The global demand for Dumore Corp manufacturers—specializing in precision motors, high-performance grinders, and industrial tooling systems—has seen steady momentum, driven by increasing automation across manufacturing, aerospace, and automotive sectors. According to Grand View Research, the global industrial motors market was valued at USD 162.7 billion in 2023 and is projected to grow at a CAGR of 6.3% from 2024 to 2030, fueled by energy efficiency mandates and advancements in motor technology. Meanwhile, Mordor Intelligence reports similar expansion in the power tools segment, anticipating a CAGR of 5.8% over the same period, citing rising infrastructure investments and industrial maintenance spending. Within this evolving landscape, a select group of manufacturers has emerged as leaders in innovation, reliability, and market reach—setting the benchmark for quality in Dumore’s niche. The following analysis highlights the top four manufacturers shaping the future of precision motion control and industrial abrasion solutions.

Top 4 Dumore Corp Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Custom DC Electric Fractional Horsepower Motor Manufacturers

Domain Est. 2000

Website: dumoremotors.com

Key Highlights: Dumore Motors is manufacturer of custom fractional horsepower OEM electric motors, gear motors and custom electromechanical motor assemblies….

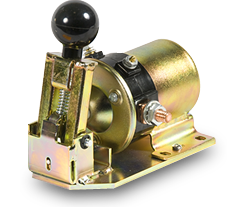

#2 About Dumore Emergency Starter Solenoids

Domain Est. 2016

Website: dumoresolenoids.com

Key Highlights: Dumore is the leading manufacturer of emergency starter solenoids (battery contactors) for fire pump diesel engines in the world. Quality Is Our Legacy…

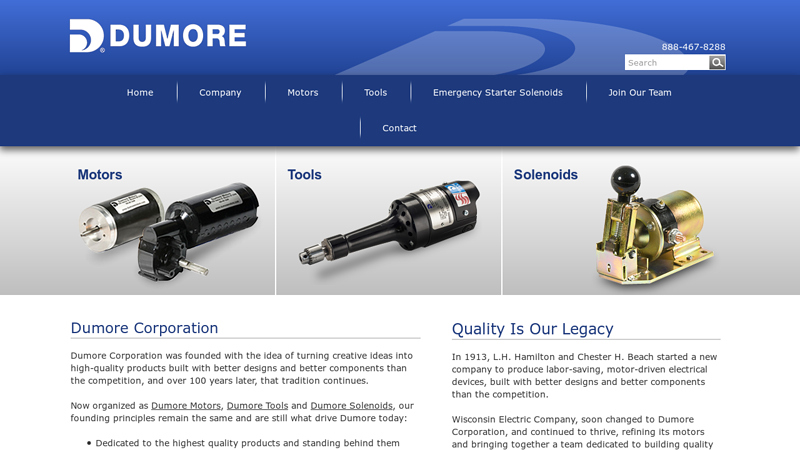

#3 Dumore Corporation

Domain Est. 1998 | Founded: 1913

Website: dumorecorp.com

Key Highlights: Since 1913, Dumore has been turning creative ideas into high-quality products and standing behind them. Dumore products are made in the USA in our 100,000 ……

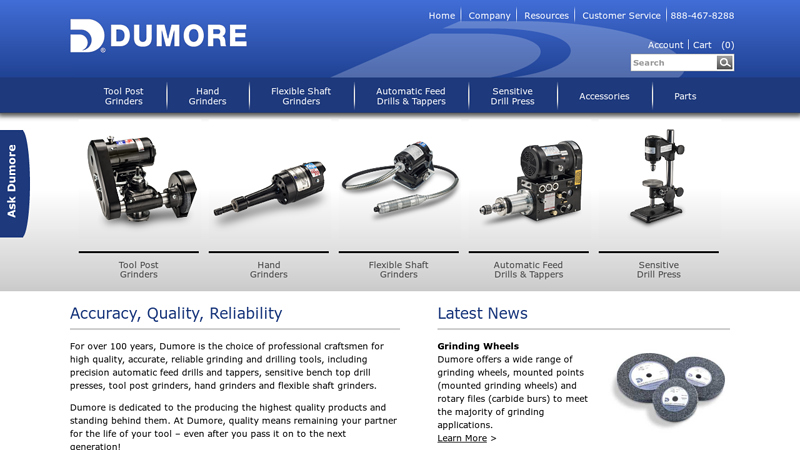

#4 Dumore Tools

Domain Est. 2000 | Founded: 1913

Website: dumoretools.com

Key Highlights: Since 1913, Dumore has been designing and manufacturing highly accurate and reliable drilling and grinding tools for tool room and production needs. Over 100 ……

Expert Sourcing Insights for Dumore Corp

H2 2026 Market Trends Analysis for Dumore Corp.

As of the second half of 2026, Dumore Corp.—a company historically associated with precision motion control, industrial motors, and automation solutions—operates within a rapidly evolving industrial technology landscape. While specific public financial or strategic updates on Dumore Corp. are limited due to its status as a subsidiary under AMETEK, Inc. (a global leader in electronic instruments and electromechanical devices), broader market dynamics and parent company strategies provide valuable insight into its positioning and performance trends in H2 2026.

1. Growth in Industrial Automation and Smart Manufacturing

H2 2026 sees continued expansion in Industry 4.0 adoption across manufacturing, aerospace, and healthcare sectors. Dumore’s high-precision motors and motion control systems benefit from increased demand for automation, robotics integration, and smart factory infrastructure. The push toward predictive maintenance, energy-efficient systems, and modular production lines has elevated the value of Dumore’s engineered-to-order motor solutions.

- Trend Impact: Positive. Dumore’s niche in custom motor design aligns with demand for reliability and precision in automated environments.

- Market Driver: Global industrial automation market projected to grow at a CAGR of 10.4% through 2026 (source: MarketsandMarkets), supporting stronger demand for specialized components.

2. Sustainability and Energy Efficiency Regulations

Regulatory pressure in North America and Europe to reduce carbon emissions and improve energy efficiency has influenced motor design standards. The enforcement of IE4 and upcoming IE5 efficiency classifications for electric motors drives demand for premium-efficiency models—Dumore’s core competency.

- Trend Impact: Highly favorable. Dumore’s product line, already compliant with advanced efficiency standards, gains competitive advantage.

- Strategic Move: AMETEK’s broader ESG commitments support investment in eco-design and low-energy consumption technologies, benefiting Dumore’s R&D pipeline.

3. Supply Chain Resilience and Nearshoring

After years of global supply chain volatility, H2 2026 sees sustained momentum in nearshoring and onshoring of industrial production, particularly in the U.S. Dumore, with domestic manufacturing capabilities under AMETEK, benefits from clients prioritizing shorter lead times and supply chain transparency.

- Trend Impact: Moderate to high. Proximity to key markets in aerospace, defense, and medical equipment enhances responsiveness.

- Evidence: AMETEK’s 2026 investor commentary emphasizes localized production networks and inventory optimization.

4. Integration with AMETEK’s Growth Strategy

Dumore operates as part of AMETEK’s Electronic Instruments Group (EIG), which reported strong organic growth in H1 2026. The parent company’s focus on high-margin, niche-engineered products supports continued investment in Dumore’s technology and market reach.

- Trend Impact: Positive. Dumore leverages AMETEK’s global distribution, R&D resources, and M&A strategy to expand application reach.

- Example: Cross-selling opportunities with AMETEK’s power supplies and sensors enhance bundled solutions for OEMs.

5. Challenges: Competitive Pressure and Raw Material Costs

Despite favorable trends, Dumore faces competition from both established players (e.g., Maxon, Siemens) and emerging Asian manufacturers offering lower-cost alternatives. Additionally, fluctuating prices for rare earth materials (used in high-performance motors) pose margin pressure.

- Mitigation: Dumore counters through differentiation—customization, precision, and reliability—rather than price competition.

- H2 2026 Outlook: Stable margins due to long-term contracts and value-based pricing.

Conclusion: H2 2026 Outlook for Dumore Corp.

Dumore Corp. is well-positioned in H2 2026 to capitalize on structural shifts in industrial automation, energy efficiency, and supply chain localization. As a specialized unit within AMETEK, it benefits from strategic alignment with high-growth sectors and global technological trends. While competitive and cost challenges persist, Dumore’s focus on engineering excellence and niche markets supports sustained relevance and profitability.

Recommendation: Continue investment in smart motor technologies, expand digital integration (e.g., IoT-enabled diagnostics), and strengthen partnerships with OEMs in medical, aerospace, and robotics industries to drive long-term growth.

Common Pitfalls When Sourcing from Dumore Corp: Quality and Intellectual Property Risks

When sourcing products or components from Dumore Corp—or any specialized industrial equipment manufacturer—companies may encounter several critical pitfalls, particularly related to quality assurance and intellectual property (IP) protection. Recognizing these risks early is essential to maintaining supply chain integrity, protecting proprietary information, and ensuring long-term operational reliability.

Quality Control Challenges

One of the primary concerns when sourcing from Dumore Corp involves inconsistent quality control, especially when dealing with legacy equipment or replacement parts. Dumore has a long history in manufacturing precision tools and motors, but as production practices evolve or are outsourced, variations in material quality, tolerances, and performance standards may occur. Buyers may receive components that do not meet original equipment manufacturer (OEM) specifications, leading to integration issues, reduced product lifespan, or field failures. Additionally, lack of standardized testing documentation or traceability can make it difficult to verify compliance with industry regulations or internal quality benchmarks.

Intellectual Property Exposure

Another significant pitfall involves intellectual property risks, particularly when reverse engineering or duplicating Dumore-designed components. Because Dumore holds patents and proprietary designs on many of its motors, grinders, and tool systems, unauthorized replication—even for internal repair or maintenance—can lead to IP infringement claims. Companies sourcing aftermarket or third-party equivalents may inadvertently purchase knock-offs that violate Dumore’s patents or trademarks, exposing the buyer to legal liability. Furthermore, sharing technical specifications or product designs with suppliers in an effort to source alternatives may result in unintended disclosure of sensitive IP, especially if proper non-disclosure agreements (NDAs) and IP clauses are not in place.

To mitigate these risks, organizations should conduct thorough due diligence on suppliers, verify component authenticity, maintain strict IP protocols, and ensure all sourcing agreements explicitly address quality standards and intellectual property rights.

Logistics & Compliance Guide for Dumore Corp.

This guide outlines the key logistics and compliance procedures for Dumore Corp. to ensure efficient operations and adherence to regulatory requirements. All employees involved in shipping, receiving, inventory management, and regulatory reporting must follow these standards.

Purpose

To standardize logistics processes and ensure full compliance with domestic and international regulations, minimizing risk, delays, and penalties.

Scope

Applies to all departments involved in the movement of goods, including procurement, warehousing, transportation, sales, and customer service.

Logistics Management

Transportation & Carrier Selection

- Partner only with pre-qualified carriers that meet Dumore Corp.’s safety, reliability, and insurance requirements.

- Maintain a Carrier Compliance Database updated quarterly.

- Use contract carriers with proven experience in handling Dumore’s product types (e.g., industrial components, temperature-sensitive materials if applicable).

Shipping & Receiving Procedures

- All incoming and outgoing shipments must be documented using standardized Dumore Shipping Manifests.

- Conduct dock inspections upon receipt to verify quantity, packaging integrity, and bill of lading accuracy.

- Report discrepancies within 2 hours of receipt to the Logistics Manager.

Inventory Management

- Utilize the Dumore Inventory Tracking System (DITS) for real-time stock visibility.

- Perform monthly cycle counts and annual physical inventory audits.

- Store hazardous or regulated materials in designated, labeled zones compliant with OSHA and EPA standards.

Warehousing Standards

- Maintain 5S principles (Sort, Set in order, Shine, Standardize, Sustain) in all warehouse locations.

- Ensure proper stacking, aisle clearance, and fire safety compliance per NFPA codes.

- Temperature and humidity controls must be monitored daily for sensitive inventory.

Regulatory Compliance

Export Controls

- All exports must be screened against the U.S. Department of Commerce’s Commerce Control List (CCL).

- Obtain required export licenses for controlled items prior to shipment.

- Maintain records of export transactions for a minimum of five (5) years.

Import Compliance

- Accurately classify all imported goods using the Harmonized Tariff Schedule (HTS).

- Ensure customs documentation (commercial invoice, packing list, certificate of origin) is complete and error-free.

- Coordinate with licensed customs brokers to facilitate smooth clearance.

Safety & Environmental Regulations

- Comply with OSHA standards for material handling, worker safety, and hazardous communication (HazCom).

- Train employees annually on handling of hazardous materials per DOT 49 CFR and EPA regulations.

- Maintain Material Safety Data Sheets (MSDS/SDS) for all regulated substances.

Trade Sanctions & Embargoes

- Screen all customers, suppliers, and end-users against OFAC’s Specially Designated Nationals (SDN) List prior to transaction.

- Immediately suspend any transaction involving a sanctioned entity and report to the Compliance Officer.

Documentation & Recordkeeping

Required Records

- Bills of lading, air waybills, shipping manifests

- Customs declarations and import/export licenses

- Inventory logs and audit reports

- Carrier contracts and insurance certificates

- Employee training records (safety, compliance)

Retention Policy

All logistics and compliance records must be retained for a minimum of five (5) years in both digital and backup formats. Access is restricted to authorized personnel only.

Roles & Responsibilities

- Logistics Manager: Oversees daily operations, carrier relations, and shipping accuracy.

- Compliance Officer: Monitors regulatory changes, ensures policy adherence, and conducts audits.

- Warehouse Supervisors: Enforce safety and inventory standards on-site.

- Procurement Team: Validates supplier compliance with Dumore’s logistics requirements.

Training & Audits

- Conduct biannual compliance training for all logistics staff.

- Perform internal logistics audits quarterly; address findings within 30 days.

- Schedule external compliance audits annually with a certified third-party auditor.

Incident Reporting & Corrective Actions

- Report all logistics incidents (delays, damages, compliance breaches) via the Dumore Incident Reporting Portal within 24 hours.

- The Compliance Officer will lead root cause analysis and implement corrective actions.

- Document all resolutions and update procedures as needed.

Policy Review & Updates

This guide will be reviewed annually or as regulations change. Updates require approval from the Operations Director and Chief Compliance Officer.

Effective Date: [Insert Date] Approved By: [Name, Title]

For questions or reporting concerns, contact: [email protected] or [email protected]

Conclusion for Sourcing Dumore Corp.

In conclusion, Dumore Corp. presents itself as a reliable and established manufacturer of high-performance precision tools and motors, with a strong reputation for quality, durability, and technical innovation. Their extensive product range, commitment to engineering excellence, and long-standing presence in industrial and aerospace markets make them a viable candidate for strategic sourcing, particularly for applications requiring precision and reliability.

However, sourcing from Dumore Corp. should be evaluated in the context of specific business needs, including cost considerations, lead times, availability of alternative suppliers, and volume requirements. The company’s focus on high-end, specialized equipment may result in higher pricing compared to standard market offerings, which could impact scalability for cost-sensitive projects.

Due diligence is recommended regarding their current production capacity, supply chain stability, and responsiveness to customer demands. Additionally, verifying compliance with industry standards and certifications relevant to your sector is essential.

Overall, Dumore Corp. is a reputable supplier worthy of consideration for niche, high-precision applications where performance and reliability are paramount. Strategic collaboration, potentially through pilot procurement or partnership discussions, could help determine the long-term viability and value of incorporating Dumore into the supply chain.