetic appeal. By 2026, hybrid fabrics combining sublimation prints with functional capabilities (e.g., temperature regulation or health monitoring) will emerge in niche markets. -

Geographic Market Expansion

While North America and Europe lead in technology adoption, the Asia-Pacific region—including China, India, and Southeast Asia—will experience the fastest market growth due to rising textile production capacity, expanding middle-class consumer demand, and government support for digital manufacturing. Local manufacturers will invest in sublimation equipment to meet export and domestic needs. -

Technological Advancements in Ink and Printer Efficiency

Printer manufacturers will continue to innovate, offering faster print speeds, lower energy consumption, and improved color gamut and durability. Enhancements in pigment dispersion and ink formulations will extend sublimation applicability to a broader range of synthetic blends and improve wash-fastness. These improvements will lower the total cost of ownership and widen market accessibility. -

Increased Competition and Market Consolidation

As the market matures, competition among ink suppliers, printer OEMs, and fabric producers will intensify. Strategic partnerships, mergers, and acquisitions are expected as companies seek to offer integrated solutions—from printers to inks to substrates. This consolidation will streamline supply chains and improve service delivery for end-users.

In conclusion, by 2026, the dye sublimation fabric market will be characterized by innovation, sustainability, and diversification. With strong adoption across fashion, sportswear, interior design, and emerging tech-integrated textiles, the industry is set for sustained growth, supported by digital transformation and evolving consumer preferences.

Common Pitfalls When Sourcing Dye Sublimation Fabric (Quality & IP)

Sourcing dye sublimation fabric requires careful attention to both material quality and intellectual property (IP) concerns. Overlooking these areas can lead to production delays, increased costs, poor end-product performance, and even legal liabilities. Here are the most common pitfalls to avoid:

Poor Fabric Quality and Inconsistencies

One of the biggest risks is receiving fabric that doesn’t meet technical specifications or varies significantly between batches. Issues include inconsistent polyester content (critical for dye bonding), uneven weaves, improper weight, or low tear strength. These defects result in poor print clarity, color fading, and fabric that doesn’t perform well in applications like flags, apparel, or soft signage.

Inadequate Color Fastness and Wash Durability

Low-quality fabrics may not bond well with sublimation dyes, leading to rapid color fading after washing or UV exposure. Suppliers may claim high durability without proper test data. Always request and verify test reports for lightfastness (e.g., ISO 105-B02) and wash fastness to ensure the fabric meets your product’s end-use requirements.

Lack of Sublimation Optimization

Not all polyester fabrics are suitable for dye sublimation. Using non-sublimation-specific fabric leads to poor dye penetration, “ghosting,” or incomplete transfer. Ensure the fabric is pre-treated or engineered for sublimation, with proper polymer structure and surface finish. Generic polyester may look similar but perform poorly.

Hidden Minimum Order Quantities (MOQs) and Lead Time Surprises

Suppliers may advertise flexible terms but impose high MOQs or extended lead times upon order confirmation. This can disrupt inventory management and increase costs. Clarify MOQs, production timelines, and sampling policies upfront to avoid project delays.

Intellectual Property (IP) Infringement Risks

Sourcing from manufacturers with weak IP compliance can expose your brand to legal action. Some suppliers may use patented dyeing processes, fabric weaves, or chemical treatments without proper licensing. Always vet suppliers for IP integrity and ensure they provide documentation confirming freedom to operate.

Unauthorized Use of Brand-Named Textiles

Some suppliers falsely claim their fabric is “equivalent to” or “compatible with” branded materials (e.g., ChromaLuxe, FlagShine), which can mislead buyers and potentially violate trademark laws. Verify whether the fabric is genuinely licensed or independently developed with comparable performance.

Lack of Traceability and Compliance Documentation

Without proper documentation, it’s difficult to prove fabric origin, chemical compliance (e.g., REACH, OEKO-TEX), or sustainability claims. This is critical for brands in regulated markets or those promoting eco-friendly products. Insist on material safety data sheets (MSDS), certificates of compliance, and batch traceability.

Overreliance on Visual Samples Without Testing

Physical samples may look promising but fail under real-world conditions. Always conduct in-house or third-party testing for color accuracy, stretch recovery, pilling resistance, and sublimation performance before committing to large orders.

Avoiding these pitfalls requires due diligence, clear specifications, and strong supplier vetting. Prioritize transparency, request documentation, and test rigorously to ensure both quality and legal safety in your dye sublimation fabric sourcing.

Logistics & Compliance Guide for Dye Sublimation Fabric

Overview of Dye Sublimation Fabric

Dye sublimation fabric is a digitally printed textile created using heat to transfer dye onto materials like polyester. The process involves printing a design onto transfer paper, then applying heat and pressure to sublimate the ink—transitioning it from solid to gas—embedding it directly into the fabric. This results in vibrant, durable prints ideal for apparel, banners, soft signage, and home textiles.

Regulatory and Environmental Compliance

REACH and RoHS Compliance

Dye sublimation inks and substrates used in the European Union must comply with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives. Ensure that inks do not contain restricted substances such as phthalates, heavy metals, or azo dyes. Suppliers should provide Safety Data Sheets (SDS) and compliance certifications.

Oeko-Tex Standard 100

For apparel and home textiles, fabrics should meet Oeko-Tex Standard 100, which certifies that the material is free from harmful levels of toxic substances and safe for human use. This is particularly important for products marketed in Europe and North America.

Prop 65 (California)

In the U.S., especially California, products must comply with Proposition 65, which requires warnings if chemicals known to cause cancer or reproductive harm are present. Ensure inks and fabrics do not contain listed substances such as certain amines or formaldehyde above permissible limits.

Packaging and Labeling Requirements

Sustainable Packaging

Use recyclable or biodegradable packaging materials to align with environmental standards. Avoid excessive plastic; opt for paper-based or compostable alternatives where possible. Clearly label packaging with recycling instructions.

Product Labeling

Label finished products with fiber content (e.g., 100% polyester), care instructions, country of origin, and any relevant certifications (e.g., OEKO-TEX, REACH-compliant). For exports, ensure labeling meets target market regulations, such as FTC rules in the U.S. or EU Textile Labeling Regulation (EU No 1007/2011).

Transportation and Handling

Temperature and Humidity Control

During shipping, protect dye sublimation fabrics from high humidity and extreme temperatures, which can cause ink bleeding or fabric degradation. Use moisture-resistant packaging and climate-controlled transport when necessary, especially for long-distance or international shipments.

Roll vs. Folded Shipping

Fabrics are typically shipped in rolls to prevent creasing and maintain print quality. Use sturdy cardboard cores and protective outer wrapping (e.g., polyethylene film). If folded, ensure minimal folding and use acid-free tissue paper to prevent marking.

Import/Export Documentation

Customs Declarations

Prepare accurate commercial invoices, packing lists, and certificates of origin. Clearly describe goods as “polyester fabric with digital sublimation print” and provide Harmonized System (HS) codes (e.g., 5407.61 for printed woven polyester fabric).

Duty and Tariff Considerations

Duty rates vary by destination country. Check applicable tariffs under the U.S. HTS, EU TARIC, or other local tariff schedules. Some regions offer reduced rates for certified eco-friendly or recycled-content textiles.

Sustainability and End-of-Life Considerations

Recyclability

Dye sublimation fabrics are typically 100% polyester, making them recyclable through mechanical or chemical recycling processes. Communicate end-of-life options to customers and support take-back programs where feasible.

Carbon Footprint and Certifications

Consider obtaining certifications such as Global Recycled Standard (GRS) or ISO 14001 to demonstrate environmental responsibility. Track and minimize carbon emissions across the supply chain, especially during printing and transport.

Best Practices for Compliance and Efficiency

- Supplier Audits: Regularly audit ink and fabric suppliers for compliance with chemical and environmental standards.

- Batch Testing: Conduct periodic testing of finished fabrics for colorfastness, pH levels, and restricted substances.

- Documentation Retention: Maintain records of compliance certificates, test reports, and shipping documents for at least five years.

- Training: Train logistics and production staff on handling procedures, safety protocols, and compliance requirements.

By adhering to these logistics and compliance guidelines, businesses can ensure the safe, legal, and sustainable distribution of dye sublimation fabrics worldwide.

Conclusion on Sourcing Dye Sublimation Fabric:

Sourcing dye sublimation fabric requires a strategic approach that balances quality, cost, sustainability, and supplier reliability. As the demand for vibrant, durable, and customizable printed textiles continues to grow—especially in apparel, home décor, and promotional products—selecting the right fabric and supplier is crucial. Polyester-based fabrics remain the standard due to their excellent ink absorption and color retention during the sublimation process.

When sourcing, it is essential to partner with experienced and reputable suppliers who offer consistent fabric quality, proper certification (such as OEKO-TEX or GRS for eco-conscious projects), and the ability to meet specific requirements for weight, finish, and roll width. Additionally, considering digital printing compatibility and pre-treatment standards ensures optimal print results.

Exploring both domestic and international suppliers can provide cost advantages and faster turnaround times, though lead times, minimum order quantities, and shipping logistics must be carefully evaluated. Sustainability is increasingly influential, making recycled or eco-friendly polyester options more desirable in many markets.

Ultimately, successful sourcing of dye sublimation fabric hinges on clear communication of technical specifications, thorough sample testing, and building strong, long-term supplier relationships. By prioritizing these factors, businesses can achieve high-quality, visually striking printed textiles that meet customer expectations and support brand integrity.