The global drywall screws market is experiencing steady growth, driven by rising construction activities and demand for energy-efficient building materials. According to Grand View Research, the global drywall fasteners market was valued at USD 1.8 billion in 2022 and is expected to expand at a CAGR of 5.3% from 2023 to 2030, fueled by increasing residential and commercial infrastructure development. As 1/2-inch drywall screws remain one of the most widely used sizes for standard wallboard installation, manufacturers are focusing on product durability, corrosion resistance, and ease of installation to meet evolving industry standards. With North America and Europe leading in market share due to strict building codes and high renovation rates, competition among top suppliers has intensified. Based on performance metrics, availability, and industry reputation, the following seven manufacturers stand out in the production of high-quality 1/2-inch drywall screws.

Top 7 Drywall Screws 1/2 Drywall Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Drywall Screw Manufacturers

Domain Est. 1997

Website: intercorpusa.com

Key Highlights: Leading drywall screw manufacturer offering bulk supply for contractors and distributors. Bugle heads, fine/coarse threads, and phosphate coatings ……

#2 Drywall Screws

Domain Est. 1996

Website: minerallac.com

Key Highlights: Categories · Coarse Thread Bugle Head Drywall Screws · Fine Thread Bugle Head Drywall Screws · Fine Thread Bugle Head Drywall Tek Screws….

#3 Drywall Screws

Domain Est. 1998

#4 Drywall Screws

Domain Est. 2002

Website: allfasteners.com

Key Highlights: 4-day delivery 30-day returnsMade specifically for securing drywall to wood or metal studs, drywall screws have become an industry standard for the building interiors sector….

#5 Drywall Screws for Metal Studs and Wood

Domain Est. 2003

Website: pro-twist.com

Key Highlights: Our high-quality drywall screws are designed for durability and strength. Perfect for all your needs from wood to metal studs. Shop our selection now!…

#6 Drywall Screws

Domain Est. 2004

#7 Drywall Screws

Domain Est. 1996

Expert Sourcing Insights for Drywall Screws 1/2 Drywall

H2: Projected 2026 Market Trends for 1/2-Inch Drywall Screws

The global market for 1/2-inch drywall screws is poised for steady growth by 2026, driven by robust expansion in residential and commercial construction, coupled with ongoing advancements in building materials and fastener technology. These screws, essential for securing gypsum drywall to wood or metal studs, remain a staple in modern construction practices, ensuring their sustained demand across key markets.

One of the primary drivers shaping the 2026 landscape is the rising volume of renovation and remodeling projects, especially in North America and Western Europe. Aging housing stock, combined with increasing homeowner investment in energy efficiency and interior upgrades, is fueling demand for drywall installations and repairs—directly boosting the need for reliable fasteners like 1/2-inch drywall screws. In parallel, urbanization and infrastructure development in emerging economies—including India, Southeast Asia, and parts of Latin America—are expanding new construction activity, further supporting market growth.

Technological improvements are also influencing market dynamics. Manufacturers are increasingly adopting corrosion-resistant coatings such as blue phosphate, ceramic, or zinc plating to enhance screw durability, especially in high-humidity environments. Additionally, self-drilling and thread-forming designs are gaining traction for their efficiency in metal stud applications, reducing labor time and installation costs—factors that appeal strongly to contractors in the 2026 building climate.

Sustainability trends are expected to play a larger role by 2026, with growing emphasis on recyclable materials and low-carbon manufacturing processes. Leading suppliers are aligning with green building certifications (e.g., LEED, BREEAM), prompting innovation in eco-friendly packaging and energy-efficient production methods. This shift may create competitive advantages for companies investing in sustainable supply chains.

Distribution channels are also evolving. The rise of e-commerce platforms and digital procurement tools is enabling contractors and DIY consumers to access drywall screws more efficiently, increasing price transparency and intensifying competition among suppliers. This trend is expected to pressure margins but expand market reach, particularly in underserved rural and remote regions.

In summary, the 2026 market for 1/2-inch drywall screws will be shaped by construction growth, product innovation, sustainability demands, and digital transformation in distribution. Stakeholders who prioritize durability, efficiency, and environmental responsibility are likely to capture stronger market positioning in this evolving landscape.

Common Pitfalls When Sourcing 1/2″ Drywall Screws (Quality & IP)

Sourcing 1/2″ drywall screws seems straightforward, but overlooking key quality and physical characteristics (IP – Iron/Physical properties) can lead to project failures, rework, safety hazards, and cost overruns. Here are the most common pitfalls to avoid:

1. Prioritizing Low Cost Over Material Quality

Choosing the cheapest screws often means sacrificing material integrity. Low-grade steel may lack the tensile strength needed to securely hold drywall, especially in ceilings or high-stress areas. This can result in screws snapping during installation or drywall sagging over time.

2. Ignoring Coating Specifications

The coating on drywall screws prevents rust and enhances drive performance. A common mistake is assuming all coated screws are equal. Inferior coatings (e.g., substandard phosphate or inadequate zinc plating) wear off quickly, leading to corrosion—especially problematic in humid environments or when used near exterior sheathing.

3. Overlooking Thread Design and Sharpness

Blunt or poorly designed threads make installation difficult, requiring excessive torque that can damage drywall paper or strip screw heads. High-quality 1/2″ drywall screws feature sharp, aggressive threads and a self-drilling point (typically Type S or Type 25) for clean, efficient installation without pre-drilling.

4. Assuming All “Drywall Screws” Are Interchangeable

Not all drywall screws meet industry standards (e.g., ASTM C1002). Generic or off-brand screws may deviate in diameter, thread pitch, or head design, leading to inconsistent performance. Using non-compliant screws can void warranties and compromise fire or structural ratings in assemblies.

5. Neglecting Head Type and Drive Compatibility

Using the wrong drive type (e.g., Phillips instead of bugle head with a Type-17 or square drive) increases the risk of cam-out, damaging both the screw and drywall surface. The correct bugle head ensures the screw sits flush without breaking the paper face, maintaining joint integrity.

6. Failing to Verify Dimensions and Tolerances

Even small deviations in screw length (1/2″) or shank diameter can impact performance. Screws that are too short won’t penetrate sufficiently into the stud; those too long may protrude or create thermal bridges. Inconsistent diameters affect holding power and can cause misfires in auto-feed screw guns.

7. Sourcing from Unverified Suppliers

Purchasing from unreliable vendors increases the risk of counterfeit or mislabeled products. Always source from reputable suppliers who provide certifications, batch traceability, and compliance documentation to ensure consistent quality and material specifications.

Avoiding these pitfalls ensures reliable installation, long-term durability, and adherence to building codes when using 1/2″ drywall screws.

H2: Logistics & Compliance Guide for Drywall Screws (1/2″ Drywall)

H2: Overview

This guide provides essential logistics and compliance information for the international shipment, storage, and regulatory adherence of 1/2″ drywall screws. These fasteners are commonly used in construction for attaching gypsum board (drywall) to wood or metal studs. Ensuring proper handling, documentation, and regulatory compliance is critical for smooth supply chain operations and legal conformity.

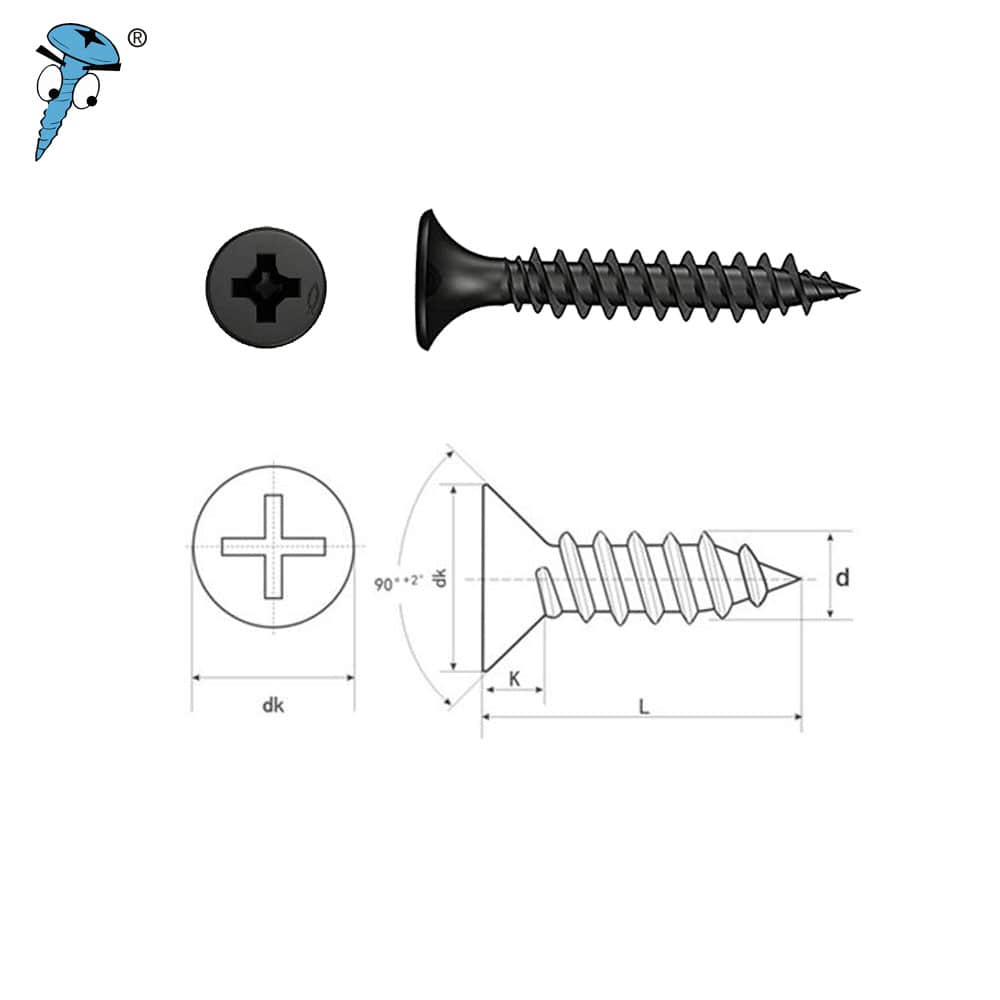

H2: Product Specifications

- Product Name: 1/2″ Drywall Screws

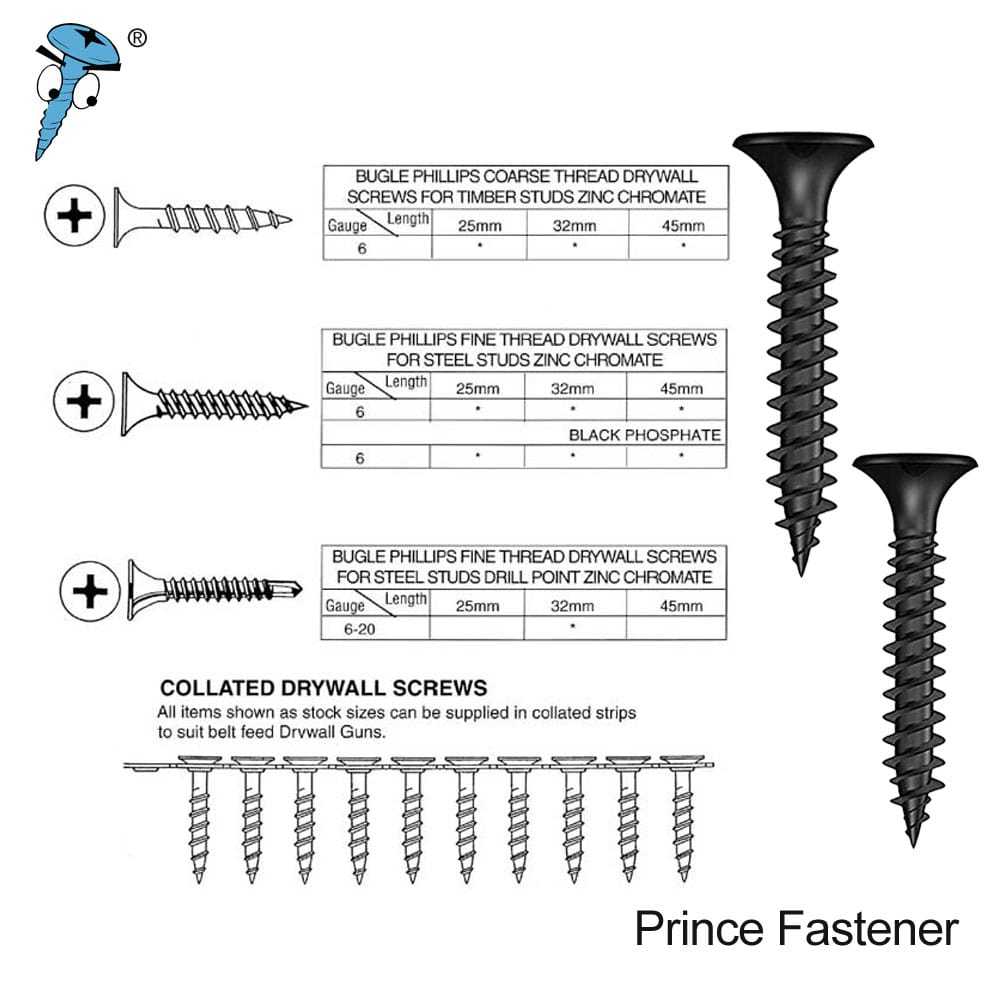

- Common Types:

- Coarse thread (for wood studs)

- Fine thread (for metal studs)

- Phillips or square drive head

- Type G (for drywall applications)

- Material: Typically carbon steel, often with phosphate or zinc plating for corrosion resistance

- Packaging: Bulk-packed in boxes, bags, or dispensers; common quantities: 1 lb, 2.5 lb, 5 lb, or 10 lb units

- HS Code (Harmonized System): 7318.15.00 – “Screws and bolts, whether or not with their nuts or washers, of iron or steel, threaded, whether or not assembled with nuts or washers”

- Note: Always verify with local customs authority; some countries may classify under 7318.19 or other subcategories based on coating or use.

H2: Logistics Requirements

Packaging & Palletization

- Use sturdy corrugated cardboard boxes with internal dividers or sealed plastic bags to prevent spillage.

- Standard pallet configuration:

- 40–50 boxes per pallet (varies by box size and weight)

- Max pallet height: ~1.8 m (6 ft)

- Pallet dimensions: 1200 mm × 1000 mm (EUR) or 48″ × 40″ (US standard)

- Secure with stretch wrap and corner boards to prevent shifting and damage.

- Label each pallet with product SKU, quantity, weight, and handling instructions (e.g., “Do Not Stack,” “Protect from Moisture”).

Storage Conditions

- Store indoors in a dry, well-ventilated area.

- Avoid exposure to moisture, salt air, or corrosive chemicals to prevent rusting (especially for uncoated or lightly coated screws).

- Maintain temperatures between 10°C and 35°C (50°F–95°F).

- Keep off concrete floors using pallets to prevent moisture absorption.

Transportation

- Mode: Suitable for road, rail, sea, and air freight.

- Sea Freight: Use moisture-resistant packaging; consider desiccants in containers to prevent condensation during long voyages.

- Air Freight: Acceptable; no hazardous material restrictions.

- Documentation: Include packing list, commercial invoice, bill of lading/air waybill, and certificate of origin if required.

H2: Compliance & Regulatory Requirements

Import/Export Regulations

- HS Code: Confirm 7318.15.00 with destination country; tariffs and duties vary by trade agreement.

- Country-Specific Requirements:

- USA: No export license required; check U.S. Census AES filing for exports over $2,500.

- EU: Must comply with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) for chemical substances (e.g., zinc, chromium in coatings). No CE marking required for screws alone, but may be required if part of a construction kit.

- UK: Post-Brexit, UKCA marking not required for standalone fasteners; follow UK REACH regulations.

- Canada: Complies with Canadian Customs Tariff under 7318.15.00; no special restrictions.

- Australia/NZ: Subject to Biosecurity import conditions; no quarantine risk for metal screws.

Environmental & Safety Compliance

- RoHS (EU/China/UK): Drywall screws (metal fasteners) are generally exempt from RoHS restrictions on hazardous substances unless coated with restricted materials.

- REACH (EU/UK): Ensure no Substances of Very High Concern (SVHC) above thresholds in plating or coatings. Declare if applicable.

- Prop 65 (California, USA): May require warning if product contains listed chemicals (e.g., lead, cadmium) above safe harbor levels—verify plating composition.

Labeling & Traceability

- Each package must include:

- Product name and size (e.g., “1/2” Drywall Screw, Coarse Thread”)

- Quantity (count or weight)

- Manufacturer/importer name and address

- Material and finish (e.g., “Zinc Plated Carbon Steel”)

- Batch or lot number for traceability

H2: Risk Management & Best Practices

- Quality Control: Perform periodic sampling to verify thread integrity, head drive compatibility, and coating consistency.

- Corrosion Prevention: Use vapor corrosion inhibitors (VCI) in packaging for humid climates or long storage.

- Documentation Retention: Keep records (invoices, test reports, compliance declarations) for minimum 5 years.

- Supplier Compliance: Require suppliers to provide Material Safety Data Sheets (MSDS/SDS) and compliance declarations (REACH, RoHS if applicable).

H2: Summary Checklist

✅ Confirm HS Code: 7318.15.00

✅ Use moisture-resistant packaging and secure pallets

✅ Store in dry, indoor environment

✅ Verify REACH/RoHS compliance for destination markets

✅ Include correct labeling on all packages and pallets

✅ File accurate export documentation (commercial invoice, packing list)

✅ Monitor for country-specific import restrictions or labeling rules

For optimal compliance, consult with a customs broker or regulatory specialist in the destination country prior to shipment.

In conclusion, sourcing 1/2-inch drywall screws requires careful consideration of quality, quantity, supplier reliability, and cost-effectiveness. These screws are essential for securing gypsum drywall to wood or light-gauge steel studs, and using the correct size ensures a secure, durable installation with minimal risk of popped screws or structural failure. When sourcing, it’s important to choose corrosion-resistant screws (such as phosphate or coated varieties) appropriate for the environment—especially in moisture-prone areas. Purchasing from reputable suppliers or manufacturers helps ensure compliance with building codes and industry standards. Whether buying in bulk for large-scale projects or smaller quantities for renovations, comparing prices, delivery options, and product specifications will lead to a more efficient and economical acquisition. Ultimately, investing in high-quality 1/2-inch drywall screws contributes to a professional finish and long-term durability of drywall installations.