The direct-to-film (DTF) printing market has experienced rapid expansion in recent years, driven by increasing demand for high-quality, cost-effective garment customization. According to a report by Mordor Intelligence, the global digital textile printing market is projected to grow at a CAGR of 6.8% from 2024 to 2029, with DTF technology emerging as a key growth segment due to its versatility, superior print durability, and compatibility with a wide range of fabrics—especially cotton and polyester blends used in apparel. This surge is further supported by Grand View Research, which highlights that the global digital textile printing market size was valued at USD 4.2 billion in 2023 and is expected to expand significantly through 2030, fueled by advancements in eco-friendly inks and rising adoption in small-to-medium enterprises and on-demand fashion. As DTF printing becomes increasingly accessible, manufacturers are innovating to deliver printers that combine precision, speed, and user-friendly operation. In this competitive landscape, identifying the top DTF printer manufacturers for shirt production is essential for businesses aiming to capitalize on this growing trend with reliable, high-performance equipment.

Top 10 Dtf Printer For Shirts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

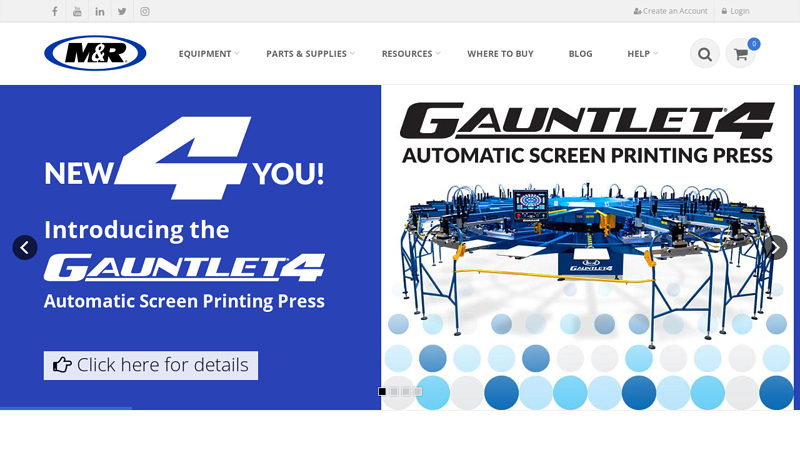

#1 M&R Printing Equipment Inc. :: DTF

Domain Est. 1996

Website: mrprint.com

Key Highlights: M&R makes a wide range of textile printing equipment, including Direct to Film (DTF), Direct to Garment, (DTG), Hybrid Digital Printing, manual & automatic ……

#2 ColDesi, Inc. Make Your Own Customized Products

Domain Est. 2010

Website: coldesi.com

Key Highlights: ColDesi’s Direct to Film (DTF) printers deliver professional-quality prints with vibrant color and long-lasting durability on a wide range of fabrics. Easy to ……

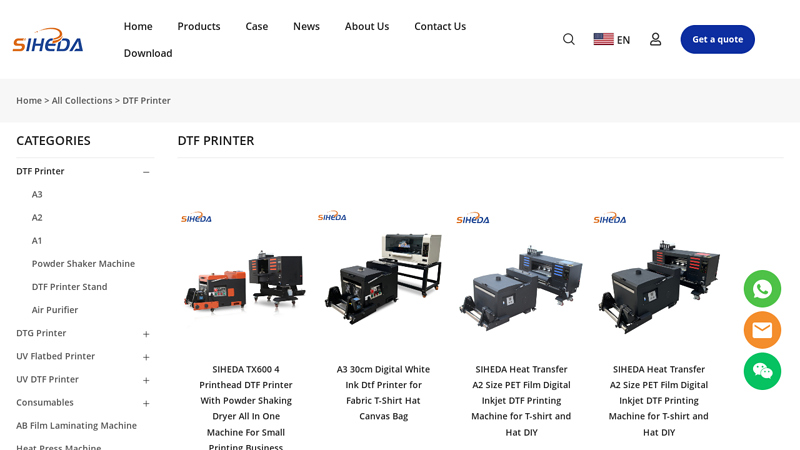

#3 DTF Printer

Domain Est. 2022

Website: siheda.com

Key Highlights: SIHEDA TX600 4 Printhead DTF Printer With Powder Shaking Dryer All In One Machine For Small Printing Business. $0.00 ……

#4 DTFilm Printers

Domain Est. 1991

Website: epson.com

Key Highlights: Built to deliver killer quality and up for almost anything, SureColor G-Series direct-to-film (DTFilm) printers are the real deal you can count on to help you ……

#5 DTF Printing

Domain Est. 2017

Website: dtgpro.com

Key Highlights: DTG PRO FUSION V2. Dependable and affordable DTG printer, known for vivid, long-lasting color prints on white or dark garments. RICOH DTG Series….

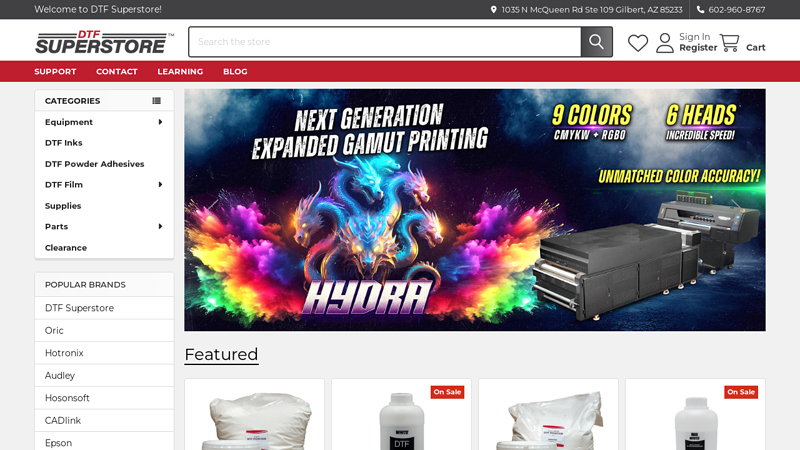

#6 DTF Superstore

Domain Est. 2020

Website: dtfsuperstore.com

Key Highlights: 30-day returnsDTF Superstore is the largest Direct to Film supplier in the USA—offering DTF printers, inks, films, powder adhesives, RIP software, cleaners, and heat ……

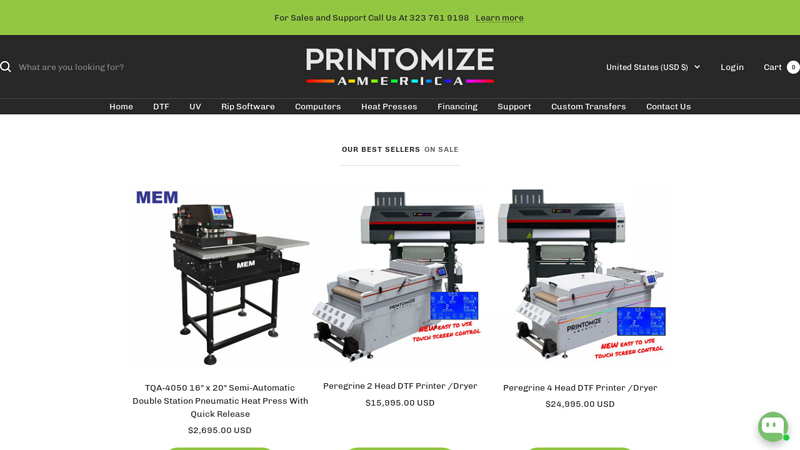

#7 Printomize America

Domain Est. 2021

Website: printomizeamerica.com

Key Highlights: Our Peregrine x4 is the fastest DTF printer on the market and can deliver 100 full-color 11″ x 11″ DTF transfers in 30 minutes. For more information, see the ……

#8 Commercial DTF Printer and UV DTF Machine Supplier

Domain Est. 2022

Website: okaimachinery.com

Key Highlights: Shop for a commercial dtf printer or uv dtf printer for high volume. Our dtf transfer printer systems ensure durable results for shirt printing….

#9

Domain Est. 2023

Website: otterdtf.com

Key Highlights: Versatile DTF/UV DTF printing solutions for textiles, soft fabrics, glossy surfaces, and beyond! Otterpro DTF SYSTEM. Textile DTF Printing. 3D PUFF…

#10 InkSonic

Domain Est. 2024

Expert Sourcing Insights for Dtf Printer For Shirts

2026 Market Trends for DTF Printers for Shirts

The Direct-to-Film (DTF) printing market, particularly in the realm of custom shirt production, is undergoing rapid transformation. As we approach 2026, several key trends are shaping the future of DTF printers for shirts, driven by technological innovation, evolving consumer preferences, and shifts in the broader apparel and printing industries.

Rising Demand for Customization and On-Demand Production

One of the most prominent trends driving the DTF printer market is the growing consumer appetite for personalized apparel. In 2026, customization is no longer a luxury—it’s an expectation. DTF printing enables high-quality, full-color designs on various fabrics, including cotton, polyester, and blends, without the need for screen setup. This makes it ideal for small-batch and on-demand production, aligning perfectly with the rise of e-commerce platforms and print-on-demand (POD) businesses.

Advancements in DTF Printer Technology

By 2026, DTF printers are expected to feature enhanced print speeds, improved color accuracy, and lower maintenance requirements. Manufacturers are integrating automation, intelligent ink management systems, and user-friendly software to streamline workflows. Additionally, eco-solvent and water-based inks are being refined to reduce environmental impact while maintaining durability and wash resistance—key factors for garment printing.

Expansion into New Markets and Applications

While DTF printing initially gained traction in the custom t-shirt segment, its application is broadening. By 2026, DTF printers are increasingly used for hoodies, sportswear, baby clothes, and even promotional merchandise. This versatility is expanding the market beyond niche custom shops into mid-sized apparel brands and fulfillment centers looking for flexible, cost-effective production solutions.

Competitive Pricing and Market Democratization

The DTF printer market is becoming more accessible. Entry-level machines are now more affordable, enabling startups and small businesses to enter the custom apparel space without significant capital investment. At the same time, premium models offer industrial-grade performance for high-volume producers. This tiered pricing strategy is democratizing the technology and fueling market growth globally.

Sustainability and Eco-Conscious Manufacturing

Sustainability is a major trend influencing DTF printer development in 2026. Consumers and regulators are demanding greener production methods. As a result, manufacturers are focusing on reducing waste, improving energy efficiency, and developing biodegradable powder adhesives and recyclable films. DTF’s advantage over screen printing—lower water and energy consumption—is being emphasized in marketing and product development.

Integration with Digital Ecosystems

DTF printers are increasingly integrated with e-commerce platforms, design software, and order management systems. In 2026, seamless connectivity allows for automated workflows from design upload to shipping, reducing labor costs and human error. AI-powered design tools are also being incorporated, enabling users to generate or modify artwork directly within the printing ecosystem.

Regional Market Growth and Supply Chain Shifts

Asia-Pacific, particularly China and India, remains a dominant force in DTF printer manufacturing and adoption. However, North America and Europe are seeing accelerated growth due to increased demand for localized, sustainable production. Supply chains are adapting to support faster delivery of consumables like film, ink, and adhesive powder, with regional distribution hubs improving service reliability.

Conclusion

By 2026, the DTF printer market for shirts is poised for robust growth, fueled by technological innovation, rising demand for customization, and a shift toward sustainable and agile production. Businesses that adopt DTF technology now will be well-positioned to capitalize on these evolving trends, offering high-quality, personalized apparel with faster turnaround times and greater environmental responsibility.

Common Pitfalls When Sourcing DTF Printers for Shirts: Quality and Intellectual Property Issues

Logistics & Compliance Guide for DTG Printer for Shirts

Overview of DTG Printing in Apparel Production

Direct-to-Garment (DTG) printing has revolutionized custom apparel manufacturing by enabling high-quality, full-color designs directly onto cotton and cotton-blend fabrics. While DTG printers offer flexibility and scalability for small to medium production runs, successful operations require careful attention to logistics and compliance standards across the supply chain, manufacturing, and shipping processes.

Equipment Sourcing and Import Compliance

When acquiring a DTG printer—especially from international suppliers—ensure compliance with import regulations. Verify that the printer meets electrical safety standards (e.g., CE, UL, or ETL certification) and complies with electromagnetic compatibility (EMC) directives. Importers must provide accurate Harmonized System (HS) codes, typically under 8443.39 (inkjet printers), and be prepared for customs duties, import taxes, and documentation such as commercial invoices, packing lists, and certificates of origin.

Ink and Chemical Handling & Safety Compliance

DTG printers use specialized water-based inks containing pigments and solvents. These inks must comply with environmental and safety regulations such as:

– REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals.

– Proposition 65 (California, USA): Requires warnings if products expose consumers to listed chemicals.

– OSHA Hazard Communication Standard (USA): Ensure Safety Data Sheets (SDS) are accessible, and staff are trained in handling, storage, and disposal of inks and pretreatment chemicals.

Store inks in a cool, dry place away from direct sunlight, and use proper labeling and spill containment procedures.

Pretreatment Chemical Usage and Disposal

Pretreatment solutions are essential for improving ink adhesion and color vibrancy on cotton garments. These solutions often contain chemicals like sodium carbonate or proprietary blends. Compliance considerations include:

– Proper ventilation in application areas.

– Use of personal protective equipment (PPE) such as gloves and goggles.

– Wastewater management: Pretreatment residue and wash-off water may contain regulated substances. Check local environmental regulations for discharge limits and consider using filtration or neutralization systems before disposal.

Fabric and Garment Sourcing Standards

Source blank shirts from suppliers that comply with textile regulations and ethical manufacturing standards:

– OEKO-TEX® Standard 100: Ensures fabrics are free from harmful levels of toxic substances.

– GOTS (Global Organic Textile Standard): If using organic cotton.

– Fair Labor Association (FLA) or WRAP Certification: Confirms ethical labor practices.

Maintain documentation for traceability and compliance audits.

Product Labeling and Consumer Safety

Finished printed garments must meet labeling requirements, including:

– Fiber content (e.g., 100% cotton).

– Care instructions (washing, drying, ironing).

– Country of origin.

– Manufacturer or importer identification.

Ensure printed designs do not infringe on trademarks, copyrights, or offensive content, especially when selling globally.

Environmental and Waste Management Compliance

DTG operations generate waste such as used ink cartridges, cleaning solutions, and misprinted garments. Follow these practices:

– Recycle ink cartridges through manufacturer take-back programs.

– Dispose of liquid waste in accordance with local hazardous waste regulations.

– Repurpose or recycle defective garments when possible.

Implement a waste management plan aligned with EPA (USA), Environment Agency (UK), or equivalent local authorities.

Shipping and Fulfillment Logistics

Optimize packaging to protect printed garments during transit:

– Use polybags or recyclable packaging to prevent ink transfer.

– Consolidate shipments to reduce carbon footprint.

– Partner with carriers compliant with transportation safety standards (e.g., IATA for air freight if shipping internationally).

Ensure shipping documentation includes proper product descriptions, values, and compliance statements for customs clearance.

Quality Control and Regulatory Testing

Conduct regular quality checks on print durability, wash fastness, and color accuracy. For commercial distribution, consider third-party testing to verify:

– Colorfastness (AATCC or ISO standards).

– Fabric shrinkage.

– Lead and phthalate content (especially for children’s apparel under CPSIA in the USA).

Maintain testing records to demonstrate compliance during audits.

Data Privacy and E-Commerce Compliance

If operating an online store for custom DTG shirts, comply with data protection laws such as:

– GDPR (EU): For customer data collection and processing.

– CCPA (California): For consumer privacy rights.

– Use secure payment processing (PCI-DSS compliant) and clearly communicate return, shipping, and privacy policies.

Conclusion

Successfully operating a DTG printing business for shirts requires more than technical expertise—it demands strict adherence to logistics and compliance protocols. From responsible sourcing and chemical handling to environmental stewardship and consumer safety, each step impacts legal standing, brand reputation, and long-term sustainability. Stay updated on evolving regulations and invest in training and documentation to ensure a compliant and efficient operation.

In conclusion, sourcing a DTF (Direct-to-Film) printer for shirt printing offers a highly efficient, cost-effective, and versatile solution for producing high-quality, full-color custom designs. With its ability to print on a wide range of fabrics—especially cotton, polyester, and blends—DTF technology provides vibrant, durable prints with excellent wash resistance, making it ideal for small to medium production volumes and custom apparel businesses.

When sourcing a DTF printer, it’s essential to consider factors such as print resolution, production speed, ink system reliability, software compatibility, and after-sales support. Investing in a reputable brand with proven performance and accessible technical assistance ensures long-term operational efficiency and print consistency.

Additionally, evaluating the total cost of ownership—including the printer, ink, film, powder adhesive, and maintenance—helps in making a financially sound decision. As DTF technology continues to evolve and become more accessible, it presents a competitive edge over traditional printing methods like screen printing and DTG, especially for intricate designs and short-run orders.

Ultimately, sourcing the right DTF printer empowers businesses to scale production, enhance customization capabilities, and meet growing customer demands for personalized, high-quality apparel—making it a strategic investment for the future of garment decoration.