The global industrial dust collection systems market is experiencing robust growth, driven by increasing regulatory emphasis on workplace safety and air quality in manufacturing environments. According to Grand View Research, the market was valued at USD 4.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This surge is particularly pronounced in the woodworking sector, where wood dust—classified as a carcinogen by occupational health agencies—necessitates reliable extraction solutions to ensure compliance and protect worker health. With North America and Europe leading in stringent emissions standards, woodwork manufacturers are increasingly investing in high-efficiency dust extraction systems. As production scales and automation advances, so does the volume of airborne particulates, making advanced filtration not just a regulatory requirement but a critical component of operational efficiency and equipment longevity. In this data-driven landscape, selecting the right dust extraction system can significantly impact productivity, safety, and compliance. Here, we present the top 10 dust extraction systems tailored for woodwork manufacturers, evaluated based on performance metrics, energy efficiency, filtration capabilities, and user reviews across industrial applications.

Top 10 Dust Extraction Systems For Woodwork Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wet/Dry Dust Extraction

Domain Est. 1995

Website: fein.com

Key Highlights: For clean results and healthy working conditions. Powerful, reliable and mobile – FEIN vacuums ensure effective dust extraction in the shop and on-site….

#2 Industrial Dust Collection Systems for Every Application

Domain Est. 2005

Website: robovent.com

Key Highlights: RoboVent designs, manufactures and installs world-class industrial dust collection systems for every industry application….

#3 DCE Limited

Domain Est. 2011

Website: dustcontrolenvironmental.com

Key Highlights: Dust Control Environmental (DCE) is the leading independent manufacturer and supplier of dust extraction systems boasting the largest range of dust collectors ……

#4 Extraction Technology & Filtration Systems for Industry

Domain Est. 2022

Website: alko-extractiontechnology.com

Key Highlights: AL-KO Extraction Technology offers filtration systems, dust extractors and other extraction solutions for virtually every application….

#5 Dust Collector Systems for Woodworking

Domain Est. 1995

Website: jettools.com

Key Highlights: 10-day returnsFind top-quality dust collectors for your woodworking lathes. Browse our selection of dust collectors designed to keep the air in your shop clean….

#6 Dust Collectors

Domain Est. 1996

Website: lagunatools.com

Key Highlights: Free deliveryLaguna Tools offers a range of woodworking dust collectors that will minimize shop debris and keep your working space clean. Explore our selection today….

#7 Moldow

Domain Est. 1996

Website: moldow.com

Key Highlights: Market leader in designing and manufacturing energy efficient, reliable systems for dust extraction and painting of plastic, metal and wood….

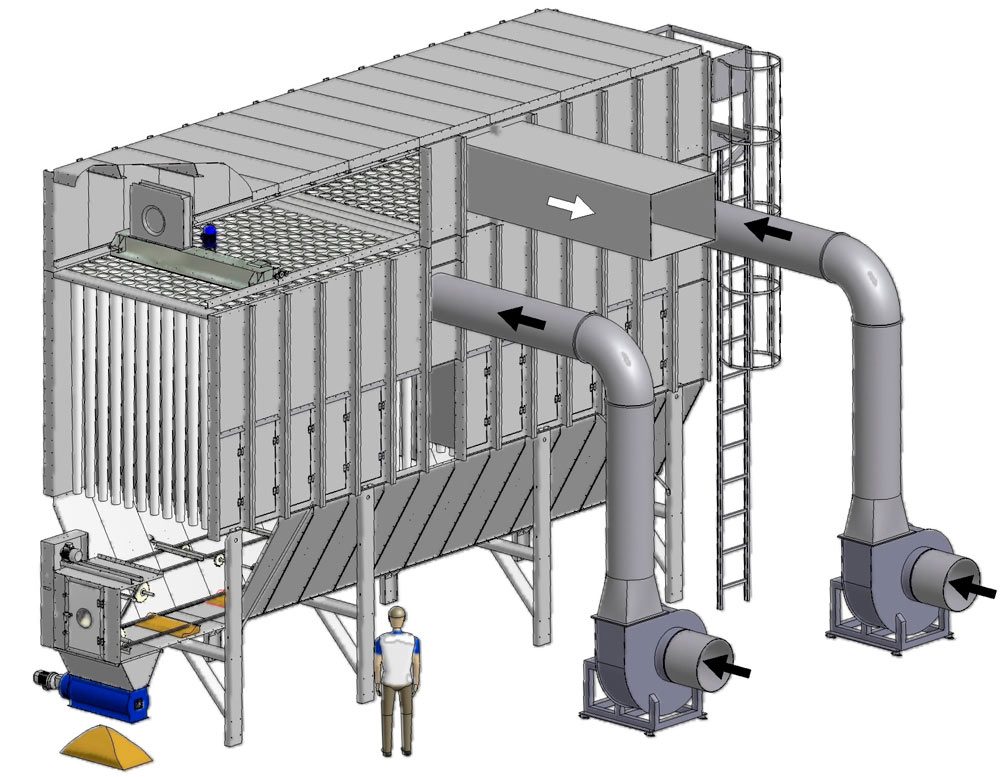

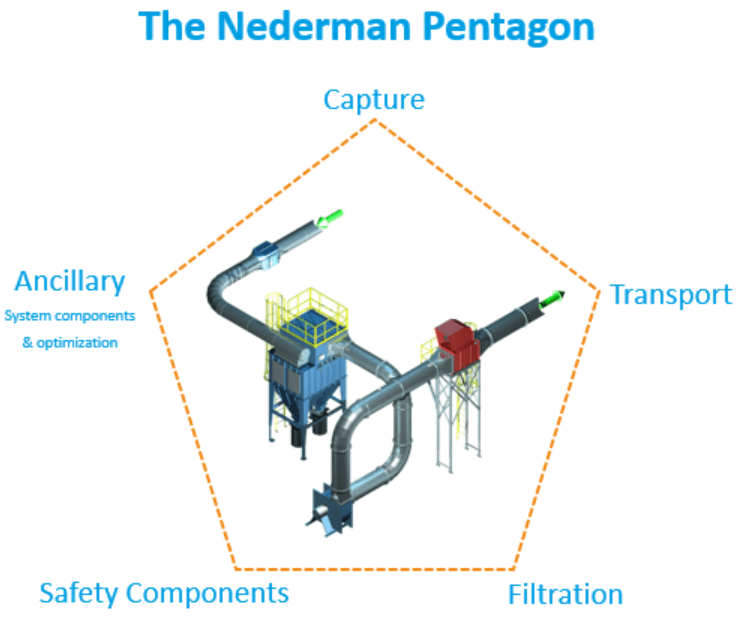

#8 Dust Collection Solutions

Domain Est. 1996

Website: nederman.com

Key Highlights: Nederman is your total solution provider for woodworking dust collection. With our vast experience and renowned expertise we guide you through the challenges….

#9 Cyclone Dust Collectors Made in USA

Domain Est. 1998

Website: oneida-air.com

Key Highlights: Free delivery · 30-day returnsWe’ve dedicated ourselves to providing the most innovative and high performance dust control solutions available – proudly made in the USA!…

#10 Power Tool Dust Extraction Solutions and Equipment

Domain Est. 2000

Website: milwaukeetool.com

Key Highlights: Shop heavy duty power tool dust management equipment including OSHA certified vacuums, filters, extractors and more….

Expert Sourcing Insights for Dust Extraction Systems For Woodwork

H2: Projected Market Trends for Woodworking Dust Extraction Systems in 2026

The global market for dust extraction systems in woodworking is expected to experience significant evolution by 2026, driven by technological innovation, regulatory changes, and increasing emphasis on workplace health and sustainability. Under the H2 category of key market trends, several interrelated developments stand out:

-

Increased Adoption of Smart and IoT-Enabled Systems

By 2026, smart dust extraction systems integrated with Internet of Things (IoT) technology are projected to gain substantial traction. These systems will offer real-time monitoring of air quality, filter performance, and system efficiency, enabling predictive maintenance and remote control via mobile applications. This shift supports Industry 4.0 initiatives in woodworking shops, enhancing operational efficiency and reducing downtime. -

Stricter Occupational Health and Safety Regulations

Regulatory bodies such as OSHA (U.S.) and the EU’s REACH and CE standards are expected to enforce tighter limits on wood dust exposure. As wood dust is classified as a carcinogen (IARC Group 1), manufacturers will be compelled to upgrade existing systems or invest in high-efficiency particulate air (HEPA)-filtered extraction units. Compliance will drive demand for certified, high-performance systems, especially in medium- to large-scale woodworking operations. -

Growth in Demand from Small and Medium Enterprises (SMEs)

SMEs in the woodworking sector are anticipated to represent a growing segment of the market. Fueled by the rise of custom furniture, cabinetry, and artisanal wood products, these businesses are increasingly investing in compact, modular dust collection systems that offer scalability and ease of integration. Affordable, plug-and-play units with low noise and high suction efficiency will be particularly sought after. -

Sustainability and Energy Efficiency as Key Buying Criteria

Environmental concerns will influence product design and purchasing decisions. By 2026, manufacturers will prioritize energy-efficient motors, recyclable filter materials, and systems with low carbon footprints. Variable frequency drives (VFDs) will become standard features, allowing systems to adjust fan speed based on usage, thus reducing energy consumption by up to 30–50%. -

Expansion in Emerging Markets

Regions such as Southeast Asia, India, and Latin America will witness accelerated market growth due to rising industrialization, urbanization, and investment in furniture manufacturing. Local production hubs will require cost-effective, durable dust extraction solutions tailored to humid or high-dust environments, creating opportunities for international suppliers to adapt and localize their offerings. -

Integration with Automated Workflows and CNC Machinery

As woodworking shops adopt more automated tools like CNC routers and robotic sanders, dust extraction systems will increasingly be designed for seamless integration. Coordinated extraction at source points will minimize dust dispersion and improve machining precision. Fully automated systems that activate in sync with machine operation will become a standard feature in advanced facilities.

In conclusion, the 2026 landscape for woodworking dust extraction systems under H2 trends points toward smarter, safer, and more sustainable solutions. Manufacturers and end-users alike will prioritize innovation, compliance, and efficiency, positioning the market for steady growth and technological advancement.

Common Pitfalls When Sourcing Dust Extraction Systems for Woodworking

Sourcing the right dust extraction system is crucial for maintaining a safe, efficient, and compliant woodworking environment. However, several common pitfalls related to quality and intellectual property (IP) can undermine your investment and operational success.

Overlooking Build Quality and Material Specifications

Many buyers focus solely on upfront cost and CFM (cubic feet per minute) ratings, neglecting the actual construction quality of the system. Low-cost units often use thin-gauge steel, poorly sealed joints, or substandard filtration media, leading to premature failure, air leaks, and reduced efficiency. Always verify the thickness of metal components, type of filtration (e.g., cartridge vs. baghouse), and compliance with industry standards such as OSHA or ATEX where applicable.

Ignoring System Compatibility with Workshop Layout

A common mistake is selecting a dust extractor without considering the workshop’s physical layout, ductwork design, or machine integration needs. An oversized or undersized system can lead to poor dust capture at tool inlets or excessive energy consumption. Ensure the system matches the number and type of tools, duct run lengths, and static pressure requirements—ideally confirmed with a professional assessment.

Falling for Misleading Performance Claims

Some manufacturers exaggerate airflow or suction capabilities without accounting for real-world conditions like duct resistance or filter loading. These inflated specs can mislead buyers into purchasing underperforming units. Always request independent test data or third-party verification of performance claims and consider systems tested under standardized conditions (e.g., AMCA certification).

Neglecting Filter Efficiency and Maintenance Access

Poor filter quality or inaccessible filter housings drastically increase long-term maintenance costs and downtime. Systems with low MERV or inefficient filters fail to capture fine wood dust, posing health risks. Additionally, designs that make filter cleaning or replacement difficult reduce adherence to maintenance schedules. Prioritize units with high-efficiency filters (e.g., MERV 12 or higher) and user-friendly access points.

Overlooking Intellectual Property and Design Infringement

Sourcing from suppliers who replicate patented designs or use counterfeit components presents legal and operational risks. Infringing systems may lack proper engineering, safety features, or spare part availability. Always verify that the manufacturer holds legitimate IP rights or certifications and avoid unusually cheap systems that mimic well-known brands, as they may be knockoffs with compromised safety and reliability.

Skipping Due Diligence on Supplier Reputation and Support

Choosing a supplier based only on price, without evaluating their track record, technical support, or warranty terms, can lead to post-purchase issues. Unreliable suppliers may disappear or offer inadequate spare parts and service. Research customer reviews, request references, and confirm after-sales support availability—especially for critical components like motors and controls.

Avoiding these pitfalls ensures that your dust extraction system delivers long-term performance, regulatory compliance, and a safer working environment.

Logistics & Compliance Guide for Dust Extraction Systems for Woodwork

Overview of Dust Extraction Systems in Woodworking

Dust extraction systems are essential in woodworking environments to maintain air quality, protect worker health, and ensure operational safety. These systems capture wood dust at the source, preventing it from becoming airborne. Proper logistics and compliance planning are crucial for the effective installation, operation, and maintenance of these systems.

Regulatory Compliance Requirements

Occupational Health and Safety Standards

Wood dust is classified as a hazardous substance under occupational safety regulations. In the United States, OSHA (Occupational Safety and Health Administration) mandates compliance with permissible exposure limits (PELs) for wood dust, typically set at 5 mg/m³ for total particulate over an 8-hour workday (29 CFR 1910.1000). Employers must implement engineering controls, such as dust extraction, to meet these standards.

National Fire Protection Association (NFPA) Standards

NFPA 664: Standard for the Prevention of Fires and Explosions in Wood Processing and Woodworking Facilities outlines critical safety requirements for dust collection systems. Key provisions include:

- Regular cleaning of dust accumulations

- Use of spark detection and suppression systems

- Proper grounding and bonding to prevent static discharge

- Design and installation of explosion venting or suppression systems for dust collectors

Compliance with NFPA 664 helps mitigate fire and explosion risks associated with combustible wood dust.

Environmental Protection Regulations

In regions governed by environmental agencies (e.g., EPA in the U.S.), emissions from dust collectors may be regulated. Systems exhausting to the outside must comply with local air quality standards, often requiring filtration efficiency (e.g., HEPA filters) and periodic emission testing.

System Selection and Sizing

Assessing Workshop Needs

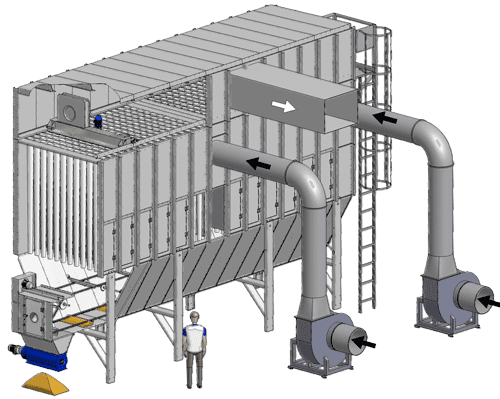

Selecting the right dust extraction system requires evaluating:

- Types of woodworking machinery (e.g., table saws, sanders, routers)

- Dust generation rates

- Facility layout and duct routing

- Total air volume requirements (measured in CFM – Cubic Feet per Minute)

A professional assessment or consultation with a system designer is recommended to ensure proper sizing.

Matching CFM Requirements

Each machine has a minimum CFM requirement for effective dust capture. The total system CFM should exceed the sum of individual machine requirements to account for duct friction and static pressure losses.

Installation and Logistics Planning

Ductwork Design and Layout

Efficient dust collection depends on a well-designed duct system. Best practices include:

- Using smooth-walled, round ducts to minimize resistance

- Maintaining proper duct velocity (typically 3,500–4,500 feet per minute)

- Installing blast gates to balance airflow

- Keeping duct runs as short and straight as possible

Equipment Placement

Locate the dust collector:

- Outside the main workshop when possible to reduce noise and explosion risk

- On a stable, level surface with adequate clearance for maintenance

- Away from ignition sources and combustible materials

Ensure easy access for filter cleaning, waste disposal, and inspections.

Operational Compliance and Maintenance

Regular Maintenance Schedule

To remain compliant and effective, dust extraction systems require routine maintenance:

- Clean filters weekly or as needed (based on usage)

- Inspect ducts monthly for blockages or leaks

- Empty dust collection bins frequently to prevent overflow

- Check belts, motors, and fans quarterly

Document all maintenance activities to demonstrate compliance during inspections.

Housekeeping Protocols

NFPA and OSHA require regular housekeeping to remove settled dust. Implement a schedule to clean floors, beams, and equipment using approved methods (e.g., vacuum systems rated for combustible dust—Class II, Division 2).

Avoid dry sweeping or compressed air, which can re-entrain dust and create explosion hazards.

Training and Worker Safety

Employee Training Programs

Train all woodworking personnel on:

- Safe operation of machinery with dust collection

- Recognition of dust hazards (respiratory, fire, explosion)

- Proper use of personal protective equipment (PPE)

- Emergency procedures in case of fire or system failure

Maintain training records as part of your compliance documentation.

PPE Requirements

Even with effective dust extraction, workers should use appropriate PPE, including:

- NIOSH-approved respirators (e.g., N95 or higher) when exposure limits are exceeded

- Safety goggles and protective clothing

- Hearing protection (due to noise from machinery and collectors)

Documentation and Auditing

Compliance Records

Maintain a compliance file including:

- System design specifications and installation records

- Maintenance logs and inspection reports

- Training records

- Air quality monitoring results (if applicable)

These documents are essential during OSHA or insurance audits.

Third-Party Inspections

Engage certified industrial hygienists or safety consultants periodically to:

- Evaluate dust control effectiveness

- Test air quality

- Verify NFPA compliance

Regular audits help identify gaps and prevent violations.

Conclusion

Effective logistics and compliance for dust extraction systems in woodworking operations require careful planning, adherence to regulatory standards, and ongoing maintenance. By following this guide, businesses can create a safer working environment, reduce fire risks, and ensure long-term regulatory compliance.

Conclusion: Sourcing Dust Extraction Systems for Woodworking

Selecting the right dust extraction system is a critical investment for any woodworking operation, whether in a small workshop or a large manufacturing facility. Effective dust collection not only enhances workplace safety by reducing airborne particulates and minimizing fire hazards, but also improves air quality, protects machinery, and ensures compliance with health and safety regulations.

When sourcing a dust extraction system, several key factors must be considered: the type and volume of dust generated, the size and layout of the workspace, the number and types of tools in use, and long-term maintenance requirements. Centralized systems offer comprehensive coverage for larger operations, while portable or downdraft tables may be more suitable for smaller or mobile setups.

Additionally, energy efficiency, noise levels, filter quality, and ease of maintenance should influence decision-making. Investing in high-quality filtration—such as HEPA filters—can significantly improve air purity and worker health. It is also essential to choose systems that are scalable and adaptable to potential future expansions or changes in production.

Ultimately, sourcing a dust extraction system should balance performance, cost, and sustainability. Consulting with reputable suppliers, reviewing system certifications, and seeking user feedback can help ensure a well-informed choice. By prioritizing effective dust management, woodworking businesses protect their workforce, maintain equipment longevity, and support a cleaner, safer, and more productive working environment.